- Wet Filament: Prevention, Symptoms & Drying - July 18, 2024

- Sovol SV08 – Best PrusaSlicer Settings & Profile - June 26, 2024

- Sovol SV08 – Best Orca Slicer Settings & Profile - June 26, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

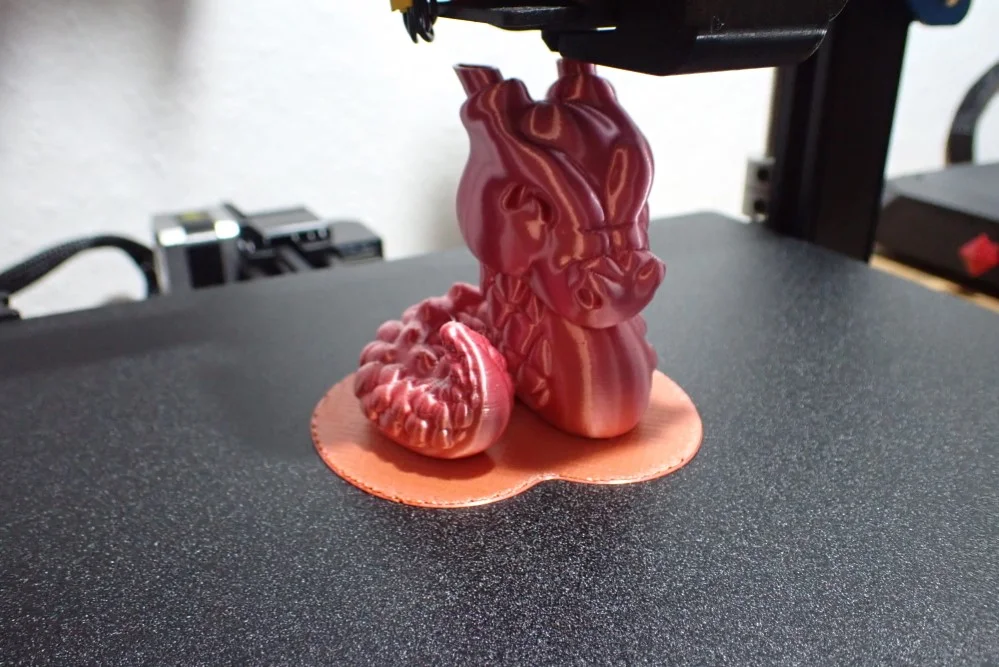

While the Sovol SV01 Pro comes with many features that improve print quality, you still need a good Cura profile with the right settings to get the most out of this 3D printer.

For a good Cura profile for the Sovol SV01 Pro, the standard profile for the Sovol SV01 can be used. The features that come with the Pro version affect the profile only minimally, making the Sovol SV01 profile a very good basis for further optimizations.

You can learn how to set up and optimize this profile in this detailed guide to the best Cura settings for the Sovol SV01 Pro. But before we go into detail, here is a small overview table with the most important settings for the most popular filament types:

| PLA | ABS | TPU | PETG | |

|---|---|---|---|---|

| Printing temperature | 195-205 °C | 225-235 °C | 210-225 °C | 225-250 °C |

| Print bed temperature | 60 °C | 85-90°C | 60 °C | 60 °C |

| Print speed | 50 mm/s | 50 mm/s | 25-35 mm/s | 50 mm/s |

| Retraction | 3 mm at 50 mm/s | 3.5 mm at 45 mm/s | 3.5 mm at 40 mm/s | 2.5-2.8 mm at 50 mm/s |

| Cooling | 100 % | 0% + enclosure | 100 % | 50-100 % |

Table of Contents:

