- Z Seam | How to Hide & Avoid | Cura & PrusaSlicer - April 20, 2024

- Qidi Tech Q1 Pro – Best Orca Slicer Settings & Profile - April 9, 2024

- Creality Ender-3 V3 Review – Will CoreXZ be the New Trend? - March 27, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

The PLA filament from ERYONE* is extremely popular. Why this filament is so popular, I wanted to find out myself! In this hands-on review, I tested it extensivly and made several calibrations and test prints with it.

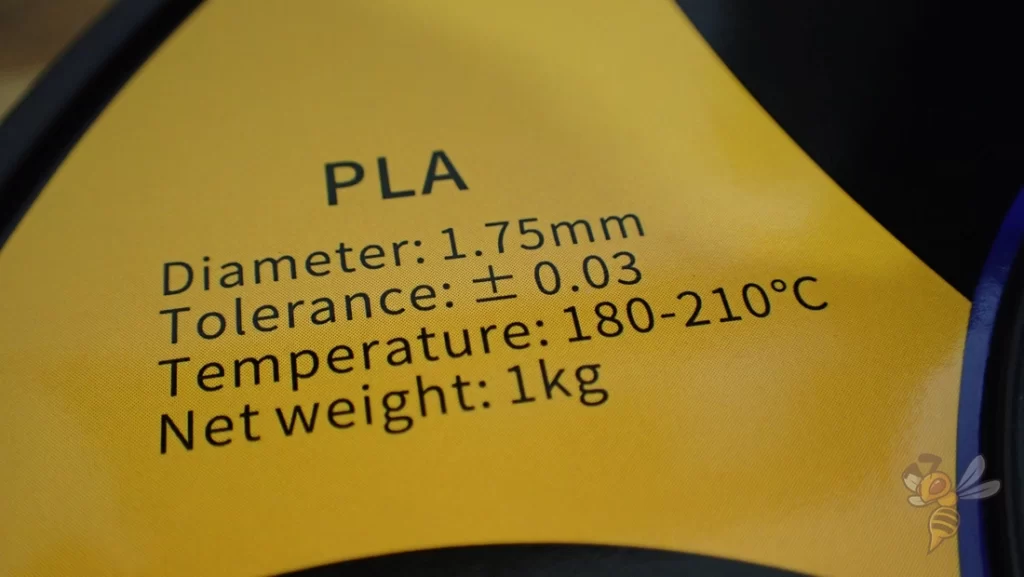

The ERYONE PLA filament has a consistent thickness, a wide temperature range of 180-210 °C and produces no stringing or blobbing with the right settings. It is vacuum packed and very neatly wound. The filament is suitable for beginners and experts alike.

In this practical test, you can see how these properties and the high-quality ingredients affect the print result.

I tested the following colors: Blue/Yellow, Blue, Green and Rainbow.

Check Price at:

Check Price at:

Table of Contents:

Technical Data

- Colors: Black, White, Grey, Blue, Clear, Red, Green, Yellow, Orange, Silver, Dual-Color, Rainbow

- Temperature range: 180 – 210 °C

- Print bed temperature: 55 – 70 °C

- Filament accuracy: 1.75 mm ± 0.03 mm

- Printing speed: 30 – 100 mm/s

- Melting temperature: 155 °C ± 5 °C

- Packing: Vacuum packed

- Weight: 1 kg filament + 0.35 kg spool

- Spool dimensions: Height = 64 mm; Inner diameter = 57 mm; Outer diameter = 200 mm

Winding

To prevent the filament from getting tangled during printing, it must be wound neatly on the spool.

With the ERYONE PLA filament* the filament is wound very orderly on the spool. I have used quite a bit of filament from the two spools and have not noticed any overlap or tangled filament.

With larger manufacturers, a good winding is now the standard. With cheap products, a bad or too loose winding unfortunately happens again and again.

Dimensions

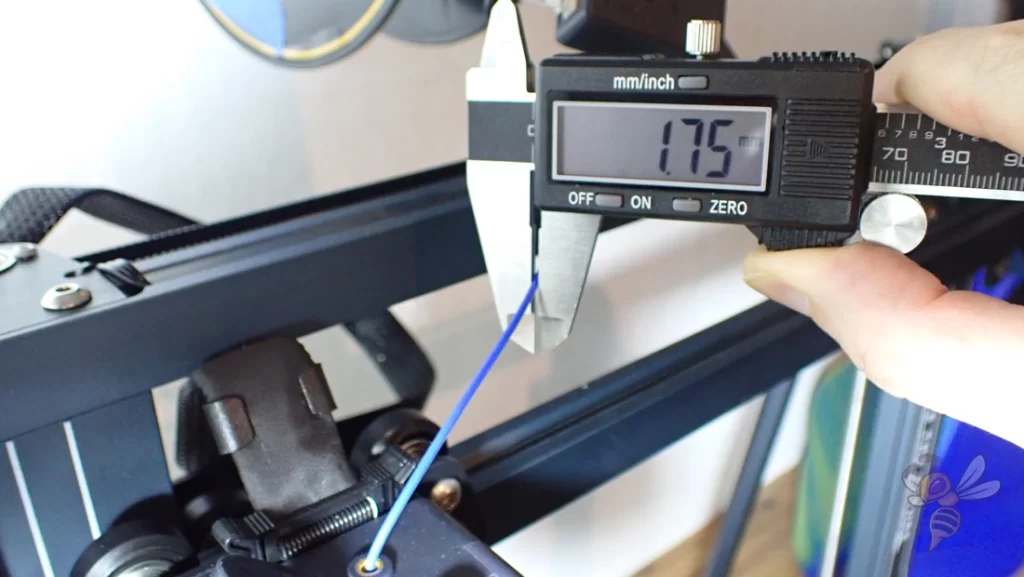

The first step when using a new filament is always to check the dimensional accuracy. More precisely, this means the thickness of the filament.

