- Is a Wash & Cure Station Worth It? Creality UW-03 Review - April 29, 2024

- Z Seam | How to Hide & Avoid | Cura & PrusaSlicer - April 20, 2024

- Qidi Tech Q1 Pro – Best Orca Slicer Settings & Profile - April 9, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

In fused deposition modeling (FDM) 3D printing, hot material from a fine nozzle is deposited in layers on top of each other to print an object.

The material for FDM 3D printing is mostly filament made from various thermoplastics. There are also 3D printers that can print food or concrete, but these devices represent a small niche.

FDM 3D printing is very popular in the private as well as in the professional and industrial sector. It can be used to produce objects of various geometries quickly, cheaply and with a wide range of materials.

In this article, you’ll learn all about FDM 3D printing and why it’s so popular, especially for hobbyists. At the end, we compare FDM with SLA 3D printing, where the object is printed from resin and not filament.

Table of Contents:

How FDM 3D Printing Works

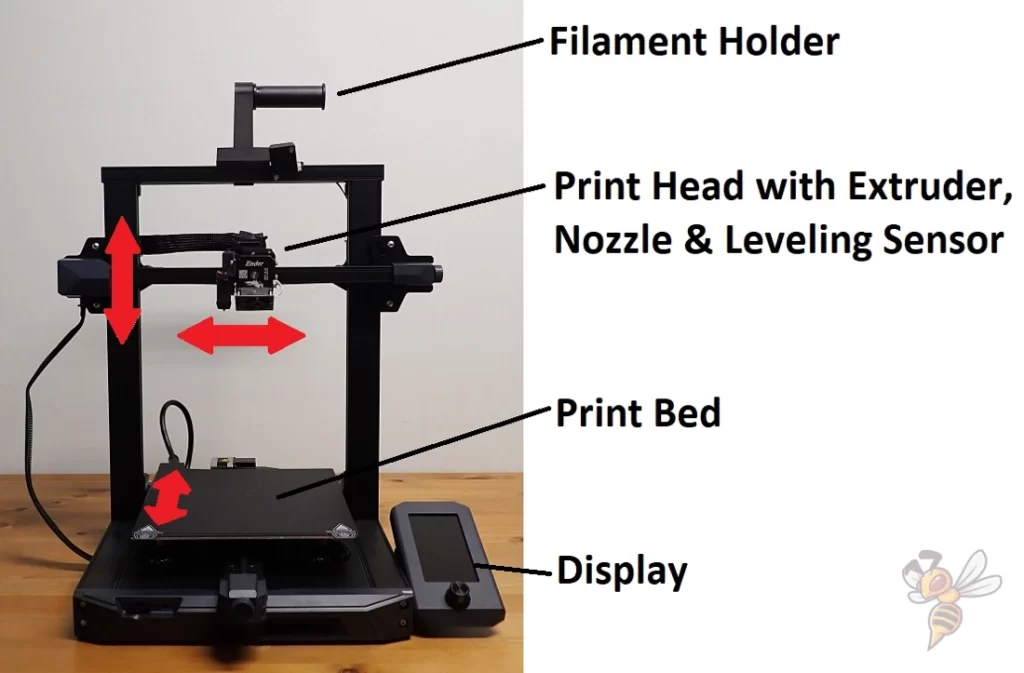

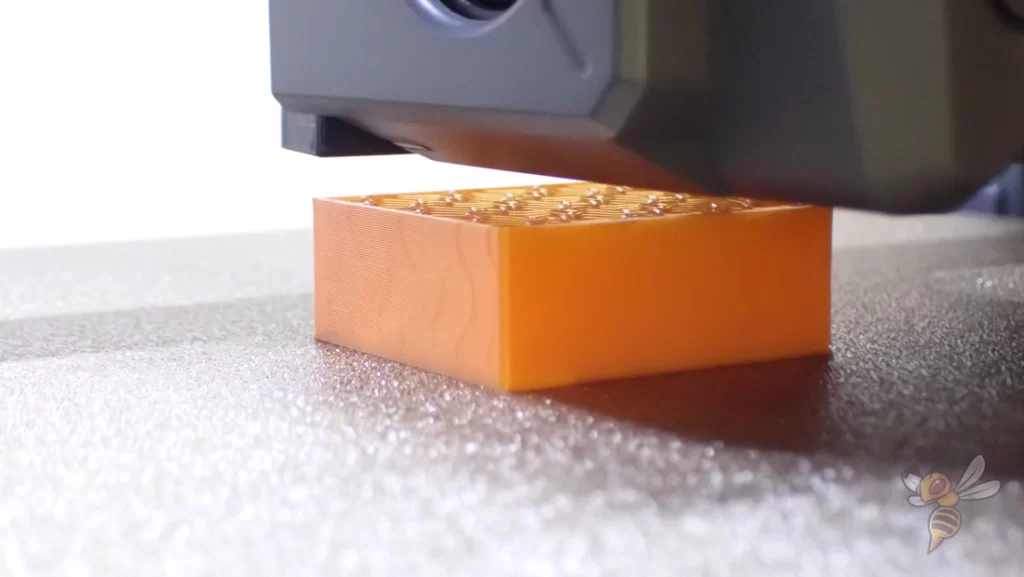

The basic principle of an FDM 3D printer is relatively simple. Hot filament is applied to a print bed through a nozzle. The nozzle moves in three-dimensional space and can print an object line by line and layer by layer.

Filament Extrusion

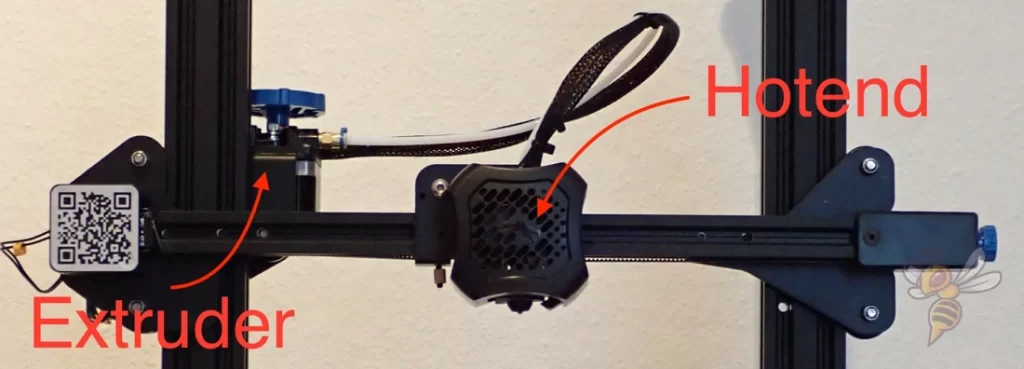

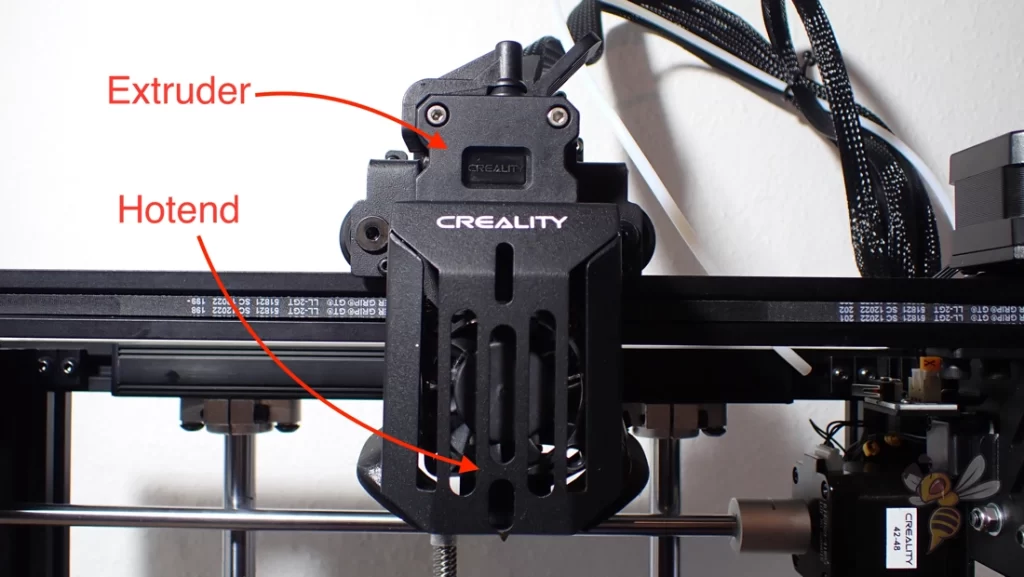

To extrude hot filament from the nozzle of an FDM 3D printer, it must be hot enough and conveyed with the necessary pressure. The two most important parts of a 3D printer for this are the extruder and the hotend.

