- Wet Filament: Prevention, Symptoms & Drying - July 18, 2024

- Sovol SV08 – Best PrusaSlicer Settings & Profile - June 26, 2024

- Sovol SV08 – Best Orca Slicer Settings & Profile - June 26, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

Finding the right Cura settings for the Sovol SV06 is sometimes not that easy. As with many other 3D printers, there is no suitable standard profile for this one in Cura.

To achieve good results with PLA using the Sovol SV06, a print temperature of about 200 °C, a print bed temperature of 60 °C, a print speed of 50 mm/s and a retraction of 0.5 mm at 40 mm/s should be set in the Cura settings.

In this article, you will learn which settings you need for other filaments and what you should consider for the individual settings in Cura. But first there is a small overview table.

| PLA | ABS | TPU | PETG | |

|---|---|---|---|---|

| Printing temperature | 195-205 °C | 235-240 °C | 210-220 °C | 225-245 °C |

| Print bed temperature | 60 °C | 90 °C | 60 °C | 65-75 °C |

| Print speed | 50 mm/s | 45 mm/s | 30 mm/s | 50 mm/s |

| Retraction | 0.5 mm at 40 mm/s | 0.5 mm at 35 mm/s | 0.5-1 mm at 40 mm/s | 0.4-0.8 mm at 40-50 mm/s |

| Cooling | 100 % | 0% + enclosure | 100 % | 50-100 % |

Table of Contents:

How to Create a Cura Profile for the Sovol SV06

The “Cura Profile” is basically composed of the machine settings and the print settings. The machine settings describe the hardware of the printer and define some G-code to be executed before and after printing. The print settings determine how the filament should be printed, i.e. at what temperature or at what speed.

Defining the machine settings only needs to happen once when adding the printer. However, the print settings must be fine-tuned to the specific filament and print file.

In this article, I will show you the correct machine settings for the Sovol SV06, as well as suitable print settings that are good starting points for the respective filaments. At the end, you will learn how to calibrate the settings to achieve perfect results.

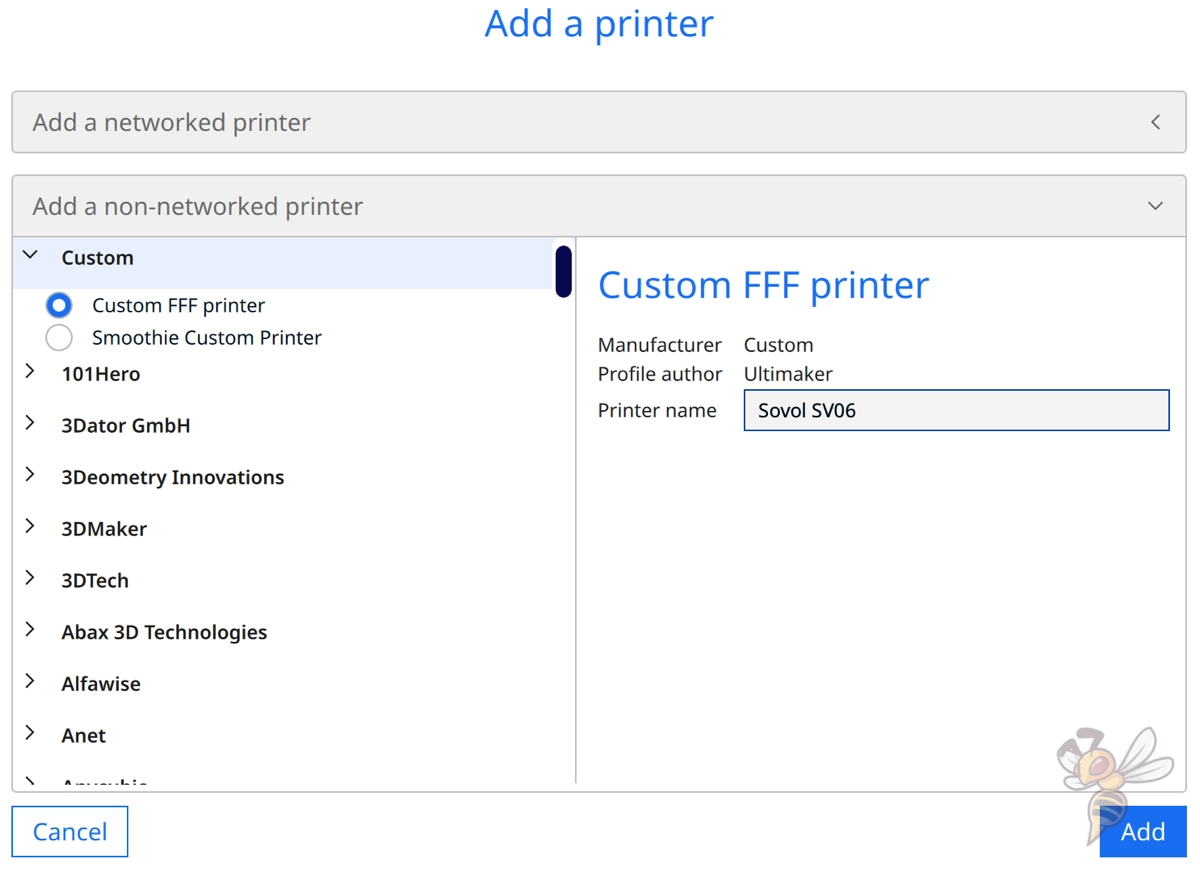

These are the steps to create a new profile in Cura for the Sovol SV06:

- Click on “Settings” in the menu bar of Cura.