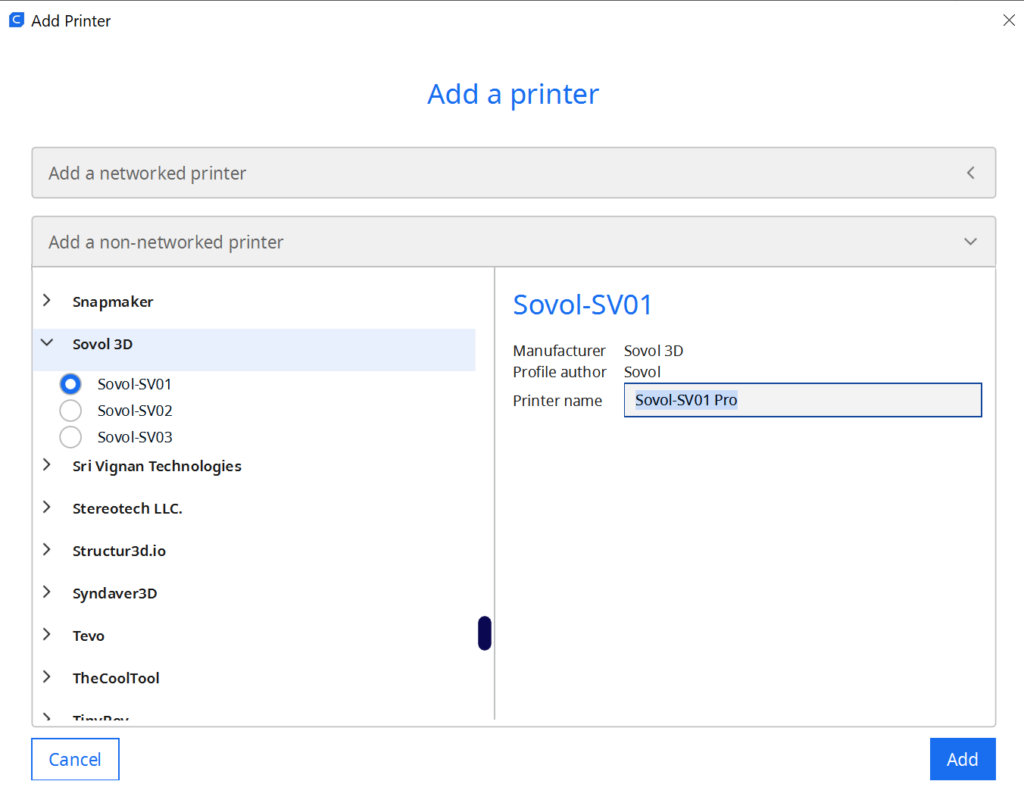

How to Create a Profile for the Sovol SV01 Pro in Cura

To create a profile for the Sovol SV01 Pro in Cura, the standard profile for its predecessor, the Sovol SV01, is loaded via the menu bar (“Settings” → “Printer” → “Add Printer…“). The machine settings do not need to be adjusted.

A 3D printer profile in Cura is a set of instructions that tell the software how to configure your printer for the print job. The profile includes machine settings for things like nozzle size, print bed size, and the number of extruders, and the print settings themselves with things like layer height, print speed, and print temperature.

If you’re just getting started with 3D printing, it’s a good idea to start with one of the default profiles that come with Cura or the 3D printer. Then you can calibrate the most important print settings to optimize the results. You’ll learn how to do this at the end of this article.

As mentioned at the beginning, it is best for the Sovol SV01 Pro to load and optimize the standard profile of its predecessor (Sovol SV01). The machine settings are identical due to the structure. While the Pro variant has gained many features, they only affect ease of use or such things as print bed adhesion. The print volume and extruder, for example, have remained the same.

You can find more information on how to create a 3D printer profile in Cura and what you need to pay attention to in this article: How to Create a Custom 3D Printer Profile in Cura

PLA Settings at a Glance

These are the correct Cura settings for the Sovol SV01 Pro for PLA:

- Printing temperature: 195-205 °C

- Print bed temperature: 60 °C

- Printing speed: 50 mm/s

- Retraction: 3 mm at 50 mm/s

- Cooling: 100%

- First layer: 5-10 mm/s, 0% cooling, 100% extrusion width, 100% layer height

PLA is definitely the easiest 3D printer filament to print with. It does not require very high temperatures for the nozzle and print bed and does not produce dangerous fumes like ABS. Any 3D printer can handle this filament. Still, there are a few things you need to keep in mind to get good results.