I measured the thickness in several places on the spool and was able to find a value of 1.75 mm ± 0.01 mm.

This is a really very high accuracy and even undercuts the accuracy of 0.03 mm stated by ERYONE!

The accuracy of the filament thickness is crucial for good printing results. If the thickness changes during printing, the extrusion width will also change. The result would be an unsightly 3D print. The more accurate the thickness of the filament is, the nicer the outer walls will be.

Calibration

Since each filament is slightly different, I always recommend you do a quick calibration when changing.

I took some extra time and did all the important calibrations with this filament. Among them are the following test methods or objects:

- Extrusion Multiplier / Flow Rate

- Temperature Tower

- Retraction Tower

- Calibration Cube

Extrusion Multiplier / Flow Rate

The correct flow rate, or extrusion multiplier on some slicers, is important to avoid a number of print defects. These include under-extrusion, over-extrusion, stringing and blobs or zits.

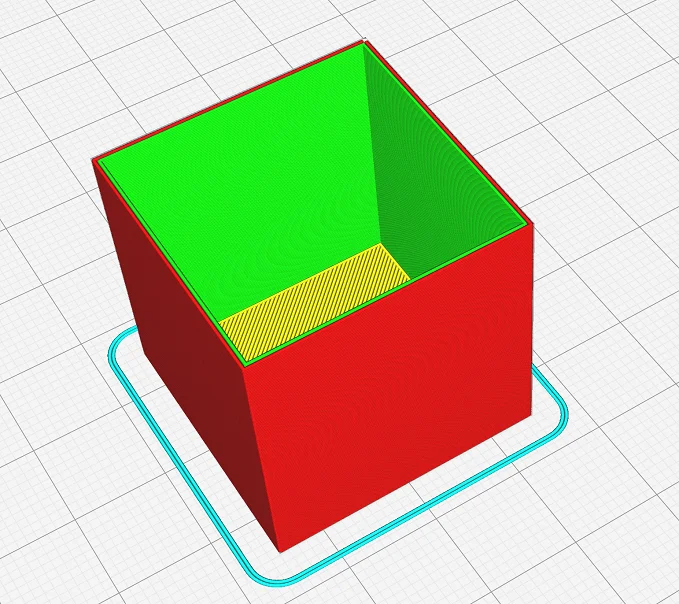

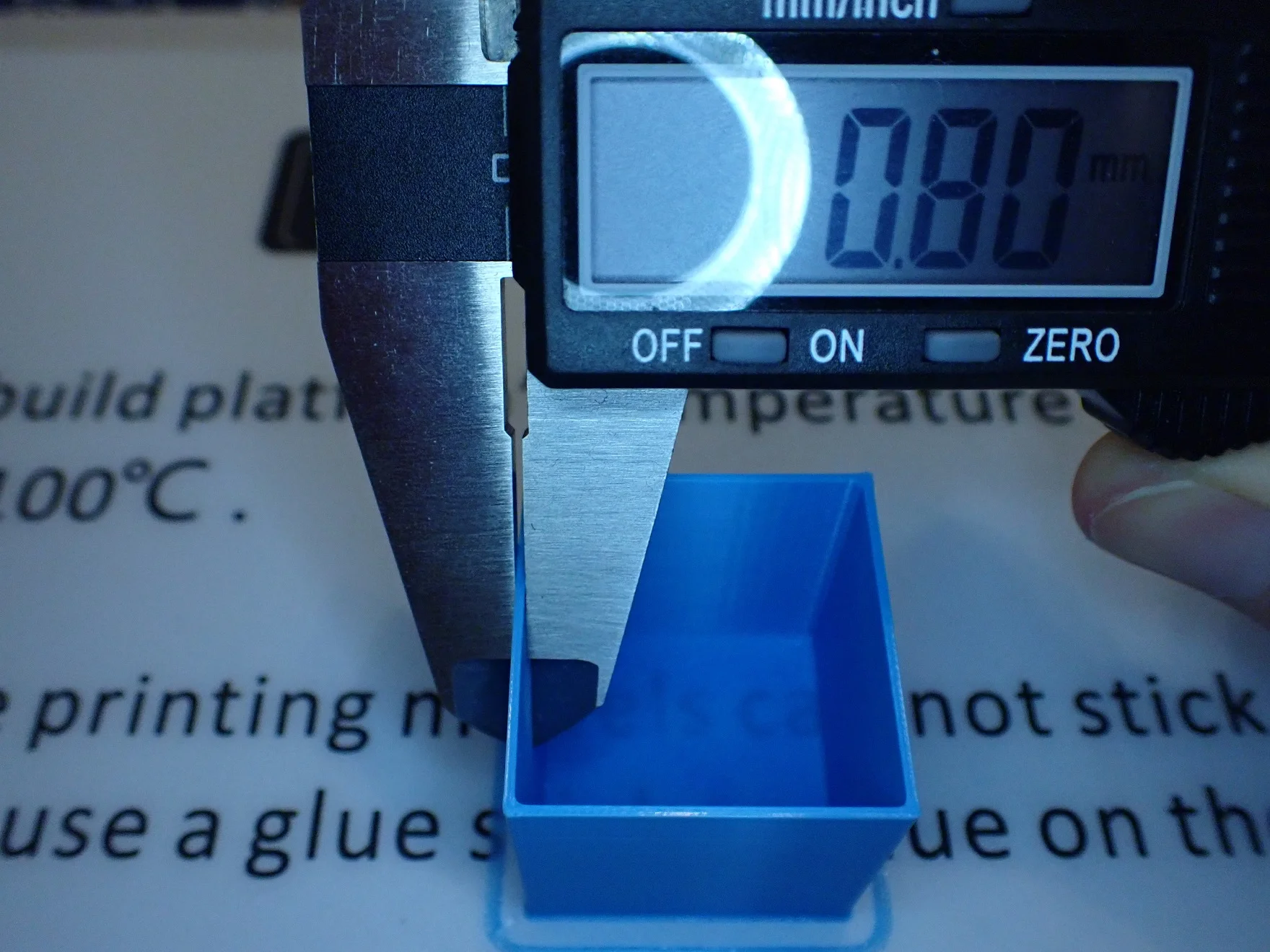

To determine the correct flow rate with the ERYONE PLA filament*, I printed a hollow calibration cube. By knowing how many walls are printed and what I specified for a line width in the slicer, I can calibrate the flow rate.

