- Wet Filament: Prevention, Symptoms & Drying - July 18, 2024

- Sovol SV08 – Best PrusaSlicer Settings & Profile - June 26, 2024

- Sovol SV08 – Best Orca Slicer Settings & Profile - June 26, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

The Sovol SV01 Pro* has many features that are popular upgrades on other 3D printers. Its price is still very attractive and it has a surprisingly large print volume.

I have tested the SV01 Pro in-depth and show you in this article whether this 3D printer is worth your money, what print quality you can expect and how it performs against its direct competitors.

Check Price at:

Table of Contents:

- 1 Key Takeaways

- 2 Who Should Buy the Sovol SV01 Pro?

- 3 Advantages & Disadvantages > Sovol SV01 Pro

- 4 Technical Specifications > Sovol SV01 Pro

- 5 Scope of Delivery > Sovol SV01 Pro

- 6 Setup > Sovol SV01 Pro

- 7 Features > Sovol SV01 Pro

- 7.1 Direct Drive Extruder

- 7.2 280 x 240 x 300 mm Print Volume

- 7.3 Automatic Print Bed Leveling via CR-Touch

- 7.4 Magnetic, Flexible Print Bed

- 7.5 Double Z-Axis

- 7.6 Supports PLA/ABS/TPU/PETG

- 7.7 Filament Sensor

- 7.8 4.3-Inch Touchscreen with Day/Night Mode

- 7.9 Compatible with Laser Modules

- 7.10 Automatic Filament Loading

- 7.11 32-Bit Silent Motherboard

- 7.12 Belt Tensioner

- 7.13 Resume Print

- 8 Handling > Sovol SV01 Pro

- 9 Heating Times > Sovol SV01 Pro

- 10 Noise Level > Sovol SV01 Pro

- 11 Power Consumption > Sovol SV01 Pro

- 12 Print Speed > Sovol SV01 Pro

- 13 Slicer > Sovol SV01 Pro

- 14 Print Quality – Practical Test > Sovol SV01 Pro

- 15 Sovol SV01 Pro vs. Creality Ender 3 S1 Pro

- 16 Sovol SV01 Pro vs. Anycubic Kobra

- 17 Sovol SV01 Pro vs. Mingda Magician X

- 18 Is the Sovol SV01 Pro Worth It?

- 19 Similar 3D Printers

Key Takeaways

- Direct drive extruder up to 260 °C

- Magnetic and very flexible print bed up to 110 °C

- Automatic print bed leveling at 16 points

- Larger print volume than comparable 3D printers

- Double Z-axis for more stability and accuracy

Who Should Buy the Sovol SV01 Pro?

The Sovol SV01 Pro is suitable for anyone who wants to get started in 3D printing and wants to achieve high-quality results quickly. With the SV01 Pro, the focus is on printing and the result, without having to tinker much. The higher price compared to low-budget 3D printers is therefore definitely justified, as a lot of frustration is saved and a higher accuracy is achieved.

Advantages & Disadvantages

> Sovol SV01 Pro

PRO:

- High accuracy

- Large print volume

- Can also print flexible filaments well

- Flexible print bed

- Touchscreen with dark mode

- Automatic print bed leveling

CON:

- No PEI print bed (would be a minimal improvement)

Technical Specifications

> Sovol SV01 Pro

PRINTING:

- Print volume: 280 x 140 x 300 mm

- Layer thickness: 0.1-0.4 mm

- Nozzle: 1 x 0.4 mm

- Printing speed: 50-80 mm/s

- Max. nozzle temperature: 260 °C

- Max. print bed temperature: 110 °C

- Filament: 1.75 mm PLA, ABS, PETG, TPU, Wood

DEVICE:

- Size: 520 x 509 x 647 mm

- Weight: 9,8 kg

SOFTWARE:

- Connectivity: Micro SD card, USB

- File format: G-Code

Scope of Delivery

> Sovol SV01 Pro

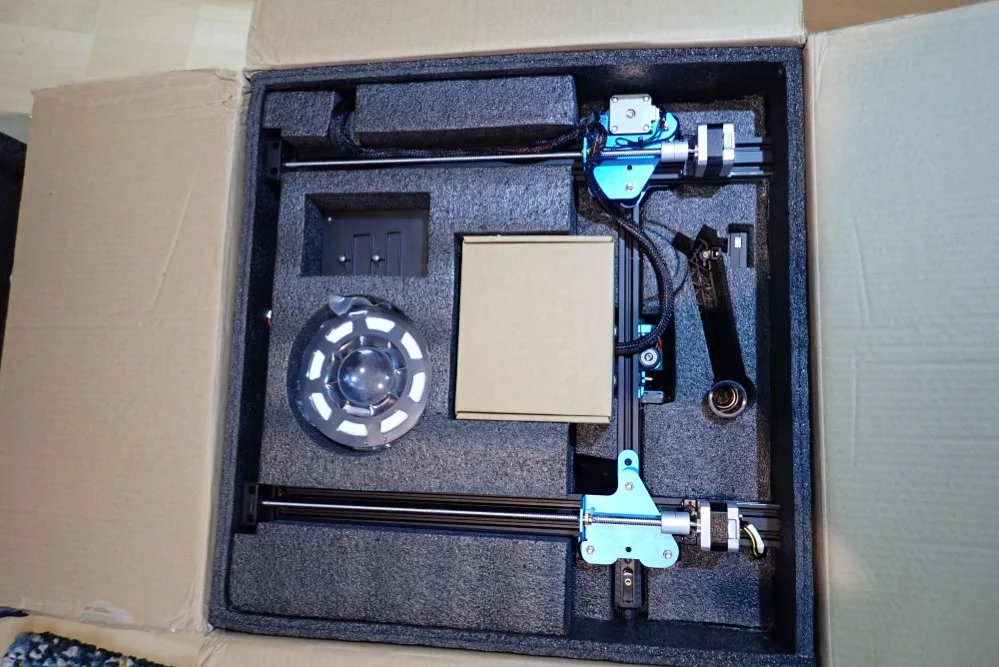

The Sovol SV01 Pro comes with everything you need to get started. The necessary tools for assembly and some PLA filament for the first test prints are included. The package contents are very well secured by foam and should withstand rough handling.

However, you should order more filament as soon as you buy the 3D printer. The PLA filament included is only a small sample and won’t last long. If you have never 3D printed before, I would recommend PLA filament to learn the basics. After that you can move on to other filaments like ABS, PETG or the flexible TPU.

In addition to the necessary tools such as a screwdriver, a print bed leveling tool is also included: a piece of paper of the correct thickness with a quick guide. You can use this paper for the print bed leveling to adjust the distance between the nozzle and the print bed correctly (more about this later).

The following items are included with the Sovol SV01 Pro:

- Pre-assembled 3D printer in four parts (frame with x-axis and print head, base with print bed, display and filament holder with filament sensor)

- Operating instructions

- Paper for print bed leveling with quick guide

- Power cable

- Cable ties

- Nozzle cleaning needle

- Replacement nozzle

- Spatula for the print bed

- Filament pliers

- Allen key set

- Screwdriver

- Wrench

- 4 screws for the setup

- USB Micro SD adapter

- Micro SD card with digital manual, software and test objects

Setup

> Sovol SV01 Pro

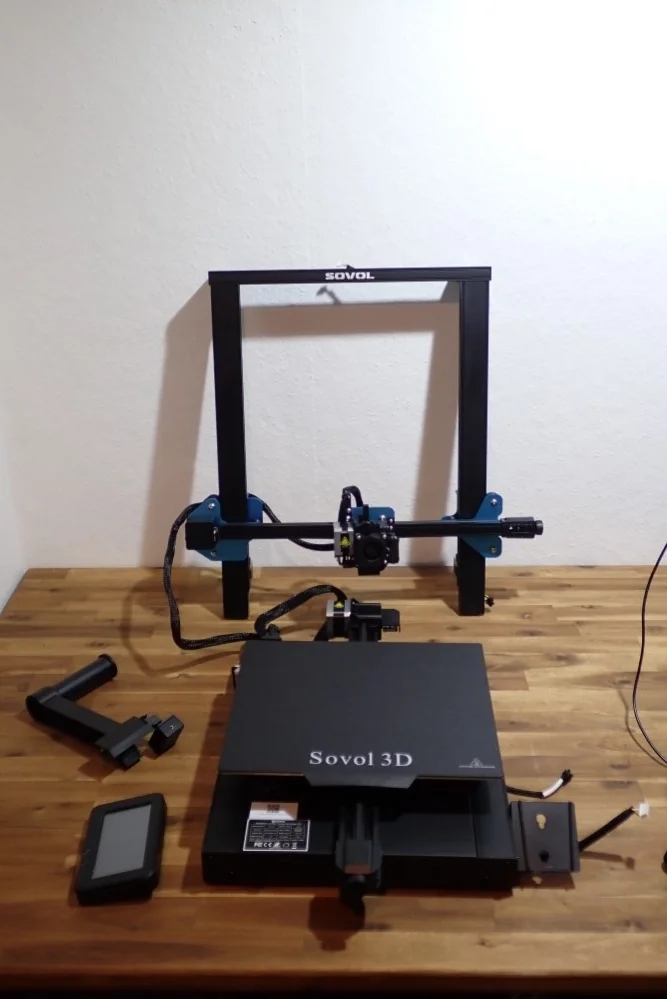

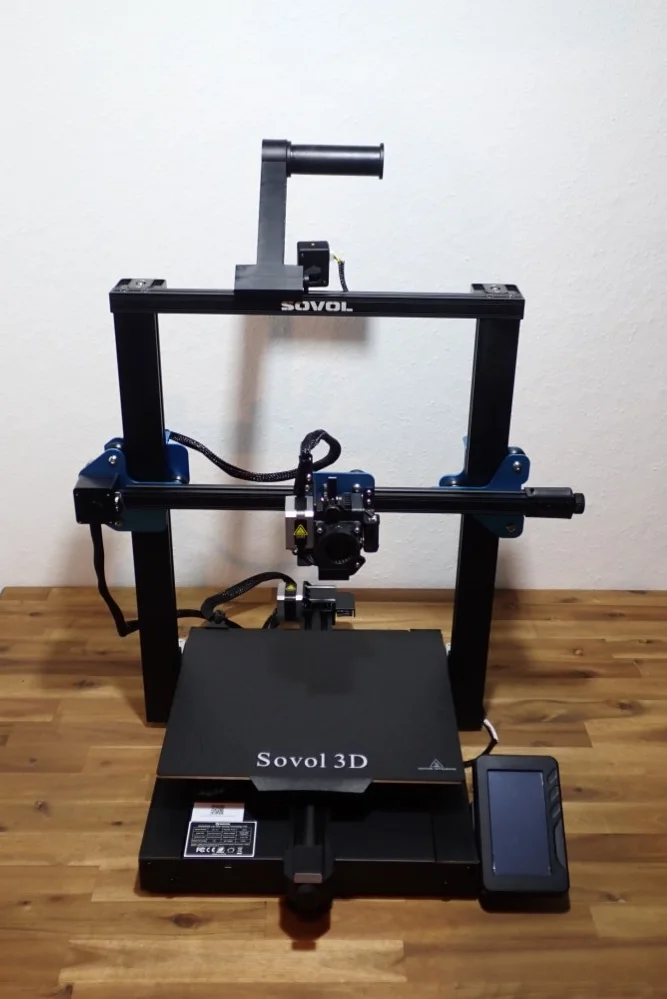

The Sovol SV01 Pro is delivered mostly pre-assembled. The setup takes only 5-10 minutes.

