- Z Seam | How to Hide & Avoid | Cura & PrusaSlicer - April 20, 2024

- Qidi Tech Q1 Pro – Best Orca Slicer Settings & Profile - April 9, 2024

- Creality Ender-3 V3 Review – Will CoreXZ be the New Trend? - March 27, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

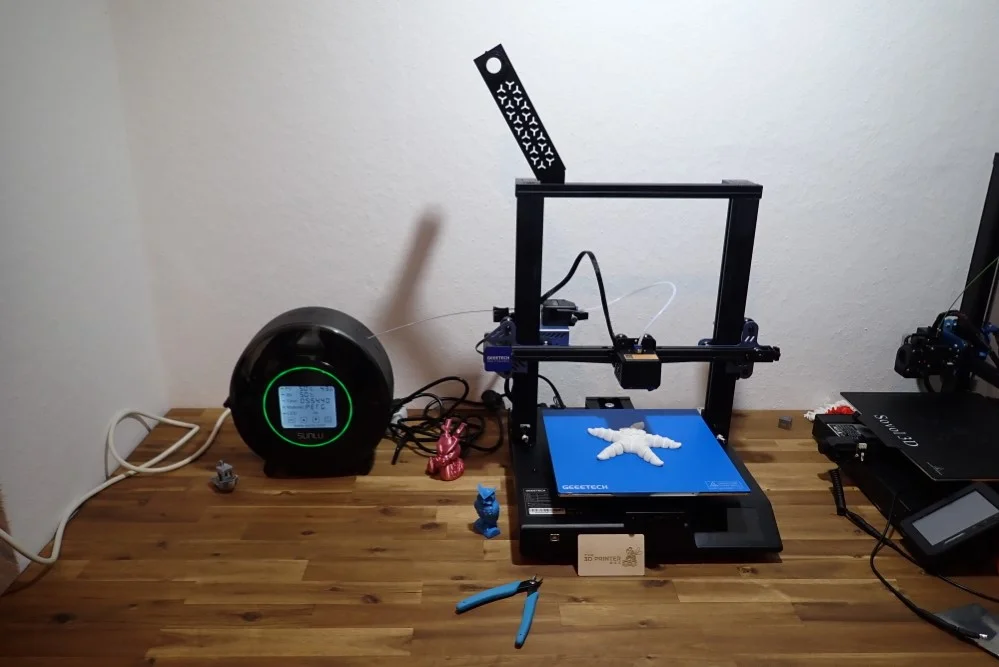

If you’re a 3D printer enthusiast, you know how important it is to keep filament dry. Sometimes it’s also necessary to dry damp filament to get it ready for use again. That’s where the Sunlu FilaDryer S2* comes in.

The Sunlu FilaDryer S2 dries whole filament spools evenly over a time of 3-6 hours and depending on the material between 35-70 °C. Especially for the particularly hygroscopic filaments such as Nylon, PVA and PETG it is very useful, but also prevents PLA from becoming brittle.

In this hands-on test of the Sunlu FilaDryer S2, I tested its effectiveness on filament that was stored open, filament that was stored in a container with silica gel, and extremely damp filament that had been in water for 2 days.

Check Price at:

Table of Contents:

- 1 Key Takeaways

- 2 Who Should Buy the Sunlu FilaDryer S2?

- 3 Scope of Delivery & Design > Sunlu FilaDryer S2

- 4 Operation > Sunlu FilaDryer S2

- 5 Practical Test: Print Quality Before & After > Sunlu FilaDryer S2

- 6 Noise Level > Sunlu FilaDryer S2

- 7 Power Consumption > Sunlu FilaDryer S2

- 8 Sunlu FilaDryer S2 vs. Creality Filament Drying Box

- 9 Is the Sunlu FilaDryer S2 Worth it?

Key Takeaways

- Suitable for PLA, PLA, Wood, PETG, PVB, ABS, HIPS, PVA, ASA, TPU, PMMA, PA, PC

- The filament can be fed directly from the dryer to the printer.

- Prevents common printing errors such as stringing or bubbles.

- Temperature range from 35-70 °C

- Dries each filament within 3-6 hours

- Max. spool size: Ø 210 x 85 mm

- Filament diameter: 1.75 mm ; 2.85 mm ; 3.00 mm

Who Should Buy the Sunlu FilaDryer S2?

