- Is a Wash & Cure Station Worth It? Creality UW-03 Review - April 29, 2024

- Z Seam | How to Hide & Avoid | Cura & PrusaSlicer - April 20, 2024

- Qidi Tech Q1 Pro – Best Orca Slicer Settings & Profile - April 9, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

The BQ-Hurakan or BIQU-Hurakan* is one of the most interesting new FDM 3D printers for beginners. It has many features that improve the print quality and user experience. And if that’s not enough for you, BIQU offers upgrades for it, like a camera, a direct drive extruder or a bigger screen.

One of the best features, however, is the cooperation and integration of Klipper as firmware. What you can expect for operating options and what print quality the BQ-Hurakan achieves, I’ll show you in this practical review.

Check Price at:

Table of Contents:

Key Takeaways

- High print quality can be achieved with the Klipper firmware

- Can be controlled and monitored via the browser interface

- Accelerometer included

- The PEI print bed provides excellent adhesion for most filaments

- Automatic print bed levelling by the BIQU MicroProbe

Who Should Buy the BQ-Hurakan?

The BQ-Hurakan is perfect for beginners because it has many features that make the printing process easier and improve the quality of the prints. In particular, the Klipper firmware offers you a wide range of options to control the printer, which also makes it interesting for experienced users who want to control multiple 3D printers at the same time.

Advantages & Disadvantages

PRO:

- High print quality

- Nearly perfect print bed adhesion

- Automatic print bed levelling

- Filament sensor

- Many upgrades available

- Controllable via browser

CON:

- Not optimally suited for flexible filaments (upgrade available)

- Small screen (upgrade available)

Technical Specifications

DEVICE

- Technology: FDM (Fused Deposition Modeling)

- Assembly: Partially pre-assembled, approx. 20 minutes

- Operation: Small monochrome screen with rotary knob

- Extruder: Bowden

- Print volume: 220 × 220 × 270 mm

- Accuracy: 0.1 mm

- Print speed: 60 mm/s (max. 180 mm/s)

- Nozzle quantity: 1

- Nozzle diameter: 0.4 mm

- Max. nozzle temperature: 260 °C

- Max. print bed temperature: 100 °C

- Filaments: PLA, ABS, PETG etc.

- Filament diameter: 1.75 mm

- Print bed: Flexible, magnetic, PEI-coated

- Print bed levelling: Automatic

- Resume Print: Yes

- Filament Sensor: Yes

SOFTWARE

- Connectivity: 2 x USB 2.0, MicroSD card, SD card, LAN, SPI interface

- Slicer: Cura, Repetier-Host, Simplify3D

Check Price at:

Scope of Delivery

Everything is included in the scope of delivery of the BQ-Hurakan to be able to start directly with the first test prints.

It’s best to buy more filament directly, as the PLA filament included is only a small sample. For the beginning, I would advise you to use PLA filament. Once you have some experience, you can try other filaments like PETG or ABS.

What was surprising is that the scope of delivery also includes a LAN cable and an accelerometer. However, since the BQ-Hurakan runs on Klipper, a LAN cable is useful for connecting to a network (although it also works via Wi-Fi). I’ll show you exactly what the accelerometer does later in the feature presentation.

The following items are included with the BQ-Hurakan:

- Partially pre-assembled 3D printer

- All tools necessary for the assembly

- Operating instructions

- Some PLA filament

- LAN cable

- Accelerometer

- MicroSD card with test models and software

- MicroSD to USB adapter

Setup

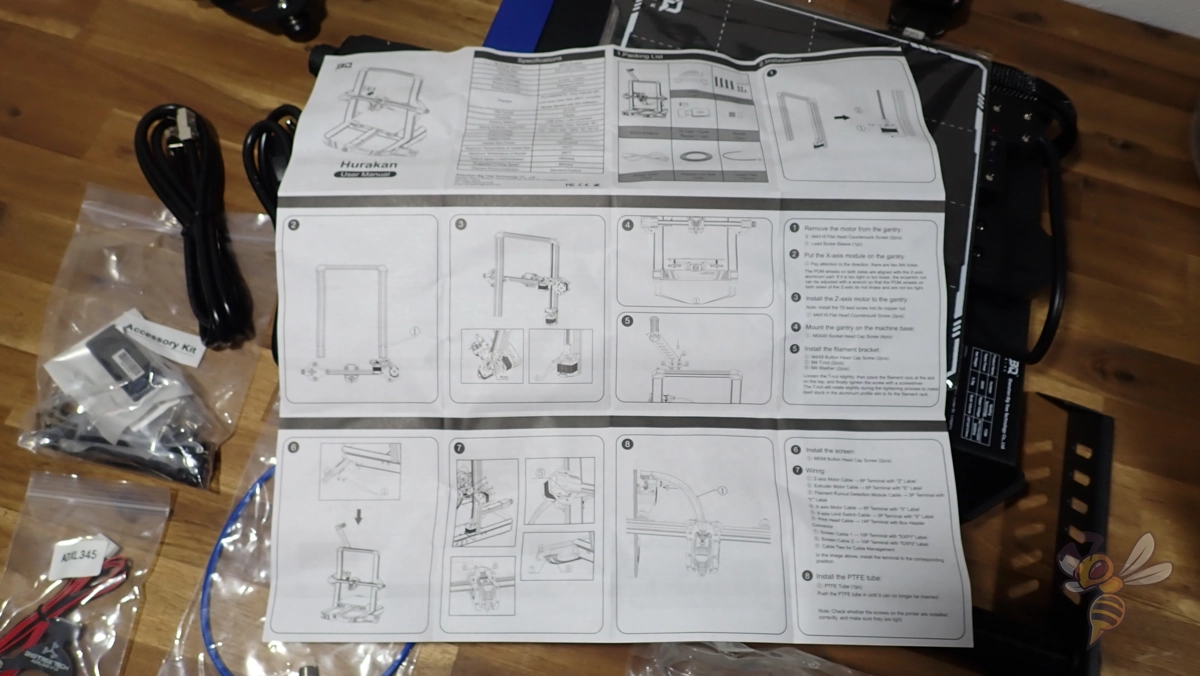

The BQ-Hurakan comes in pre-assembled parts that take about 20 minutes to assemble. The digital instruction manual is better than the one included in the package.

The package in which the BQ-Hurakan comes is very compact. In return, the assembly also takes a little longer, since there are more individual parts that need to be put together.

However, the most complicated parts such as the print head or the print bed are already pre-assembled. All assembly steps are therefore relatively simple and easy to complete even by people who have no technical talent.

While the instruction manual that comes with the package is relatively good, the digital instruction manual on GitHub (see link above) is a bit better. The illustrations are easy to understand and there are a few more details covered.