If the wall is too thick, I have to reduce the flow rate, if it is too thin, I have to increase the flow rate.

Here are my measurements:

- Number of walls = 2

- Line width = 0.4 mm

- Thickness of the wall target = 0.8 mm

- Thickness of the wall measured = 0.8 mm

In this case, I was lucky and the flow rate was already perfectly set. This is also proof of the high dimensional accuracy of the filament. With inferior filaments, I have to recalibrate and adjust the flow rate every time.

With the ERYONE PLA filament, the wall thickness was the same on all four walls and very homogeneous. This indicates that the thickness of the filament was consistent over the entire area used for printing. A confirmation of my results with the caliper!

Temperature Tower

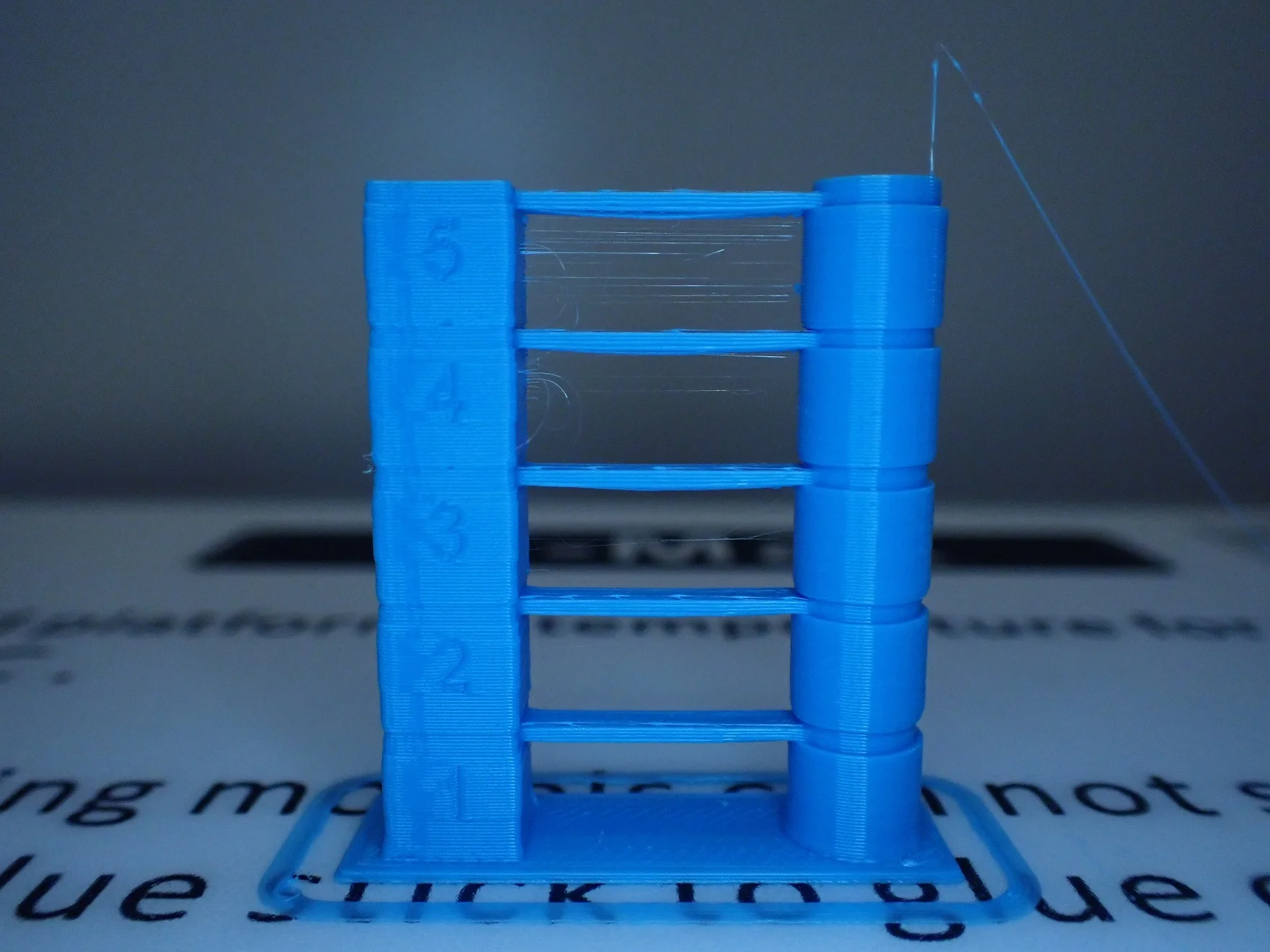

I used the Temperature Tower to test the ideal print temperature for the ERYONE PLA Filament. With this object, the temperature of the nozzle is reduced by 5 °C per stage in order to find the best setting in a print.

The best results were obtained at 195 °C to 200 °C. At these temperatures, there was virtually no stringing or over-extrusion. At lower temperatures, under-extrusion and ghosting occurred in some cases.

At higher temperatures, especially 220 °C and above, the stringing became extreme and there was a lot of over-extrusion. The filament simply became too liquid at these temperatures.

Even though the manufacturer specifies a fairly wide temperature range, the sweet spot is still somewhere in the range of 5-10 °C. This sweet spot can vary from 3D printer to 3D printer, but is usually somewhere in the middle.

