- Z Seam | How to Hide & Avoid | Cura & PrusaSlicer - April 20, 2024

- Qidi Tech Q1 Pro – Best Orca Slicer Settings & Profile - April 9, 2024

- Creality Ender-3 V3 Review – Will CoreXZ be the New Trend? - March 27, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

There are many different patterns for 3D printing infills. Some of them are more suitable for stable objects than others. This article discusses the specifics and applications of the tri-hexagon Infill pattern and compares it to similar patterns.

Related Article: 3D Printing Infill Guide | Basics, Patterns and Stability

Table of Contents:

- 1 What is the Tri-Hexagon Infill Pattern?

- 2 Tri-Hexagon Infill Pattern Application

- 3 Best Infill Density for the Tri-Hexagon Pattern

- 4 Tri-Hexagon vs. Honeycomb

- 5 Tri-Hexagon vs. Cubic

- 6 Which Slicers Have the Tri-Hexagon Infill Pattern?

- 7 Other Infill Patterns and their Application

- 8 Conclusion: How Good is the Tri-Hexagon Infill Pattern?

What is the Tri-Hexagon Infill Pattern?

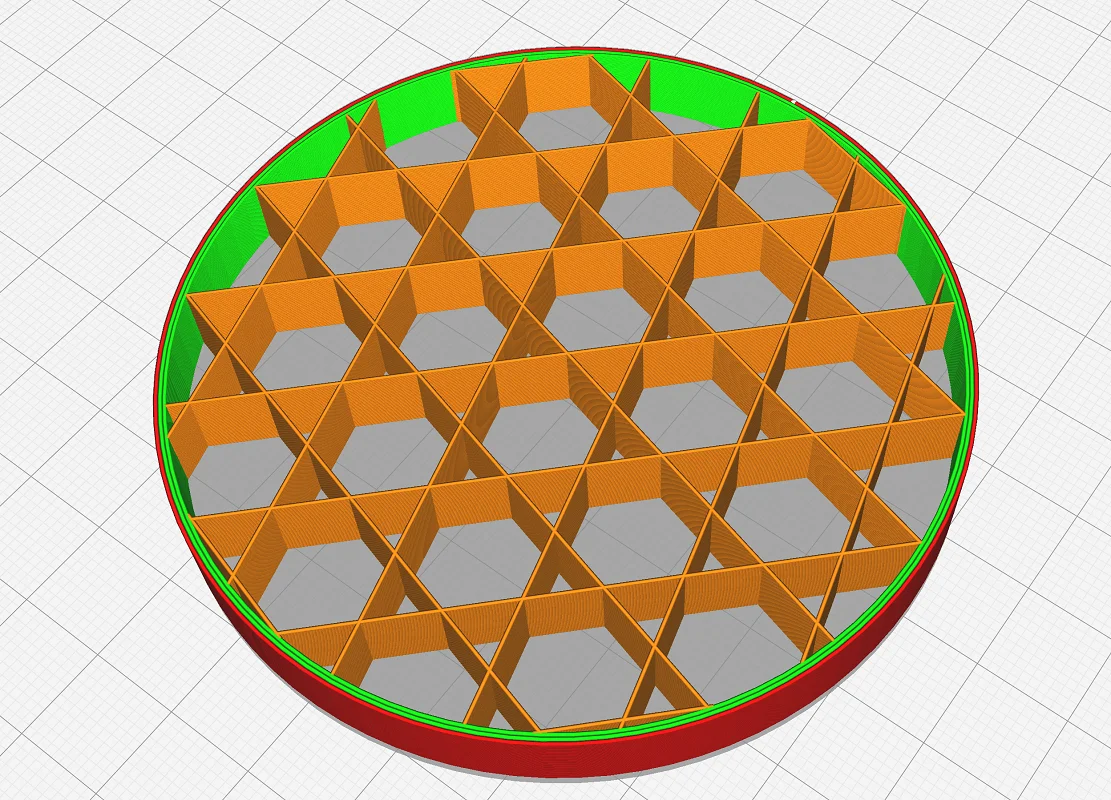

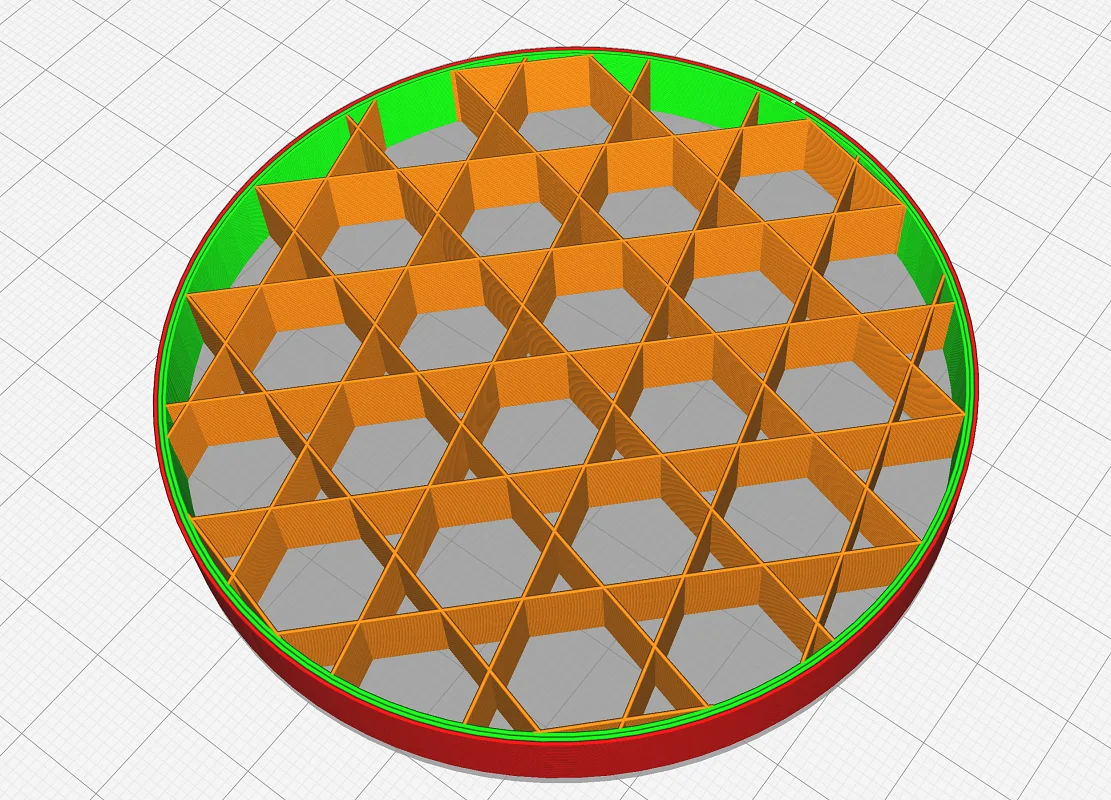

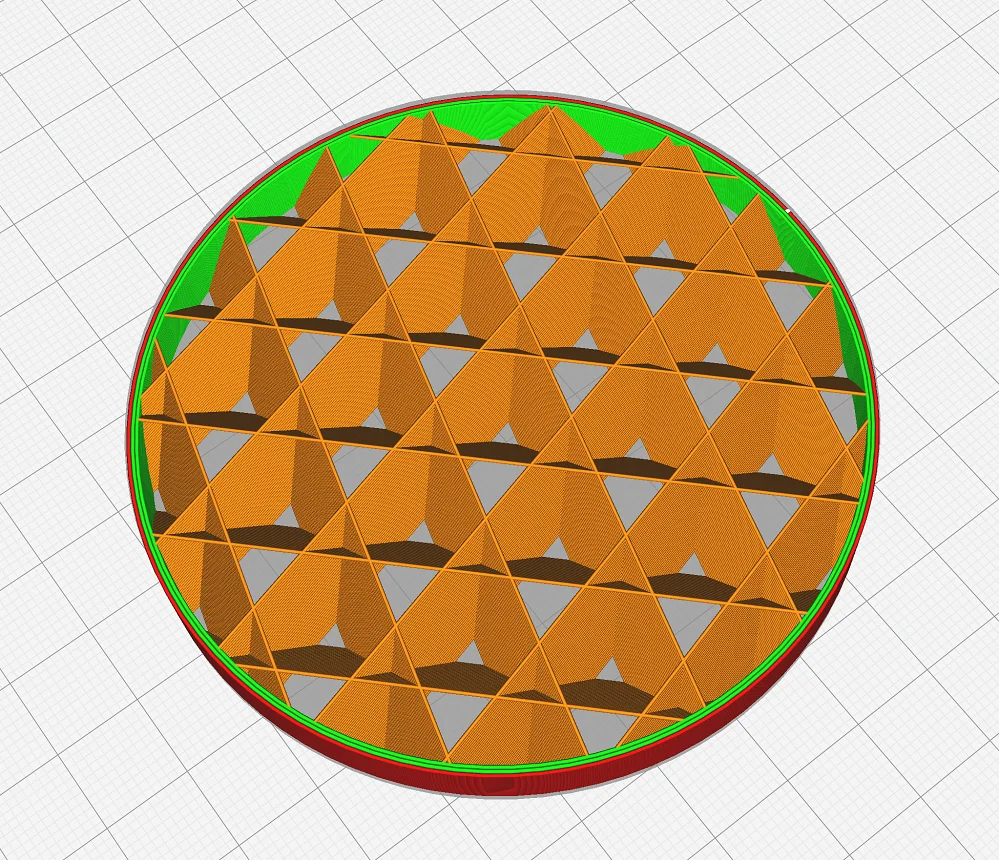

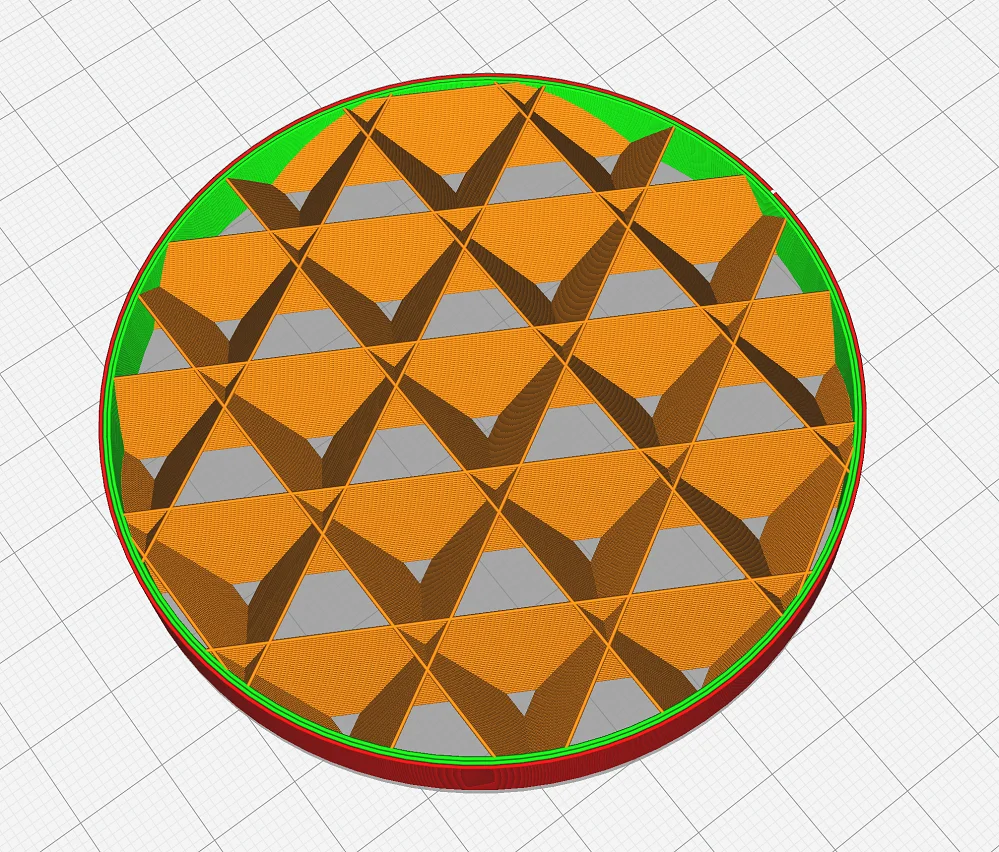

The tri-hexagon infill pattern is a stable 2D pattern. It provides high stability in X and Y directions and moderate stability in Z direction. The pattern consists of hexagons connected by triangles.

Hexagonal structures are generally very stable. They are often used in architecture, engineering and packaging materials to increase mechanical stability with as little material consumption and weight as possible. This principle is also very advantageous in 3D printing, as you need less filament and time for a more stable object.

Another advantage of the tri-hexagonal infill pattern is that the individual lines are shorter than in other infill patterns. This can avoid irregularities during printing, such as the bending of the walls. However, this printing error is extremely rare and hardly ever occurs with many standard filaments such as PLA or ABS.

