- Is a Wash & Cure Station Worth It? Creality UW-03 Review - April 29, 2024

- Z Seam | How to Hide & Avoid | Cura & PrusaSlicer - April 20, 2024

- Qidi Tech Q1 Pro – Best Orca Slicer Settings & Profile - April 9, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

Anycubic is a very well-known manufacturer of 3D printers. But also the filaments are very popular in the 3D printing community. The Anycubic PLA filament* has been a bestseller for a long time. In this article, the filament is put through its paces.

Anycubic PLA filament has a homogeneous thickness with a tolerance of ± 0.02 mm and a temperature range of 190-230 °C. It produces excellent print bed adhesion, is very neatly wound and vacuum packed. The filament is worthwhile for both beginners and experts.

In addition to the properties of the filament, this article also tests the processability and performance in printing. You will also learn how to calibrate the 3D printer for each new filament.

Check Price at:

Table of Contents:

Technical Data

- Temperature range: 190 – 230 °C

- Print bed temperature: 50 – 80 °C

- Filament accuracy: 1.75 mm ± 0.02 mm

- Packing: Vacuum packed, neat winding, tangle free

- Weight: 1 kg filament + 0.35 kg spool

- Spool dimensions: Height = 60 mm; inner diameter = 75 mm; outer diameter = 200 mm

Winding

With poor quality filaments, not only is the material inadequate, but the winding on the spool is also chaotic. If the filament is not wound properly, it can become tangled as it unwinds through the 3D printer. Then the extruder tries to load more filament but pulls on the filament to no avail and the print fails.

This printing error is always very annoying, which is why it is worth investing in high-quality filament for this reason alone. In the case of Anycubic PLA filament, every single winding was perfectly wound on the spool. You can clearly see that the manufacturer has the winding under control.

Thickness

The thickness of the filament must be consistent so that the same amount of filament is always extruded. If the thickness of the filament is not uniform, the line width will vary depending on whether a thicker piece of filament has just been extruded or a thinner piece of filament.

So to ensure consistent quality across the entire object, the thickness of the filament must only move within a specific and very small tolerance. Anycubic specifies a tolerance of ± 0.02 mm for this.