Retraction Tower

This test is not really an indicator of how good the filament is, but it is important to avoid stringing. The retraction length always depends on which 3D printer you use and which nozzle is mounted.

However, with the temperature tower, I noticed that sometimes stringing can occur more often. That’s why I calibrated the retraction length again with the retraction tower. As you can see, at least one setting of it is just right. After that, virtually no stringing occurred.

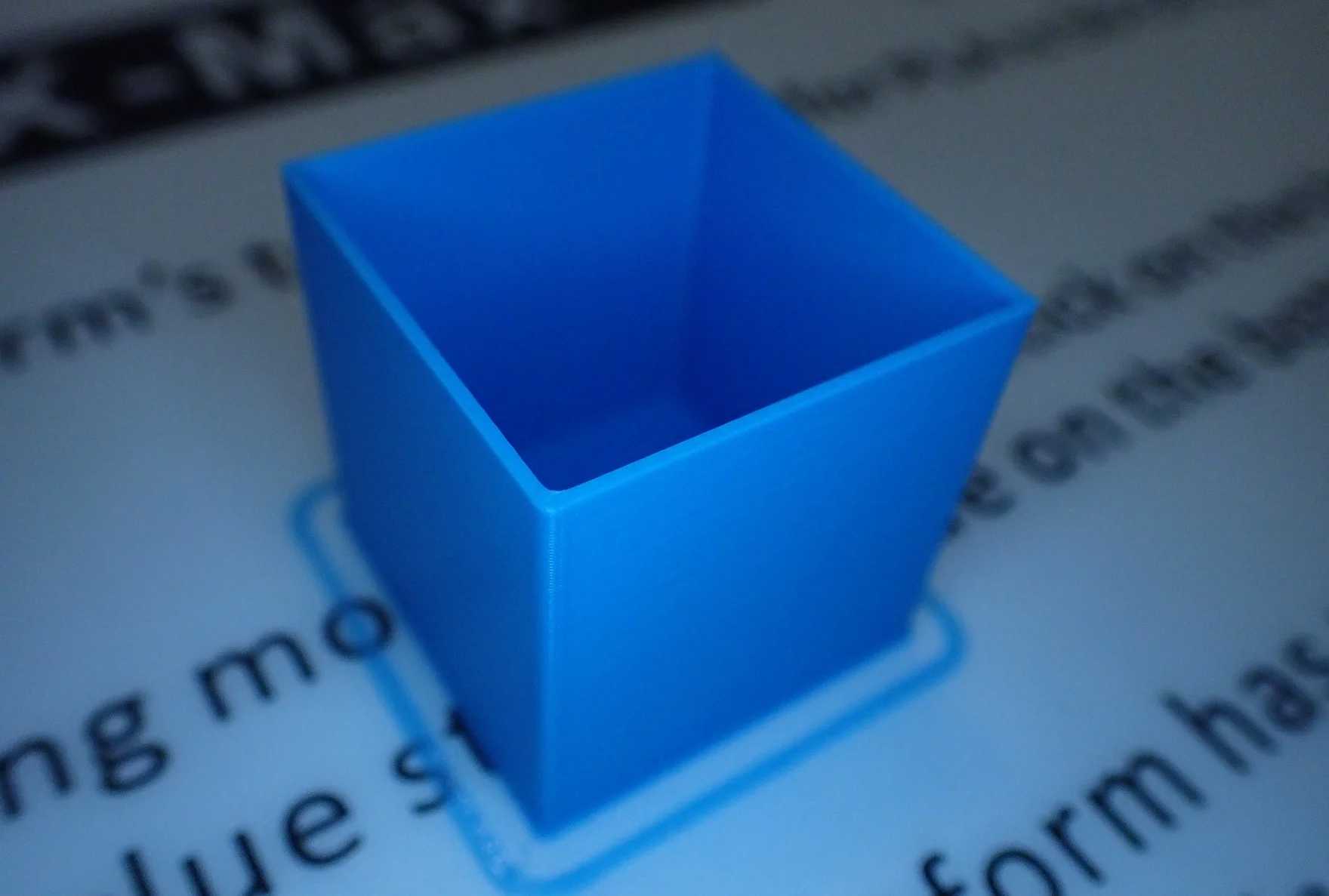

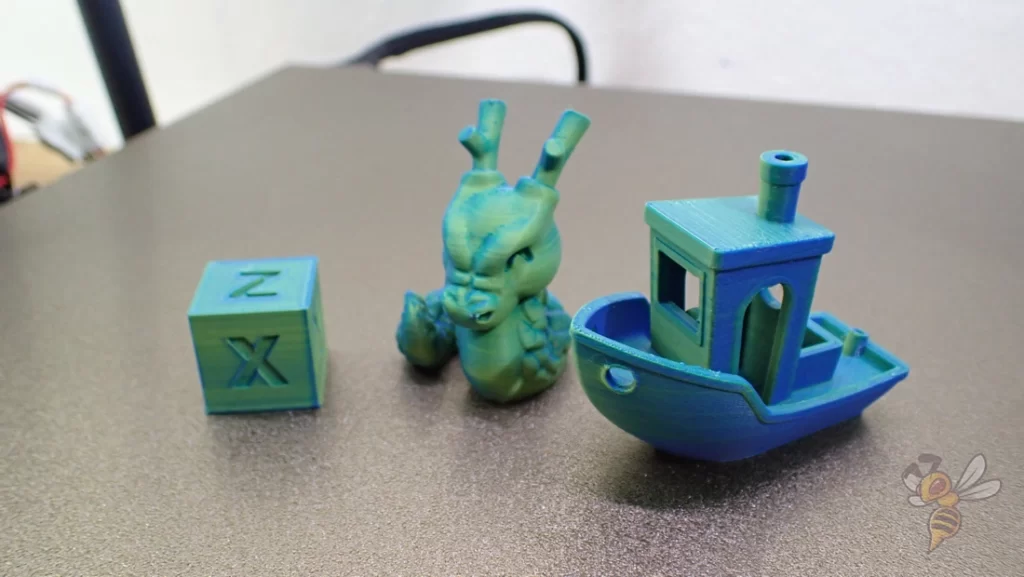

Calibration Cube

At the end, I checked the settings again with a classic calibration cube. The dimensions were correct, the extrusion took place without gaps or blobs.