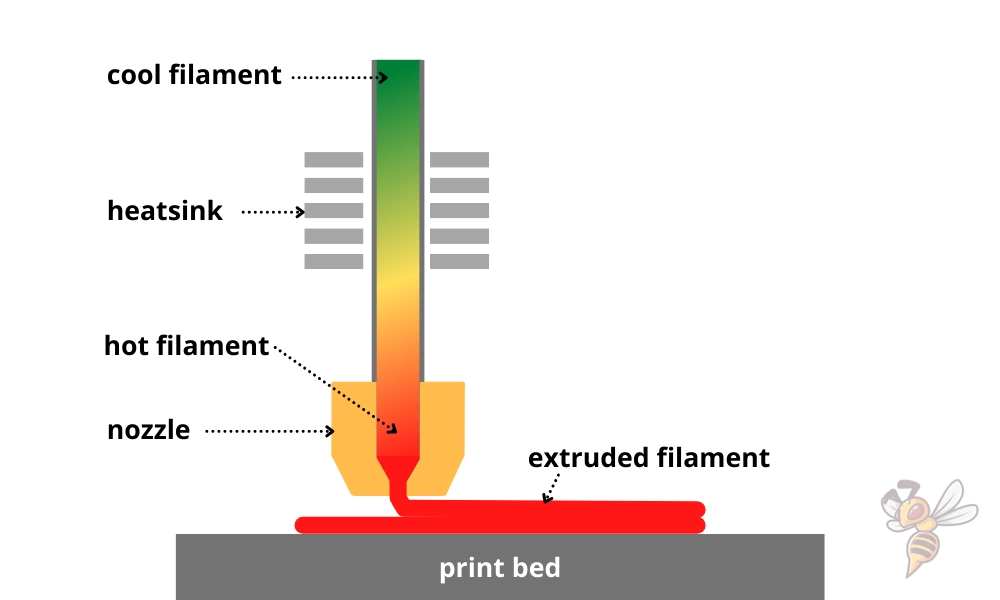

The hotend heats the filament to temperatures above its melting point. At the end of the hotend is the nozzle, through which the hot and liquid filament is pressed and applied to the print bed.

The extruder of an FDM 3D printer conveys the filament to the hotend with gears. The accuracy of the extruder is essential for the final result. The extruder determines how much filament comes out of the nozzle per second.

There are two different types of extruders: Bowden extruders and direct drive extruders. In this article you will learn the exact differences, advantages and disadvantages of both variants in detail. In short, the only difference is the position of the extruder. Either the extruder sits far away on the frame of the 3D printer (Bowden) or directly in the print head above the hot end (direct drive).

The print head of an FDM 3D printer thus includes the nozzle, the hot end, the heatbreak and, in the case of a direct drive extruder, the extruder as well.

The heatbreak or heatsink above the hotend limits the heating of the filament to the hotend and prevents liquid filament from passing over the hotend. Without the heatbreak, the liquid filament would get too far up, cool down and clog the print head.

In addition to all these components, there are fans in the print head that cool the heatbreak and the exiting filament. In FDM 3D printing, it is important that the filament stays hot longer in some places and sometimes it needs to cool down as quickly as possible.

If the filament remains hot and liquid on the print bed for longer, better print bed adhesion will result. However, if overhangs are printed, the filament should cool as quickly as possible so that it cannot fall down.

Hot filament is extruded with all these components in the print head. In order for an object to be created from this, the print head must move in three-dimensional space.

Layer-by-Layer

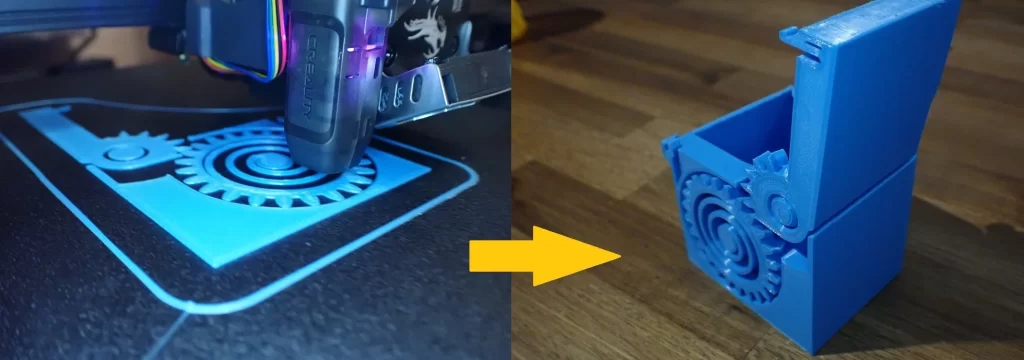

To create a finished object from the hot filament extruded from the nozzle, the print head must systematically apply the filament layer by layer.