The installation of the acceleration sensor, which noticeably improves the print quality, is also discussed there.

Features & Design

The design of the BQ-Hurakan is very modern with blue accents. The design of the print head in particular is well done. The print bed sensor sits in a prominent position and the rest of the components like the fans are very cleverly mounted to save weight. This makes the print head look very compact and lightweight.

Nevertheless, many of the features that make the BQ-Hurakan so special are built into and around the print head. In addition to the sensor for automatic print bed levelling, this also includes LEDs and the acceleration sensor.

These are the key features of the BQ-Hurakan:

- Klipper integration: More convenient operation, better print quality, browser interface.

- Acceleration sensor: AI-assisted compensation of print head accelerations to minimize printing errors caused by vibrations.

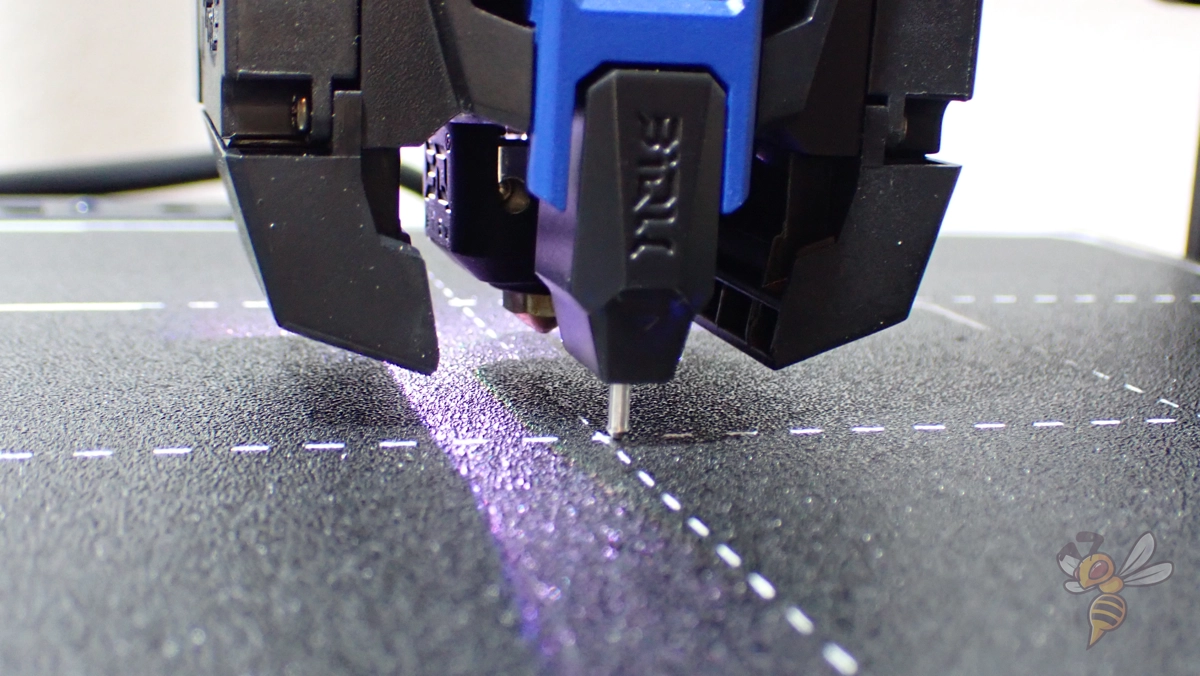

- Automatic print bed levelling: The BIQU MicroProbe in the print head measures the inclination of the print bed at several points.

- PEI-coated print bed: Provides near perfect print bed adhesion for most filaments.

- Print bed with several heating zones: For small objects, the heating zone can be reduced in size to save energy.