This is exactly how the result should always look!

Check Price at:

Check Price at:

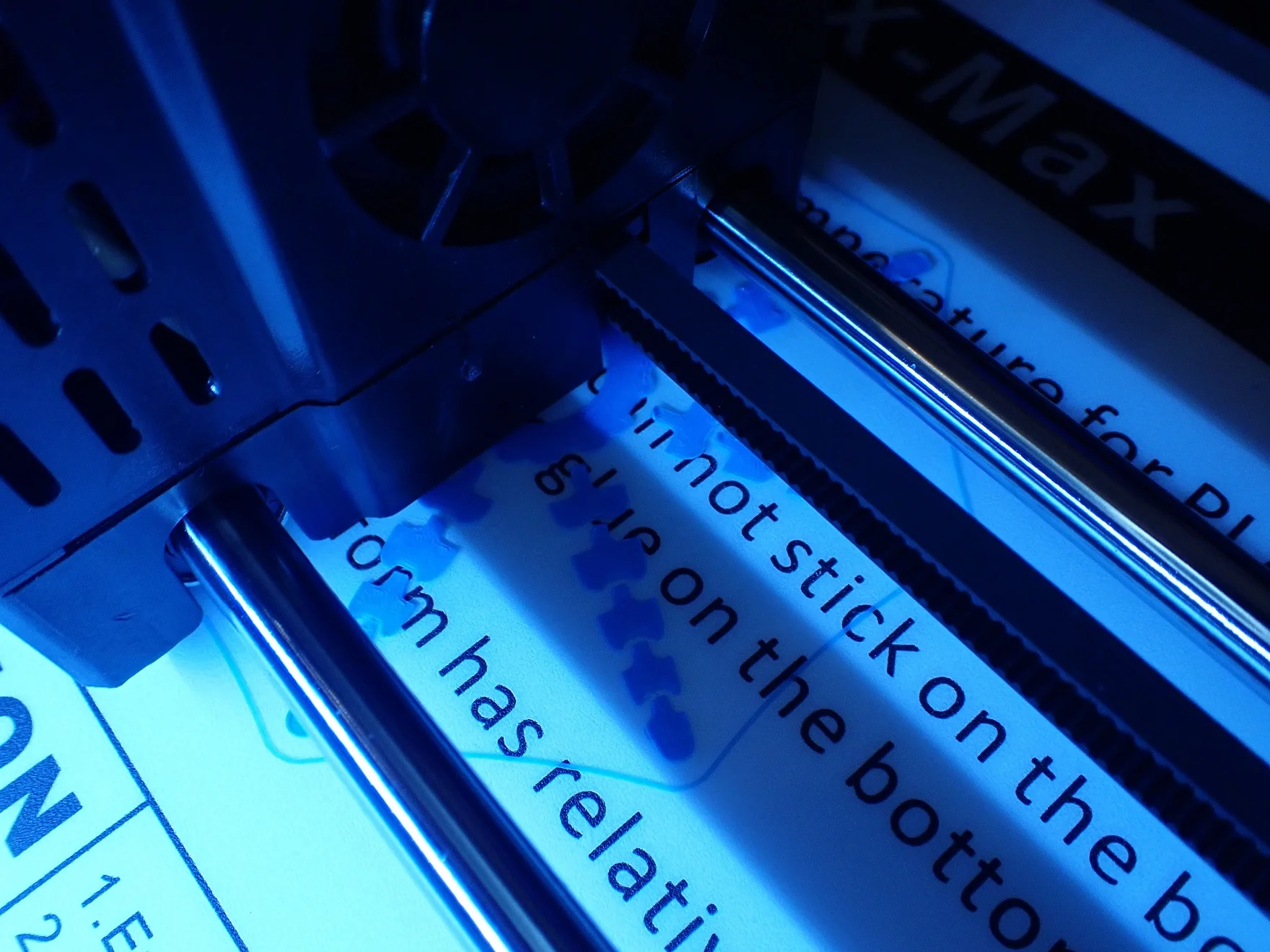

Print Bed Adhesion

With the ERYONE PLA filament* there are no problems with print bed adhesion. It even holds better than other PLA filaments and is compatible with most print bed surfaces.

I never once had to resort to Blue Tape or any other method to increase print bed adhesion.

In my test, I tried the following print bed surfaces:

- Magnetic print bed

- Glass print bed

- BuildTak*

- PEI Sheet*

On none of these surfaces did I have problems with the print bed adhesion. I left the print bed temperature at 60 °C, except for the magnetic print bed of the X-Max. There I used 55 °C, as the print bed is extremely well heated and often has higher temperatures than expected.

