- Z Seam | How to Hide & Avoid | Cura & PrusaSlicer - April 20, 2024

- Qidi Tech Q1 Pro – Best Orca Slicer Settings & Profile - April 9, 2024

- Creality Ender-3 V3 Review – Will CoreXZ be the New Trend? - March 27, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

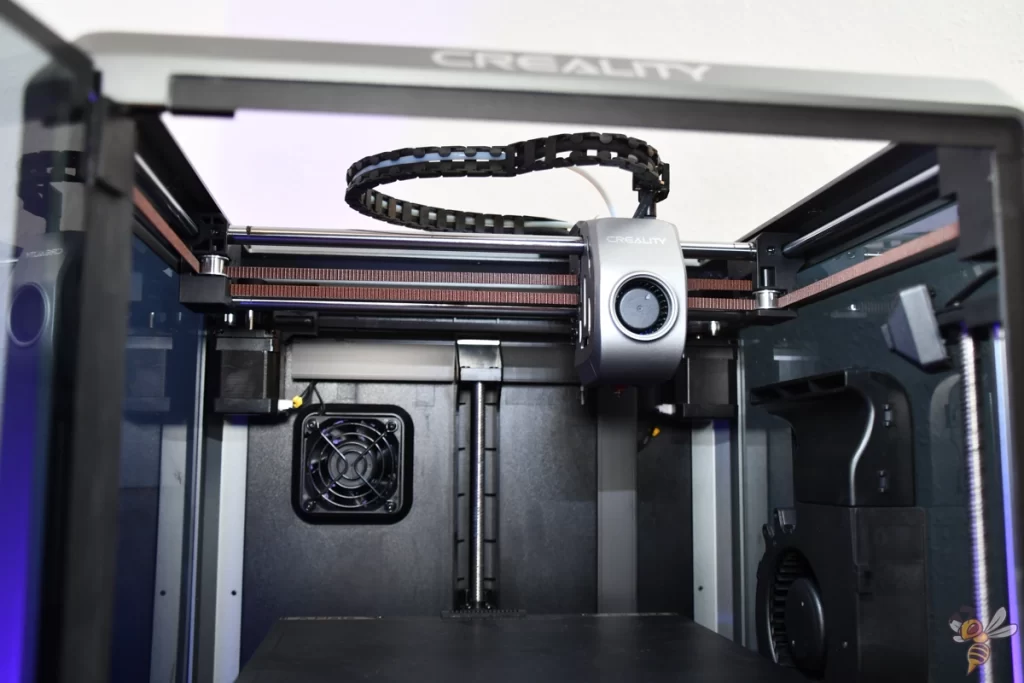

The Creality K1C* differs more from its predecessors than you would expect from its appearance. It combines their advantages with an additional specialization in abrasive filaments, such as those with carbon fibers (hence the C for carbon in the name).

I have tested the K1C and share my experiences with it in this hands-on review. After this review, you will know whether the K1C is the right 3D printer for you or not!

Review Summary

Overall, the Creality K1C sets itself apart as a top choice for 3D printing with carbon fiber filaments thanks to its optimized nozzle design and robust extrusion system. Its ability to reliably process complex materials such as PLA-CF and PETG-CF, coupled with high printing speed and precision, makes it a must-have tool for anyone looking for industrial strength and lasting quality.

These are my highlights of the Creality K1C:

Print quality

High print precision thanks to input shaping and stable construction.

Speed

Up to 600 mm/s, normal is 300 mm/s. 3DBenchy in 16 minutes!

Optimal for carbon fiber

The hardened tri-metal nozzle does not wear out from abrasive filaments.