The Sunlu FilaDryer S2 is suitable for anyone who has problems with wet filament. Especially when using Nylon, PVA and PETG this filament dryer is particularly suitable, but also PLA can benefit from drying.

Scope of Delivery & Design

> Sunlu FilaDryer S2

The scope of delivery of the Sunlu FilaDryer S2 includes the device itself, a clear instruction manual and the power cable with power supply unit.

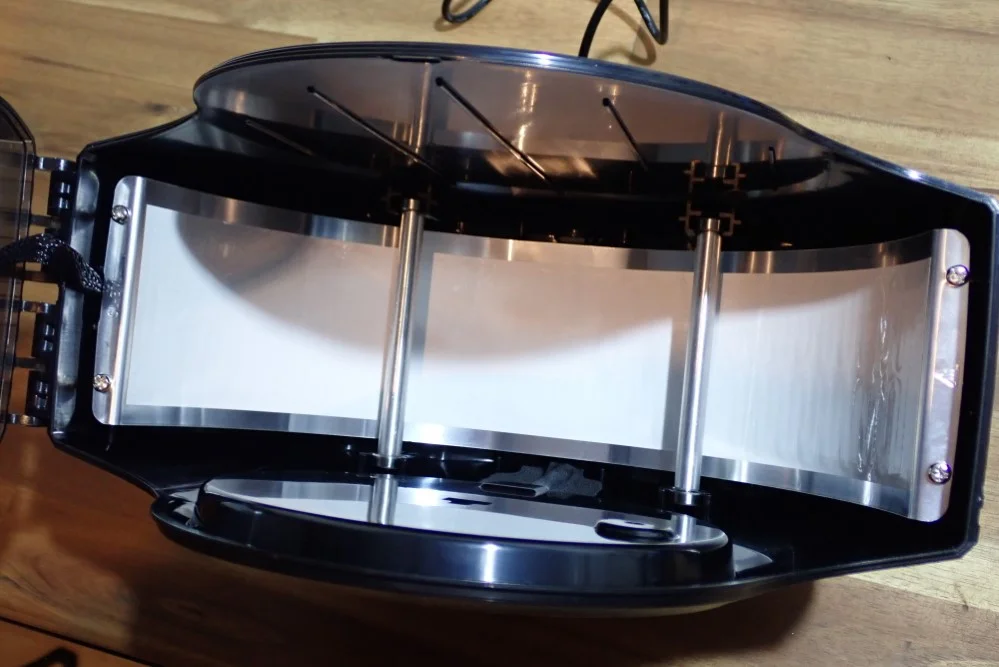

The device has a slightly egg-shaped form with four feet on the bottom. It can be opened from the top and has space for a filament spool. The filament gets heat from all sides via two heating surfaces.

The storage of the filament inside is designed so that the spool can be unrolled freely. In the hood is a small hole through which the filament can be fed to the printer. This makes it possible to use the dry filament directly for printing. This way you don’t give the filament a chance to get wet. Especially for larger prints, this is a practical feature.

Especially with Bowden extruders, the direct feeding from the filament dryer into the extruder is very easy, because the angle of the filament is exactly right. With direct drive extruders, it is a bit more difficult because the filament has to come from above.

Also, there are many 3D printers with direct drive extruders where the filament sensor is mounted on top of the frame. This makes it even more difficult to feed the filament directly from the dryer to the printer. But if the advantages of drying outweigh the disadvantages, an individual solution can be found.