I have rarely experienced such an easy assembly of an FDM printer as with the Sovol SV01 Pro. It is delivered so far pre-assembled that there are only four individual modules that need to be connected: The frame with pre-assembled X-, Z-axis and print head, the base with print bed, the display and the filament holder.

There are only four screws included. They are needed for mounting the frame to the base. Unlike most other 3D printers, the frame is attached to the side of the base and not from below. This not only makes mounting easier, it also gives the printer even more print volume with a comparatively small base.

Print Bed Leveling

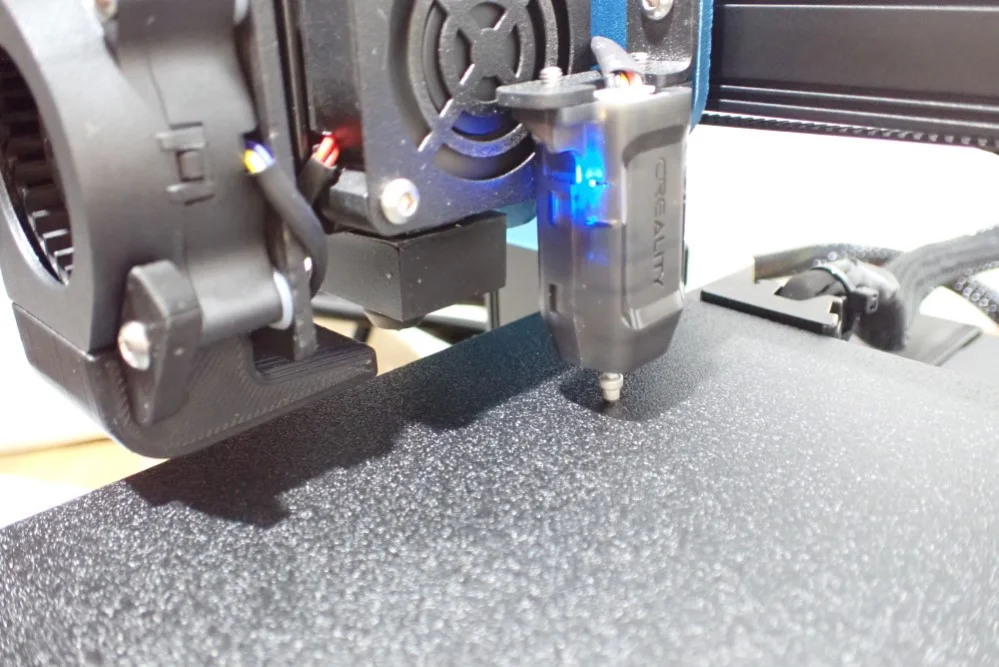

Leveling the Sovol SV01 Pro can be done manually or automatically. For the automatic leveling it has a CR-Touch which is installed on the print head.

Immediately after the setup, it is advisable to manually level the print bed once to compensate for very large inclinations that the sensor cannot compensate for. After that you will probably not have to level manually for a long time, because the automatic print bed leveling with the CR-Touch is very reliable and accurate.

It measures the print bed at 16 points and calculates the inclination which is automatically compensated during printing.

Check Price at:

Features

> Sovol SV01 Pro

With a 3D printer that calls itself “Pro”, you expect a few features that should not be missing. In addition to these features, the Sovol SV01 Pro also offers a few special ones.

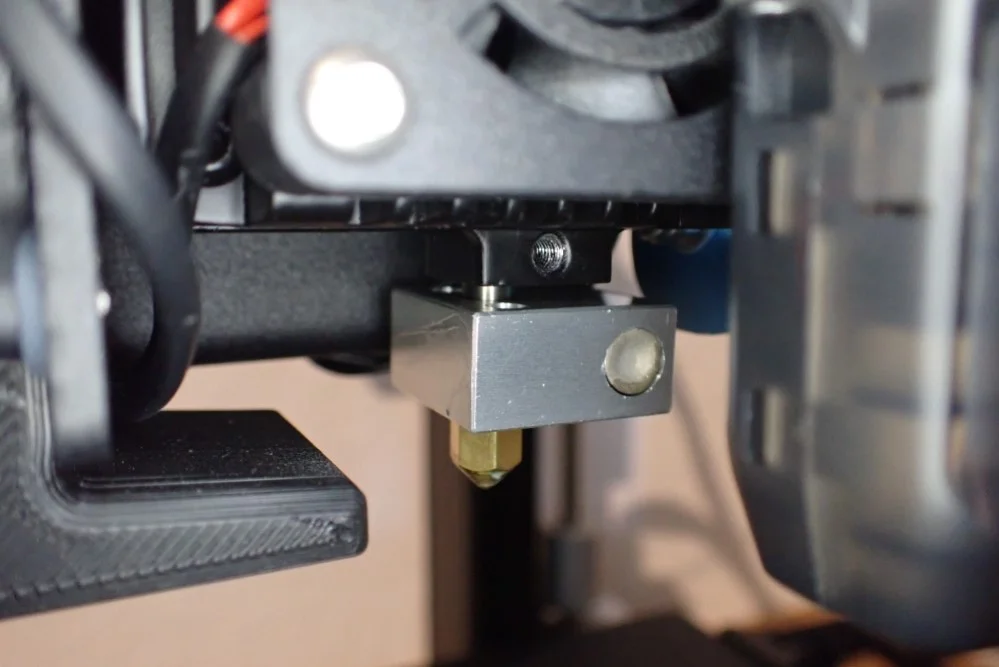

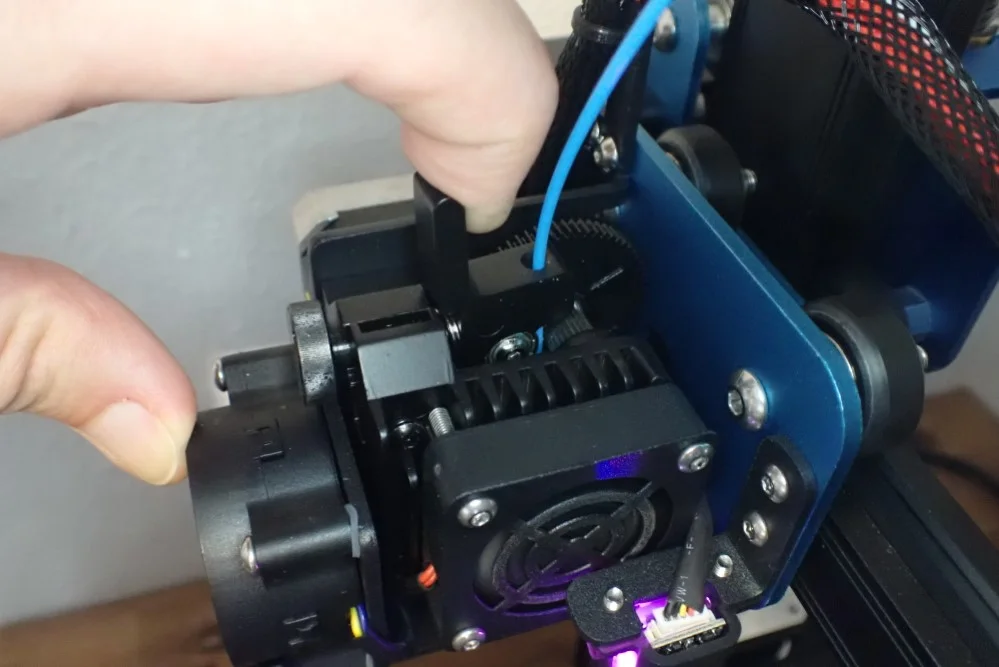

Direct Drive Extruder

The Sovol SV01 Pro has a direct drive extruder which has a low weight and is also suitable for printing flexible filaments. The maximum printing temperature is 260 °C.

The design of the extruder is very compact and does not require a housing. The individual components are virtually only screwed together to save weight. There was even room for a CR-Touch level sensor.

Although the accuracy of the extruder is very high and the insertion of the filament is very easy, there is also a disadvantage. The part cooling fan covers the nozzle from the front. You have to look from the side to see the nozzle when printing. This also makes it difficult to change the nozzle.

280 x 240 x 300 mm Print Volume

The print volume of the Sovol SV01 Pro is 280 x 240 x 300 mm. This is larger than most other 3D printers in this price and performance range. This means that even larger objects can be printed in one piece.

As I had already pointed out during the setup, the frame is not mounted vertically on the base, but from the sides. This extends the X-axis in both directions by the width of the individual frame struts. This allows a much larger print bed to be used than the base would normally allow.

If you compare the Sovol SV01 Pro with its direct competitors, it always comes out on top in terms of print volume.

Automatic Print Bed Leveling via CR-Touch

The Sovol SV01 Pro has a CR touch sensor for automatic print bed leveling. This sensor is a probe that measures the distance between the print bed and the nozzle. This sensor is very accurate and levels the print bed reliably and precisely.

I have already tested the CR-Touch in many 3D printers and compared it against the BL-Touch. It is currently my favorite of the leveling sensors. There are a few other types of sensors that also deliver precise results, such as the pressure sensor on the Elegoo Neptune 3, but the CR-Touch has proven itself many times over.

The sensor ensures that the tilt of the print bed is ideally balanced. The CR-Touch leveling sensor can quickly and easily level the print bed, minimizing the chance of irregularities in your prints.

The Sovol SV01 Pro has a 16-point leveling system with the CR-Touch, which makes the calibration of the print bed very accurate. You can also run the automatic leveling every time before printing with the G-code “G29”. That way you play it safe every time. For me, however, it is enough that it only finds the home position with “G28”. I start the leveling irregularly after several prints.