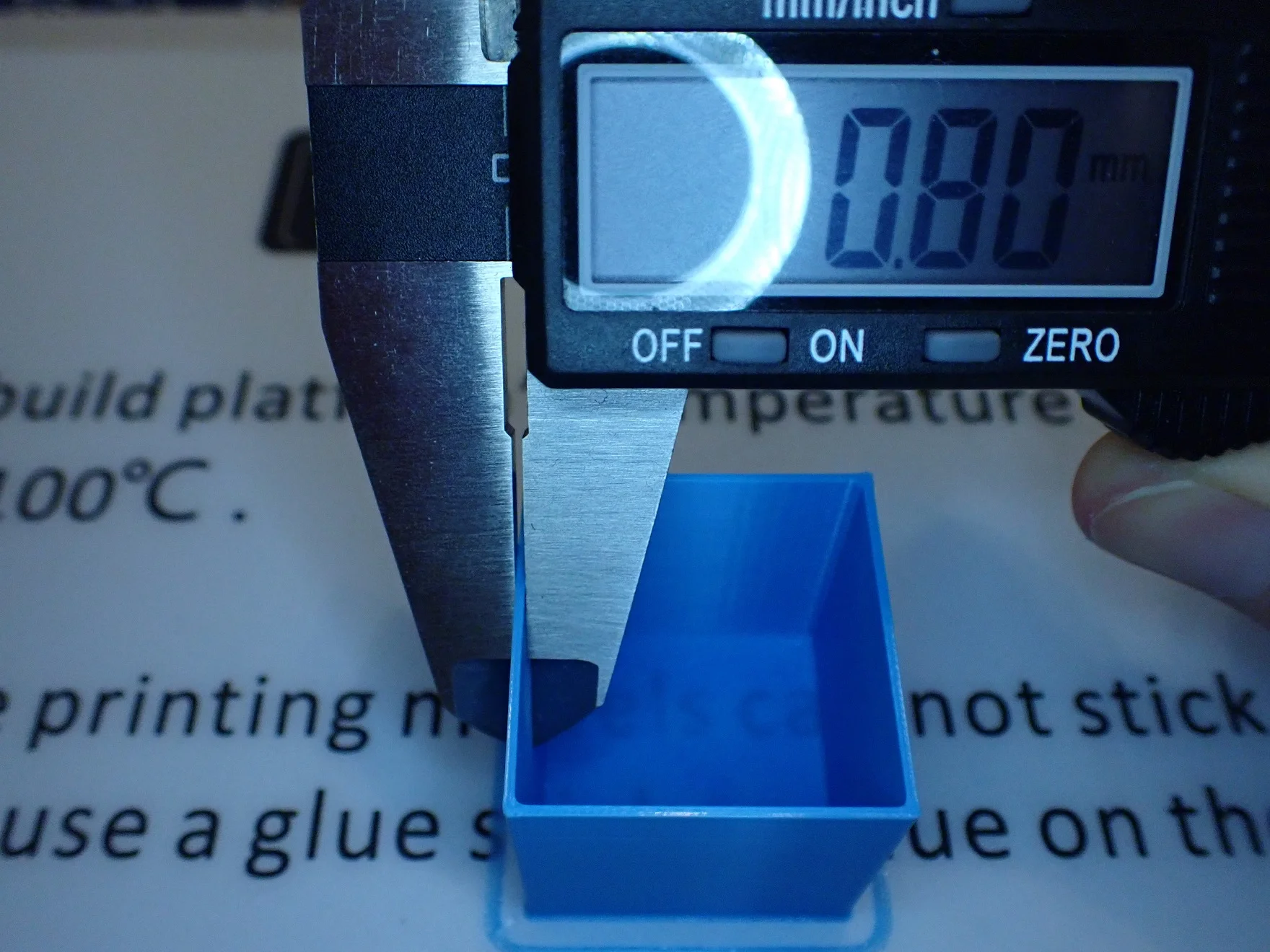

I measured the filament over several windings with a caliper gauge and came up with a maximum deviation of 0.01 mm. This is extremely good, lies within the measurement uncertainty and should ensure consistent print quality – at least as far as extrusion is concerned.

Calibration

Whenever you change basic things on your 3D printing system (like the nozzle, the filament, or even the 3D printer) you should calibrate the new combination to get good results.

With the PLA filament from Anycubic, I didn’t need much calibration effort to find the perfect settings. The high quality of the filament forgives many mistakes!

Even though there are dozens of settings in the slicer with which you can optimize the result of the 3D print, these three settings in particular are important:

- Flow rate

- Printing Temperature

- Retraction

There are countless calibration objects for these three important 3D printing parameters. You can find them on portals like Thingiverse or in plugins of popular slicers. I like to use the “Calibration Shapes” plugin in Cura. With this plugin, you can load and adjust calibration objects directly in Cura.

The best strategy for calibrating a 3D printer is to start from an existing default profile in the slicer. You then try to approach the perfect setting in small steps, changing only one setting at a time so that you know which change is responsible for the result.

Here you can find the best Cura profiles of popular 3D printers:

- Best Cura Settings for the Ender 3 S1 – Guide & List

- Best Cura Settings for the Ender 3 – Guide & List

- Best Ender 6 Cura Profile | Best Settings

- Ender 5 (Plus/Pro) Cura Profile | The Best Settings

- The Best Cura Settings for the Anycubic Mega S

Flow Rate

If the flow rate is not calibrated correctly, too much or too little filament will be extruded and the line width will not correspond in reality to what you have entered in the slicer.

To calibrate the flow rate, you need to print a hollow cube, without infill, without top layers and with two walls. After printing the cube, you can measure the wall thickness and check the flow rate.

Example:

- Number of walls = 2

- Line width = 0.4 mm

- Target wall thickness = 0.8 mm

- Real wall thickness = 0.82 mm

- So the flow rate is too high by 2.5%

Formula: ((thickness-target)/(number of walls))/line width - New flow rate = 97.5%

To test the new flow rate you should repeat the print once and adjust the flow rate again if necessary.