Operation

> Sunlu FilaDryer S2

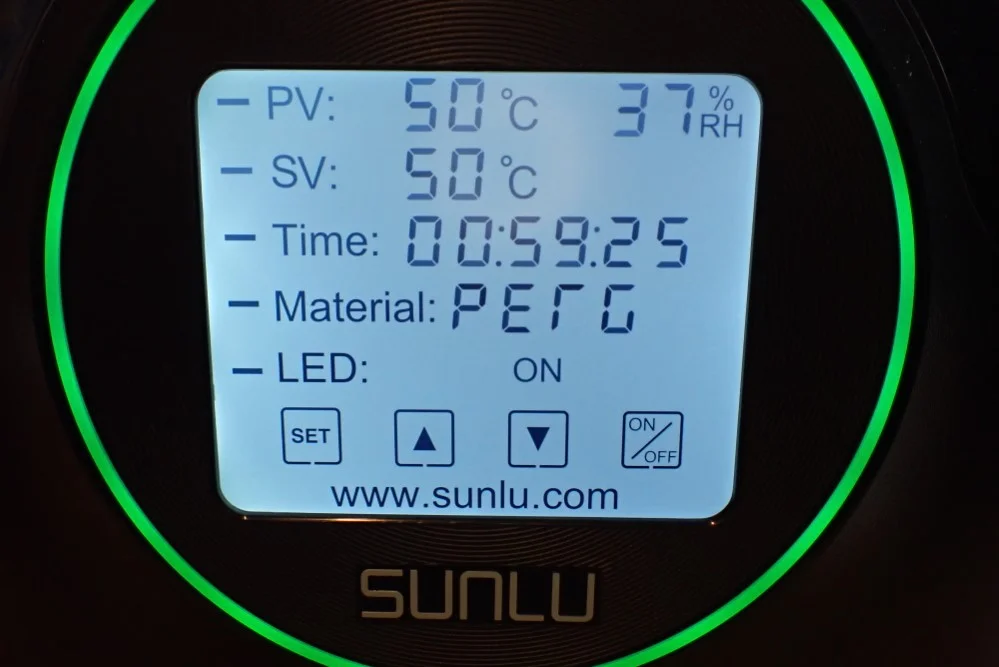

The operation is done via a large touchscreen on the front of the device. The current temperature, the target temperature, the relative humidity, the remaining drying time and the material are displayed there. Via a simple menu with a “set” button and two arrows you can change the different parameters.

Different temperatures are recommended for the different filaments. These can be found in a reference table in the operating instructions.

You can place the filament into the flame dryer either before or after you have made the settings. If you plan to print directly with the filament afterward, you can also thread the end of the filament into the hole of the hood.

