- Printing BIG with the JUPITER SE – A Review - May 13, 2024

- Is a Wash & Cure Station Worth It? Creality UW-03 Review - April 29, 2024

- Z Seam | How to Hide & Avoid | Cura & PrusaSlicer - April 20, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

In this article I test the UW-03 Wash & Cure Station from Creality* and try to answer the question of whether such a device is really worthwhile or not.

I love painting miniatures. And for a few years now I’ve been printing my minis with resin 3D printers instead of buying them ready-made.

The only problem is that I hate the post-processing! It takes forever and always produces a huge mess! I always have to get over myself to print a new figure.

But Creality gave me the chance to test whether a Wash and Cure Station makes post-processing easier or not.

Review Summary

The UW-03 Wash & Cure Station from Creality makes post-processing easier and faster. If you want to save time and nerves during post-processing, I can recommend this machine!

I could only find one disadvantage in my test, which has nothing to do with the function itselsf – a much too loud beep when the device is switched on.

Overall Rating:

4,8/5

Advantages

✓ Large volume

✓ Easy operation

✓ Powerful rotor

✓ Double row of LEDs

Disadvantages

× Very loud beep when switching on

The Creality UW-03 Wash & Cure Station can wash objects with a maximum height of 200 mm and cure up to 300 mm. It is the perfect accessory for any resin 3D printer!

Table of Contents:

Design

The UW-03 Wash & Cure Station consists of the base, a turntable for even curing, a large container for washing the prints and a matching hood to protect them from the UV light of the LEDs.

The volume is huge – you can also use it to process large objects. There are four buttons on the front with which you can operate the entire device. But before I can test it, I first have to 3D print something!

Test Prints

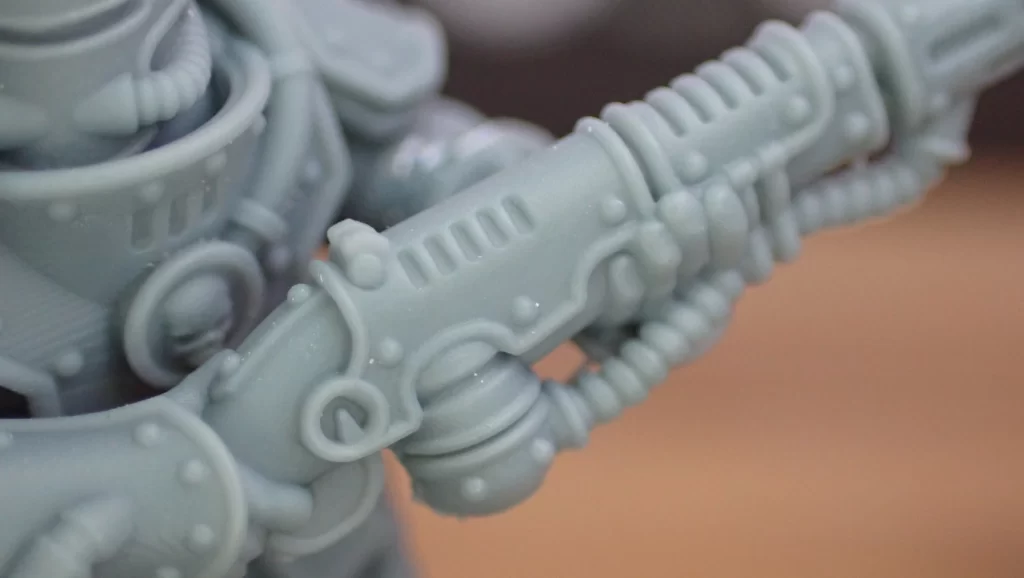

I searched for a long time to find the right object and finally decided on the Solar Guard from RedMakers. These figures are extremely detailed, which makes them ideal for painting. Refinishing must also be done well so that no resin residue remains in fine holes and cracks and is accidentally hardened.

Washing without Wash & Cure Station

The real work starts after printing. The first thing I have to do is remove the individual parts from the print bed.

I printed a total of ten figures with all the associated parts. One half I treat as improvised, and for the other half I use the UW-03 Wash & Cure Station to get a feel for whether it’s really worth it and simplifies the process.

So far I have been hand washing the freshly printed parts in a small container with alcohol and trying to get into the smallest cracks and holes with a brush.

This process takes a long time, especially when you have so many objects printed at the same time.

But what bothers me the most is that you are hanging over the container of alcohol the whole time and either have to breathe in the fumes or wear a mask.

Washing with Wash & Cure Station

With the Wash & Cure Station, this is much easier: put the parts in, close the lid and start the wash program!

You can set the speed of the rotor and the duration of the washing process.

Incidentally, the rotor is fixed at the bottom so that the container cannot leak. You can also remove it for cleaning.

As soon as the washing process is complete, you can remove the basket inside the container with the objects and allow them to drain and dry.

Removing the Supports

The Wash & Cure Station has no influence on the removal of the supports. If the supports have been placed well and are correctly dimensioned, they can be removed without leaving any residue.

Curing without Wash & Cure Station

Finally, the parts need to be completely cured to make them more durable. In principle, all you need is a UV lamp with the right wavelength.

Most resins for 3D printing cure at a wavelength of around 405 nanometers.

Coincidentally, most nail polish curing lamps also emit this wavelength.

The only problem with this variant is that you have to turn the objects regularly so that all sides are cured evenly. In addition, the volume is limited, making it difficult to cure larger objects.

Curing with Wash & Cure Station

With the UW-03 Wash & Cure Station from Creality, curing is much more convenient. Instead of the wash container, a small turntable is now placed on the base. Next, all objects are placed on the turntable. Then the hood is placed on top. The program cannot be started without it.

After starting the program, you have to wait. But unlike the improvised hardening variant, you don’t have to keep turning the objects to reach every point of the object, as the turntable rotates. I only turn the objects once halfway through the program so that the other side can also be cured.

Results

The Wash & Cure Station has no influence on the quality of the objects, unless you forget some resin in small cracks or holes in the model during manual washing. Then this residue is also cured and may swallow up important details. Automatic washing is not only faster, it also avoids such mistakes.

The continuously moving washing medium in the container ensures that even the smallest hole and the narrowest crack of the object is reached. And to be on the safe side, the rotor changes its direction in between and thus also the flow.

Conclusion

Is a Wash & Cure Station and in particular the UW-03 from Creality worthwhile?

The bottom line is that both washing and curing are much more convenient and easier with the Wash & Cure Station. Basically, it depends on how often you work with a resin 3D printer. I print new figures every few weeks, which makes this device definitely worth it for the time savings alone!

The Creality UW-03 Wash & Cure Station can wash objects with a maximum height of 200 mm and cure up to 300 mm. It is the perfect accessory for any resin 3D printer!

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.