Tri-Hexagon Infill Pattern Application

The tri-hexagon infill pattern is suitable for objects that require moderate stability with low filament consumption. The pattern is therefore ideal for standard 3D prints and with low infill density, it is also well suited for decorative objects.

The tri-hexagon Infill pattern is very suitable for objects that are particularly subject to mechanical stress in one plane. In normal alignment, the pattern provides very good stability in the XY direction and moderately good stability in the Z direction.

The disadvantage of this infill pattern is that it is not very resistant to bending. It is only extremely stable against forces on the XY direction, such as shear forces for example. Since it is a 2D pattern, “3D forces”, such as rotational forces, are more of a problem.

Best Infill Density for the Tri-Hexagon Pattern

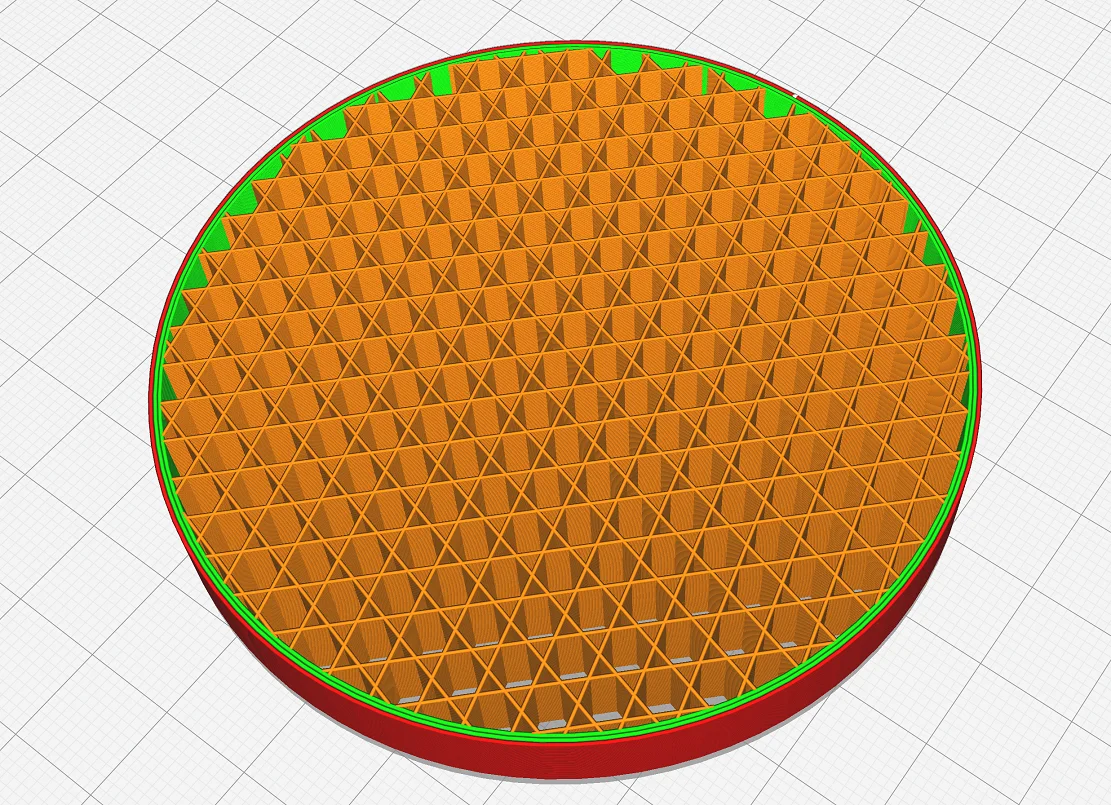

The best infill density for the tri-hexagon pattern is between 5% and 30%. These densities are ideal for decorative and standard objects. Higher densities can be used, but for extremely stable objects, other infill patterns such as gyroid or cubic would be more suitable.

In addition to the pattern, the infill density determines the stability of the object. The higher the density, the more stable the object. However, the printing time and material consumption also increase. Therefore, it is always important to find the right balance between stability, printing time and material consumption.

Since the tri-hexagonal Infill pattern has moderate stability, it is also best suited for objects that require such stability. These are most standard objects printed with densities between 15% to 50%. But even large decorative objects can be made more stable with this pattern without greatly increasing the density.