Practical Test: Print Quality Before & After

> Sunlu FilaDryer S2

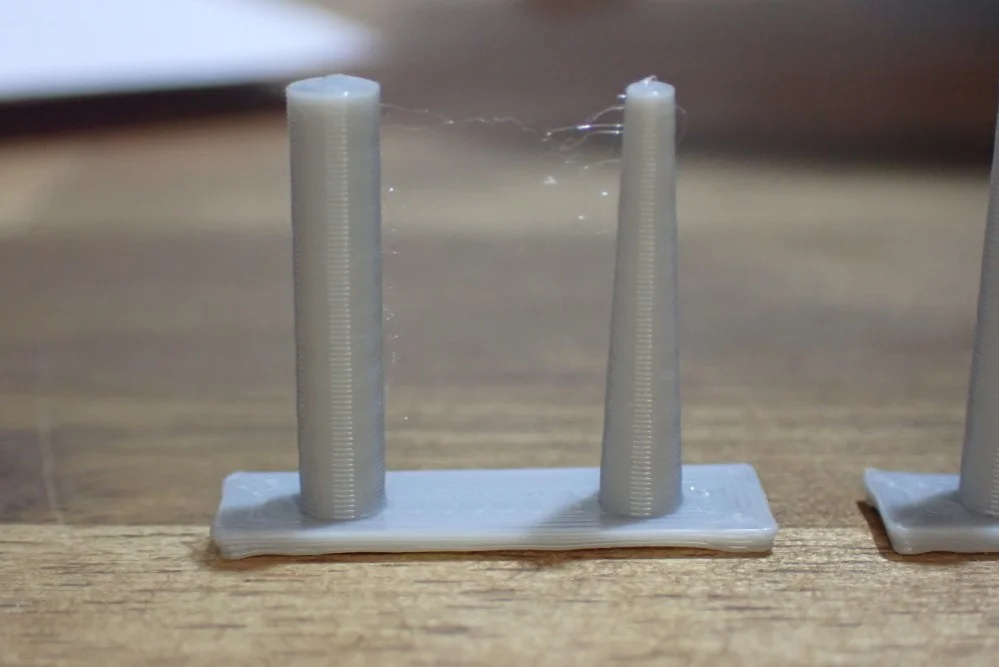

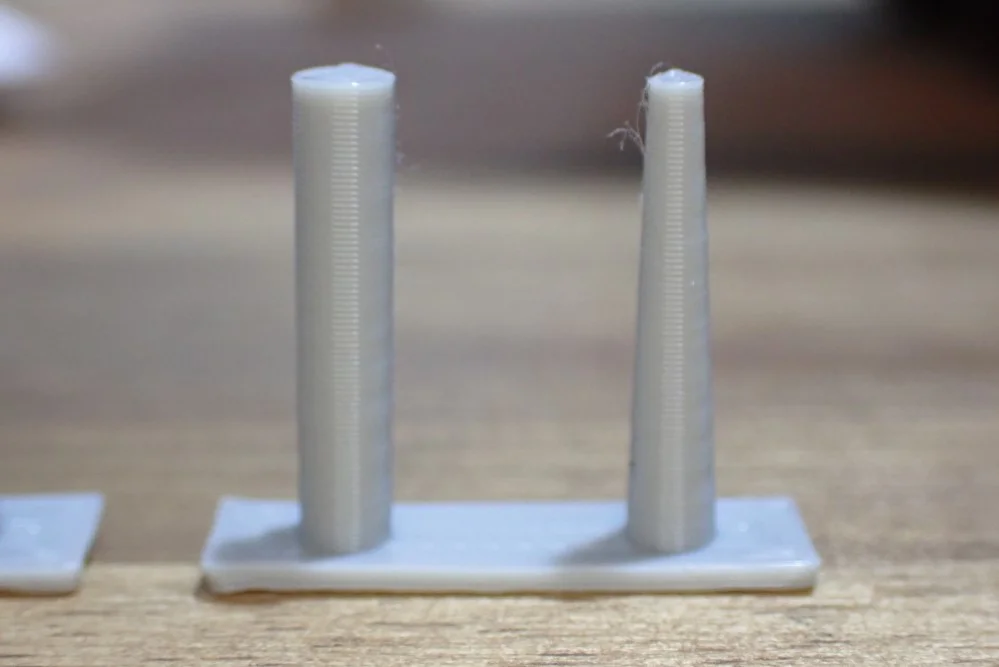

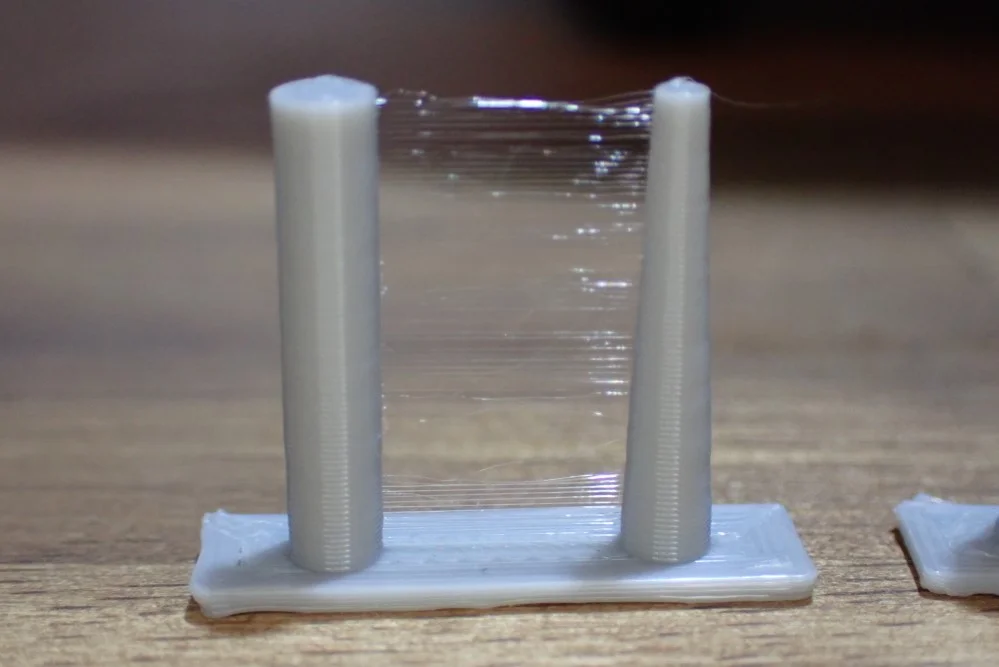

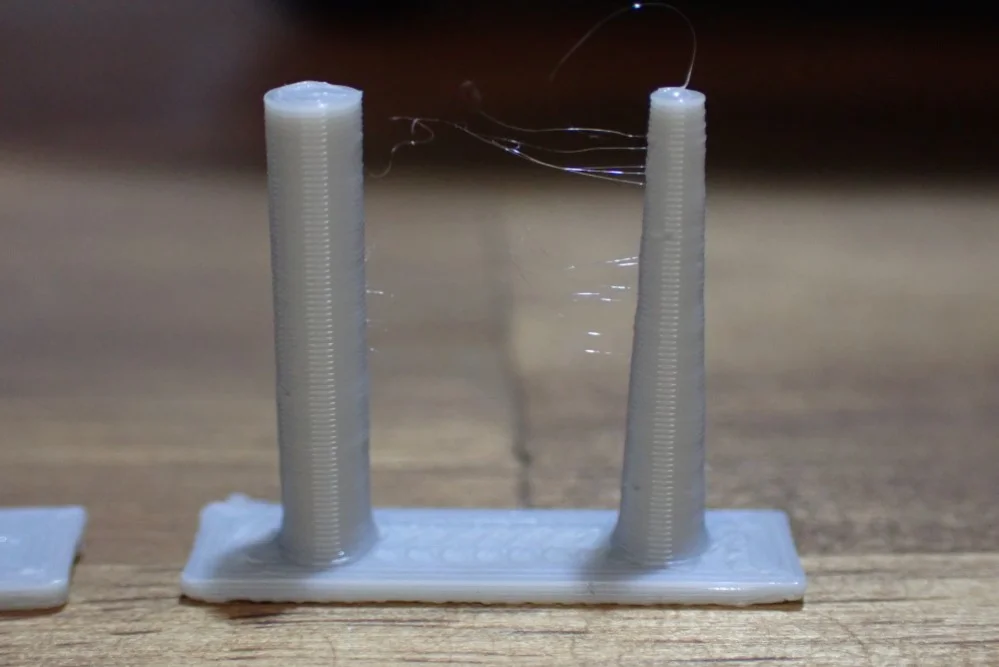

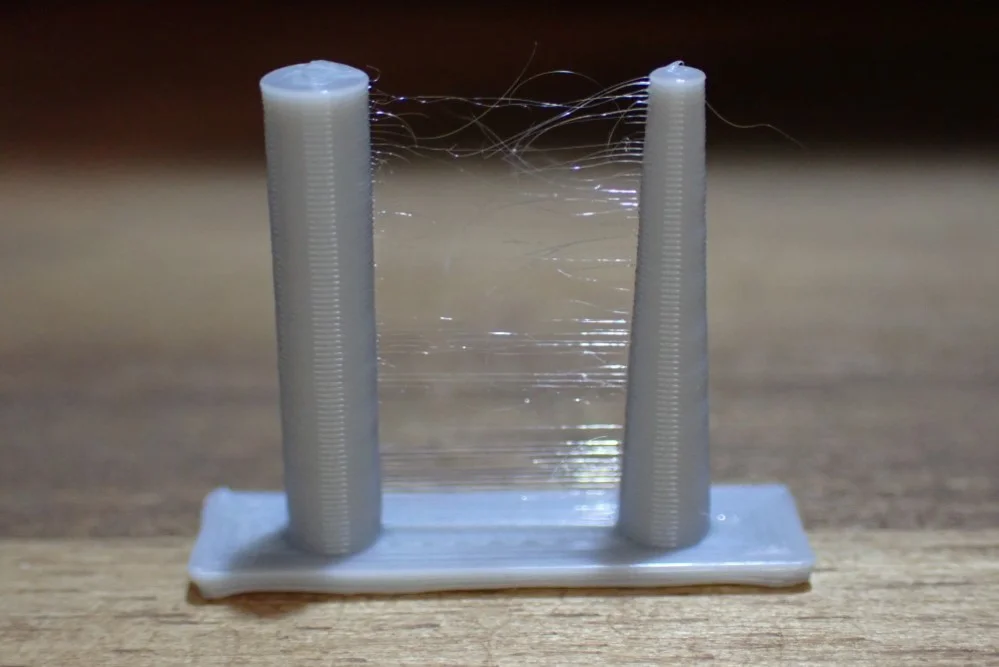

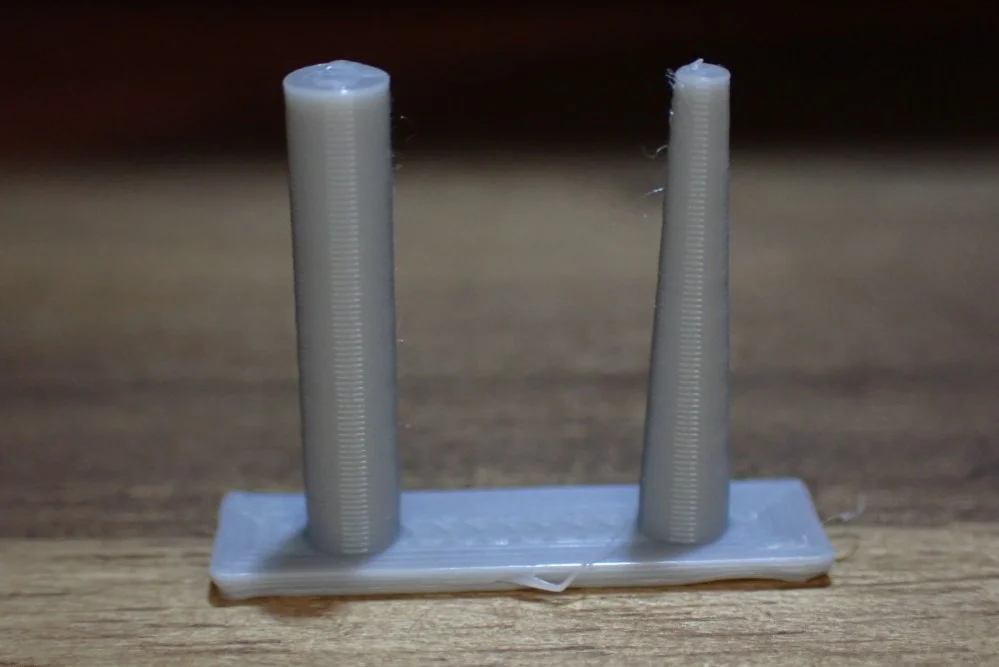

I wanted to know if the Sunlu FilaDryer S2 delivers what it promises and have tested it practically. For this I used PETG, which is known to absorb water from the air, which leads to more stringing when printing.

For comparison, I printed a retraction test with the filament before and after drying to observe any changes. For this, I stored or dried the PETG in three different ways:

- PETG in the open air for one week (about 40-50 % humidity at 20-24 °C)