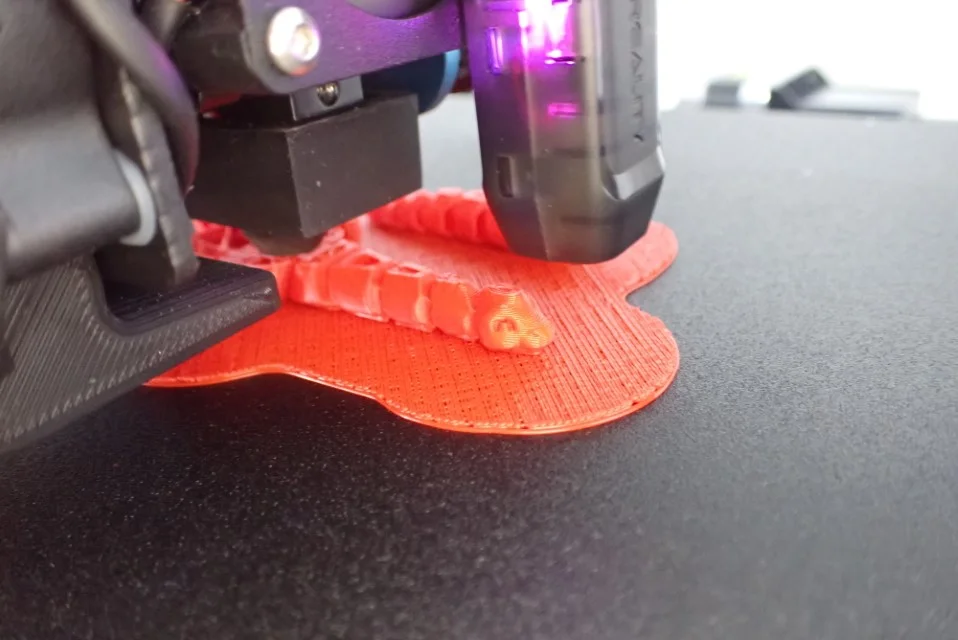

Magnetic, Flexible Print Bed

The Sovol SV01 Pro has a magnetic print bed that can be bent to easily release cooled print objects from it. The coating provides very good print bed adhesion for most filaments.

I am a big fan of coated print bed surfaces that lie on a magnetic print plate. It’s just so much more convenient to release the finished print object from it without fear of damaging the print or using a spatula on the print bed underneath. Although I find the print bed adhesion on a PEI print bed even better than the print bed of the SV01 Pro, but I can not really complain about the print bed adhesion.

Especially for PLA, it is more or less perfect if you reduce the print speed of the first layer a lot. I have not once had to use an adhesive for the print bed to increase the adhesion. With a print speed of 5-10 mm/s for the first layer even the most filigree first layer held very well.

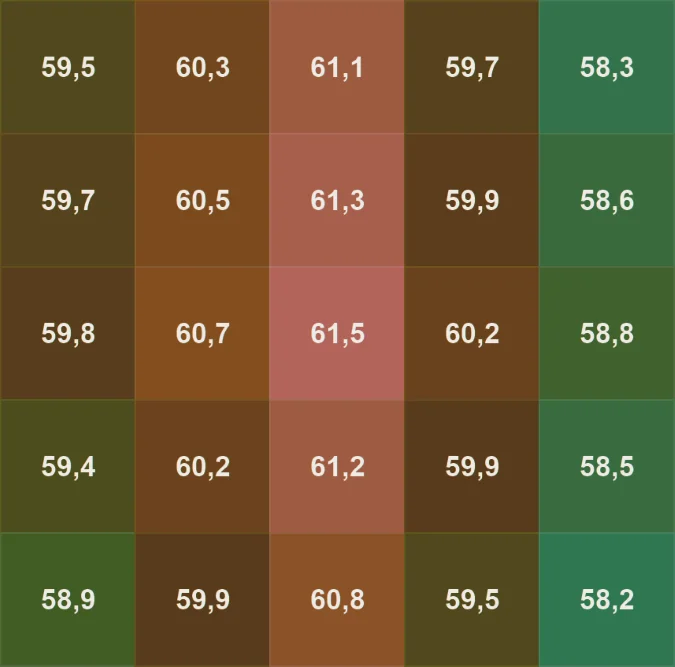

The homogeneity of the print bed temperature is not as good as it would be best for some filaments. I measured the print bed temperature with a pyrometer at 25 points. The difference between the highest and the lowest value is almost 3 °C! For many filaments like PLA this is not a big deal as the print bed adhesion is very good, but for very large ABS objects, this could lead to difficulties in the outer areas of the print bed.

Double Z-Axis

Due to the double Z-axis, the movements of the Sovol SV01 in the Z-direction are vibration-free and precise.

The Sovol SV01 Pro 3D printer’s dual Z-axis gives it an advantage over other 3D printers in its class. This feature is especially important for printing complex objects with sharp edges and fine details.

For 3D printers with a medium to large print volume, a dual Z-axis is a must in my eyes. Without a second stepper motor on the other side of the X-axis, it becomes difficult for a single stepper motor to move the X-axis along the Z-direction accurately and vibration-free – especially when the print head is on the other side.

The Sovol SV01 Pro 3D printer’s dual Z-axis also gives it an advantage over other 3D printers in terms of safety. If one of the stepper motors fails, the other can take over and keep the X-axis from crashing.

Supports PLA/ABS/TPU/PETG

Due to the relatively wide temperature range of the Sovol SV01 Pro, its direct drive extruder and the well-adhering print bed, this printer is suitable for most standard filaments such as PLA, ABS, TPU and PETG.

PLA: PLA is the easiest filament to print. It doesn’t take much for a printer to process this filament well. As long as the print bed has the necessary adhesion, and it does with the Sovol SV01 Pro, you can print PLA. The double Z-axis and the direct drive extruder will only benefit the accuracy. You can also print PLA filaments with additives, such as wood PLA or similar filaments. Make sure, however, that you use a hardened nozzle for very abrasive filaments.

ABS: ABS is more demanding to print than PLA. This is not only due to the higher temperatures this filament requires. The higher difficulty is mainly due to the fact that it warps a lot when cooling down and can lead to warping or cracks if it cools down uncontrolled and too fast during printing. This is why it makes sense to have a closed print volume for ABS – especially for larger models. You can improvise a bit and print a draft shield or invest directly in a suitable enclosure.

PETG: PETG combines in many cases the ease of printing of PLA and the good mechanical properties of ABS. The Sovol SV01 Pro is excellent at printing PETG – as long as the filament is dry. Always make sure PETG is stored properly as it tends to soak up moisture from the surrounding air. If necessary, invest in a filament dryer if you can’t get stringing under control with PETG.

TPU: As long as you use a direct drive extruder, TPU is relatively easy to print. Since the Sovol SV01 Pro reaches the necessary temperatures and has such an extruder, you can print TPU very well. However, the print bed adhesion may not be ideal at times. Magigoo can help here.

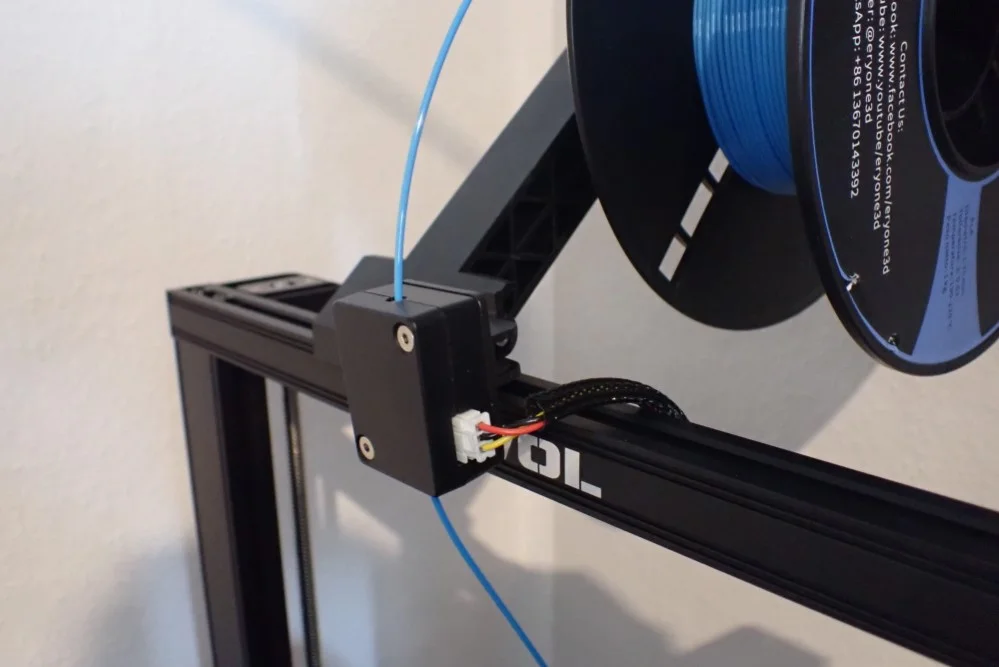

Filament Sensor

The Sovol SV01 Pro has a filament sensor that is flexibly attached directly below the filament holder. It is connected via a cable that is hidden in the frame.

As soon as the filament sensor detects no more filament, it pauses the print. This gives you the possibility to change the filament without the print being destroyed.

The only disadvantage of the filament sensor is that it is so far away from the extruder. This leaves quite a large piece of filament after the print is stopped. On the other hand, it keeps the weight of the extruder down, which in my eyes is worth more than the 30 cm of filament to the sensor.