Tri-Hexagon vs. Honeycomb

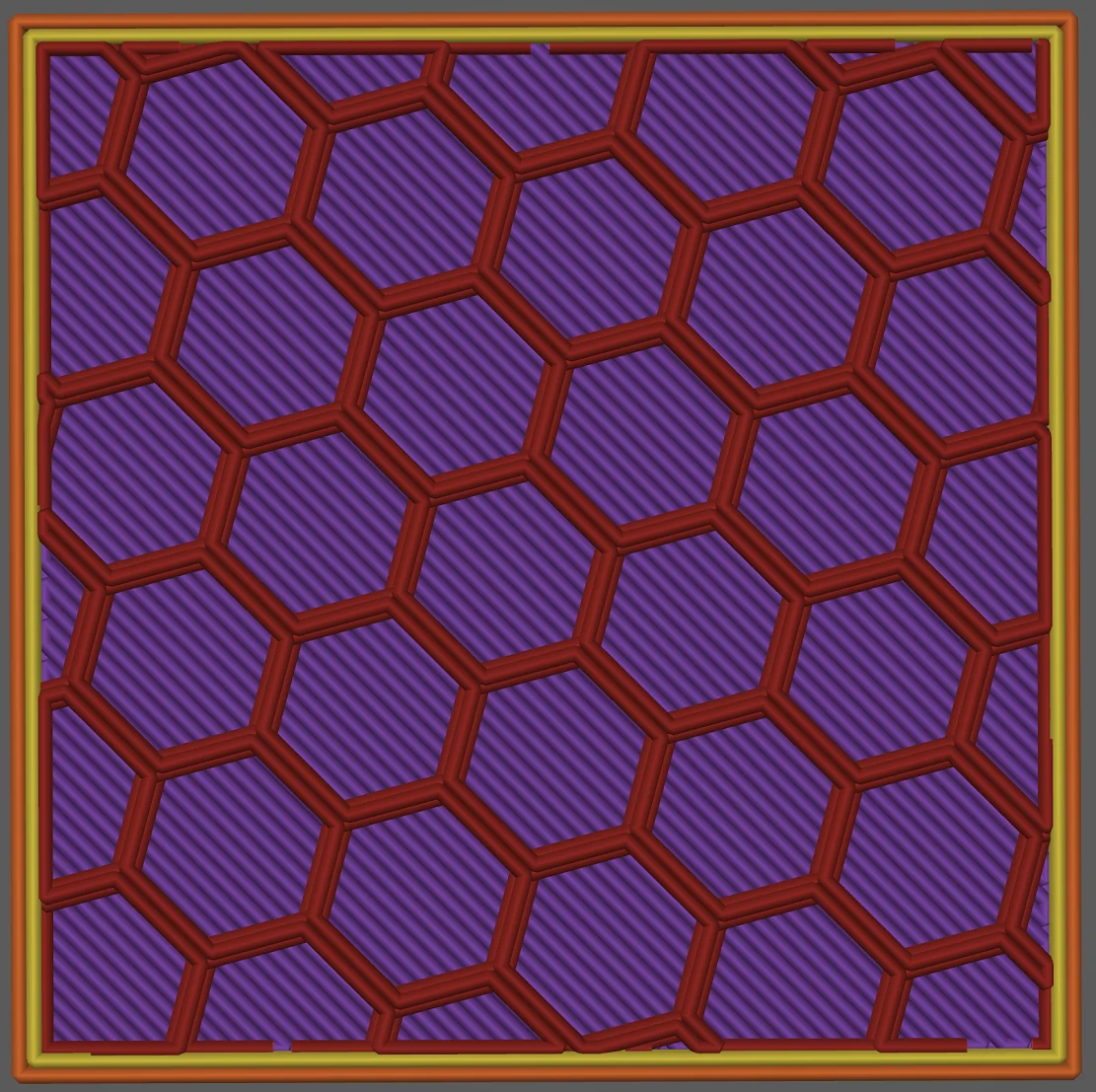

The tri-hexagon Infill pattern consists of continuous lines arranged in three directions to create hexagons and triangles. The Honeycomb pattern consists only of hexagons with no spaces between them and no line longer than one hexagon side.

Hexagons have long been known as a stable pattern. Even bees use this pattern in honeycombs because it is stable with as little material consumption as possible.

Just like the tri-hexagon pattern, honeycombs provide excellent stability in the XY direction and moderate stability in the Z direction. They are very similar in stability, with the tri-hexagon pattern being slightly more stable.