- PETG stored dry (closed container with silica gel)

- PETG soaked in water for 12 hours

The result is quite clear: Drying improved the stringing behavior in each of these tests. Only with the dry stored filament, there was hardly any change – a confirmation that my storage system works!

Noise Level

> Sunlu FilaDryer S2

There is not much to say about the noise level, as the filament drying unit is completely silent.

Power Consumption

> Sunlu FilaDryer S2

During the heating phase of the heating surfaces, the Sunlu FilaDryer S2 consumes about 46 watts. In idle mode, on the other hand, it is only about 2 watts. Once the device has reached the temperature, it only has to activate the heating again in between, which brings it over the 3-6 hours of drying on a very low power consumption.

Sunlu FilaDryer S2 vs. Creality Filament Drying Box

Compared to the drying box from Creality*, the Sunlu FilaDryer S2 has a few advantages. With the Creality device, only the duration can be set via a rotary knob and there are no other setting options.

Due to the missing display, it is also not possible to set the temperature or to read the current humidity.

Is the Sunlu FilaDryer S2 Worth it?

If you have problems with damp filament, the Sunlu FilaDryer S2* is definitely worth it! Especially in humid areas or during heat waves with humid air in the summer, it is sometimes impossible to print certain filaments like PETG without some form of drying.

Check Price at:

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.