Thanks to the coated flexible printing plate, print bed adhesion is less of a problem than with the glass print bed of its predecessor. As long as you print the first layer at a relatively low print speed, you will have no problems with print bed adhesion. In my practical test of the Sovol SV01 Pro I measured the print bed in several places with a contactless thermometer. The homogeneity of the print bed is not perfect, but it is definitely sufficient for PLA.

Therefore, the most important settings for the Sovol SV01 Pro for PLA are the print temperature, the print speed and the retraction. With the print speed you should achieve good results with 50 mm/s. The theoretical maximum print speed should only be used if you really want to make very rough prints and the quality does not matter.

The print temperature and retraction are among the print settings that can differ slightly between two printers of the same type, especially for PLA. They are also different from filament to filament. Therefore it is important to calibrate these two settings also for PLA. Otherwise it can quickly come to printing errors such as stringing.

Unlike other 3D printers, the temperature of the extruder is very accurate, so you will find the right printing temperature very quickly. A good starting point is the values given above or those given by the manufacturer for the respective filament you are using.

ABS Settings at a Glance

When it comes to 3D printing filament, ABS is one of the most popular options thanks to its stability and durability. However, not all 3D printers are capable of processing ABS filament without error. In order for you to successfully print with ABS, your 3D printer must have a heated build platform and preferably a closed print volume. The heated build platform and enclosure ensure that the ambient temperature remains constant throughout the printing process and that the ABS does not warp due to rapid cooling.

The print bed of the Sovol SV01 Pro is well suited for ABS. For larger objects, you should slightly increase the print bed temperature to improve adhesion over the entire surface. Otherwise, the lower temperature at the edge of the print bed may cause the ABS print to peel.

The second prerequisite for perfect ABS printing is the enclosure, which the Sovol SV01 Pro does not have. If you want to print more often with ABS and especially want to produce large objects from this filament, you can retrofit a suitable enclosure. The 3D printer tent from Creality fits perfectly for the Sovol SV01 Pro.

If you only want to print smaller objects from ABS, you don’t necessarily need such a tent. To protect the print object from cold drafts you can also use a draft shield.

TPU Settings at a Glance

These are the correct Cura settings for the Sovol SV01 Pro for TPU:

- Printing temperature: 210-225 °C

- Print bed temperature: 60 °C

- Printing speed: 25-35 mm/s

- Retraction: 3.5 mm at 40 mm/s

- Cooling: 100%

- First layer: 5-10 mm/s, 0% cooling, 100% extrusion width, 100% layer height

When using TPU filament, it is important to set the print speed and retraction correctly to avoid clogging and get the best print quality. TPU is a flexible filament that can be difficult to process with some 3D printers. You’ll get the best results with a direct drive extruder. The Sovol SV01 Pro is therefore made for TPU.

With a direct drive extruder, the path between the extruder and the nozzle opening is very short. This means that the flexible filament has very little chance to compensate for the extrusion and retraction movements through its flexibility. Nevertheless, it is important to reduce the printing speed to minimize the inaccuracies caused by this flexibility.

The retraction can be very difficult to calibrate with TPU. Also, a lot depends on which TPU filament you are dealing with. With some filaments the sweet spot for retraction is larger than with others, making it sometimes very easy to prevent stringing and sometimes almost hopeless. Since the extruder of the Sovol SV01 Pro is very precise, it is easier to find the right value than with other 3D printers.

PETG Settings at a Glance

These are the correct Cura settings for the Sovol SV01 Pro for PETG:

- Printing temperature: 225-250 °C

- Print bed temperature: 60 °C

- Printing speed: 50 mm/s

- Retraction: 2.5-2.8 mm at 50 mm/s

- Cooling: 50-100%

- First layer: 5-10 mm/s, 0% cooling, 100% extrusion width, 100% layer height

One type of filament that has become increasingly popular in recent years is PETG. PETG combines many of the best properties of PLA and ABS. It is relatively easy to print and is still durable and stable in its finished state. However, printing with PETG filament can sometimes be tricky. PETG is known for problems such as strong stringing or hard removal of supports.

Because PETG is so prone to stringing, retraction is the most important print setting you need to optimize for this filament. Therefore, it is important to experiment with or calibrate your retraction settings before starting a large print job.