4.3-Inch Touchscreen with Day/Night Mode

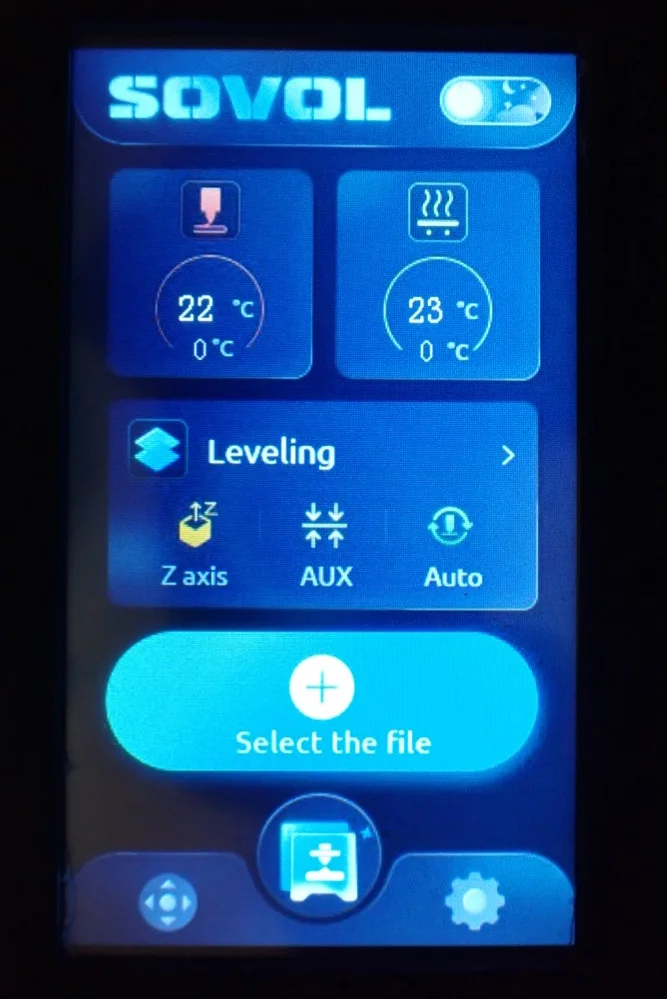

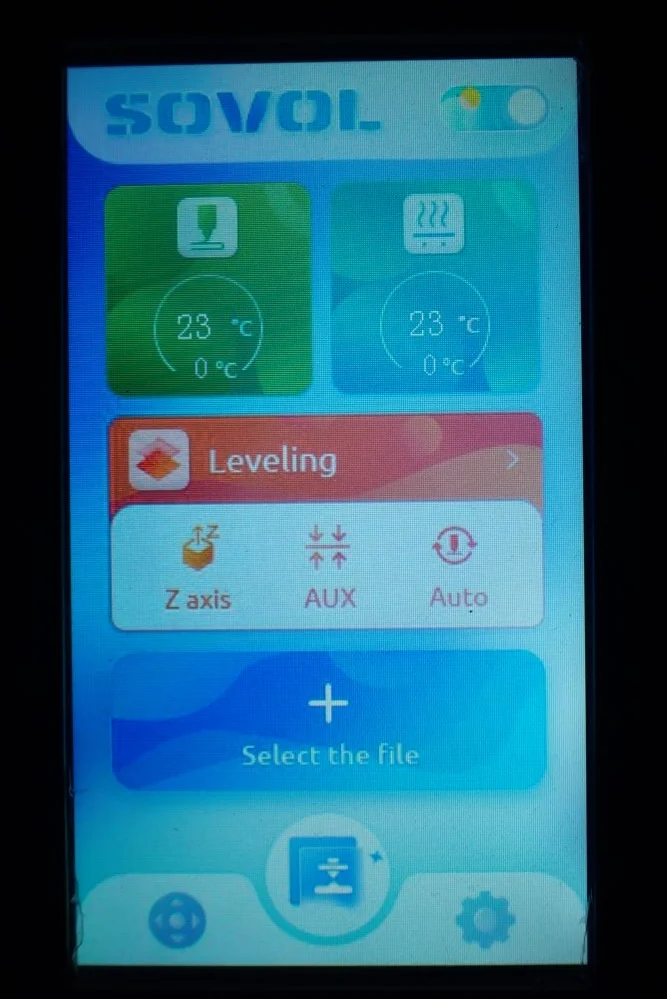

All important settings can be made in no time via the 4.3-inch touchscreen of the Sovol SV01 Pro. The menu is very intuitively designed and can be switched between day and night mode.

The menu structure is as follows:

- Movement: Here you can move to the home position, move the axes manually, or disable the stepper motors.

- Main Menu: In the main menu you can set the temperatures, use predefined PLA or ABS heating modes, start the leveling and select the print files.

- Other Settings: This menu contains advanced options, filament loading, printer properties, and EEPROM initialization.

I’ve held many 3D printer touchscreens in my hand that had a poor response to touch. Fortunately, that’s not the case with this touchscreen – you never have to press something multiple times until the command is registered.

Two small advantages are also that the screen automatically goes into a power-saving mode after a few minutes, and you can switch it between a light and dark or day and night mode in the main menu.

Compatible with Laser Modules

The Sovol SV01 Pro is compatible with the Sovol laser engraving modules. The extruder is simply exchanged for this laser module. This turns the 3D printer into a CNC laser engraving machine.

The laser head has a power of up to 10 watts and can not only engrave but also cut many materials. Materials that can be engraved include glass, plastic, coated metal, leather, wood, clothing, steel, ceramics and paper. If the following materials are not too thick, they can also be cut: Wood, felt, leather, paper and cardboard.

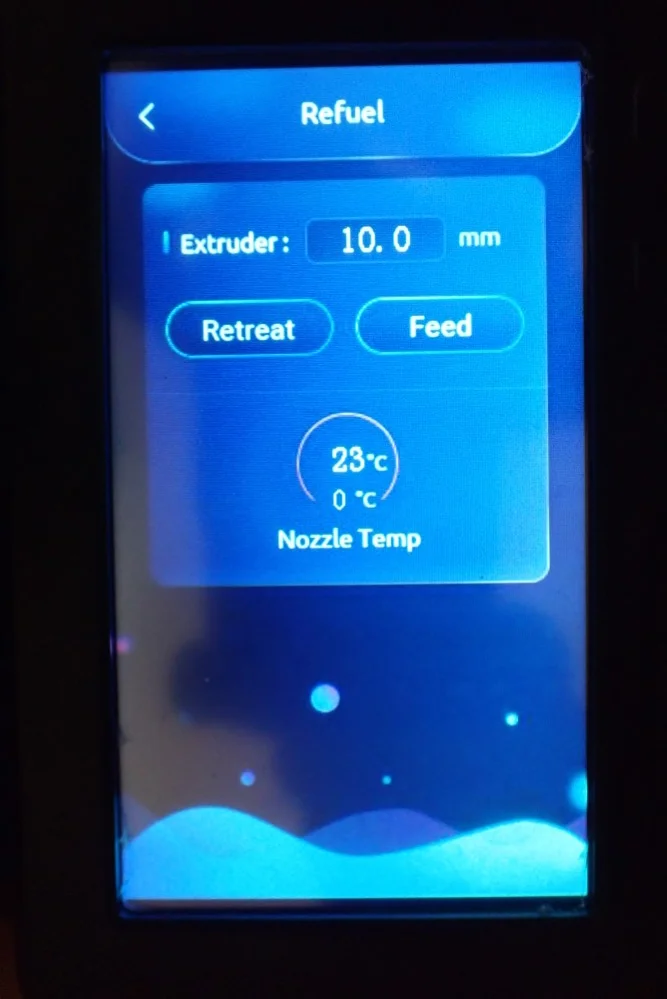

Automatic Filament Loading

Via the menu of the Sovol SV01 Pro the filament change can be supported. For this purpose, the nozzle is heated up and the stepper motor of the extruder can be moved forward or backward by 10 mm via two buttons.

However, you can also change the filament manually, as I like to do. To do this, you have to remove the pressure on the filament via the lever on the extruder. As long as the nozzle is heated to the melting temperature of the filament, you can easily pull the filament out by hand from above.

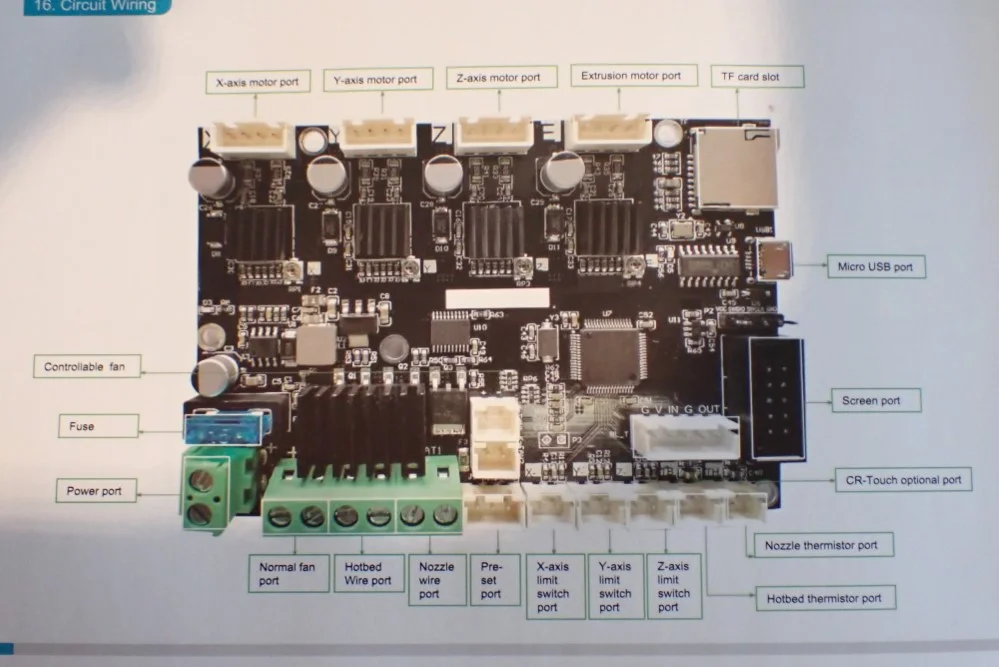

32-Bit Silent Motherboard

The Sovol SV01 Pro’s 32-bit motherboard is very quiet and features TMC 2208 stepper motor drivers.

The motherboard comes from Creality and is installed here in version 4.2.2. Not only the motherboard is from Creality, but also the level sensor, the CR-Touch and probably also the filament sensor are from this manufacturer. And that is nothing bad because especially these components have proven themselves in many 3D printers from Creality for a long time.

Belt Tensioner

On both the X and Y axes of the Sovol SV01 Pro there are rotary knobs for easy tensioning of the belts on the respective axes.

Fortunately, this feature is now becoming standard and is no longer reserved for the “pro” devices. With earlier low-budget 3D printers, you still had to take half the axis apart to re-tighten the belt. With the rotary knobs, however, this is done within seconds.

The tension has to be tight enough to prevent the stepper motors from slipping. However, the tension should also not be too strong, otherwise inaccuracies can occur and the belt can also be damaged.

Resume Print

The Sovol SV01 Pro has the Resume Print function. This feature allows it to resume printing exactly where it was interrupted by an unforeseen power failure.

This feature is now also available in every newly released 3D printer. I have not tested it with the Sovol SV01 Pro, because I assume that it works the same as with any other 3D printer. If there are frequent power outages in your region, you do not have to worry that you have to restart the print every time.

Handling

> Sovol SV01 Pro

User interface: The menu of the Sovol SV01 Pro is very intuitive and clear. You will find your way around here immediately. What I find very pleasant about this menu is that it is also switchable in a dark mode. This is easier on the eyes.

Printing: Printing is very easy with the Sovol SV01 Pro. However, it is pretty much no different between most other 3D printers in this price range. However, a few features, such as the print bed and extruder, mean that fewer errors occur, making printing less frustrating. You’ll need to be patient when calibrating the key print settings for the first time (see the slicer below for more on this).

Print bed adhesion: Even if the print bed has no PEI coating, the print bed adhesion is very good for most filaments. For PLA, the print bed is even more and less ideal. As long as you keep the print speed of the first layer low (I’ve got good results at 5-10 mm/s), the print bed adhesion is perfect. While a PEI coating is a popular upgrade for many 3D printers, it would only make sense in a few cases with the Sovol SV01 Pro, as it would only be a small improvement.