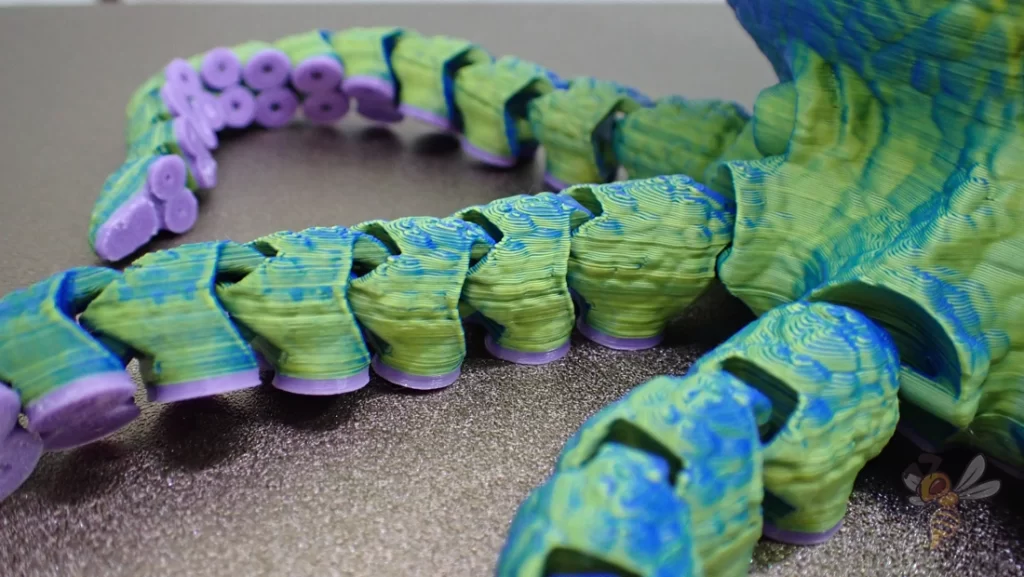

Objects are created in FDM 3D printing from the bottom up. After the first layer is printed from individual lines, the next layer is printed on top of it, again from individual lines. In this way, layer by layer, an object is created that ultimately consists of several hundred or thousand layers.

The print head of an FDM 3D printer moves in three-dimensional space and can reach any point within its print volume.

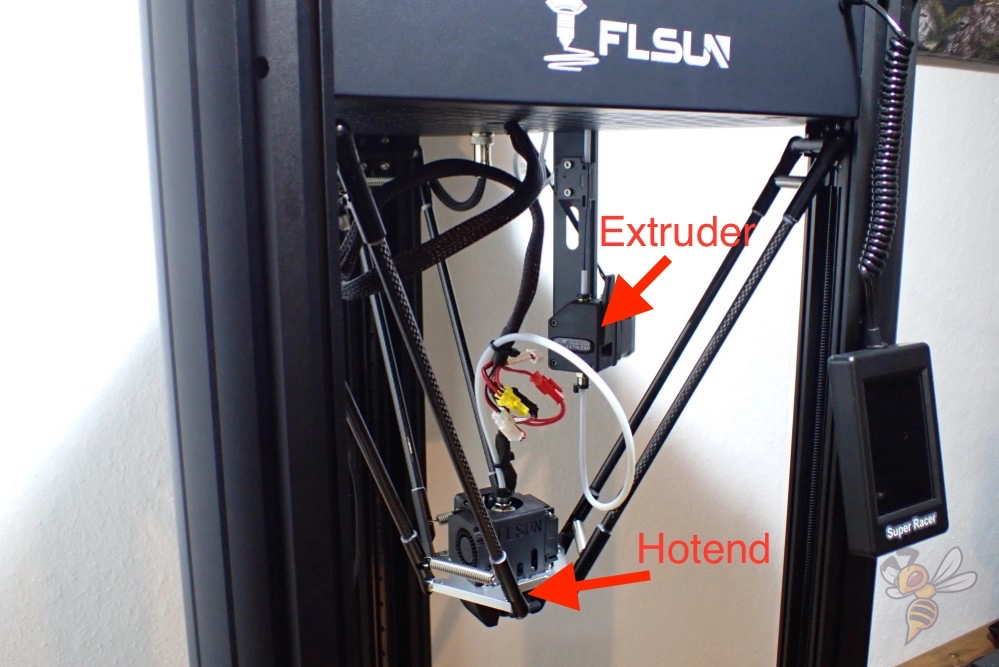

FDM 3D printers mainly have two different designs: Cartesian or Delta. In a Cartesian 3D printer, the print head moves on the horizontal x-axis, which in turn can move vertically in the z-direction. The print bed, which can move on the y-axis, serves as the print surface.

Simple movements in only one axis are realized by moving only one axis. If diagonal movements in two directions or even in three directions are to be executed, two or three axes move simultaneously.