The maximum printing temperature of the Sovol SV01 Pro is 260 °C. This is sufficient for PETG. Since its heat break between the nozzle and extruder is made of metal and not PTFE as in many other 3D printers, no toxic gases are produced when printing with PETG (apart from the usual PETG filament fumes).

Best Cura Settings for the Sovol SV01 Pro

Printing Temperature

The best printing temperatures for the Sovol SV01 Pro in Cura:

- PLA: 195-205 °C

- ABS: 225-235 °C

- TPU: 210-225 °C

- PETG: 225-250 °C

If the printing temperature is too high, problems such as stringing can occur. Fine plastic hairs form between the nozzle and the object to be printed. If the temperature is too low, holes can form in the layer or the print bed adhesion is poor. In any case, it is important to find the right temperature for the respective combination of printer and filament to achieve a successful print.

The Sovol SV01 Pro can reach printing temperatures of up to 260 °C and can therefore process any standard filament with confidence.

The print temperature has a very large influence on the print quality and on many of the most common print errors. Therefore, the temperature is one of the settings that should be optimized and calibrated for each new filament. You will learn how to do this later in this article.

Print Bed Temperature

The best print bed temperatures for the Sovol SV01 Pro in Cura:

- PLA: 60 °C

- ABS: 85-90°C

- TPU: 60 °C

- PETG: 60 °C

The print bed temperature is a crucial element in the 3D printing process. The right temperature ensures that the object adheres well to the print bed, while too high a temperature can result in an elephant foot. The best way to find the ideal print bed temperature is to start with the guidelines above and then experiment with different settings to see what works best for your printer and material.

The print bed of the Sovol SV01 Pro can reach a maximum temperature of 110 °C and has an excellent coating that creates a very good print bed adhesion for most filaments. Therefore, you don’t have to experiment too much to find the right print bed temperature.

Print Speed

The best printing speed for the Sovol SV01 Pro in Cura:

- PLA: 50 mm/s

- ABS: 50 mm/s

- TPU: 25-35 mm/s

- PETG: 50 mm/s

The Sovol SV01 Pro reaches a maximum print speed of 80 mm/s. In my experience, however, you get the best results with 50 mm/s for most filaments.

If the print speed is set too high, it may result in poor print quality. Do not allow the print head to move too fast, as this can cause vibrations that can adversely affect quality. The associated printing error is called ringing or ghosting.

Flexible filaments are a special case. Due to their flexibility, they can only be printed relatively slowly. Imagine the filament between the extruder and the nozzle as jello – when you push it at the extruder, it takes a little time for the movement to reach the other end at the nozzle.

Although flexible filament is not quite as flexible as jello, the effect is more or less the same, only much weaker. Due to the fast movements, this effect still has an impact on the local synchronicity of the movement at the nozzle and the extruder. To give the movement time to reach the end of the filament, the printing speed should be reduced for a flexible filament.

Layer Height

The best layer height for the Sovol SV01 Pro in Cura:

- Decorative objects: 0.1-0.15 mm

- Standard: 0.20 mm

- Coarse, fast prints: 0.3-0.4 mm

3D printers build an object layer by layer. The thickness of each layer is determined by the printer’s settings, and the smoothness of the object’s surface depends on how thin the layers are. In general, the thinner the layer, the smoother the surface.

However, printing with very thin layers can take a long time, so it is sometimes useful to increase the layer height to save time.

Decorative objects usually benefit from thinner layers, as they create a finer surface. However, for functional objects where appearance is less important, thicker layers may be perfectly adequate. Ultimately, it depends on what results you want to achieve.

Flow Rate

The best flow rate for the Sovol SV01 Pro in Cura:

- Default value: 100%

- For over-extrusion: 90% to 99

- For under-extrusion: 101% to 110%.

If the flow rate is too high, the plastic will be applied too thickly. This can cause blurring of details or printing errors due to over-extrusion. If the flow rate is too low, the plastic is applied too thinly and in extreme cases, holes or cracks may occur.

In the vast majority of cases, you will not need to change the flow rate from the default value of 100%. If the profile is well calibrated, you should not need to make any changes here. However, with some 3D printers, you can use the flow rate to correct many things, eliminate printing errors and increase dimensional accuracy.