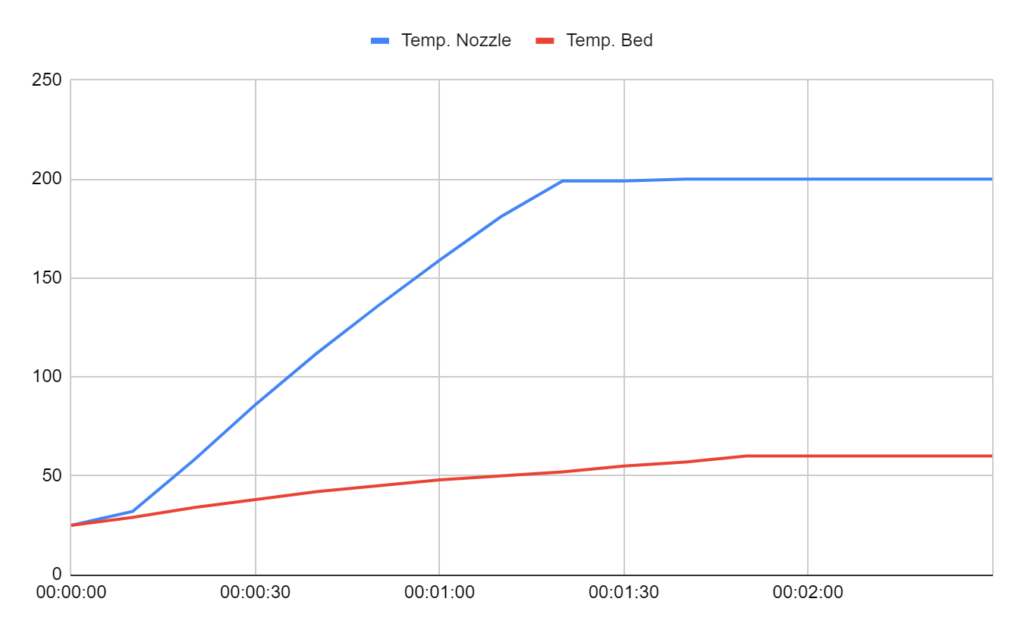

Heating Times

> Sovol SV01 Pro

The Sovol SV01 Pro heats up to the standard temperatures of PLA within 2 minutes (200 °C for the nozzle and 60 °C for the print bed).

Given the large print bed, this time is very fast. This is mainly because the layer on the print bed is very thin and the temperature does not have to pass through a thick layer of glass like other 3D printers. So the printer is ready to use very quickly.

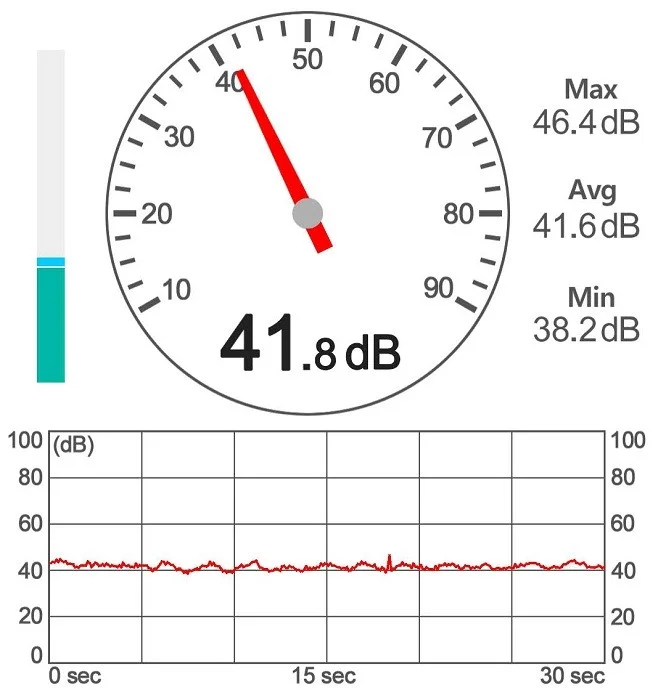

Noise Level

> Sovol SV01 Pro

The Sovol SV01 Pro’s noise level averages around 42 decibels. This is comparable to a quiet conversation.

By far the loudest component of the SV01 Pro is the parts fan on the front of the print head. There is definitely upgrade potential here. In contrast, the 32-bit motherboard is inaudible.

Power Consumption

> Sovol SV01 Pro

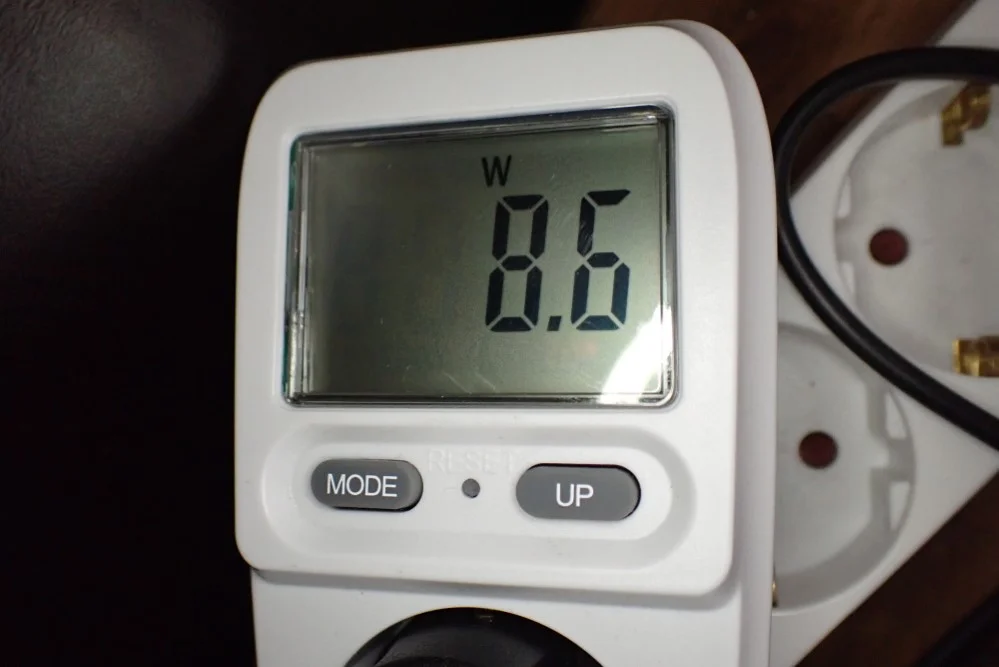

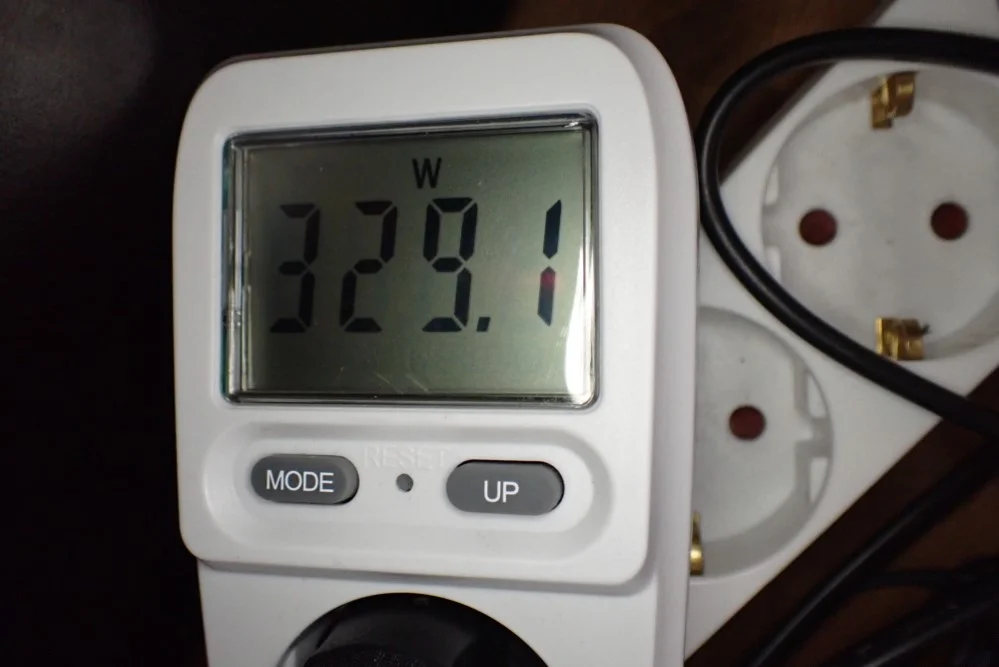

The power consumption of the Sovol SV01 Pro is only about 9 watts in idle mode and about 30 watts during printing. If the nozzle and print bed are heated up at the same time, over 300 watts are reached.

Considering the relatively large print bed, these values are not surprising. However, the total power consumption of a print is kept within limits and is comparable to other printers with such a print bed.

Print Speed

> Sovol SV01 Pro

The printing speed of the Sovol SV01 Pro is 50-80 mm/s. For the first layer, the printing speed should be strongly reduced to guarantee a good print bed adhesion.

This print speed is quite good and can be achieved thanks to the lightweight print head and stable Z-axis. However, the actual printing time also depends on how large the layer height is and how high the infill density is. The more layers needed to print the object, the longer the print time. And the more massive the object becomes, the more filament has to be extruded, which also leads to a higher print duration.

Slicer

> Sovol SV01 Pro

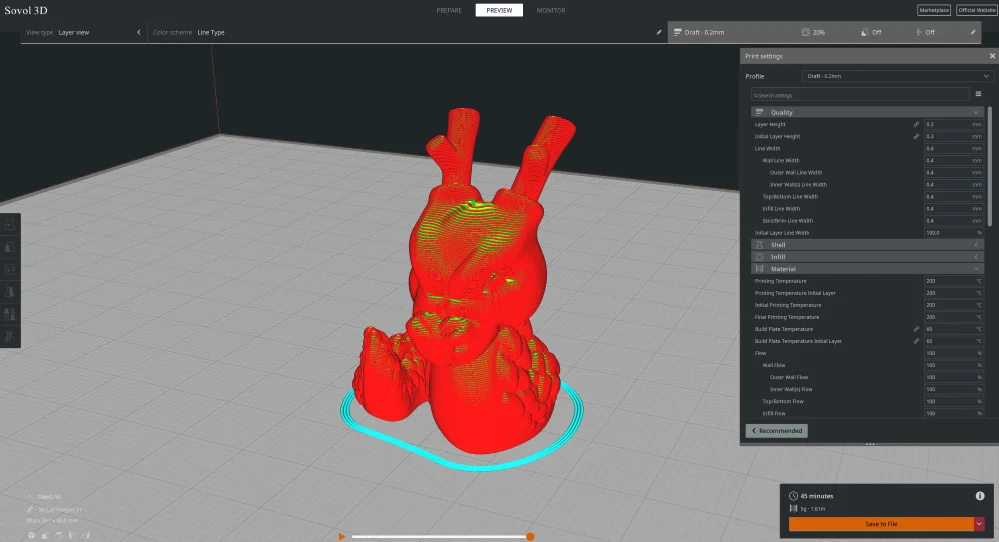

The Sovol SV01 Pro is compatible with Cura and the Sovol3D Cura Slicer. The Sovol3D Cura Slicer is a clone of Cura and can therefore be operated in a similar way and the settings are almost identical.