- Self-developed Manta mainboard: 32-bit, 64 MHz, 4 cores, 512 MB DDR3

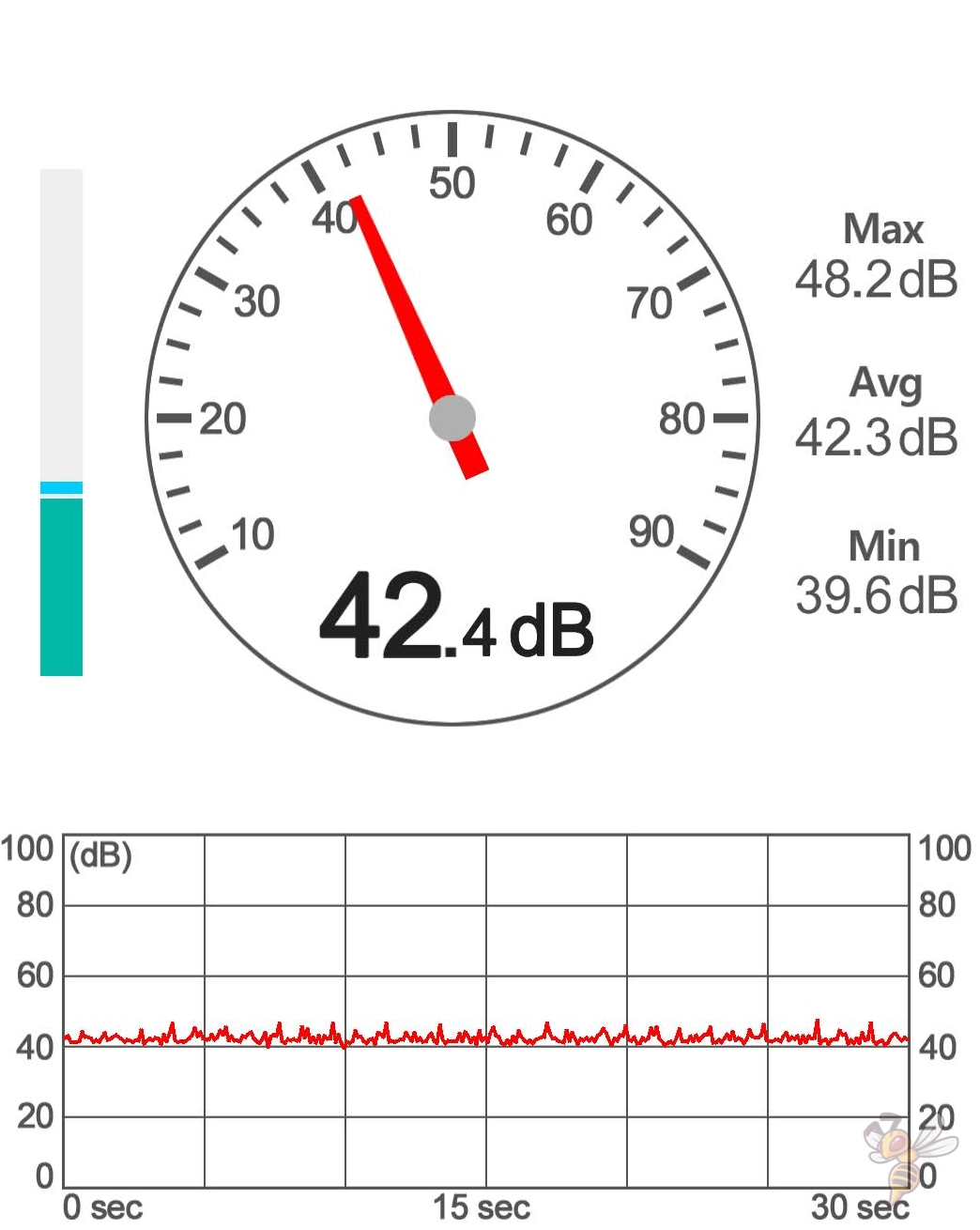

- Very quiet: TMC2209 stepper motor driver keeps the noise level below 50 dB.

- LEDs in the print head: Useful for remote monitoring via camera and the web interface.

- Filament Sensor: Detects broken or empty filament and pauses printing.

- Many connection options: 2 x USB 2.0, MicroSD card, SD card, LAN, SPI interface

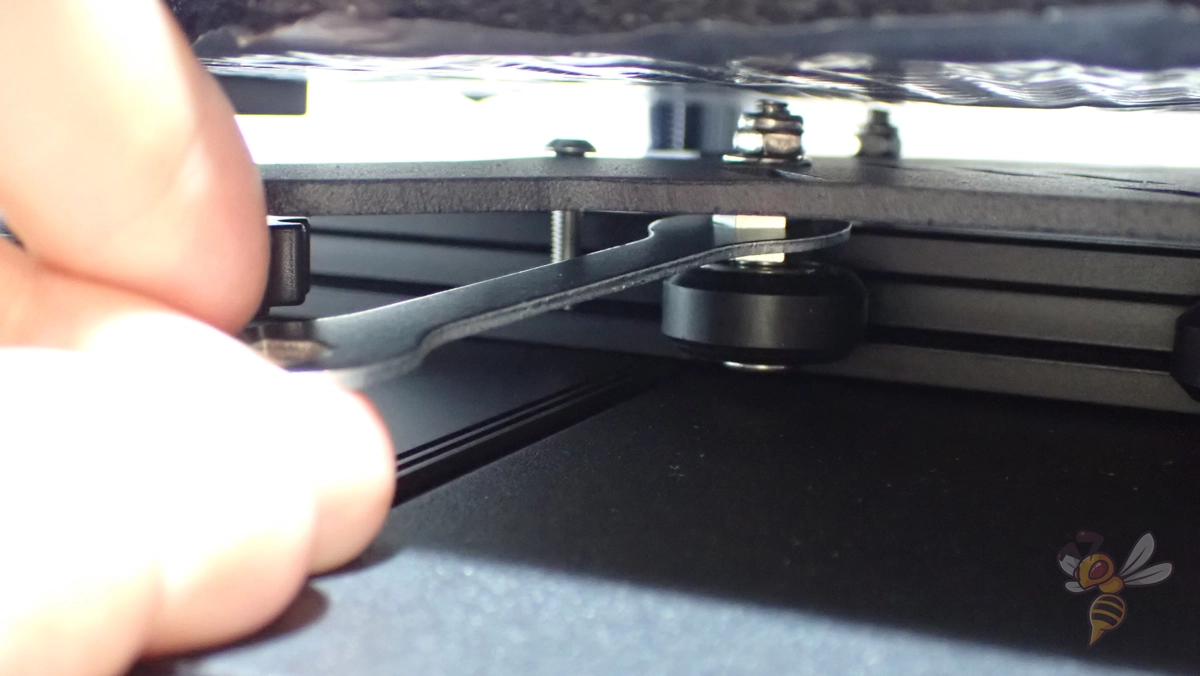

- Belt tensioner: Easy tensioning of the toothed belts of the x-axis and the print bed.

- Many upgrades: Direct drive extruder, camera, HDMI Series screen.

Check Price at:

Klipper Integration

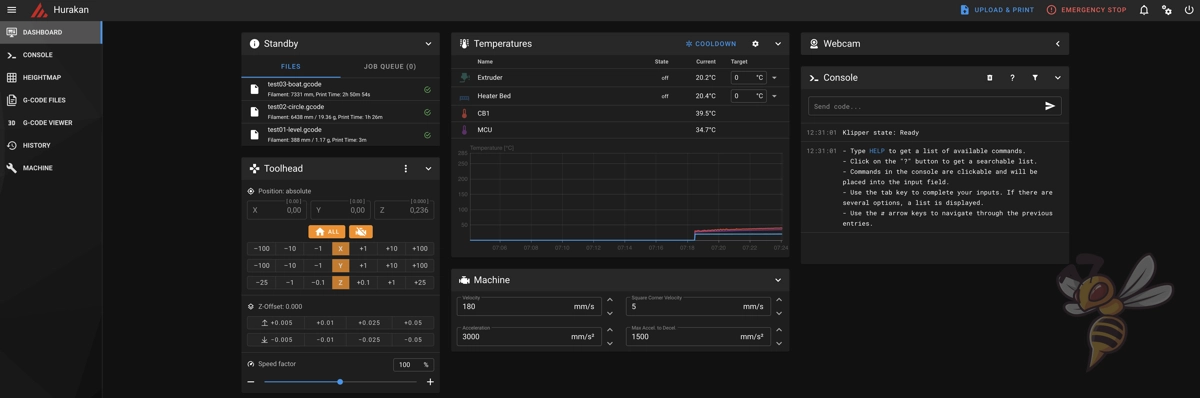

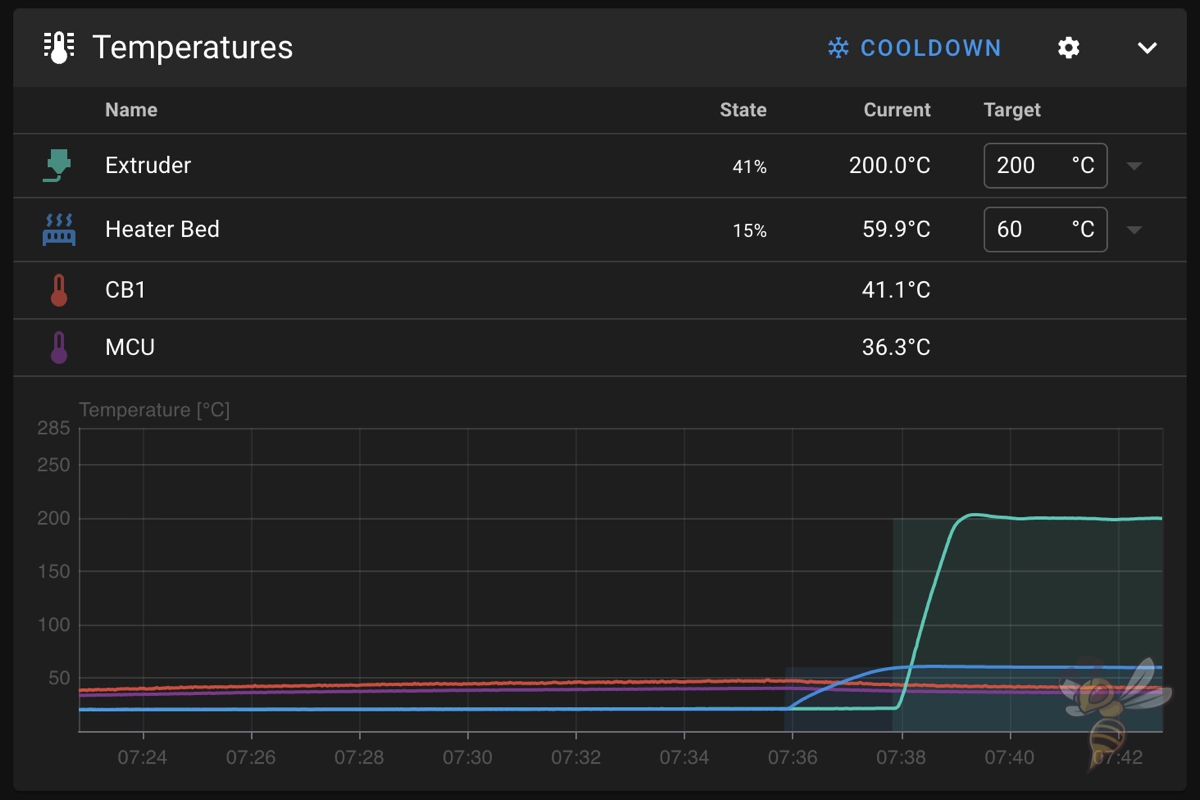

Klipper is a powerful firmware that enables high-quality 3D printing with great ease of use. It offers an intuitive user interface, advanced print settings, and reliable and fast communication with the printer.

Klipper also offers clever features like user-defined macros or camera integration.

Thanks to the cooperation between Klipper and BIQU, the BQ-Hurakan benefits from these advantages and achieves outstanding printing qualities.

One of the best things about Klipper is the browser interface, which makes it easy to control the printer, for example. Throughout my testing and continued use of the BQ-Hurakan, I operated the printer exclusively through the browser. As a result, the small screen didn’t bother me much, as it’s basically superfluous after the initial setup.

Besides the better operation, the integration possibility of an acceleration sensor is definitely the best feature that Klipper brings along.

Accelerometer

An accelerometer is an electronic device that measures the acceleration of an object. In 3D printing, it is used to detect and compensate for the vibrations of the print head. This minimizes the printing errors caused by vibrations and improves the print quality.