If you have problems with print bed adhesion, you can increase the flow rate for the first layer. This will increase the diameter of the applied filament, allowing it to cool more slowly and bond better to the print bed.

Retraction

The best retraction settings for the Sovol SV01 Pro in Cura:

- PLA: 3 mm at 50 mm/s

- ABS: 3.5 mm at 45 mm/s

- TPU: 3.5 mm at 40 mm/s

- PETG: 2.5-2.8 mm at 50 mm/s

Retraction is one of the most important print settings. It determines how far and how fast the filament is pulled back into the nozzle after an extrusion movement. This is necessary to prevent the liquid filament from escaping uncontrolled from the nozzle between two extrusion movements which results in stringing.

With the direct drive extruder of the Sovol SV01 Pro, it is not that difficult to find the right values for the retraction. The extruder works very precisely. The values given above provide you with a good basis for further optimization. How you can calibrate the retraction, you will learn later in this article.

Infill

The best infill density for the Sovol SV01 Pro in Cura:

- Decorative objects: 0-15%

- Standard objects: 15-50%

- Stable objects: 50-100%

When 3D printing an object, the infill density – or how much material is printed inside the object – is an important factor. If the object is just for decoration, it doesn’t need to be as densely filled with material, and less material means a lighter object that is cheaper and faster to print.

However, if the object needs to be very stable, such as a gear or a hook, then a higher infill density is much less likely to break or warp over time. So the right infill density for your 3D printed object depends on its purpose – more density for stability, less density for decoration.

In addition to the density of the infill, the pattern is also crucial. The most common patterns in 3D printing are lines or grids. The line pattern is less sturdy, but it also prints faster. Apart from these, there are a few other patterns that can be used depending on the desired result.

High stability (for stable objects):

- Cubic

- Cubic subdivision

- Octet

- Gyroid

Medium stability (for standard objects):

- Grid

- Triangles

- Tri-Hexagon

Low stability (for decorative objects):

- Lines

- Zigzag

- Lightning

First Layer

These are the best Cura settings for the first layer on the Sovol SV01 Pro:

- Layer height: 100-200% of normal layer height (higher values to increase print bed adhesion)

- Line width: 100-200% of normal line width (higher values to increase print bed adhesion)

- Print temperature: Same as the rest of the object or 5-10 °C higher for better print bed adhesion.

- Print speed: 50% of normal print speed (i.e. 25 mm/s for a normal print speed of 50 mm/s) or 5-10 mm/s for high print bed adhesion

- Flow rate: 100-110% (higher values in case of poor print bed adhesion)

Many beginners watch with a sweaty brow as the first layer of their 3D print is printed. This layer is very critical to whether or not the 3D print will work. There are a few settings you can use to increase the likelihood that the object will adhere well to the print bed without losing dimensional accuracy.

The print speed also falls under these settings. The first measure I use when I have poor print bed adhesion is to reduce the print speed massively. Usually, a value between 5 and 10 mm/s is good to increase the print bed adhesion.

Due to the low printing speed, the applied material has a longer time to cool down. The longer it stays hot, the better the bond to the print bed.

The other settings do basically the same thing and in their own way increase the time it takes for the filament to cool down.

How to Calibrate the Cura Settings for the Sovol SV01 Pro

Calibrating a 3D printer is important to ensure accurate and consistent prints. Calibration is the process of adjusting the print settings to the optimal value in small increments. This ensures that the 3D printer creates objects of the correct size and shape, avoiding printing errors.

Calibration may seem like a daunting task, but it’s essential to getting the most out of your 3D printer. With a little time and patience, you can produce high-quality prints you can be proud of.

The most important print settings that should be calibrated are the printing temperature, the flow rate and the retraction. If you have calibrated these three settings well, you will be able to eliminate most printing errors.

There are a few other settings like the print speed that are important after that. But if you stick to the recommended print speeds, you don’t have to calibrate anything here. Only if you go to the maximum possible print speed, you should experiment a little.