In a Delta 3D printer, the print head hangs from three very movable arms, each of which can move independently in the Z direction. Depending on how the individual arms move, the print head can be moved in all spatial directions. The advantage of delta 3D printers is that higher printing speeds are possible. The disadvantage is that they are usually much pricier than Cartesian 3D printers.

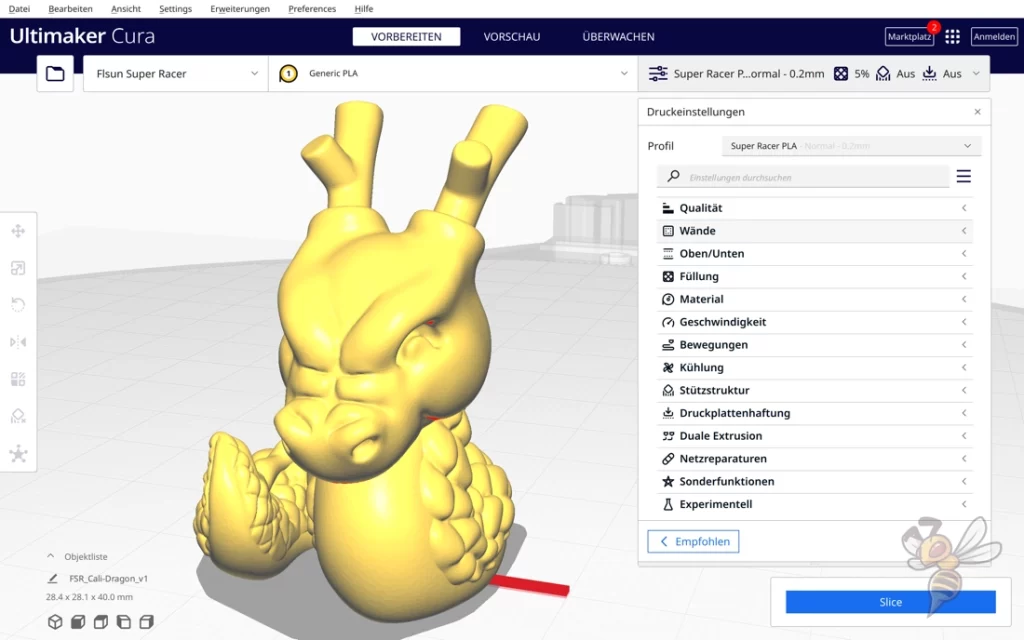

FDM Software – Slicer

In order for the 3D printer to know how the print head should move, software must translate the 3D model into a language that the 3D printer understands. The 3D models are usually available as STL or OBJ files. The software calculates how the filament lines and layers must be constructed to best mimic the contour of the object.

The object is cut into individual layers in the software, so to speak, hence the name “slicer”.

For FDM 3D printers, there are many slicers that you can use. These are among the most popular of them:

I myself use the most popular slicer for FDM 3D printers, Cura from Ultimaker, for all my FDM 3D printers.

The settings in the slicer must be adjusted to the respective FDM 3D printer, the filament used and the object. This is the real art of 3D printing. If the settings are not optimal, annoying printing errors will occur. Calibration is therefore essential for perfect results.

The most important settings in the slicer include the layer height, print temperature, print speed and retraction.

The layer height determines to a large extent the texture of the surface of the finished object and how large the steps are between the individual layers. The smaller the layer height, the smoother the surface.

The printing temperature depends on the filament used. It must not be too high. Otherwise, the filament is too liquid and can escape in an uncontrolled manner. However, it must also not be too low, as otherwise the layer adhesion suffers and other printing errors such as holes can occur.

The print speed determines how fast the print head moves during extrusion. The higher the speed, the faster the object is printed. However, printing errors can occur if the speed is too high. The maximum speed of an FDM 3D printer depends mainly on its stability and how accurately the extruder works.

Retraction defines how much filament is pulled back into the nozzle at what speed at the end of an extrusion motion. The object is not printed from a continuous line. The print head moves sometimes without extruding filament.

To prevent filament from escaping uncontrollably from the nozzle and causing printing errors such as stringing, the filament is pulled back into the nozzle by the retraction. As you might imagine, it is necessary to optimize this setting to achieve error-free results.

If all settings in the slicer are correct, the filament is extruded without errors and the object is printed layer by layer.

For most 3D printers, there are ready-made slicer profiles in which the settings already fit relatively well. Often, almost perfect results can be achieved with these. Calibration is necessary for perfect results.