- Go to “Printer” and “Add Printer”.

- Select “Custom FFF printer”, name it “Sovol SV06” and press “Add”.

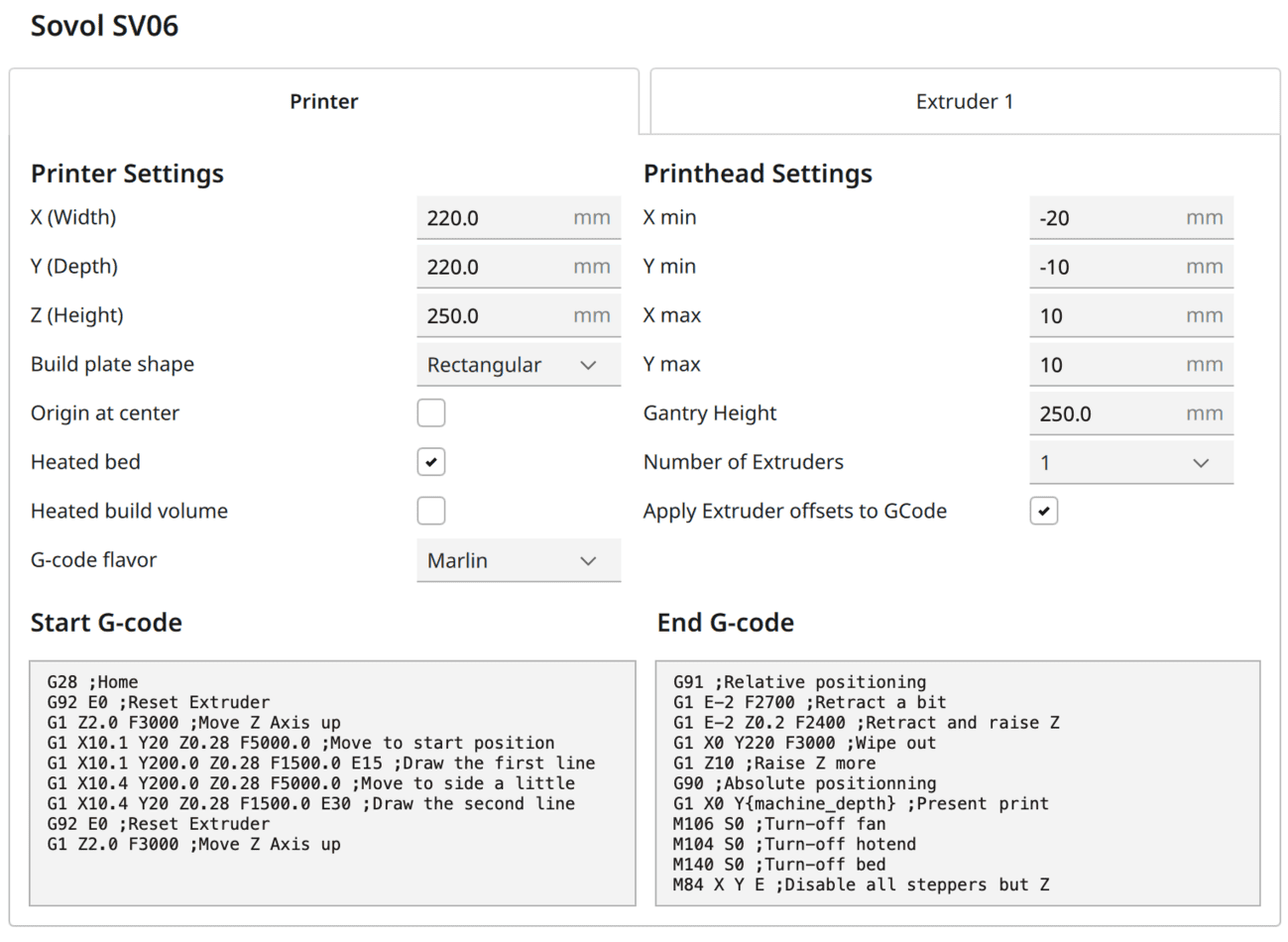

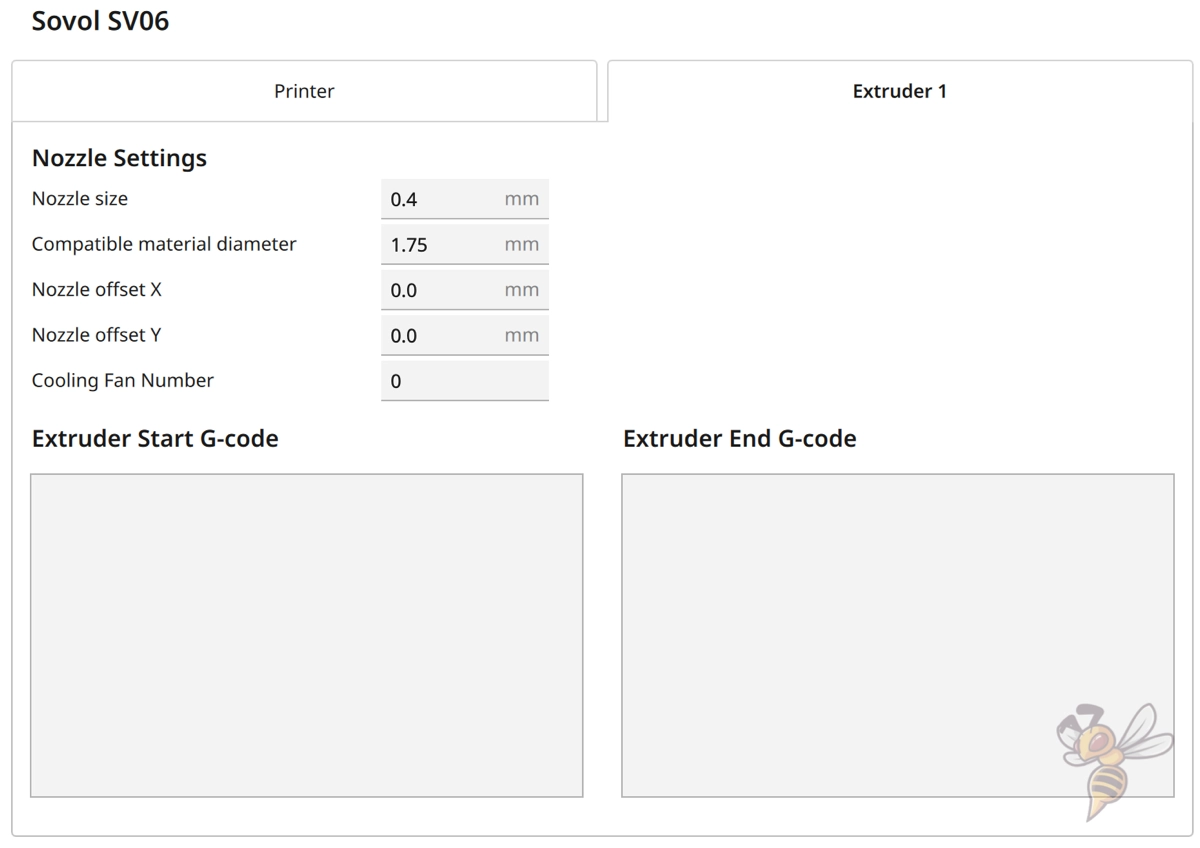

- Adjust the machine settings according to the information in the screenshots and the G-code snippets.

- After that, you can close the window and adjust the print settings.

Here are the G-code snippets for the Sovol SV06 machine settings:

Start G-code:

- G28 ;Home

- G92 E0 ;Reset extruder

- G1 Z2.0 F3000 ;Move Z Axis up

- G1 X10.1 Y20 Z0.28 F5000.0 ;Move to start position

- G1 X10.1 Y200.0 Z0.28 F1500.0 E15 ;Draw the first line

- G1 X10.4 Y200.0 Z0.28 F5000.0 ;Move to side a little

- G1 X10.4 Y20 Z0.28 F1500.0 E30 ;Draw the second line

- G92 E0 ;Reset extruder

- G1 Z2.0 F3000 ;Move Z Axis up

End G-code:

- G91 ;Relative positioning

- G1 E-2 F2700 ;Retract a bit

- G1 E-2 Z0.2 F2400 ;Retract and raise Z

- G1 X0 Y220 F3000 ;Wipe out

- G1 Z10 ;Raise Z more

- G90 ;Absolute positioning

- G1 X0 Y{machine_depth} ;Present print

- M106 S0 ;Turn-off fan

- M104 S0 ;Turn-off hotend

- M140 S0 ;Turn-off bed

- M84 X Y E ;Disable all steppers but Z

Now you can start adjusting the print settings to your particular filament.

You can find more information on how to create a 3D printer profile in Cura and what you need to pay attention to in this article: How to Create a Custom 3D Printer Profile in Cura

PLA Settings at a Glance

These are the correct Cura settings for the Sovol SV06 for PLA:

- Print temperature: 195-205 °C

- Print bed temperature: 60 °C

- Printing speed: 50 mm/s

- Retraction: 0.5 mm at 40 mm/s

- Cooling: 100%

- First layer: 5-10 mm/s, 0% cooling, 100% extrusion width, 100% layer height

PLA is the easiest of all filaments to print. Especially with SV06, only a few things have to be considered to achieve good results with this filament.