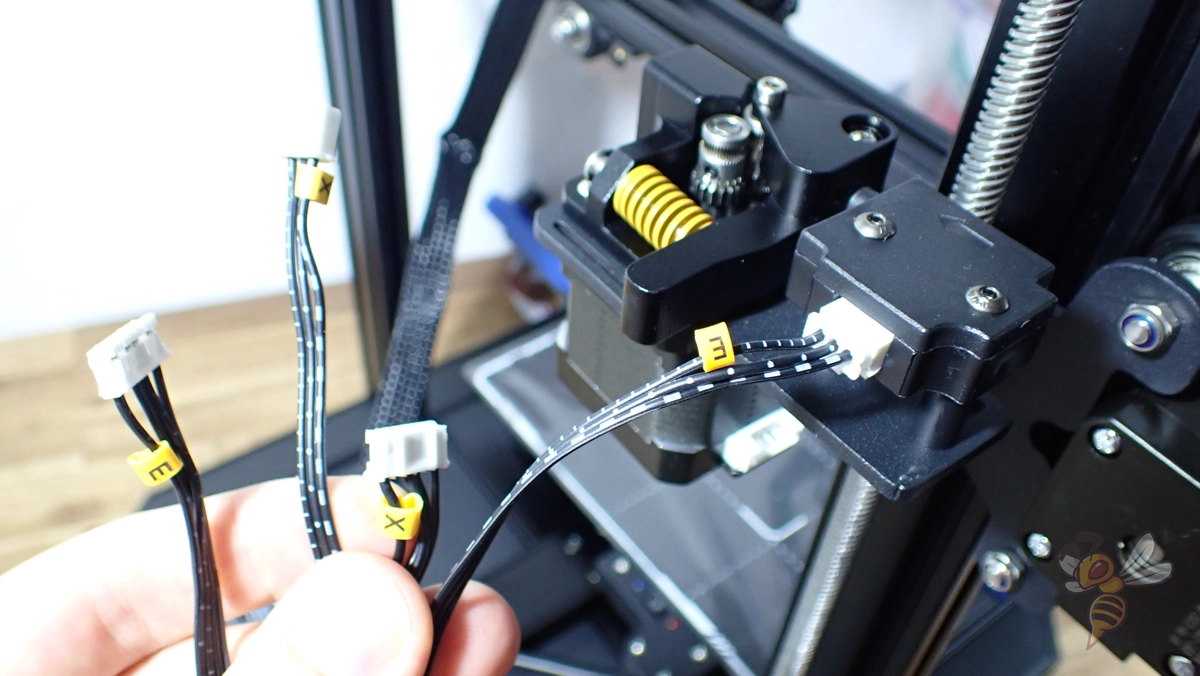

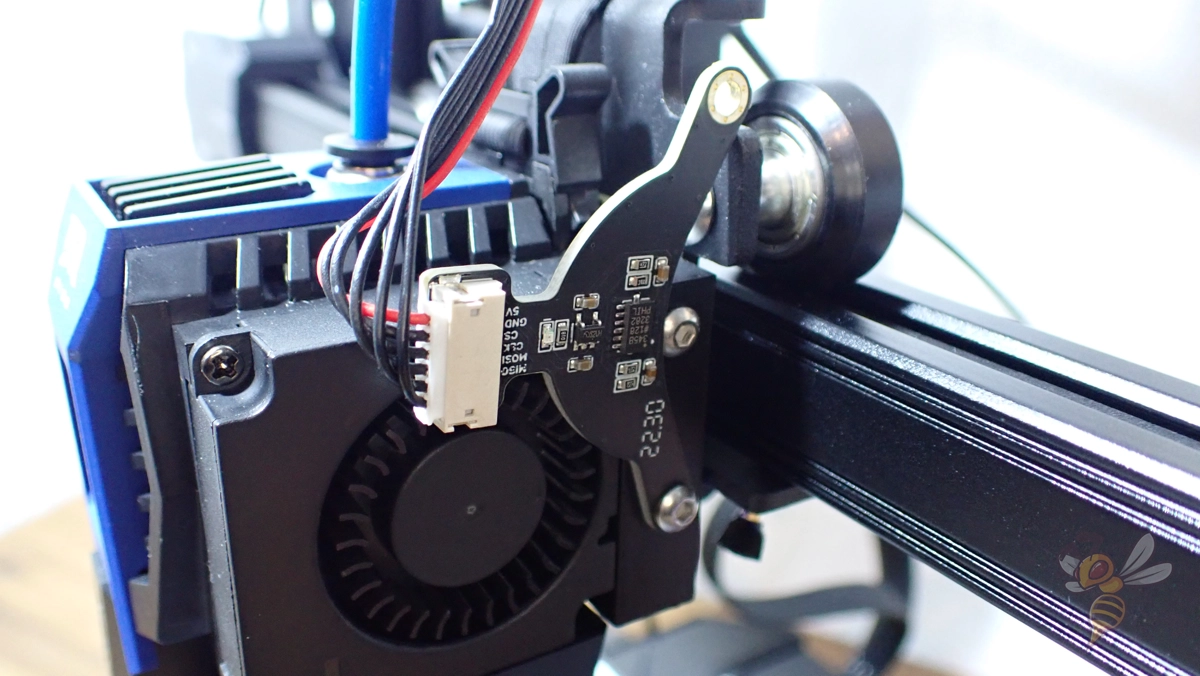

On the BQ-Hurakan, the accelerometer is mounted on the right side of the print head and plugged into the SPI interface connector. After calibrating the X-axis, the accelerometer can also be attached to the print bed to measure its accelerations.

The compensation of the acceleration forces has a great influence on the print quality – especially at fast print speeds and quick changes of direction. The typical print errors triggered by the resulting vibrations, ringing and ghosting, are visibly minimized. A really ingenious trend that is slowly making its way into newer 3D printers.

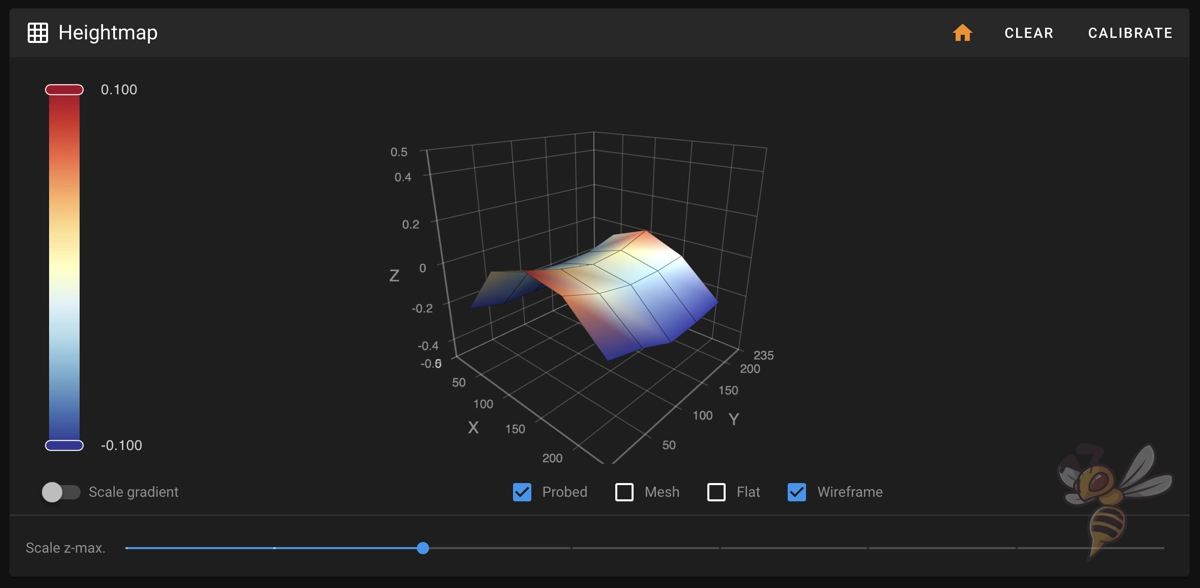

Automatic Print Bed Levelling

The print head of the BQ-Hurakan is equipped with a BIQU MicroProbe. This is a sensor that measures the inclination of the print bed at several points.

The measured data is used to automatically level the print bed. The advantage over other leveling methods is that the print bed only needs to be manually leveled once. During assembly, the print bed is roughly leveled manually once to eliminate strong inclinations.

After that, you only need to have the print bed automatically leveled occasionally.

A big advantage over other print bed sensors (BL-Touch or CR-Touch) is that the MicroProbe is tiny and light. This reduces the inertial mass of the print head even further and results in even less disturbing vibrations.