Filaments for FDM 3D Printing

One of the advantages of FDM 3D printing is the wide choice of materials. Not only are there an infinite number of colors, but the types of the filaments can also be selected to meet specific needs.

The four filaments PLA, ABS, PETG and TPU have become particularly popular in hobby 3D printing.

PLA filament is easy to print. Every FDM 3D printer can process PLA. It is therefore ideal for beginners. It is also biodegradable. The downside is that it doesn’t have the best mechanical properties, making it mainly suitable for decorative purposes.

ABS filament is the most popular filament after PLA. It is much more stable and is therefore often used for mechanical applications. The disadvantage is that it is more difficult to process. It shrinks when cooling and can warp in the process. An enclosure around the 3D printer helps keep the ambient temperature homogeneous and warm to prevent warping.

PETG filament combines many of the advantages of PLA and ABS. It is easier to print than ABS and much more stable than PLA. Additionally, it is very resistant to water and chemicals, making it ideal for outdoor applications.

TPU filament is flexible. It is therefore suitable for very specific applications. However, flexible filaments also require the right hardware to be able to process them. This is where 3D printers with direct drive extruders pay off, as there is less chance of the flexible filament getting tangled.

There are many other filaments that are suitable for special applications. There are also standard filaments that have additives to give them special properties. These include, for example, PLA filament with wood fibers, carbon fibers and even stone powder.

Advantages of FDM 3D Printing

Some advantages of FDM 3D printing have already been briefly mentioned in this article. Due to these advantages, FDM 3D printing has spread in a very short time and will continue to do so.

Acceptable Print Quality

The print quality of FDM 3D printers is influenced by many factors. One of the most important factors is the layer height. The higher a layer is, the coarser the surface becomes. The smaller the layer height, the smoother it becomes.

Modern 3D printers achieve a reliable and relatively good print quality of 0.1 mm. For medium and large objects, this print quality is good enough to be suitable for decorative purposes.

A layer height of 0.1 mm is visible to the naked eye. Especially on round surfaces, the steps are clearly visible and can be felt with a fingernail.

The print quality can be quickly adjusted in FDM printing. It can be reduced, for example, to save printing time. Thicker layers are printed just as quickly as thinner layers, but the resulting object consists of fewer layers and is therefore printed faster.

Besides the optical print quality, the mechanical quality of the object is also important. In contrast to objects made of resin that are printed with an SLA 3D printer, objects made of filament are usually much more stable and robust. Therefore, FDM 3D printing is much more suitable for mechanical applications.

Cheap

FDM 3D printing is very cost-effective compared to other manufacturing processes. The flexibility of a 3D printer in particular reduces the costs that would be incurred for specialized tools or molds for injection molded parts, for example.

The filament is also inexpensive. With a normal 1 kg filament spool, many objects can be printed until new filament must be added.

So, when it comes to prototypes or product series with small runs, FDM 3D printing is very affordable. However, for mass production, injection molding is still the better choice because of the higher quality.