Layer Adhesion

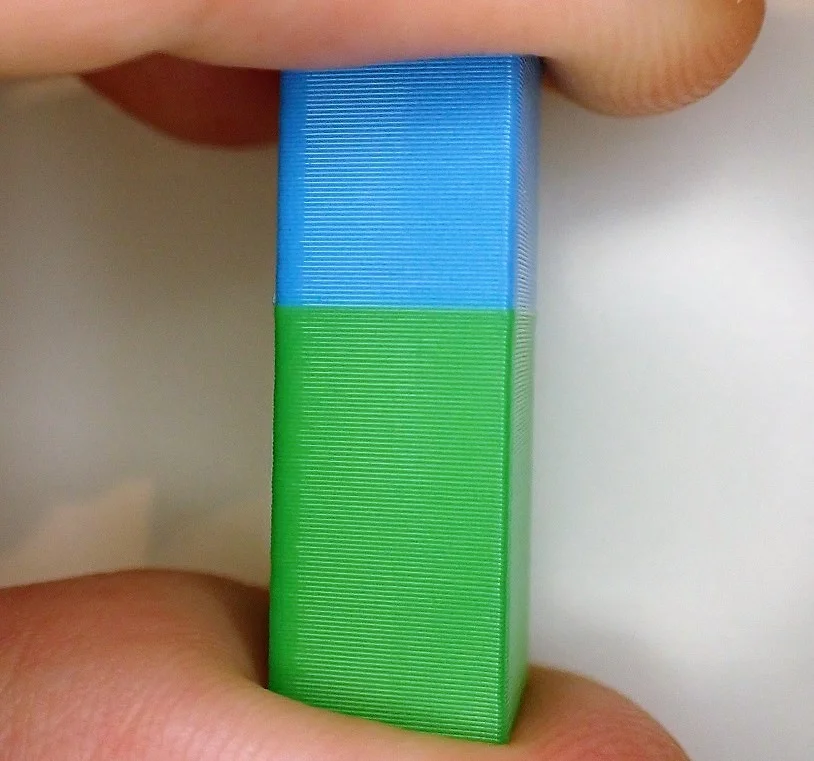

To test the adhesion of the individual layers to each other, I built in a pause during a test print and changed the filament.

Both the filament before and the filament after the pause was a PLA filament from ERYONE.

Although the pause lasted several minutes, the next layer could be printed flawlessly on top of the old one. After printing, I tried to break the test object to check if the filament transition had created a predetermined breaking point. But this was not the case, so I assume that the bond there is just as good as with all other layers.

Stringing

Once I got the temperature and retraction right, stringing was no longer a problem. Apart from a few isolated smaller strings, which could be removed without leaving any residue, my models were ‘hairless’.

Contaminants

Impurities and the homogeneity of the material itself also play a very large role in the quality of a filament. If the filament is made of low-quality material or contains impurities, printing errors or a clogged nozzle can occur very quickly.

During all my testing, the nozzle of my printers has never clogged and the outer walls show no trace of contamination.