Temperature

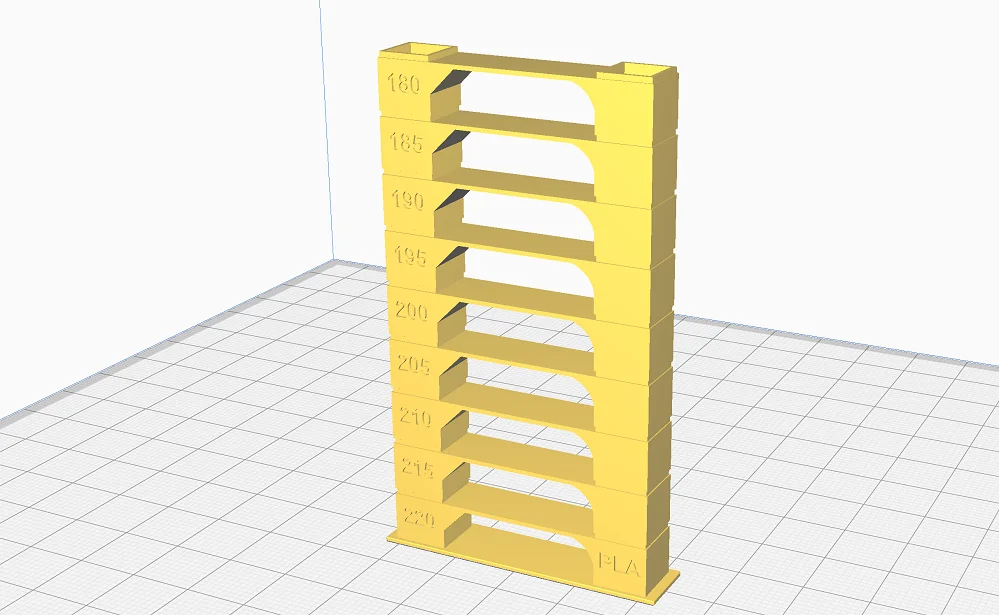

An incorrect printing temperature can lead to many printing errors. To calibrate it correctly you only need to print a single object. A so-called temperature tower is divided into several floors that are printed with different temperatures by a script in the slicer.

The geometry of the tower is designed to favor printing errors. Therefore, after printing, you will quickly see which temperature produced the fewest print errors. In the plugin “Calibration Shapes” in Cura are also suitable scripts included with which you can print the temperature tower. In this script, you can specify at which layers which temperatures should be used.

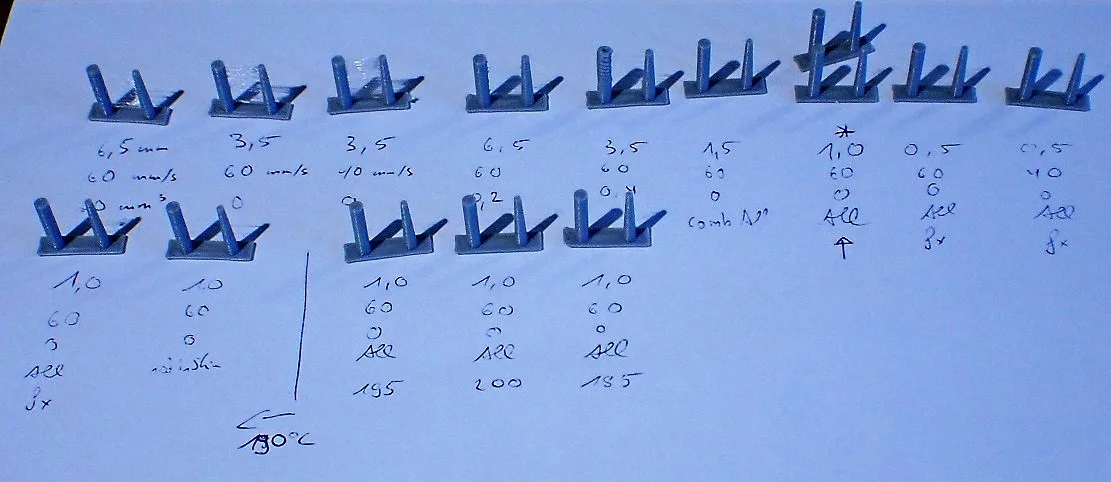

Retraction

Stringing is one of the most common problems in 3D printing. Even PLA is not spared from this. In addition to the temperature and the quality of the filament, the feed or retraction is one of the most important factors in stringing. The wrong settings can quickly lead to frustration, which is why it is so important to calibrate them.

There is no shortage of calibration objects for retraction, but my favorite also comes from the “Calibration Shapes” plugin in Cura. This small test is printed within a few minutes, allowing you to quickly test different settings one after the other.

Print Bed Adhesion

I tested the PLA filament from Anycubic on different print bed surfaces. The best print bed adhesion was on a PEI print bed*.

But also glass, blue tape and other print bed surfaces are suitable for the PLA filament from Anycubic. However, with these surfaces, I needed aids such as Magigoo to generate sufficient adhesion for very filigree first layers.