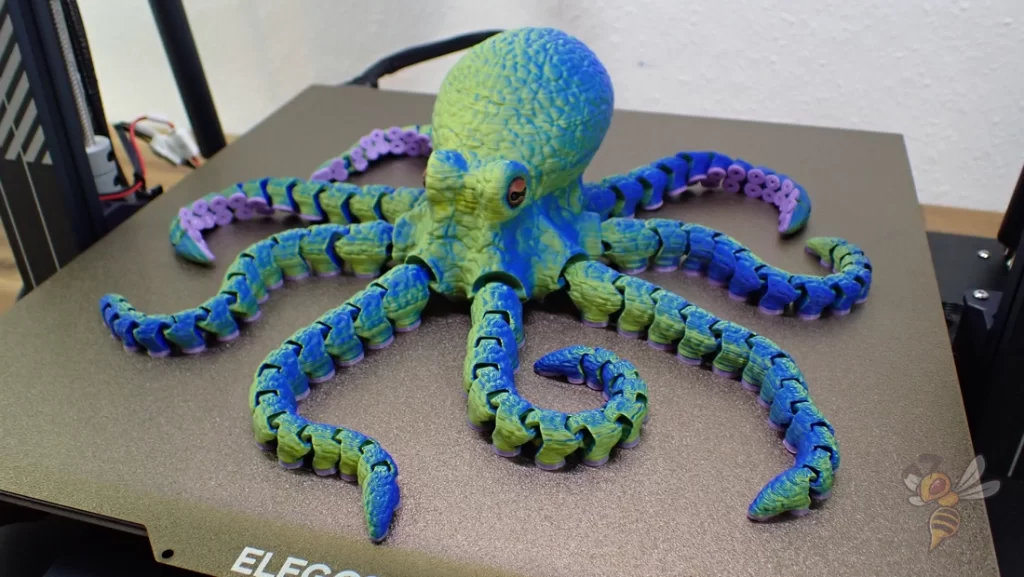

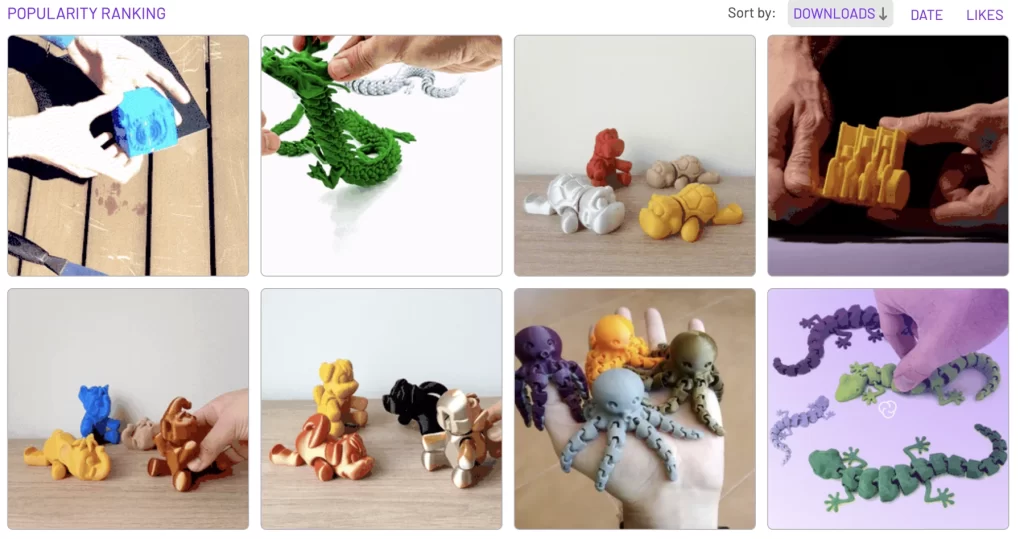

However, the inexpensive use of FDM 3D printers also makes this technology very attractive in the hobby sector. In addition to practical parts for everyday use, creative ideas can also be easily implemented. On portals like Thingiverse or Cults, there are seemingly endless objects from the community that can be printed at the push of a button and often for free.

This makes it possible to print parts at home that would otherwise have high acquisition costs and a long transport route elsewhere. If 3D printing continues to develop as it has so far, it could move entire sectors of industry into the home, reducing costs and protecting the environment.

Fast

Unlike other manufacturing methods, FDM 3D printing is very fast. Therefore, it is particularly suitable for prototyping and the production of small series in the professional sector and for creative ideas in the private sector.

Smaller objects, about the size of a glass, are printed within a few hours. Medium-sized objects can be printed comfortably overnight. Larger objects sometimes take several days to finish.

In industry, certain geometries can thus be tested quickly without having to develop special tools or manufacturing processes for them. This accelerates the development process and prevents costs that would later arise in the manufacturing optimization or revision of a product.

Easy

Modern FDM 3D printers are characterized by a high level of user-friendliness. In the early days of the 3D printing hobby, DIY kits still had more to do with tinkering than printing. Today, even inexpensive entry-level 3D printers resemble plug-and-play products.

Most devices already come with all the necessary features to ensure good print quality without many errors. This makes getting started with 3D printing straightforward and the first sense of achievement can be achieved on the very first day.

No extensive technical knowledge is required to operate a 3D printer. The software for 3D printers is also very intuitive and well documented in most cases. Even laymen can quickly find their way around.

Wide Range of Materials

There is a considerable selection of filaments in FDM 3D printing. There is a suitable filament for most applications. Not only can the color be chosen almost freely, but the different types of plastic also have different properties.

In addition to filaments with interesting optical properties such as rainbow filament, there are also filaments that are optimized for mechanical applications. These include blends of different types of plastic or sophisticated filaments, such as ASA or PEEK.

Disadvantages of FDM 3D Printing

In addition to the many advantages that make FDM 3D printing so successful, there are also a few disadvantages that limit the application possibilities to some extent.

No Small Details

Unlike SLA 3D printers, which can achieve layer heights of just 0.01 mm with resin, the accuracy of FDM 3D printers averaging 0.1 mm is unsuitable for some purposes.

For small objects with fine details, FDM printing is only suitable to a limited extent. For objects that are only a few centimeters in size, the steps and the individual layers become all the clearer.