Since the print bed is coated with PEI, you don’t have to worry much about print bed adhesion. As long as you have leveled the print bed correctly and the Z-offset is not too large, PLA will adhere perfectly with print bed temperatures around 60 °C.

The only thing you need to be aware of with SV06 for PLA is the retraction. The above values are a good start for most PLA filaments. I’ve had good results with these settings on several types of PLA.

If you want to perfect the results, you should calibrate the retraction in any case. You’ll learn how to do this later in this article.

ABS Settings at a Glance

If you want to print stable objects that can withstand mechanical forces well, ABS is probably interesting for you. ABS is more resistant than PLA and is therefore often used for such applications.

The problem with ABS, however, is that it shrinks quite a bit when it cools down. Especially with large objects, this can lead to difficulties like warping.

Smaller objects made of ABS can be printed with the SV06 without any issues. For larger objects, I would advise you to use an enclosure. This one from Creality should fit the SV06 perfectly.

With such a tent, the ambient temperature of the object remains homogeneous and warm enough during printing that it does not warp. As soon as the print is finished and the print bed cools down, the interior of the tent and thus also the object slowly cools down to room temperature. This prevents warping from occurring.

TPU Settings at a Glance

These are the correct Cura settings for the Sovol SV06 for TPU:

- Print temperature: 210-220 °C

- Print bed temperature: 60 °C

- Printing speed: 30 mm/s

- Retraction: 0.5-1 mm at 40 mm/s

- Cooling: 100%

- First layer: 5-10 mm/s, 0% cooling, 100% extrusion width, 100% layer height

Thanks to the direct drive extruder, it is possible for the Sovol SV06 to print flexible filaments in reliably good quality. The distance between the extruder and the nozzle is so small that the flexible filament cannot compensate for the extrusion movements as much as with a Bowden extruder. Therefore, the extrusion accuracy of flexible filaments is much better with direct drive extruders.

Nevertheless, the speeds of the print movements and the retraction must be finely tuned to the respective filament. The values given above worked perfectly with my TPU filament. Since TPU filament comes in many types, it is important to calibrate especially the retraction very precisely.

If you set the z-offset correctly and set a very slow print speed for the first layer, you should have no problems with print bed adhesion. If you do, Magigoo would be a good adhesive to use.

PETG Settings at a Glance

These are the correct Cura settings for the Sovol SV06 for PETG:

- Print temperature: 225-245 °C

- Print bed temperature: 65-75 °C

- Printing speed: 50 mm/s

- Retraction: 0.4-0.8 mm at 40-50 mm/s

- Cooling: 50-100 %

- First layer: 5-10 mm/s, 0% cooling, 100% extrusion width, 100% layer height

Because the SV06 has a full metal hotend, you can print regularly at the high temperatures of PETG without having to constantly replace wear parts like a PTFE heatbreak.

PETG is ideal for many applications. It is easier to print than ABS, but more difficult than PLA. But it is also more sturdy than PLA and can also be used perfectly for outdoor applications. The problem with PETG, however, is that it is extremely prone to stringing.

Stringing is influenced by many print settings. Besides the printing temperature and the cooling, the retraction has the greatest effect on the stringing behavior of PETG.

It is also necessary to protect PETG from too much humidity. Damp PETG filament is hardly printable without errors. Otherwise, you can check out this article if you have problems with stringing with PETG.

Best Cura Settings for the Sovol SV06

Print Temperature

The best print temperatures for the Sovol SV06 in Cura:

- PLA: 195-205 °C

- ABS: 235-240 °C

- TPU: 210-220 °C

- PETG: 225-245 °C

An incorrectly set print temperature can have a strong impact on the print result. The hotend of the SV06 is very accurate, so it is not too difficult to find the optimal temperature for the filament from the above values.

The extruder of the SV06 can regularly reach 260 °C. With this, you can print all standard filaments without any issues. If you want to print more exotic filaments that require even higher temperatures, you can also increase the temperature up to 300 °C.

Print Bed Temperature

The best print bed temperatures for the Sovol SV06 in Cura:

- PLA: 60 °C

- ABS: 90 °C

- TPU: 60 °C

- PETG: 65-75 °C

The print bed of the SV06 reaches 100 °C. This allows you to create a good print bed adhesion for all standard filaments and most exotic filaments.

While it is unlikely that you will have print bed adhesion issues with the PEI print bed, you can increase the adhesion of the object by slightly increasing the print bed temperature. The higher temperature will cause the hot filament to spread better on the print bed and flow into the small crevasses in the PEI coating.

However, you must not increase the print bed temperature too much. Otherwise, the filament will flow away to the sides and create an elephant foot.

Print Speed

The best printing speed for the Sovol SV06 in Cura:

- PLA: 50 mm/s

- ABS: 45 mm/s

- TPU: 30 mm/s

- PETG: 50 mm/s

The Sovol SV06 reaches print speeds of up to 80 mm/s. Due to the weight of the direct drive extruder, the maximum print speed is somewhat lower than comparable 3D printers with Bowden extruders. Nevertheless, the recommended print speeds of approx. 50 mm/s are relatively normal.