The standard profile for the Sovol SV01 Pro is already quite good but must be individually calibrated for the respective printer and the filament. In the following, I show you how I have calibrated the most important settings.

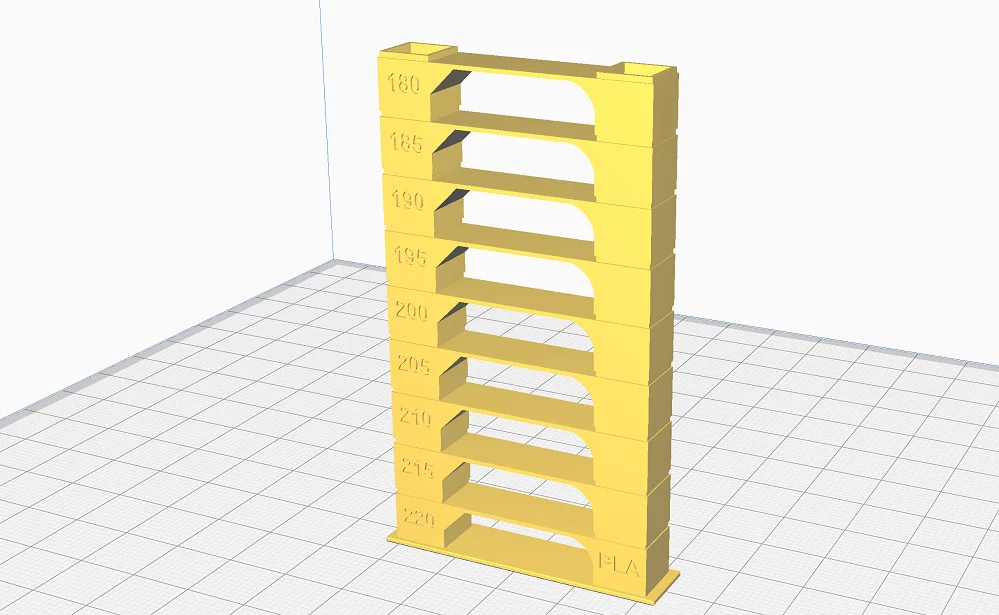

Temperature Calibration with the Sovol SV01 Pro

To calibrate the printing temperature of a 3D printer, a temperature tower can be used. It consists of several levels that are printed at different temperatures. The level at which the least errors occur is the best printing temperature for the printer-filament combination.

You can find suitable models for this on portals like Thingiverse. I prefer to use the Calibration Shapes plugin in Cura to calibrate my 3D printers. There are the most important objects for the calibration included.

The plugin also includes the appropriate script for the temperature tower. It changes the temperature per level by 5 °C.

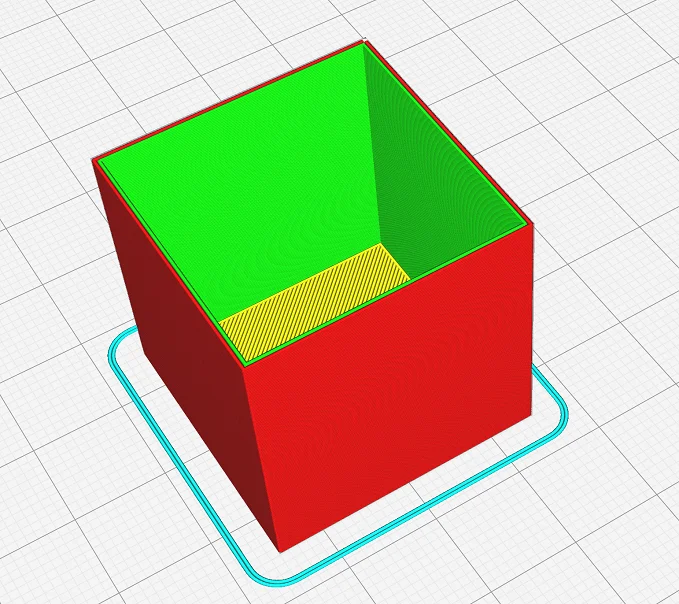

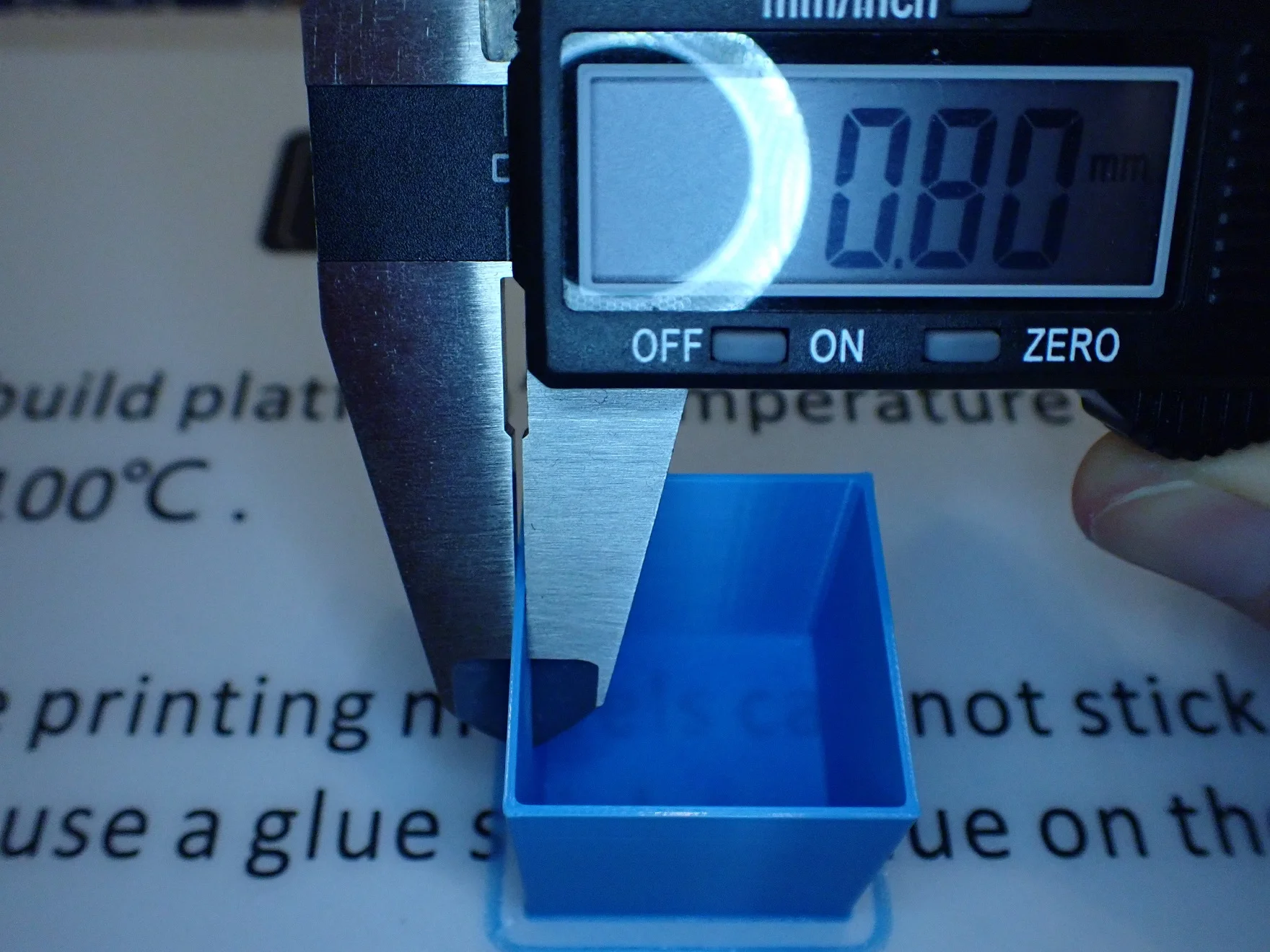

Flow Rate Calibration with the Sovol SV01 Pro

The best way to test the flow rate of a 3D printer is to use a hollow calibration cube. The theoretical and actual wall thickness are compared to determine the correct flow rate.

The calibration of the flow rate is in principle very simple. You can also pull this calibration cube from the calibration shapes plugin. Then you only have to print the cube with 0% infill and without upper layers.

After the cube has been printed, you can measure the wall thickness with a caliper gauge. Depending on the direction in which the measured wall thickness deviates from the theoretical wall thickness in the slicer, you have to increase or decrease the parameters in the slicer.

In my case, I was lucky that the wall thickness and the flow rate were directly set ideally. However, I have often had the case that the flow rate had to be adjusted by several percent and I have printed the cube 2-3 times until I had found the right setting. Since the object is quite small and consumes little filament, the calibration is nevertheless quite fast.

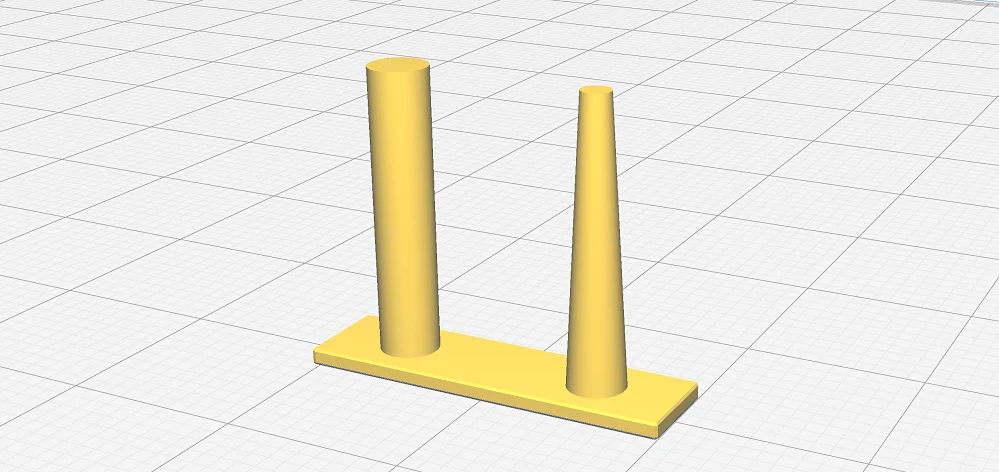

Retraction Calibration with the Sovol SV01 Pro

There are many calibration objects that can be used to calibrate the retraction of a 3D printer. However, the retraction test from the Calibration Shapes plugin in Cura is the fastest printed object.

To calibrate the retraction with this object, you change the values for the retraction distance and the retraction speed only in small steps and check the result. Keep in mind that you should only change one of these values at a time, so that you know afterwards what caused the changed retraction behavior. This way you can quickly find the perfect values.

The object consists only of two small columns that are printed within a few minutes. For me, the calibration took a total of 10 to 15 minutes until I had the correct values.

If you can’t get stringing under control with this method, the first thing you should do is check that you don’t have too high a flow rate and make sure the filament is dry.