In the hobby sector, it is very popular to print small figures, which are otherwise produced with injection molding, at home with the 3D printer. Of course, resin 3D printers are mainly suitable for this. With FDM 3D printers, the fine details would be lost and the result would be more or less unusable.

The accuracy of FDM 3D printers is also too low for some professional applications. Jewelers, for example, need a high resolution to realize the small details of their shapes.

However, as long as the accuracy of FDM 3D printers is sufficient, the advantages outweigh the other manufacturing processes or resin 3D printing. I too would choose an FDM 3D printer every time for an object where surface accuracy is only a secondary priority. Especially if it is a medium or large object where the small layers are not noticeable, FDM printing is so much faster and easier than resin 3D printing.

Printing Errors

Depending on what kind of 3D printer you use and how well you have optimized the settings in the slicer to the respective object, filament and 3D printer, the likelihood of printing errors is sometimes greater and sometimes smaller.

Typical print defects include stringing, where fine filament hairs are pulled between two areas of the object, or poor print bed adhesion, which can cause the object to detach from the print bed during printing or not adhere to it at all.

Such print errors can be very frustrating, as there can often be many causes for an error. Also, most print settings are coupled together, so it is not always clear which setting the print error is related to.

Especially with inexpensive 3D printers, it is difficult to calibrate the settings perfectly. However, 3D printers are getting better and better and more user-friendly. Modern entry-level 3D printers are already so good that they can achieve almost perfect results with the default settings.

Post-Processing of FDM Objects

The principle of FDM 3D printing creates small steps that are sometimes more and sometimes less visible, depending on the orientation of the object. For many projects, these steps are irrelevant, but sometimes you want a surface that is as smooth as possible – especially for decorative objects.

Post-processing FDM objects is about getting the surface as smooth as possible and minimizing the visibility of steps between layers.

These are the typical steps in the post-processing of FDM 3D prints:

- Removing support structures that support overhangs of an object during printing so that they do not fall off.

- Sanding and polishing to smooth the edges of the steps.

- Paint or coat to fill and further smooth the layer transitions left after sanding and polishing.

Typically, however, such post-processing is not necessary and is mainly limited to removing the remains of support structures or auxiliary constructions such as a raft as good as possible.

If smooth surfaces are important to you, you’re better off with resin 3D printing.

Applications of FDM 3D Printing

FDM 3D printing is the most popular form of 3D printing in the hobby sector. However, it is also used in the professional sector.

Here are a few examples of applications of FDM 3D printing in both professional and consumer contexts:

- DIY Projects: At home, FDM 3D printers are very popular for all sorts of applications from making spare parts, cosplay items and armor, decorative objects like vases or figurines.

- Prototyping: FDM 3D printing can be used to quickly produce objects from a CAD program. This allows developers in industry to test and optimize their products within hours

- Medical devices: Specialized 3D printers can produce tools for surgical purposes, prostheses and even implants.

- Architectural models: Architects can quickly visualize and present their digitally designed buildings with an FDM 3D printer.

- Schools and universities: FDM 3D printers can improve students’ technical understanding and teach manufacturing technologies.

- Art: There are artists who produce and present sculptures, jewelry or other art objects with FDM 3D printers.

- Rapid manufacturing: FDM 3D printers can be used to quickly and cost-effectively mass-produce small product batches. One example of this would be transport locks.

- Lightweight: In some industries, such as automotive or aerospace, FDM 3D printing is used for particularly lightweight parts that do not need to be as strong as aluminum parts.

FDM vs. SLA 3D Printing

The most significant difference between FDM and SLA 3D printing is the surface accuracy. This is about 0.1 mm for FDM 3D printing and up to 0.01 mm for SLA 3D printing.

The typical stairs of 3D printing are barely visible to the naked eye in modern SLA 3D printers. As soon as a slight edge smoothing is set in the slicer, the surface becomes as smooth as an injection-molded part.

However, there are two major drawbacks to SLA 3D printing. The first of these is that handling the resin is relatively laborious and requires complicated post-processing. The second major drawback is that the finished objects made from resin are often not as stable as comparable objects made from filament. In addition, the material selection is nowhere near as high and cannot be optimized for the application purpose as with FDM 3D printing.

However, SLA 3D printing is ideal for certain applications. For example, for small figures in the hobby sector. More precisely, these are figures of board games with a size of a few centimeters with countless details that are often painted with great care and detail. For this use case, the 3D printer has to transfer all details of the digital object into reality. This is not the case with FDM 3D printing.

Conclusion

FDM 3D printers extrude liquid plastic onto a print bed, creating an object line by line and layer by layer. The freedom, flexibility and speed that FDM 3D printing brings makes it attractive for many applications in the private and professional sectors.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.