User-friendliness

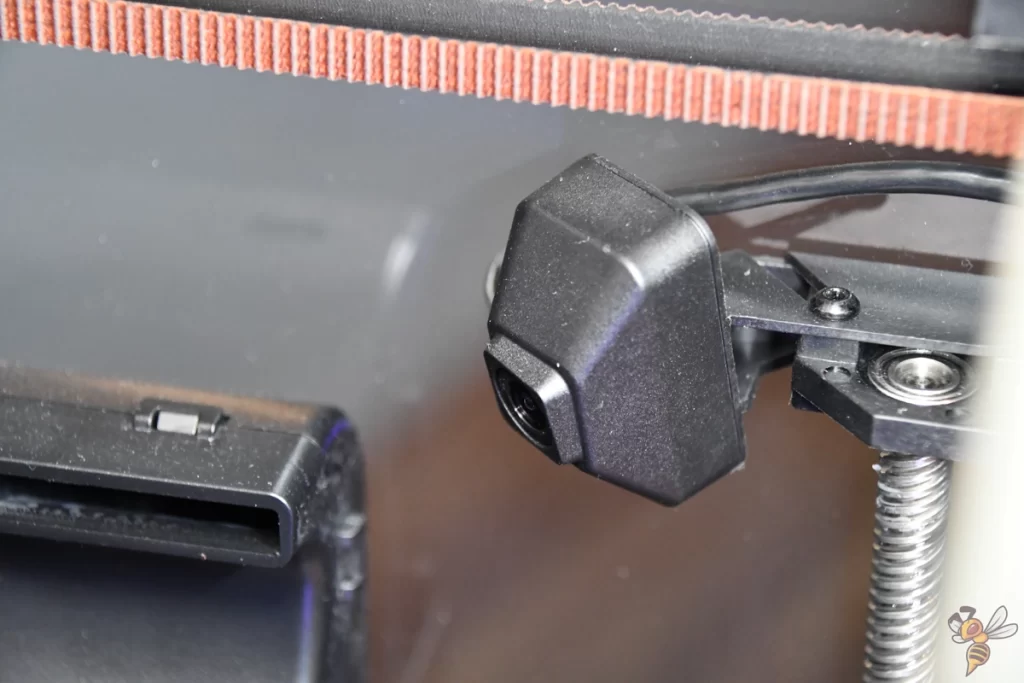

Simple operation with self-calibration, automatic print bed leveling and AI camera.

Overall Rating:

4,8/5

Advantages

✓ Perfect for carbon fiber filaments

✓ Easy assembly & operation

✓ High printing speed

✓ Excellent print quality

✓ Built-in AI camera

Disadvantages

× Relatively small print volume

× Loud at high speeds

The Creality K1C is specialized for 3D printing with carbon fiber filaments. It is also very fast and precise!

Table of Contents:

My Experience with the Creality K1C

My overall experience with the Creality K1C was very good. As someone who has tested dozens of different 3D printers, including the previous models, the K1 and K1 Max, I had a good basis for comparison.

The standout feature for me was definitely the compatibility with carbon fiber filaments. I was impressed with how well the nozzle held up without showing any signs of wear, which is very different with standard nozzles.

The print quality was another point that positively surprised me. Without much calibration effort, the K1C consistently delivered almost perfect results. This, combined with the impressive printing speed that I was already familiar with from its brothers, made the printing process efficient and reliable.

However, there were also aspects that I did not like. I would have liked a slightly larger print volume. Although the price-performance ratio is great overall, I still saw room for improvement in this area. The printer was also relatively loud. Although this was to be expected with the high print speeds, it would have been nice if there had been improvements in noise reduction. (But, there is also a low-volume print mode, which is slower at under 45 dB).

Overall, my experience with the Creality K1C was great. It combines speed, precision and impressive compatibility with challenging materials. For anyone getting into 3D printing or looking to expand their capabilities, the K1C is worth considering!

Who is the Creality K1C for?

The Creality K1C 3D printer is of interest to a wide range of users due to its advanced features and high print quality. It is particularly suitable for:

- Hobbyists and makers: those who like to experiment and realize a wide variety of projects will find the K1C a reliable 3D printer. Its compatibility with carbon fiber filaments and high print quality make it ideal for demanding hobby projects.

- Professional designers and engineers: With its precision and speed, the K1C is perfect for professionals who need prototypes or final parts with high detail and strength. The ability to use advanced materials greatly expands the range of projects that can be realized.