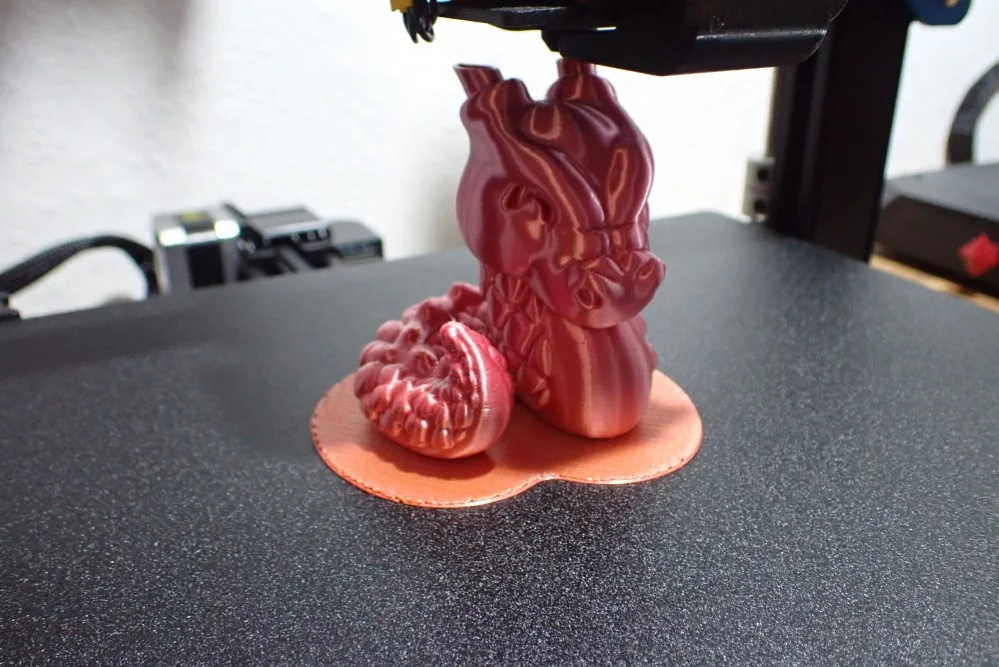

After calibrating these three important printer settings, I usually print a calibration object that is quite demanding for the printer. I chose the Cali Dragon (again) for the Sovol SV01 Pro. It was designed to provoke various printing errors and printed perfectly after my calibration.

Tip: If you want to learn more about the correct Cura settings, check out this article: Sovol SV01 Pro | Cura Settings & Profile – Guide & List

Print Quality – Practical Test

> Sovol SV01 Pro

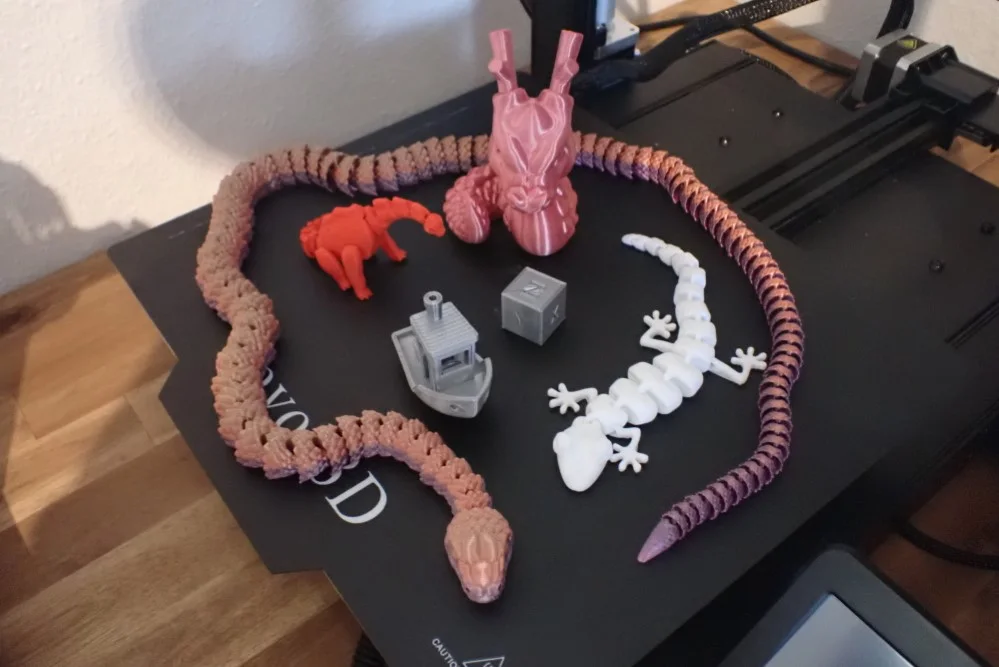

To test the print quality of the Sovol SV01 Pro I printed several models. Most of them I printed with PLA filament, but one of them with ABS filament.

3D Benchy

Probably the most iconic of all calibration objects is 3D Benchy (link to object). The little ship has various features that provoke various printing errors. Depending on how well the settings are calibrated, these printing errors occur more often or less often.

Except for very slight stringing in some places, the quality turned out very well. If a 3D Benchy is printed with this quality, you can confidently switch to more complicated objects.

Cali Dragon

Another calibration object is this Cali Dragon (link to object). It was designed so that the different parts of its body should provoke different printing errors. The only major irregularities on the surface is the Z seam on the back of the model, which is completely normal.

Arti-Brachi

Objects that have a mechanical function are also a good test. Therefore I printed this Arti Brachi out of PLA (link to the object) and scaled the model down a lot.

If something didn’t run perfectly during extrusion, the function would be compromised and the details of the surface would suffer. However, this was neither the case, the function is given and the surface looks very good.

Articulated Lizard

Next I wanted to try a different filament and decided on ABS. ABS is suitable for many applications, including toys – many of the LEGO bricks are made of ABS. Therefore I printed this Articulated Lizard (link to the object).

The quality has surprised me a bit, as I have not done any calibrations before. There is some over-extrusion here and there but otherwise the quality is very good. I printed this object entirely without a draft shield or enclosure, as its low height makes it less susceptible to rapidly fluctuating ambient temperatures. However, with larger ABS models this becomes necessary to prevent uncontrolled contraction.

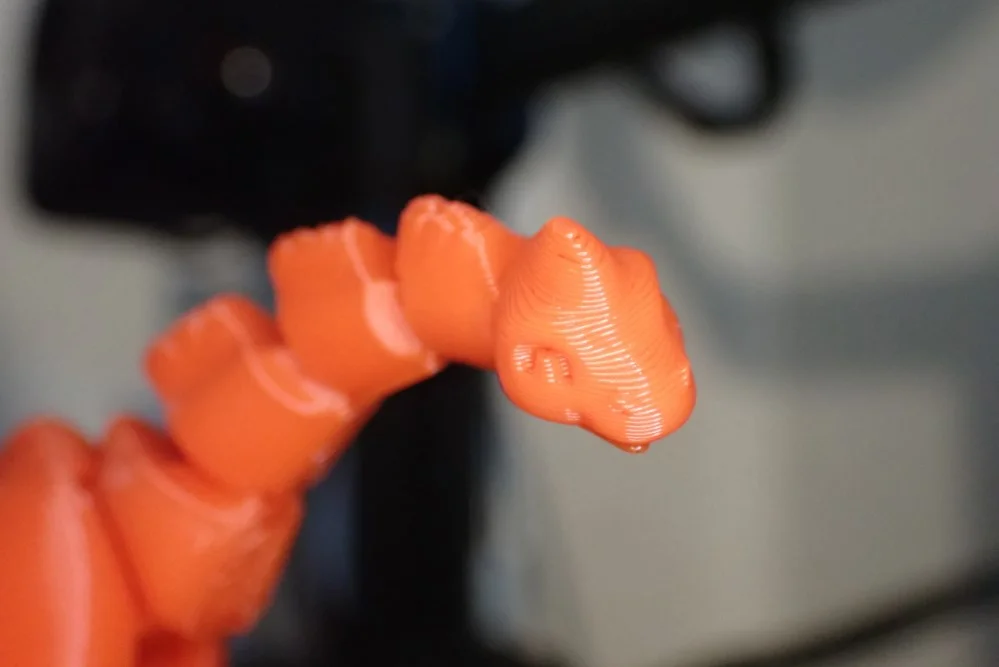

Snake

Finally I printed this snake out of rainbow PLA filament (link to the object). As expected the result is very good, there was hardly any stringing or other extrusion problems. The print bed adhesion was also ideal. I didn’t need any glue or raft. A very slow print speed for the first layer (8 mm/s) was sufficient to ensure a good print bed adhesion.

Sovol SV01 Pro vs. Creality Ender 3 S1 Pro

Probably the biggest competition to the Sovol SV01 Pro at the moment is the Ender 3 S1 Pro*. They have similar features and parameters and are aimed at the same target group.

Check Price at:

| Sovol SV01 Pro | Creality Ender 3 S1 Pro | |

|---|---|---|

| Extruder | Direct drive extruder | Direct drive extruder |

| Print volume | 280 x 240 x 300 mm | 220 x 220 x 270 mm |

| Nozzle temperature | 260 °C | 300 °C |

| Print bed temperature | 110 °C | 110 °C |

| Print bed leveling | Automatic & manual | Automatic & manual |

| Print bed | Flexible, magnetic | PEI, flexible, magnetic |

| Double Z-axis | Yes | Yes |

| Filament sensor | Yes | Yes |

| Display | 4.3-inch touchscreen | 4.3-inch touchscreen |

Direct drive extruder: Both 3D printers have a direct drive extruder and can process all standard and flexible filaments very well. However, the extruder of the Ender 3 S1 Pro is slightly better in the sense that it can reach up to 300 °C and not only 260 °C like the extruder of the Sovol SV01 Pro. So with the SV01 Pro you can’t print polycarbonate (PC) and also some nylon filaments, because they need a printing temperature of more than 260 °C.

Print volume: The Sovol SV01 Pro has a print volume of 280 x 240 x 300 mm and the Ender 3 S1 Pro of 220 x 220 x 270 mm. The SV01 Pro clearly won on this point. So you can print larger objects with it. This is mainly because not only is the Z-axis higher than the S1 Pro, but the frame is attached to the outside of the base rather than on top of it, which frees up a lot of space on the X-axis and allows for a larger print bed. A handy feature of the Ender 3 S1 Pro is the LED bar above the print volume.

Automatic Print Bed Leveling: Automatic print bed leveling is virtually identical on both 3D printers. Both use the CR-Touch leveling sensor to scan 16 points on the print bed. They measure the distance between the print head and the print bed to calculate the tilt of the print bed. The tilt is then automatically compensated for during printing. The only thing you have to do manually with these printers is to adjust the Z0 distance and a rare manual leveling if the print bed has shifted a lot.