PEI-Coated Print Bed

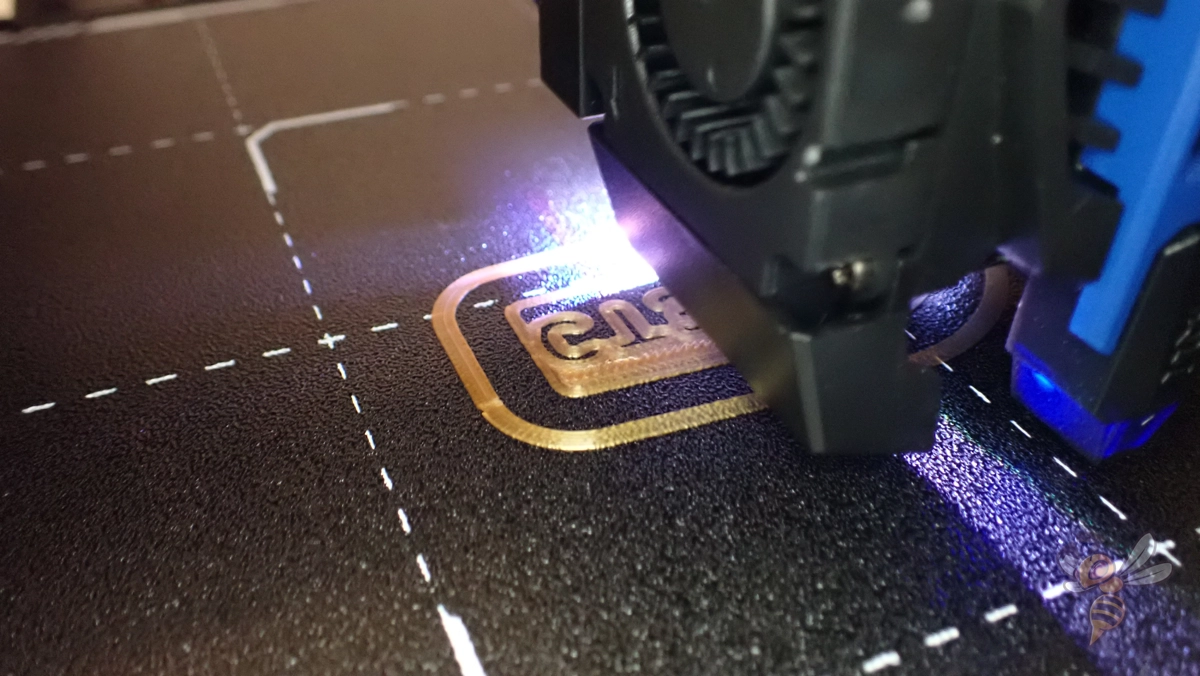

The BQ-Hurakan has a PEI-coated print bed. PEI is a material with excellent adhesive properties. It is also dimensionally stable and can be used at high temperatures.

Therefore, it is also ideal for 3D printing. Most filament types have excellent adhesion to a PEI print bed.

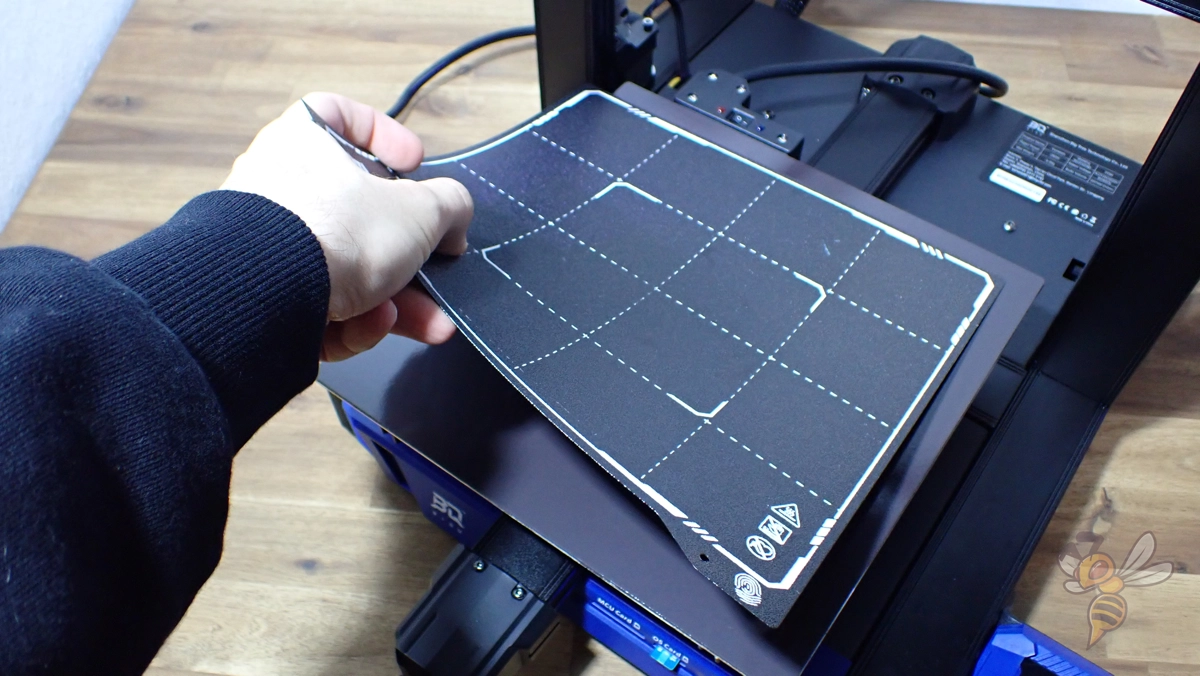

In addition, a PEI coated spring steel print bed is flexible, making it easy to remove the object from the print bed after printing. You can simply remove the magnetic print bed and bend it. The print object will then come off by itself.

Print Bed With Multiple Heating Zones

Many 3D printers on the market today have a heated print bed, which can improve the quality of the printed object by increasing print bed adhesion. However, most heated print beds are only heated in one zone, which can be a waste of energy if you are only printing a small object.

The BQ-Hurakan 3D printer is different: it is equipped with a print bed that can be heated in two zones. This means that you can heat the print bed only where it is actually needed, which can save a lot of energy when printing a small object.

The print bed of the BQ-Hurakan is divided into 16 areas. Most objects that are printed are so small that they fit into the middle four areas, so only these areas need to be heated. This saves energy and makes the BQ-Hurakan more environmentally friendly.

Self-Developed Manta Main Board

The BIQU Manta is a powerful and versatile motherboard that is perfect for the BQ-Hurakan 3D printer. The board was developed by BIQU itself and offers support for Klipper, various sensors and other functions.

One of the best features of the Manta is its HDMI display output. This allows you to connect an HDMI display to the board and easily keep an eye on the print progress. So if you’re not a fan of browser control and prefer to work on the printer via a screen, this upgrade would be right up your alley.

Very Quiet

The motherboard of the BQ-Hurakan is equipped with TMC2209 stepper motor drivers. These drivers are known to be very quiet, and BIQU states that the noise level is below 50 dB when printing.

In my test, I found that the average noise level was 42 dB, with peaks of around 48 dB. So, the noise level is really quiet and hardly bothers you if you are in the same room as the printer. I’m very impressed with how quiet this printer is, and that’s a big plus for me.

LEDs in the Print Head

LEDs are built into the print head of the BQ-Hurakan. This allows the object to be illuminated during printing. This is especially handy if you want to monitor the print with a camera in the browser interface. Then you don’t need to leave the room light on during printing.