Results

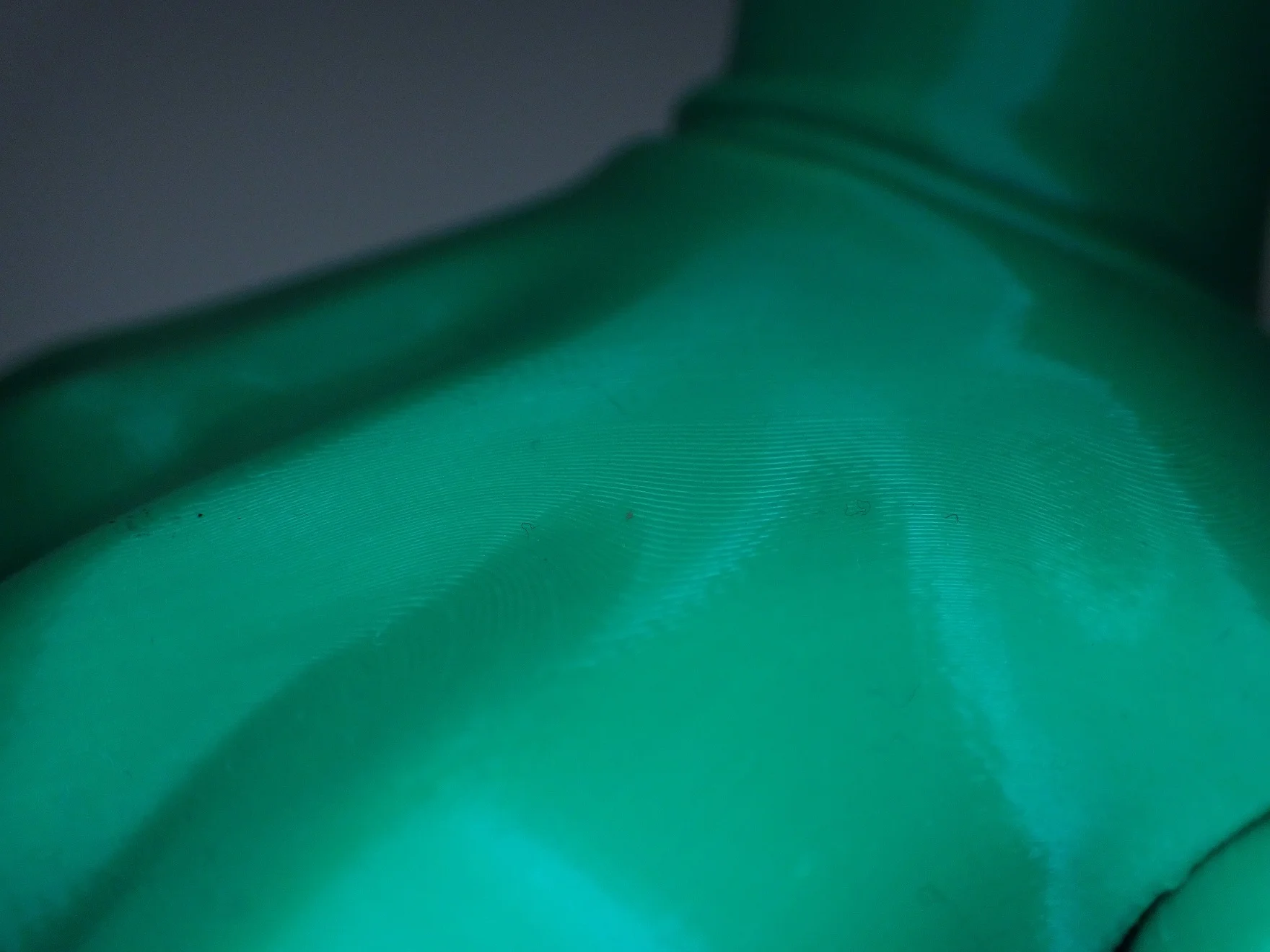

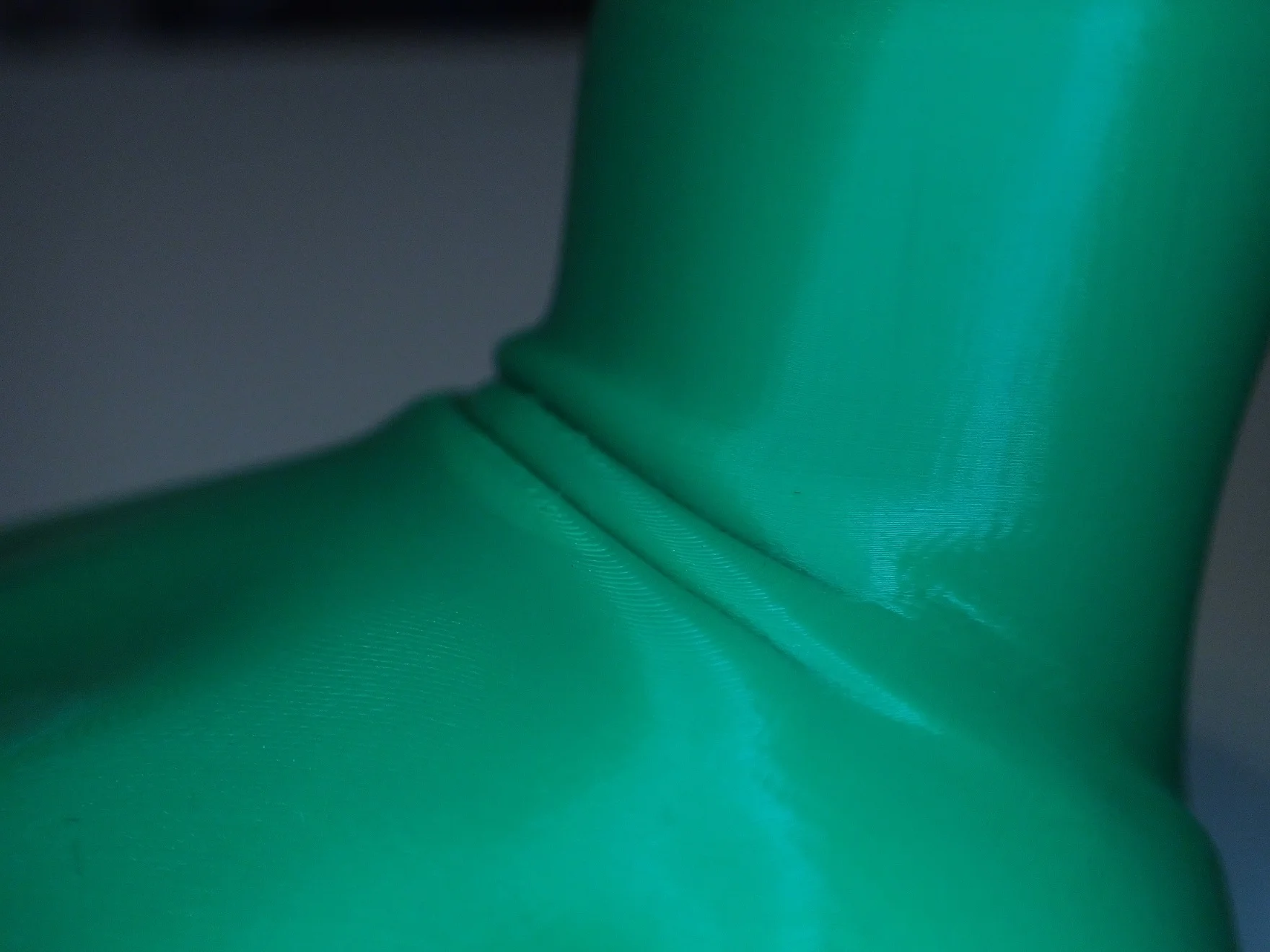

I printed a total of 4 objects and various test prints with the ERYONE PLA filament*. Each of the objects worked the first time.

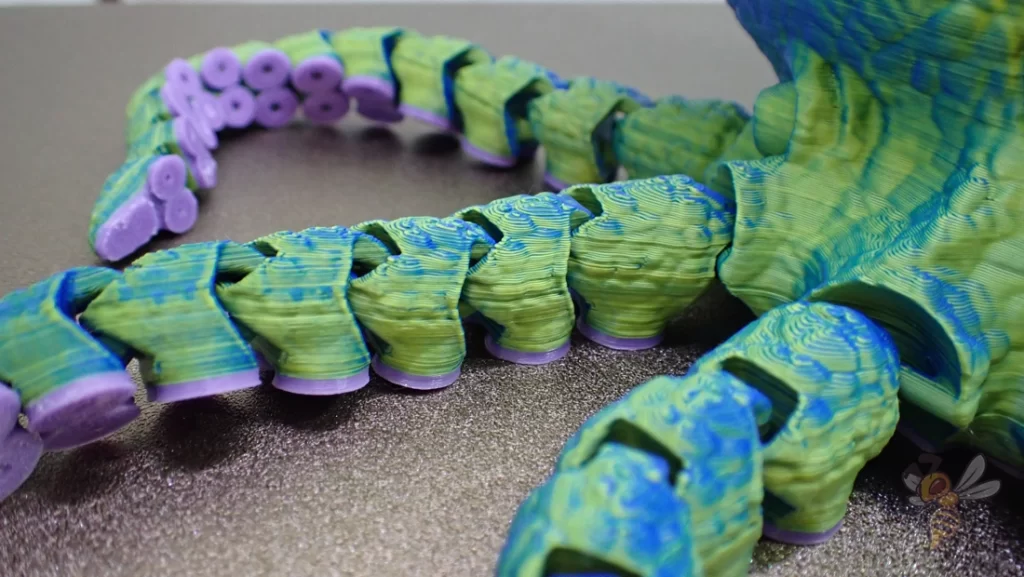

I needed some presents for my niece and printed several figures with movable joints.