If print quality is only of secondary importance to you, you can, of course, set the print speed to 80 mm/s. However, at these high speeds, print errors such as ringing or ghosting are more likely to occur because of the slight vibrations that occur during the fast movements. These vibrations of the print head leave artifacts on the surface of the print.

So for better print quality, it is always advisable to reduce the print speed.

Layer Height

The best layer heights for the Sovol SV06 in Cura:

- Decorative objects: 0.1 mm

- Standard: 0.2 mm

- Coarse, fast prints: 0.3 mm

The layer height should always be between 25% and 75% of the nozzle diameter. Since the SV06 comes with a 0.4 mm nozzle, this would be 0.1 to 0.3 mm.

For decorative objects, a layer height of 0.1 mm would be suitable, as the layers will then be finer and the surface smoother. If you only want to print quick prototypes, a layer thickness of 0.3 mm would be more suitable, as this will save you a lot of time.

Flow Rate

The best flow rate for the Sovol SV06 in Cura:

- Default value: 100%

- For over-extrusion: 90% to 99

- For under-extrusion: 101% to 110%.

You can use the flow rate to compensate for certain print defects. If you observe print defects caused by over-extrusion, you can decrease the flow rate so that less material is extruded per unit time.

On the other hand, if you find under-extrusion such as holes or cracks, you can also increase the flow rate to extrude more filament.

Sometimes the flow rate is also used to increase the print bed adhesion for the first layer. You can also adjust the flow rate for the first layer only, but there is a big risk of creating an elephant foot. Before you do, there are a few other steps you can take to increase print bed adhesion.

Retraction

The best settings for retraction for the Sovol SV06 in Cura:

- PLA: 0.5 mm at 40 mm/s

- ABS: 0.5 mm at 35 mm/s

- TPU: 0.5-1 mm at 40 mm/s

- PETG: 0.4-0.8 mm at 40-50 mm/s

Retraction is often a source of frustration for many 3D printing enthusiasts. If the retraction is not set correctly, numerous printing errors can occur. These include stringing, blobs, or a strong Z-seam.

The settings for the retraction are mainly composed of the retraction distance and the speed.

The above values worked fine for my SV06 with the respective filament types. However, for filaments where retraction is especially important, such as TPU and PETG, you will have to experiment a bit until you find the right value for your filament (see retraction calibration further down).

Infill

The best infill density for the Sovol SV06 in Cura:

- Decorative objects: 0-15%

- Standard objects: 15-50%

- Stable objects: 50-100%

For the settings for the structure inside the object, the values depend solely on the application of the object and not on the 3D printer used.

You can adjust the stability of the printed object through the infill. The density and pattern of the infill are the main factors. The higher the density, the more stable the object will be. But there are also a few patterns that are particularly sturdy.

High stability (for stable objects):

- Cubic

- Cubic subdivision

- Octet

- Gyroid

Medium stability (for standard objects):

- Grid

- Triangles

- Tri-Hexagonal

Low stability (for decorative objects):

- Lines

- Zigzag

- Lightning

First Layer

These are the best Cura settings for the first shift on Sovol SV06:

- Layer height: 100-200% of normal layer height (higher values to increase print bed adhesion)

- Line width: 100-200% of normal line width (higher values to increase print bed adhesion)

- Print temperature: Same as the rest of the object, or 5-10 °C higher for better print bed adhesion.

- Print speed: 50% of normal print speed (i.e., 25 mm/s for a normal print speed of 50 mm/s) or 5-10 mm/s for high print bed adhesion

- Flow rate: 100-110% (higher values in case of poor print bed adhesion)

With the SV06, if you set the Z-offset not too large and the print speed to 5 to 10 mm/s, you will achieve excellent print bed adhesion with most filaments.

If not, you can improve it with the tips for Cura given above or with adhesives or auxiliary constructions like a raft.

How to Calibrate the Cura Settings for the Sovol SV06

The values recommended in this article worked perfectly for my SV06 and my filaments. The likelihood that the settings will give you good results is quite high, but you will probably need to calibrate them to get perfect results.

You should mainly calibrate the retraction, the print temperature and the flow rate. These three settings have a considerable influence on the print quality.

However, it is sometimes unfavorable that they partially influence each other. So, you may have to calibrate the settings more often one after the other to find the perfect values.

Read the full calibration guide:

3D Printer Calibration: Step-by-Step to Perfect Results

How to Calibrate the Print Temperature

The correct printing temperature significantly reduces the chance of printing errors. Even a difference of 5 °C can significantly influence the quality. It is therefore important to calibrate the print temperature to the filament you are using.

The values given in this article are good guidelines, but you will not get good results with all filaments at these temperatures.