So if you are looking for the tri-hexagonal or the Honeycomb pattern in your slicer, often only one of them is available. But since they are very similar, they are more or less interchangeable.

Tri-Hexagon vs. Cubic

Sometimes the tri-hexagonal pattern is confused with the cubic pattern or the cubic subdivision pattern.

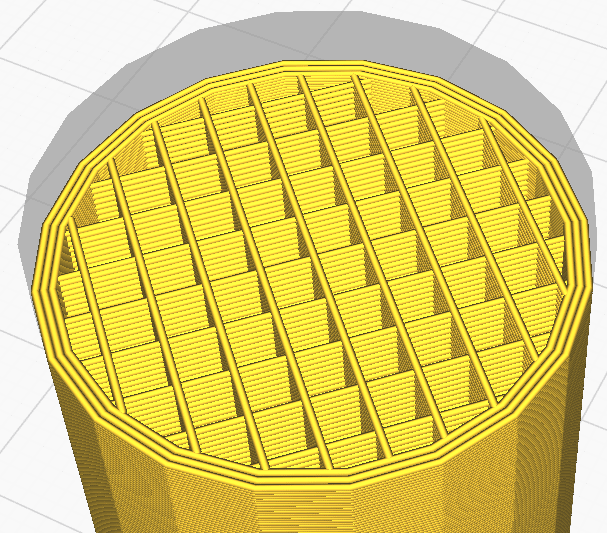

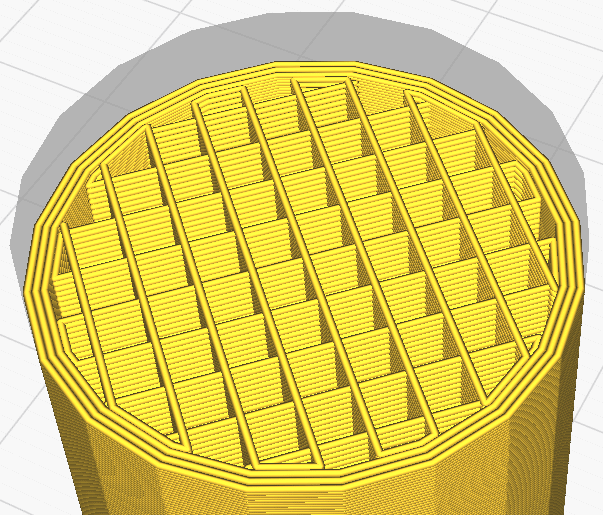

The main difference, however, is that the tri-hexagonal pattern is a 2-dimensional pattern and does not change in the Z-axis. The cubic patterns are 3-dimensional infill patterns that are very stable not only on one plane but in all three directions.

Due to the 3-dimensional pattern, the cubic patterns are often used for extremely stable objects with infill densities of 30% to 60%. The resulting objects are mechanically very stable in all directions. The downside to this stable pattern, however, is that they require slightly more filament and time than other infill patterns.

Which Slicers Have the Tri-Hexagon Infill Pattern?

Not all slicers have the tri-hexagonal Infill pattern. However, many use patterns similar to the honeycomb pattern as a substitute.

Here is an overview of which popular slicers can handle the tri-hexagon Infill pattern:

- Cura: Yes

- Simplify3D: No

- Slic3r: No

- PrusaSlicer: Yes (but here it is called “stars” infill)

Other Infill Patterns and their Application

All slicers offer many different infill patterns. They not only look different, but they also serve different purposes and are sometimes more and sometimes less suitable for different objects. Here is a small overview of the most important infill patterns that exist besides tri-hexagonal, honeycomb and cubic.

Lines (low stability): The line pattern is probably the simplest pattern you can print. Here, parallel lines are printed in one direction at a time and rotated 90° for the next layer. It is not very stable and therefore best suited for decorative objects.

ZigZag (low stability): The zigzag infill pattern is an improved form of the lines pattern. Here, lines are printed in one direction per layer, but the nozzle changes its direction in a zigzag pattern between the lines. This way you get a continuous printing process without the interruptions as with the line pattern.