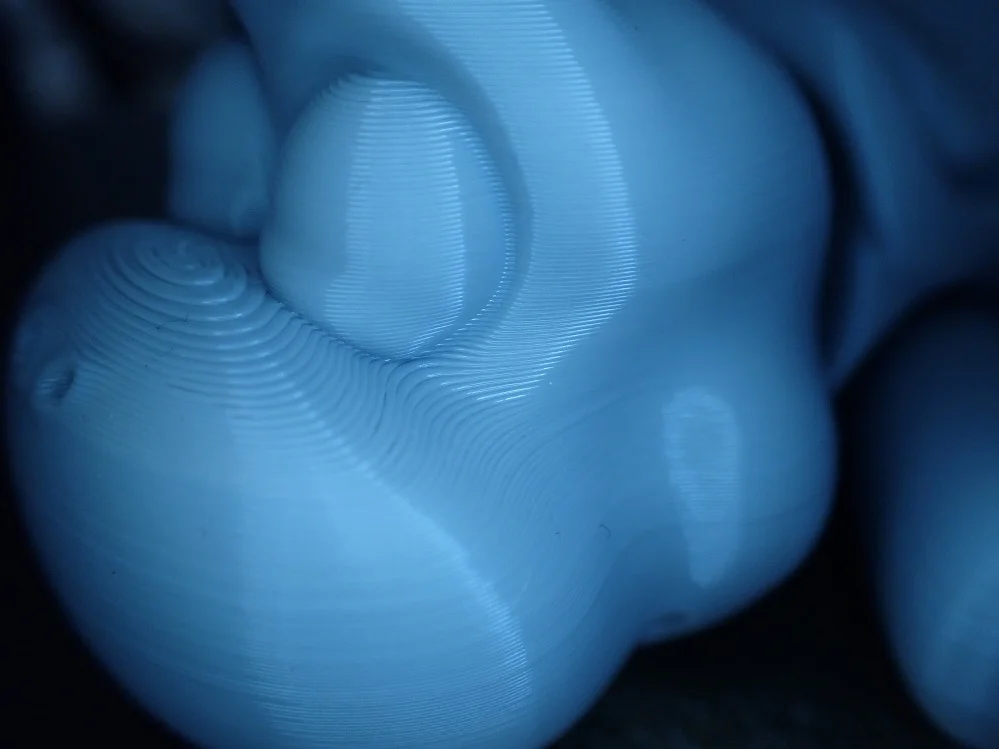

Layer Adhesion

The adhesion of the individual layers to each other is important for the mechanical stability of the finished object. If the adhesion is too low, the cooled layers can separate from each other. But good adhesion to each other during printing is also important for a successful result.

With the correct settings, which I calibrated as described above, there were no problems with layer adhesion with the Anycubic PLA filament.

Stringing

Stringing can also be dependent on the quality of the filament. Lower quality filament tends to string more often, as poorer quality materials and impurities may be present.

If the material is not homogeneous, stringing will occur quickly. The PLA filament from Anycubic is professionally manufactured and produced from high-quality materials. Of course, stringing can still occur with the wrong settings for the printing temperature and retraction. But with high-quality filaments, it is much easier to find the right settings.

Impurities

If a filament is made from low-quality materials with impurities, these can lead to various problems during printing. As just mentioned, this can lead to stringing. But it can also be that these impurities lead to bubbles or discoloration during extrusion.

After several hundred meters of used PLA filament from Anycubic, I have not noticed any contamination.