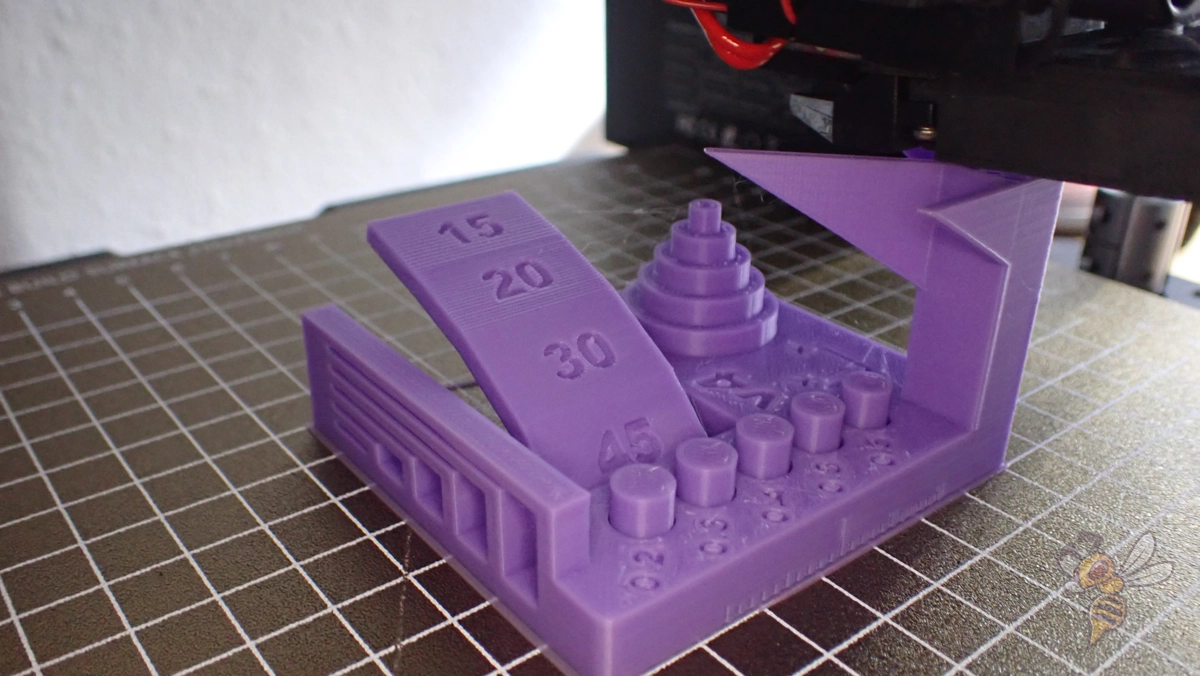

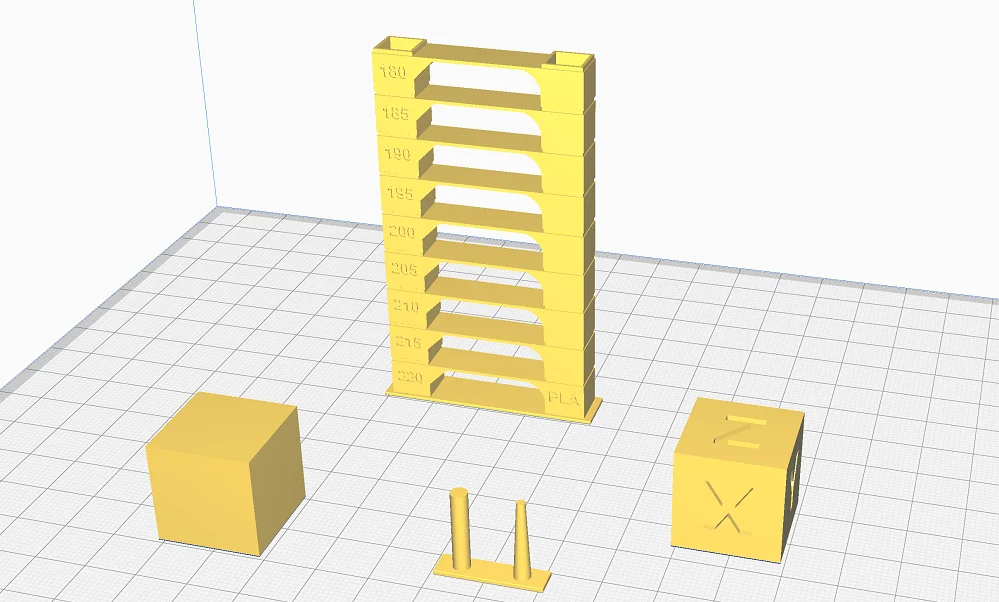

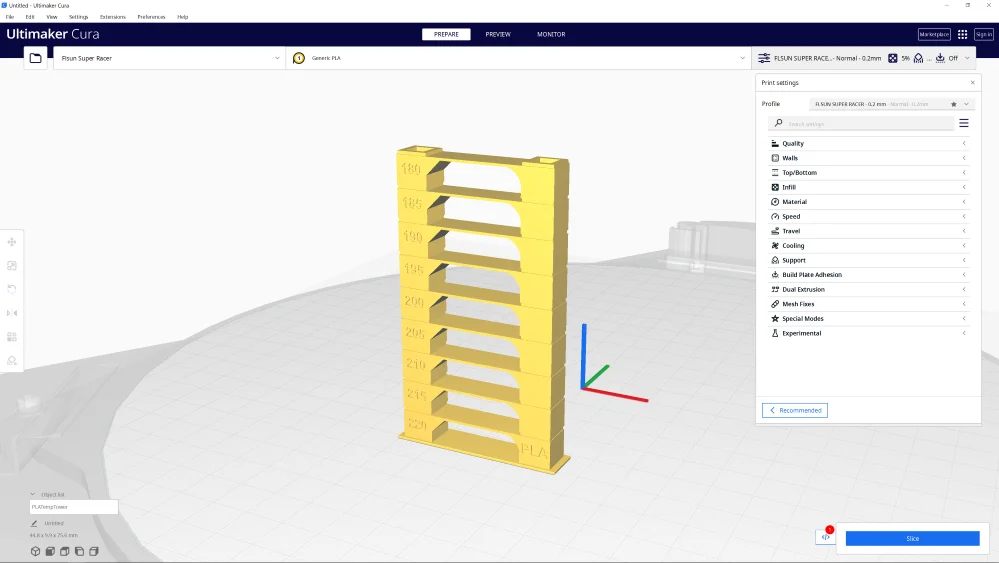

A good way to calibrate the print temperature is a so-called temperature tower. You can find these objects on portals like Thingiverse or in the Calibration Shapes plugin from Cura.

Ideally, a temperature tower only needs to be printed once. It consists of many layers that are printed at different temperatures. So, you can see directly at the end at which printing temperature the filament was printed best.

How to Calibrate the Flow Rate

The flow rate is exactly 100% in most cases. Also, most printing errors can be eliminated without adjusting the flow rate. However, sometimes severe extrusion errors can only be eliminated by calibrating the flow rate.