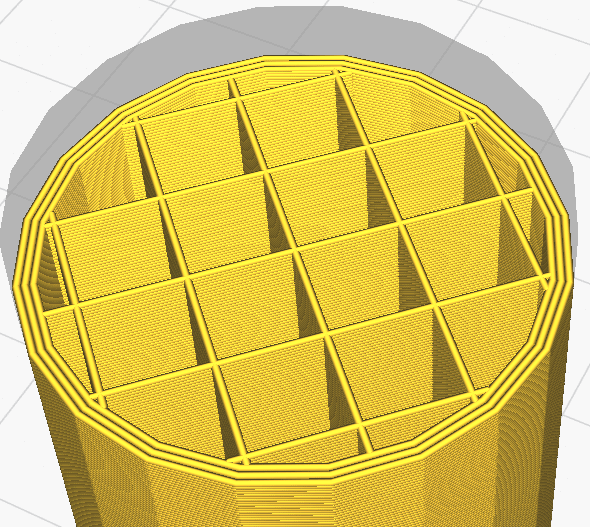

Grid (medium stability): Visually, the grid pattern looks almost identical to the line pattern. Here, all directions of the grid are printed per layer and not just one. This results in a somewhat higher stability, but also a somewhat higher filament consumption.

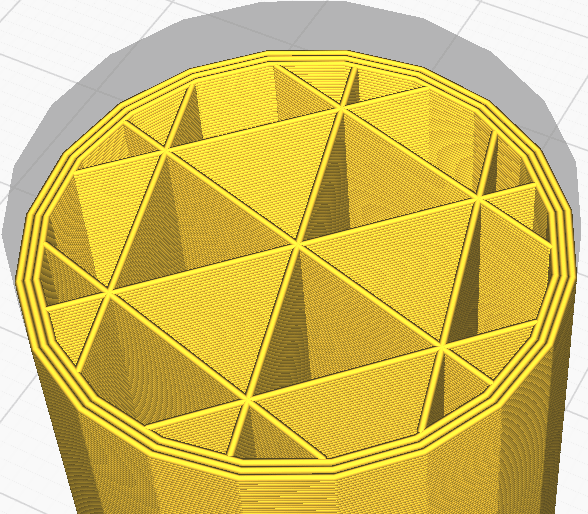

Triangles (medium stability): The Triangle Infill pattern creates a grid of triangles. This pattern is also good for standard objects that require moderate stability. The stability is greatest on the XY plane.

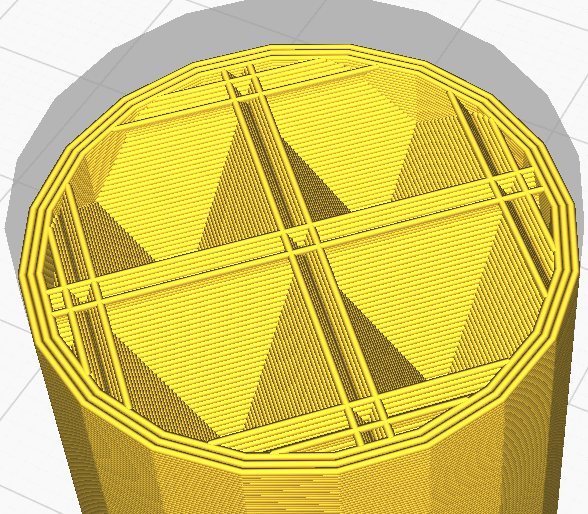

Octet (high stability): This pattern is formed by stacked pyramids. It is especially suitable for medium-sized objects that need to be very stable. The disadvantage is that you need many upper layers to get a smooth surface.