Print bed: As far as the print bed surface is concerned, the Ender 3 S1 Pro is slightly ahead. It has a spring steel print bed with a PEI coating. You can remove it just like the Sovol SV01 Pro after printing, bend it and easily release the object. However, the PEI coating is slightly better than the Sovol SV01 Pro. In my experience, it adheres to most filaments a little better. Nevertheless, I did not have to use adhesives like Magigoo in my test prints for the Sovol SV01 Pro.

Dual Z-axis: For 3D printers that have the word “Pro” in their name, a dual Z-axis is a must. The dual design makes the 3D printer’s control over the movements in the Z-axis much more accurate and smoother. As a result, accuracy in this direction is better and fewer printing errors occur. In both 3D printers, the respective axis is equipped with an independent stepper motor.

Supported Filaments: Because the nozzle on the Ender 3 S1 Pro can reach a higher temperature, it can also handle a few more filaments than the Sovol SV01 Pro. This includes mainly polycarbonate and nylon filaments that are at the upper limit of the nylon temperature range.

Compatible with laser modules: Creality and Sovol both offer laser modules that are compatible with the 3D printers compared here. You can use them to replace the print head with a laser module and do laser engraving. So if you’re looking for a combo device, either of these two 3D printers will work well for you.

Filament Sensor: The filament sensors of the two 3D printers are very similar and virtually identical. They are both located directly on the filament holder and are connected via a cable that is hidden in the frame. The suspension of the filament sensors is flexible so that they can adapt to the movements of the filament.

Operation: The operation of the two 3D printers is also very similar. They both have a 4.3-inch touchscreen, support all common languages and guide you in a few touches to the most important settings. Also, both displays have an energy-saving function that dims the display after 3 minutes. However, the Sovol SV01 Pro has an option that allows you to switch between a light and dark mode.

Sovol SV01 Pro vs. Anycubic Kobra

The Anycubic Kobra is one of the best 3D printers for beginners. It has several useful features and is usually a bit cheaper than the Sovol SV01 Pro. The biggest differences between the Kobra and the SV01 Pro are the double Z-axis, the print bed surface and the print volume.

Check Price at:

| Sovol SV01 Pro | Anycubic Kobra | |

|---|---|---|

| Extruder | Direct drive extruder | Direct drive extruder |

| Print volume | 280 x 240 x 300 mm | 220 x 220 x 250 mm |

| Nozzle temperature | 260 °C | 260 °C |

| Print bed temperature | 110 °C | 110 °C |

| Print bed leveling | Automatic & manual | Completely automatic |

| Print bed | Flexible, magnetic | PEI, flexible, magnetic |

| Double Z-axis | Yes | No |

| Filament sensor | Yes | Yes |

| Display | 4.3-inch touchscreen | 4.3-inch touchscreen |

Direct drive extruder: The Anycubic Kobra also has a direct drive extruder. This makes it very suitable for flexible filaments like TPU. Even though the print head of the Kobra looks quite chunky, the weight is still so low that it does not lead to vibrations or severely limit the print speed. The housing is made of a lightweight plastic. The advantage of the Kobra’s extruder is that you can see the nozzle very well. The fan for the nozzle is behind it and does not block the view like the Sovol SV01 Pro.

Print volume: The print volume of the Kobra is 220 x 220 x 250 mm. This is smaller in every dimension than the Sovol SV01 Pro’s print volume of 280 x 240 x 300 mm. This means that you can print larger objects with the SV01 Pro, but it is also larger overall and takes up more space.

Automatic print bed leveling: The Sovol SV01 Pro uses a CR touch to level the print bed. It scans 16 points on the print bed. However, you still have the option of manually leveling the print bed using the rotary screws under the print bed. The Anycubic Kobra uses the self-developed LeviQ leveling function which scans the print bed at 25 points. The Kobra also no longer has any screws under the print bed. The only thing you have to do manually is adjust the Z0 offset with a piece of paper.

Print bed: In terms of print bed surface, the Anycubic Kobra wins with its flexible PEI print bed. The PEI coating provides excellent print bed adhesion for most filaments. The Sovol SV01 Pro also has a flexible magnetic print bed, but no PEI coating. Despite this, I had no issues with print bed adhesion with the SV01 Pro, however PEI would be a bit better. The advantage of the SV01 Pro print bed is that it is much more flexible than the Kobra. This allows you to remove the finished print objects much easier after they have cooled down.

Double Z-axis: The Anycubic Kobra does not have a double Z-axis. A double Z-axis would make positioning in this direction more accurate and cause less vibration. Although the print head is very light, a double Z-axis would still be an advantage here. The longer the X-axis, the more important a double Z-axis is in order to be able to move the weight of the printhead vibration-free and accurately at the other end of the X-axis. Since the Sovol SV01 Pro has a larger print volume, the double Z-axis is also necessary here to avoid unnecessary vibrations.

Supports PLA/ABS/TPU/PETG: Both 3D printers have the same temperature range and a direct drive extruder and can therefore process the same filaments. There is a slight advantage here with the Kobra as it has a slightly better print bed surface and therefore better adhesion for some filaments. Both 3D printers will have difficulty with larger ABS prints as they do not have a sealed print volume. Here a suitable enclosure would be a good upgrade.

Filament Sensor: The Sovol SV01 Pro has a flexible filament sensor just below the filament holder. The Anycubic Kobra does not have a filament sensor. So you have to be careful with the Kobra that you don’t load too little filament for printing. The printer won’t know when the filament is running low and will just keep printing in the air without filament when it runs out. I’ve actually never had filament run out unexpectedly, so this feature is not a purchase decision for me.

Operation: There are no major differences in operation. They both have a 4.3-inch touchscreen and both have an intuitive menu. The only advantage here is the Sovol SV01 Pro, which also has a dark mode.

Sovol SV01 Pro vs. Mingda Magician X

The biggest difference between the Sovol SV01 Pro and the Mingda Magician X is the print bed surface and the print volume. In both cases, the SV01 Pro is ahead. However, the Magician X has a more professional design and better cabling.

Check Price at:

| Sovol SV01 Pro | Mingda Magician X | |

|---|---|---|

| Extruder | Direct drive extruder | Direct drive extruder |

| Print volume | 280 x 240 x 300 mm | 230 x 230 x 260 mm |

| Nozzle temperature | 260 °C | 260 °C |

| Print bed temperature | 110 °C | 110 °C |

| Print bed leveling | Automatic & manual | Completely automatic |

| Print bed | Flexible, magnetic | Textured glass |

| Double Z-axis | Yes | Yes, synchronized |

| Filament sensor | Yes | Yes |

| Display | 4.3-inch touchscreen | 3.5-inch touchscreen |

Direct drive extruder: Both 3D printers have a direct drive extruder. The extruder on the Magician X is slightly larger and looks chunkier, but that’s mainly due to the large housing. It is just as well suited for use with flexible filament as the SV01 Pro. The advantage of the extruder from the Magician X is that it rides on a wider X-axis, making it even better at avoiding vibration. In addition, the extruder of the Mingda Magician X has another rather subjective advantage: the cabling looks fancier and gives off a more professional vibe than the SV01 Pro.

Print volume: The Sovol SV01 Pro also wins against this 3D printer in terms of print volume. The space for your objects is larger here in every dimension, which gives you more creative freedom. The large print area in the XY direction of the SV01 Pro is mainly due to the fact that the frame is mounted on the side of the base and not perpendicular to it. This allows the 3D printer to use a print bed that is almost as wide in the X direction as the base itself. I am a big fan of this setup as it saves a lot of costs. However, I can’t say which design is more stable and causes less vibration.

Automatic print bed leveling: The print bed leveling runs automatically with both 3D printers. With both systems, the print bed is measured and calibrated at 16 points. The SV01 Pro also has 4 rotary screws under the print bed to perform a manual leveling. The print bed of the Magician X is fixed. The only thing you have to do manually is to adjust the Z-Offset. As far as the accuracy of the two print bed leveling is concerned, I could not find any differences.

Print bed: I am not a big fan of glass print beds. While the surface of the bottom layer is nice and smooth, I am more often forced to use adhesives like Magigoo or Blue Tape on filigree first layers without a raft than on coated print beds like the Sovol SV01 Pro. The print bed adhesion of the SV01 Pro is also not as perfect as with a PEI print bed, but still better than the glass print bed of the Magician X.

Double Z-axis: Both 3D printers have a double Z-axis. However, on the Magician X, these two axes are still connected with a belt so that they have no chance to run asynchronously. I don’t know how big the influence of this feature is on the accuracy of the Z-movement, but I suspect that vibrations can be avoided even better here.

Supports PLA/ABS/TPU/PETG: Because both 3D printers have the same temperature range for the nozzle and print bed, they are both suitable for all standard filaments. However, you will have better print bed adhesion with many of these filaments on the Sovol SV01 Pro than you will on the Magician X’s glass print bed. Also, both will have difficulty with large ABS models unless you use an enclosure.

Filament Sensor: The filament sensor on the Sovol SV01 Pro is located directly below the filament holder and is flexibly mounted to follow the movements of the filament. With the Magician X, the filament sensor is built into the print head. This has the advantage that the design is cleaner and you can use up all the filament. The disadvantage, however, is that the print head becomes somewhat heavier.

Operation: The touchscreen of the Sovol SV01 Pro is slightly larger at 4.3 inches than that of the Magician X at 3.5 inches. In addition, the orientation of the SV01 Pro is upright and that of the Magician X is horizontal. Still, you’ll find your way around the Magician X’s menu just fine. All menus and submenus are clearly labeled and illustrated.

Is the Sovol SV01 Pro Worth It?

The Sovol SV01 Pro* does not belong to the low-budget entry-level 3D printers due to its price, but is slightly above. Due to the larger print volume, the direct drive extruder, the automatic print bed leveling and the magnetic print bed, it has some features that the low-budget 3D printers lack.

But especially for beginners these features are an advantage, because they prevent a lot of frustration. So if you are looking for a 3D printer that allows you to quickly achieve good printing results without a lot of trial and error, you are exactly right with the Sovol SV01 Pro.

Check Price at:

Similar 3D Printers

Creality Ender 3 S1 Pro

The Creality Ender 3 S1 Pro* has a direct drive extruder that reaches a temperature of up to 300 °C, a print volume of 220 x 220 x 270 mm, a double Z-axis and a flexible magnetic PEI print bed. The print bed is automatically leveled via a CR-Touch.

Check Price at:

Anycubic Kobra

The Anycubic Kobra is a good entry-level 3D printer with a print volume of 220 x 220 x 250 mm. It reaches 260 °C (nozzle) and 110 °C (print bed). It has only a single Z-axis, but an automatic print bed leveling and a PEI print bed.

Check Price at:

Mingda Magician X

The Mingda Magician X reaches a print bed temperature of 110 °C and a print temperature of 260 °C. It has a print volume of 230 x 230 x 260 mm and has a double Z-axis. Due to its direct drive extruder it is also perfectly suitable for flexible filaments.

Check Price at:

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.