Read the full calibration guide:

3D Printer Calibration: Step-by-Step to Perfect Results

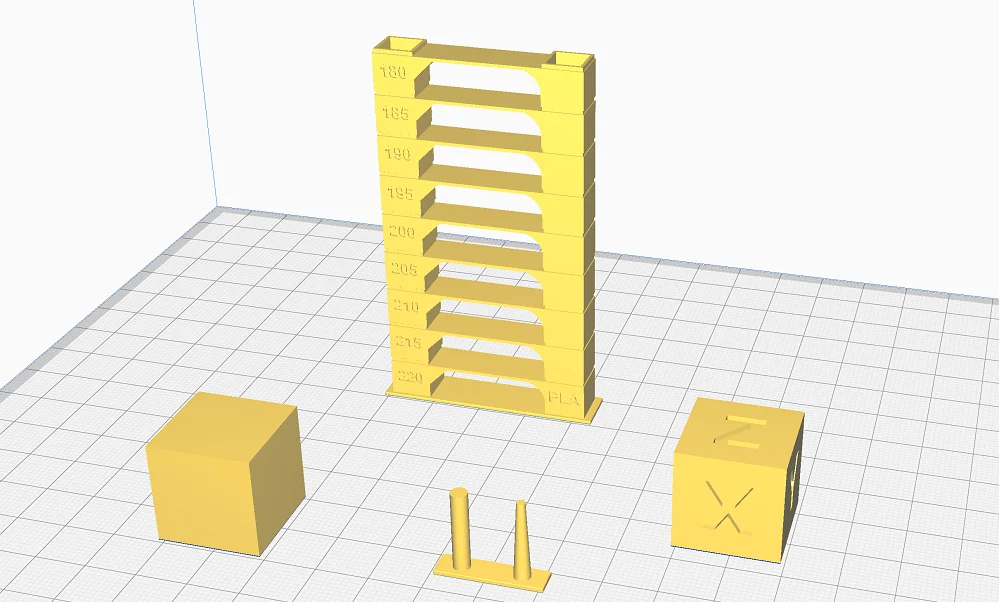

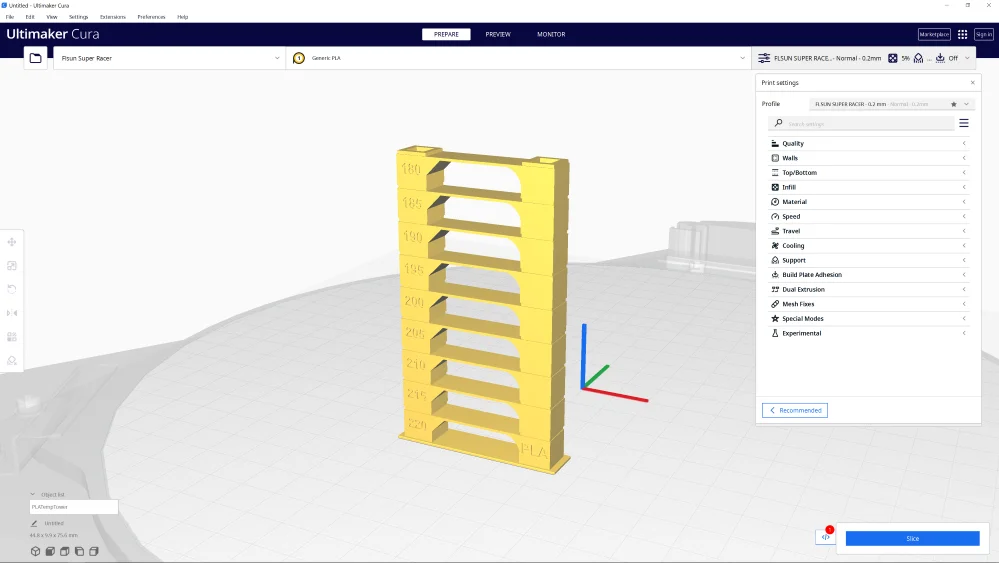

How to Calibrate the Printing Temperature

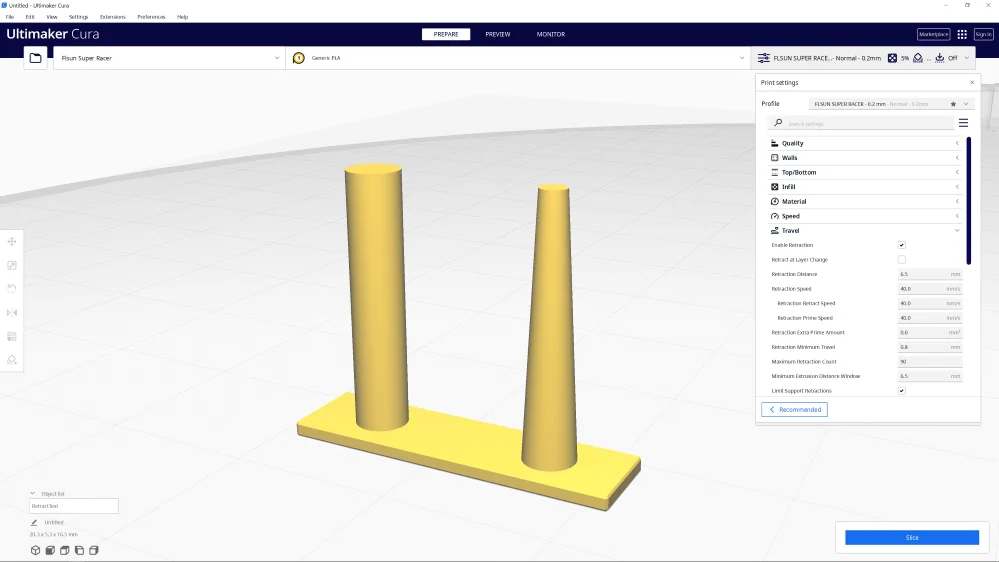

To calibrate the printing temperature you can use a temperature tower. You can find suitable objects on portals like Thingiverse or in the Calibration Shapes Plugin in Cura (free via the Marketplace in Cura).

Such a calibration object is built up of several layers with the same geometry. These geometries provoke printing errors and are printed at different temperatures. This allows you to see after printing at which temperature the fewest printing errors were produced.

How to Calibrate the Retraction

When calibrating the retraction, pay attention to stringing and approach the perfect values of the two retraction settings (distance and speed) in small steps.

Most calibration objects for retraction are made up of at least two small columns. There are also objects that are not unlike a temperature tower.