- Green frog with movable joints (by Flexi Factory on Cults3d)

- Green zombie hand with movable joints (by Flexi Factory on Cults3d)

- Blue starfish with movable joints (by Flexi Factory on Cults3d)

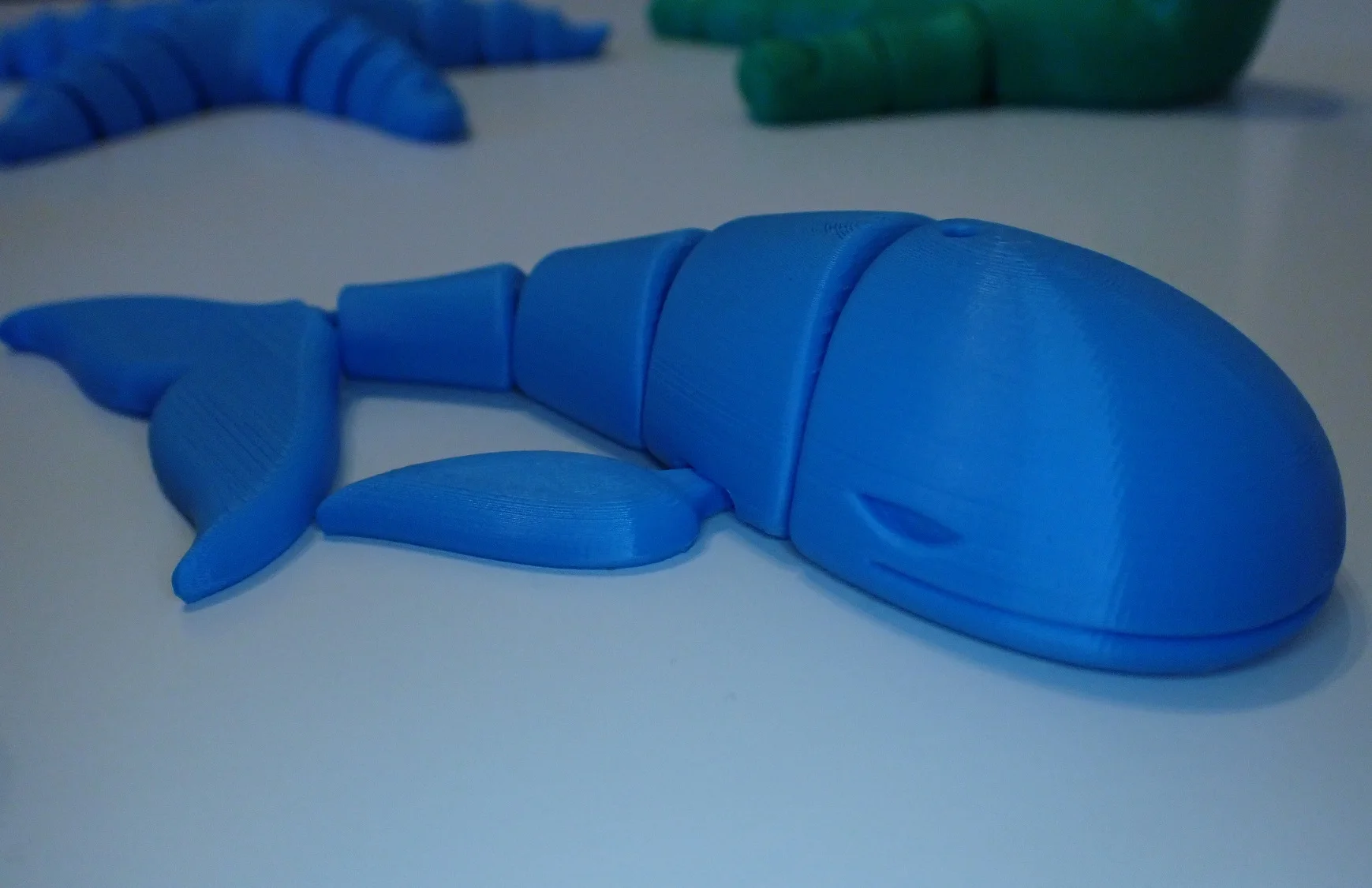

- Blue whale with movable joints (by Hom_3D_Lab on Cults3d)

The surface of all objects has succeeded flawlessly. Here and there was some stringing, but I could remove it with my hand and fingernail without a trace.

Only on the starfish, apparently, the room temperature was too low and some under-extrusion occurred. After I normalized the room temperature, the next print (the blue whale) was perfectly fine again.

The bone and the red flesh of the zombie hand I painted afterward with acrylic paints. I could have realized the white bone also by a filament change and only had to repaint the red. But I got the idea only after printing 😉

I printed an octopus with the blue/yellow filament, where the double-color effect of the filament creates an impressive effect. I printed the first layers with a different color to make the suckers stand out from the rest of the object.

Only the eyes are painted with oil paints and varnished with clear varnish.

With the rainbow-colored PLA filament, I printed a vase and an axolotl. Especially with the vase, the colors create a nice pattern!

Conclusion

The ERYONE PLA filament* has excellent properties. It is suitable for beginners as well as for experienced 3D printers.

It scores not only with its high-quality ingredients and professional production, but it is also problem-free in use. The windings are perfect over the complete spool, there are never tangles or knots.

The printing characteristics have also proven to be very good. There is almost no stringing, the nozzle remains free and never clogs.

Another plus is that with the right temperature, the print bed adhesion is so good that you don’t need to resort to aids like Blue Tape or the like.

All around a definite recommendation!

I tested the following colors: Blue/Yellow, Blue, Green and Rainbow.

Check Price at:

Check Price at:

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.