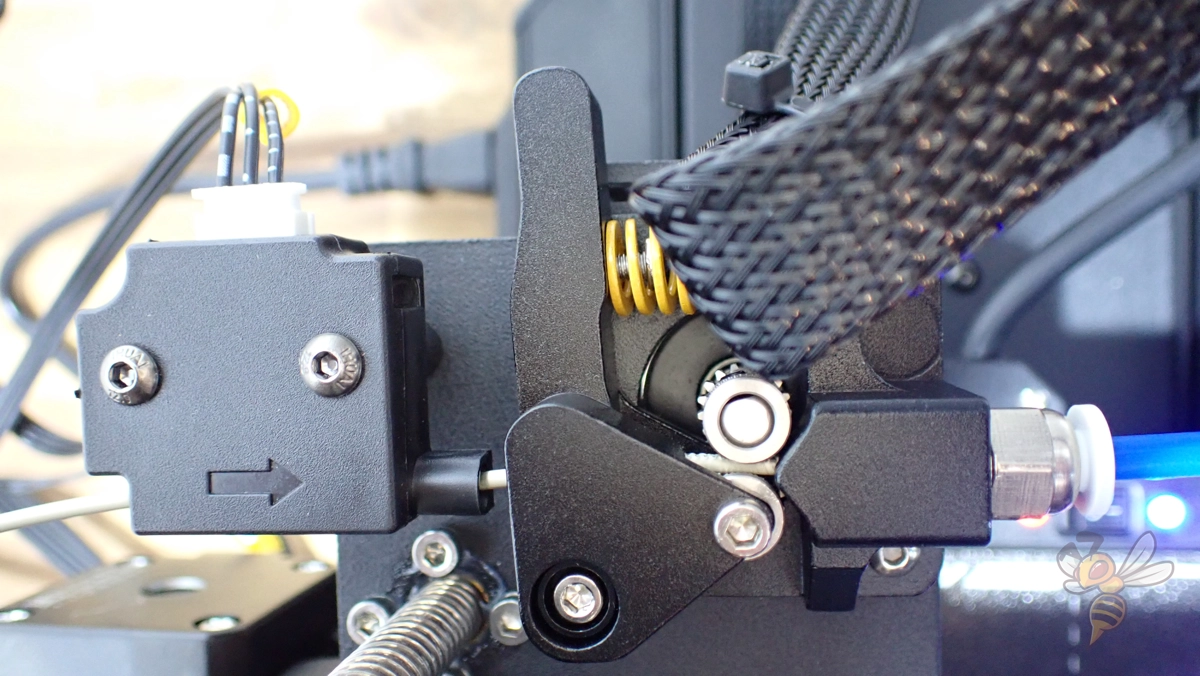

Filament Sensor

The filament sensor in the BQ-Hurakan detects when there is no filament left in the spool and pauses the print job, so you can reload the printer with fresh filament. Printing will also be paused if the filament is broken.

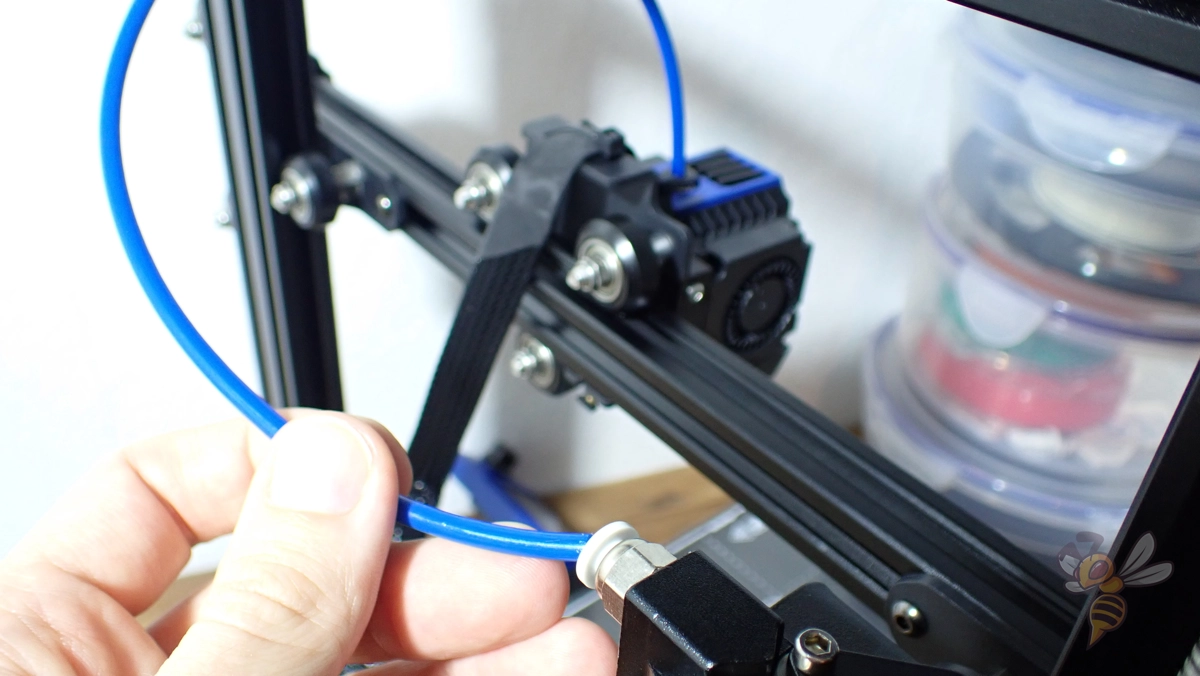

Placed is the sensor directly in front of the extruder. So, you have to thread the filament through the filament sensor to the extruder when loading the filament.

Many Connection Options

The BQ-Hurakan has many connectivity options. It has 2 x USB 2.0, MicroSD card, SD card, LAN and an SPI interface option.

The SPI interface is a bus system that allows different hardware components to communicate with each other.In the BQ-Hurakan, the accelerometer can be connected here.

Many users also find it very convenient that they can use a normal SD card. MicroSD cards are too small and difficult to handle for many users.

But theoretically, you don’t need a storage medium to transfer print files to the BQ-Hurakan. You can easily upload the files via the web interface.

Belt Tensioner

With the belt tensioners on the X and Y axis, you don’t have to half disassemble the printer to tension the respective belts. While this feature is now available on just about every new 3D printer that comes on the market, if you still know the “old DIY printers”, this feature is always welcome!

Many Upgrades

The BQ-Hurakan is designed to be easily upgradable. BIQU has already developed a few upgrades for it: the H2 Series Extruder, a camera for print monitoring and a large HDMI display.