How to Calibrate the Flow Rate

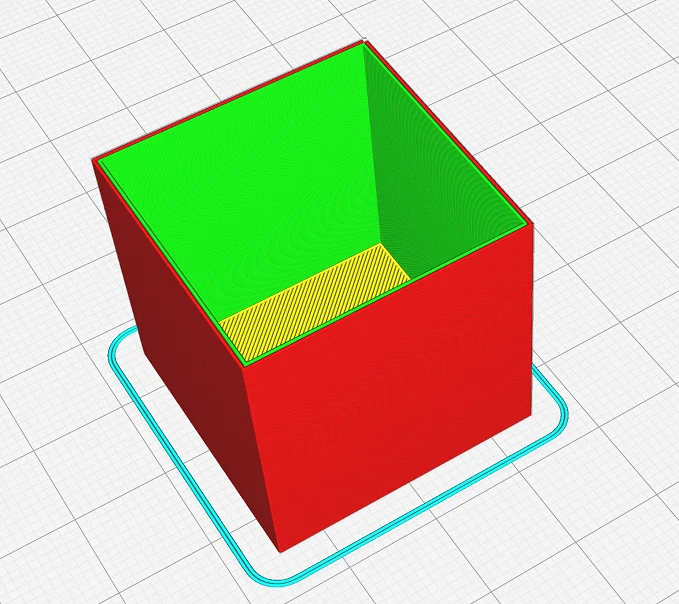

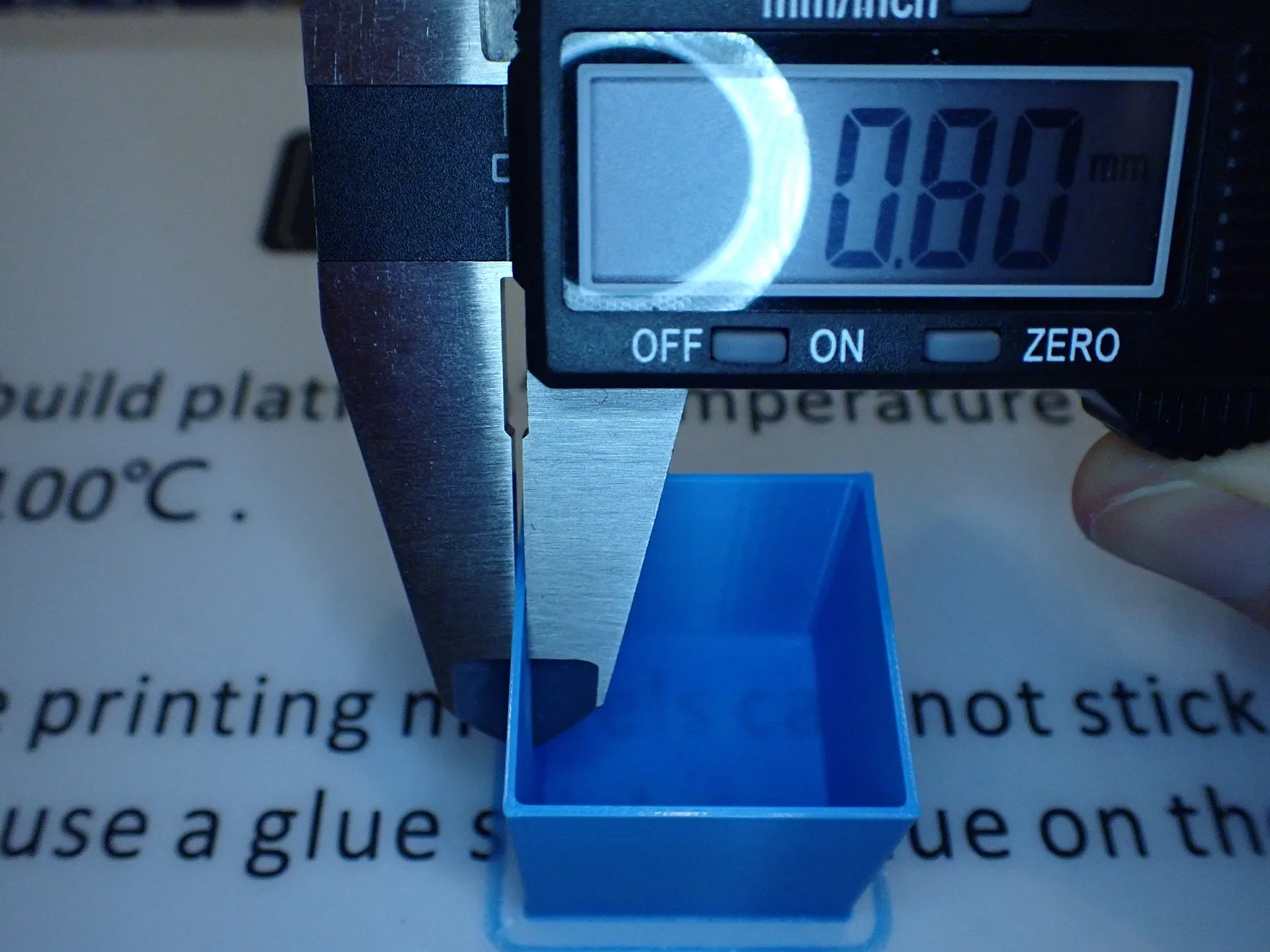

When calibrating the flow rate, the goal is to ensure that the theoretical dimensions of the object match the real values of the printed object.

There are many methods to calibrate the flow rate. I prefer to print a hollow cube with no top layers and compare the wall thickness after printing to the wall thickness in the slicer. If the flow rate is set too high, the wall thickness will be too thick and vice versa.

Sometimes large changes in flow rate can affect other print settings. For example, if you greatly increase the flow rate, this can also cause stringing or other phenomena of over-extrusion. Then it may be necessary to reduce the printing temperature or adjust the retraction.

Conclusion

The Sovol SV01 Pro is a fantastic 3D printer with which you can achieve excellent results. With the Cura settings given in this article you have a good basis for further optimizations. If you have the most important print settings under control, you will quickly get good results.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.