Results

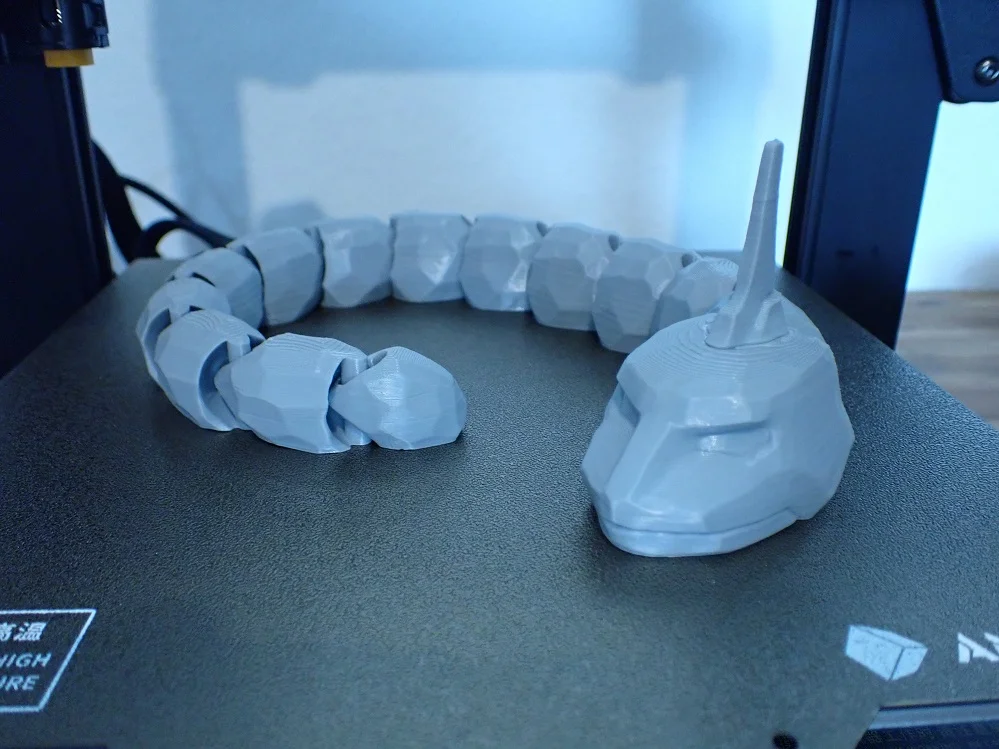

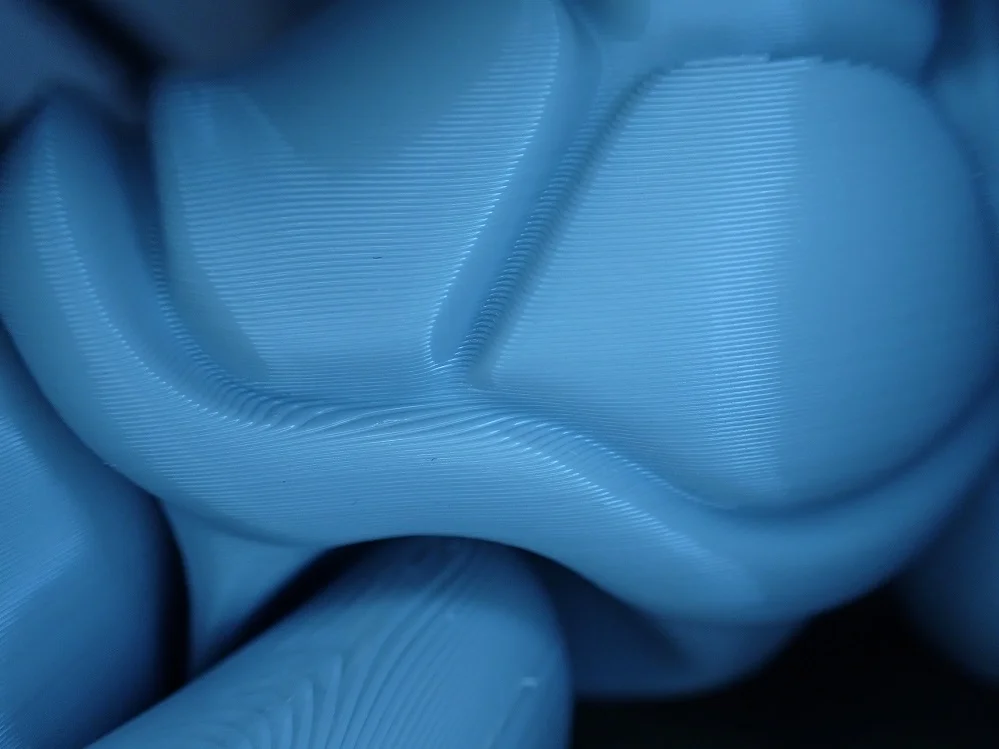

Besides various calibration objects, I also printed other models with the PLA filament from Anycubic:

All of these objects printed almost flawlessly with a little stringing here and there.

Check Price at:

Conclusion

The PLA filament from Anycubic* offers a very good price-performance ratio. I could not discover any major drawbacks in my practical test, which is why I can recommend it to everyone.

If you decide to use this filament, you should also remember to store it in a dry place. This is best done in suitable, airtight filament boxes*.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.