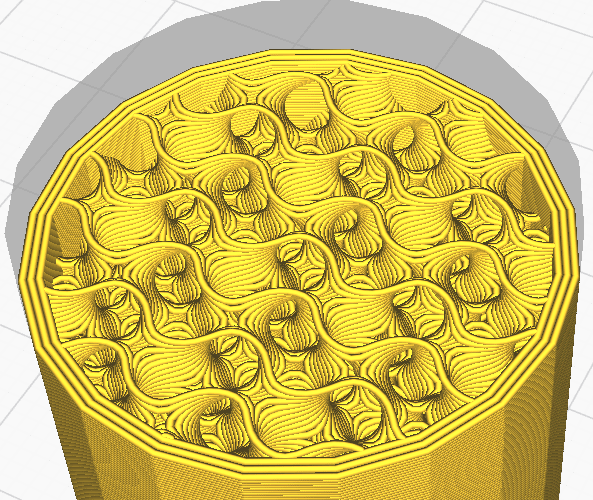

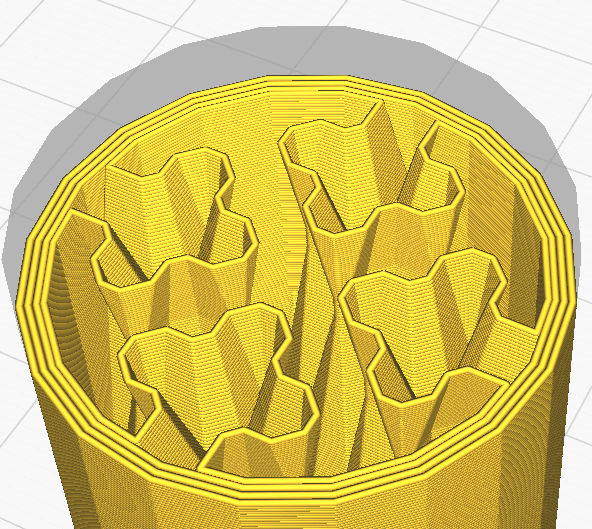

Gyroid (high stability): This pattern is extremely popular due to the unique look it produces. The curved lines that change direction slightly per layer create a slightly psychedelic or organic looking object. This pattern is very stable in all directions and also lends itself well to flexible prints. The downside is that most slicers take a long time to calculate it.

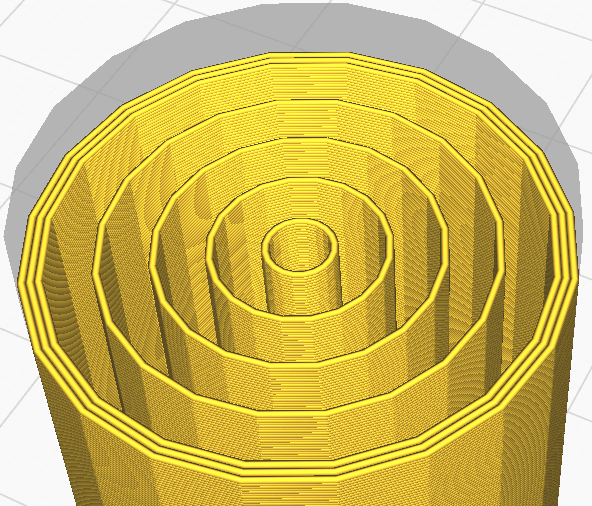

Concentric (for flexible filaments): This infill pattern is very weak and is mainly used for flexible filaments. Because the inner walls of the infill do not form intersections, the strength in the XY direction is virtually zero. The strength in the Z-direction is low and clearly noticeable with flexible filaments compared to the XY-directions.

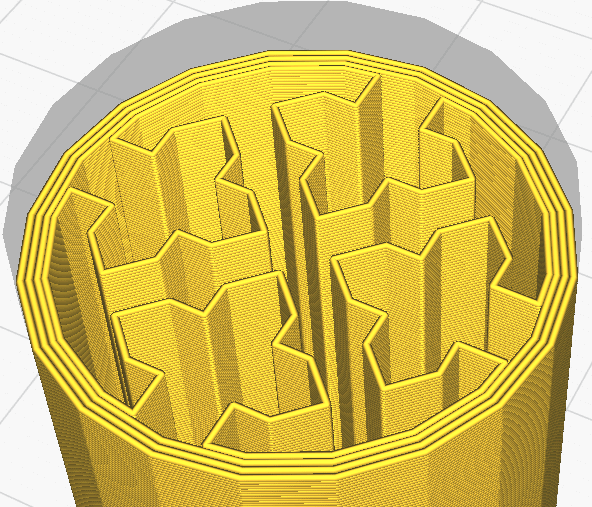

Cross and Cross 3D (for flexible filaments): Flexible filaments want to have as few direction changes as possible from retraction movements. Therefore, infill patterns consisting of continuous lines are suitable. Besides the concentric pattern, there is also the cross or cross 3D pattern.

Here, cross-like patterns are formed inside the object and are printed without the need to stop extrusion. They have a low stability in all directions and are therefore well suited for flexible objects.

Conclusion: How Good is the Tri-Hexagon Infill Pattern?

The tri-hexagon infill pattern is well suited for normal objects and decorative objects with low to medium infill densities. The tightly packed hexagons and triangles create high strength in the XY direction.

If you decide to use this pattern and the stability of the object is important, you should think about where this stable plane should sit when aligning the model or infill.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.