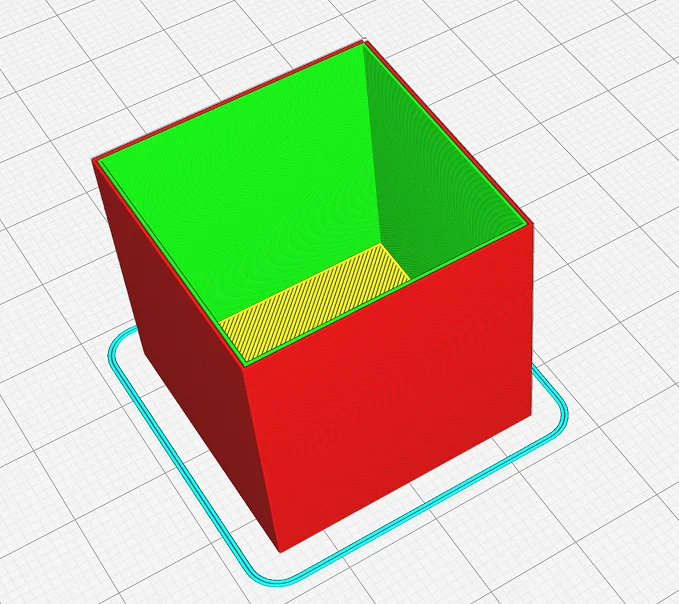

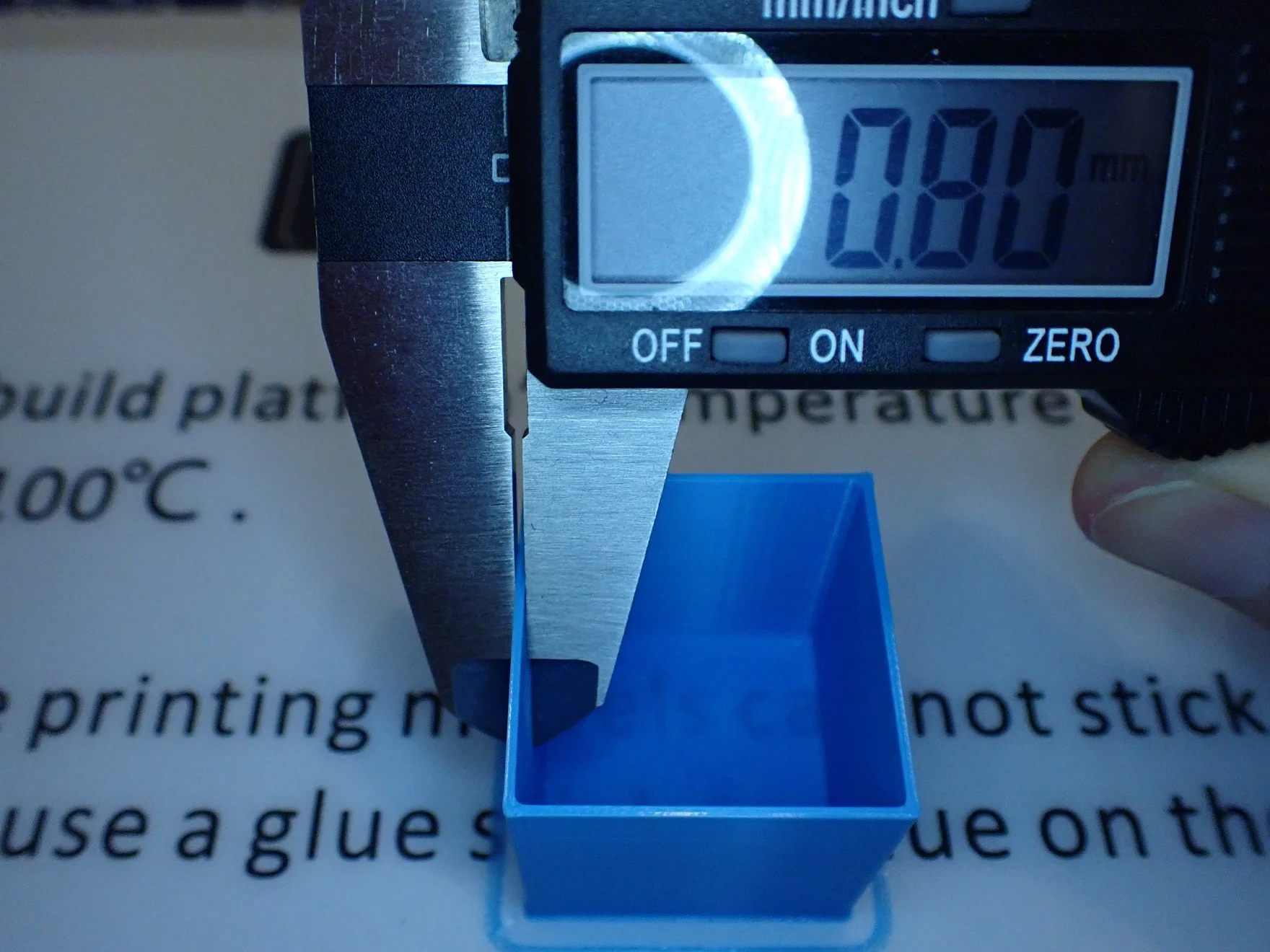

To calibrate the flow rate, compare the wall thickness set in Cura with the actual printed wall thickness.

In my opinion, it is easiest to print a hollow cube without upper layers. After printing, you can easily measure the wall thickness.

The measured value is the product of the number of wall lines and the line width. So, you have to divide the value by the number of wall lines to compare it with the set wall thickness. If the actual wall thickness is greater than the value in the slicer, you have to reduce the flow rate and vice versa.

How to Calibrate the Retraction

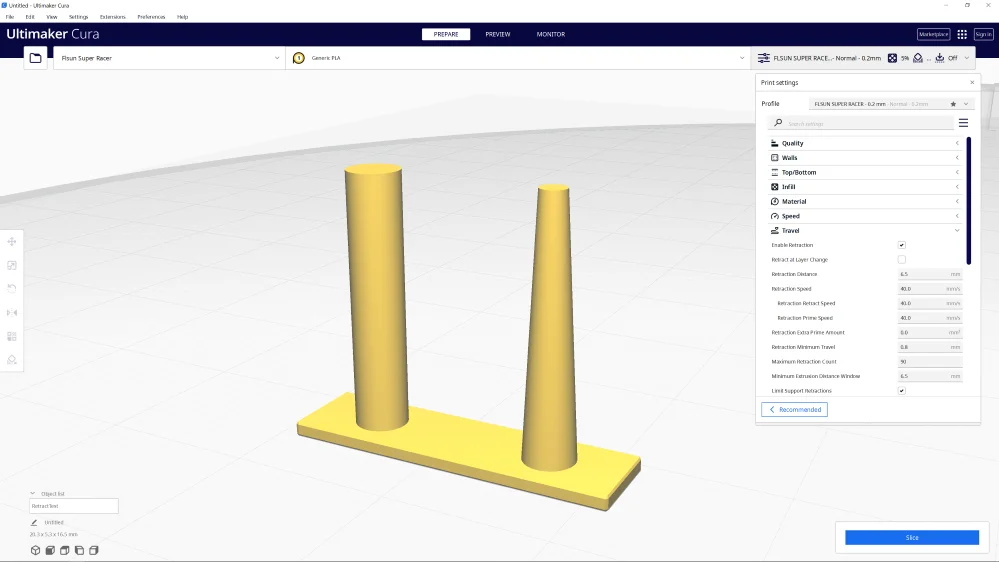

Calibrating the retraction can fix many printing errors – like the common stringing, for example. To calibrate the retraction, you need a suitable object that can be printed quickly.

In Cura’s Calibration Shapes plugin, there is an object for this that consists of only two columns that are printed side by side.

When calibrating the retraction, you adjust the retraction distance and speed in small steps until there are no or hardly any hairs between these two columns.

There are a number of other retraction settings that you can experiment with until you find the optimal values. The combing mode is disabled by default on the SV06, but can be just the solution to optimize retraction for some filaments.

Conclusion

I hope you will get good results with the Cura settings for the Sovol SV06 and the tips in this article. Remember that perfect results always require some experimentation.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.