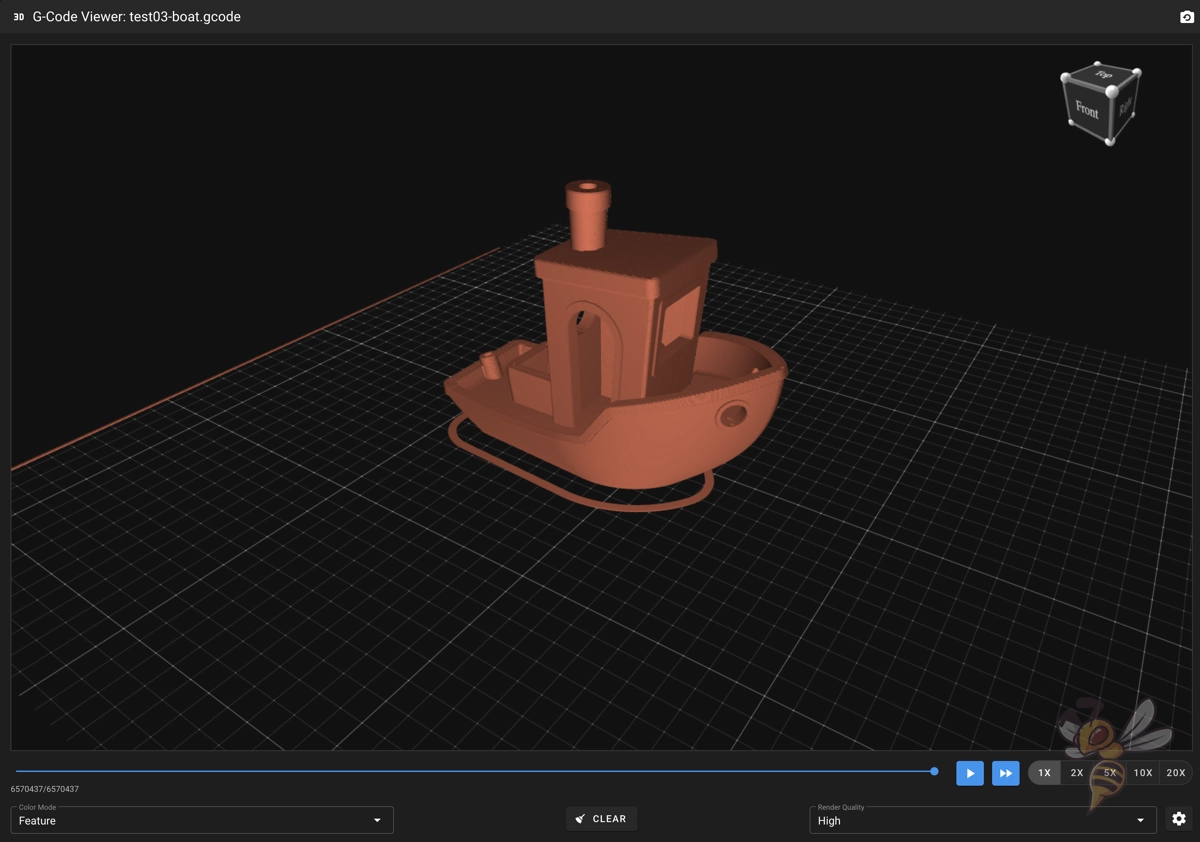

Print Quality – Practical Test

The print quality of the BQ-Hurakan is 0.1 mm. Due to the Klipper firmware and the acceleration sensor, many printing errors are avoided, which further increases the print quality.

To convince myself of the good print quality, I started with the calibration of the accelerometer. After that, I used a few calibration objects to optimize the settings in Cura. Finally, I calibrated the accelerometer via Klipper.

After calibration, I tested the print quality on complicated geometries and am very pleased. The bust in particular turned out flawless and shows how the accelerometer compensates for vibration. There is no sign of ringing or other printing errors due to vibrations of the print head.

You can find the most important Cura settings for the BQ-Hurakan in this article: BQ-Hurakan | Cura Settings & Profile – Guide & List

BQ-Hurakan vs. Ender 3 V2 Neo

Check Price at:

The main difference between the BQ-Hurakan and the Ender 3 V2 Neo is that it runs the Klipper firmware by default. The Ender 3 V2 Neo has to be combined with the Creality Sonic Pad for this.

Otherwise, the two 3D printers differ only slightly. The design of the BQ-Hurakan is better in my eyes and it also has a print bed that can be divided into heating zones to save power on small objects.

| BQ-Hurakan | Ender 3 V2 Neo | |

|---|---|---|

| Klipper integration? | Yes | Yes, with the Sonic Pad from Creality |

| Print volume | 220 × 220 × 270 mm | 220 × 220 × 250 mm |

| Max. hotend temperature | 260 °C | 260 °C |

| Max. print bed temperature | 100 °C | 100 °C |

| Print bed heating zones | 2 | 1 |

| Extruder | Bowden | Bowden |

| Display | Monochrome, rotary knob, text only | 4.3-inch color screen with rotary knob |

| Driven Z-axes | 1 | 1 |

| Print bed | PEI-coated spring steel | PC-coated spring steel |

| Levelling | MicroProbe, automatic | CR-Touch, automatic |

| Filament sensor | Yes | No |

| Resume print | Yes | Yes |

| belt tensioner | Yes | Yes |

| Tool drawer | No | yes |

| Release | 2022 | 2022 |

BQ-Hurakan vs. Sovol SV06

Check Price at:

The BQ-Hurakan differs from the Sovol SV06 mainly in that it has Klipper as firmware and a print bed with two heating zones. The advantages of the SV06 is the direct drive extruder and the double Z-axis.

If you would rather not print with flexible filaments regularly, I would therefore advise you to use the BQ-Hurakan, as it can print faster and with a better quality due to Kipper.

| BQ-Hurakan | Sovol SV06 | |

|---|---|---|

| Klipper integration? | Yes | No |

| Print volume | 220 × 220 × 270 mm | 220 × 220 × 250 mm |

| Max. hotend temperature | 260 °C | 260 °C |

| Max. print bed temperature | 100 °C | 100 °C |

| Print bed heating zones | 2 | 1 |

| Extruder | Bowden | Direct Drive |

| Display | Monochrome, rotary knob, text only | Monochrome, rotary knob, text only |

| Driven Z-axes | 1 | 2 |

| Print bed | PEI-coated spring steel | PEI-coated spring steel |

| Levelling | MicroProbe, automatic | Induction sensor, automatic |

| Filament sensor | Yes | No |

| Resume print | Yes | Yes |

| Belt tensioner | Yes | Yes |

| Tool drawer | No | No |

| Release | 2022 | 2022 |

Is the BQ-Hurakan Worth It?

The BQ-Hurakan* absolutely convinced me in my practical test. The combination of Klipper and accelerometer is always a big plus. Especially with entry-level 3D printers, models with this feature stand out strongly from the competition.

Anyone looking for a reliable 3D printer with excellent print quality is well advised with the BQ-Hurakan. Only for flexible filament it is not so well suited, but for that BIQU also has a suitable direct driver extruder upgrade ready!

Check Price at:

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.