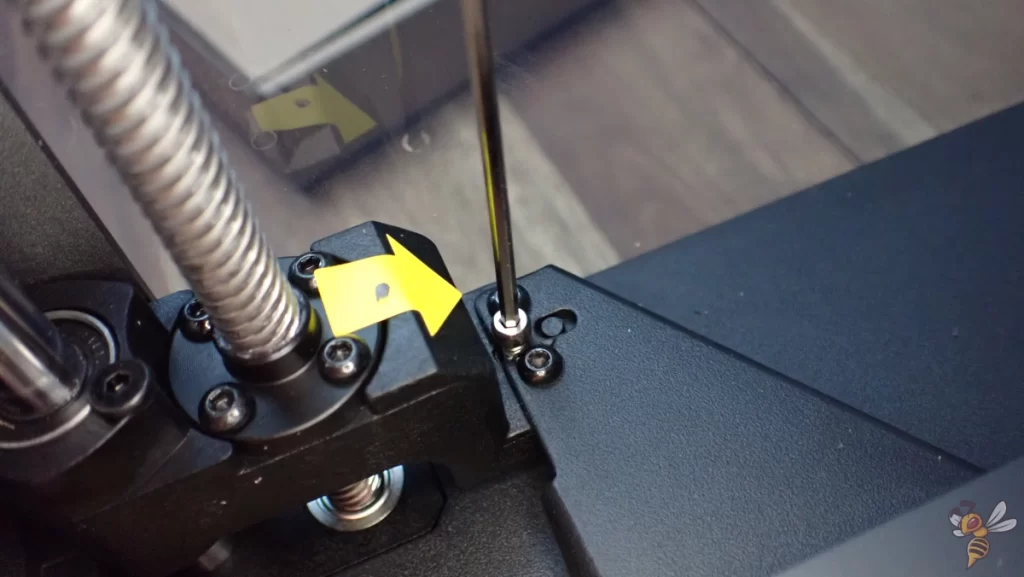

Setup

The Creality K1C arrives almost completely pre-assembled, so you hardly lose any time setting it up. You’re ready to go in less than 5 minutes: simply insert the activated carbon filter, screw on the display, fit the filament holder and remove the transport locks – that’s it.

In the past, I and many other users have criticized 3D printers that could only be loaded with filament from the back. The USB stick now not only contains the instructions, the slicer software and a few test models, but also ready-sliced print files for alternative filament holders that can be attached to the side of the device. A small but nice gesture that shows that the community’s suggestions are being taken serios!

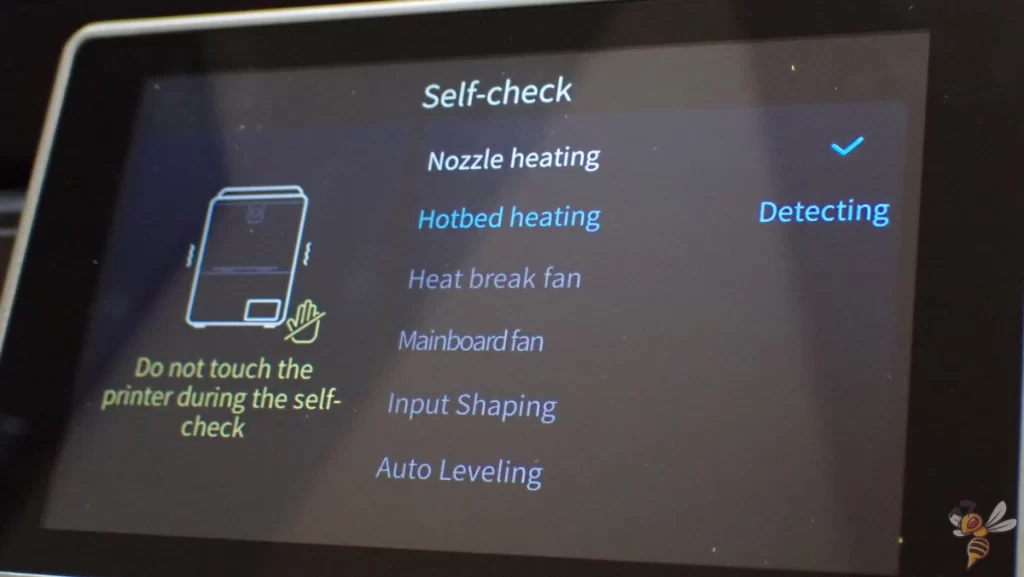

As soon as you press the power button, the K1C takes you by the hand and guides you through the self-calibration process. Input shaping, print bed leveling and more – the printer checks everything without you having to lift a finger. This is a dream come true, especially for beginners, as it takes the uncertainty and stress out of the first steps.

Filament Compatibility

The Creality K1C has broad filament compatibility, especially with carbon fiber filaments. But what makes it a true all-rounder when it comes to 3D printing materials? The answer lies in a combination of features that set it apart from many other printers.

Compatible filaments include PLA, PETG, ABS, PA, ASA, PC, TPU and especially PLA-CF, PA-CF and PET-CF.

At the heart of this compatibility is the all-metal extruder, which ensures precise and even filament feeding. In addition, the tri-metal “unicorn” nozzle combines durability with the ability to withstand high temperatures. This is particularly important when working with abrasive materials such as carbon fiber filaments, which can quickly wear out conventional nozzles.

I used an entire roll of carbon fiber filament in this practical test, and the nozzle looks exactly the same as before!

The ability to reach printing temperatures of up to 300 °C also opens the door for high-performance filaments that require high temperatures for their applications in industry and technology.

Another point that speaks for the broad material compatibility is the PEI print bed. It is known for its excellent adhesion and enables a wide range of filaments to be printed without any problems and without the models slipping or warping during the printing process. The smooth version from Creality in particular is my absolute favorite at the moment!

Finally, the closed print volume rounds off the package by creating a stable environment, which is particularly essential for temperature-sensitive materials. For example, printing objects made of ABS without warping would not be possible without a closed print volume.

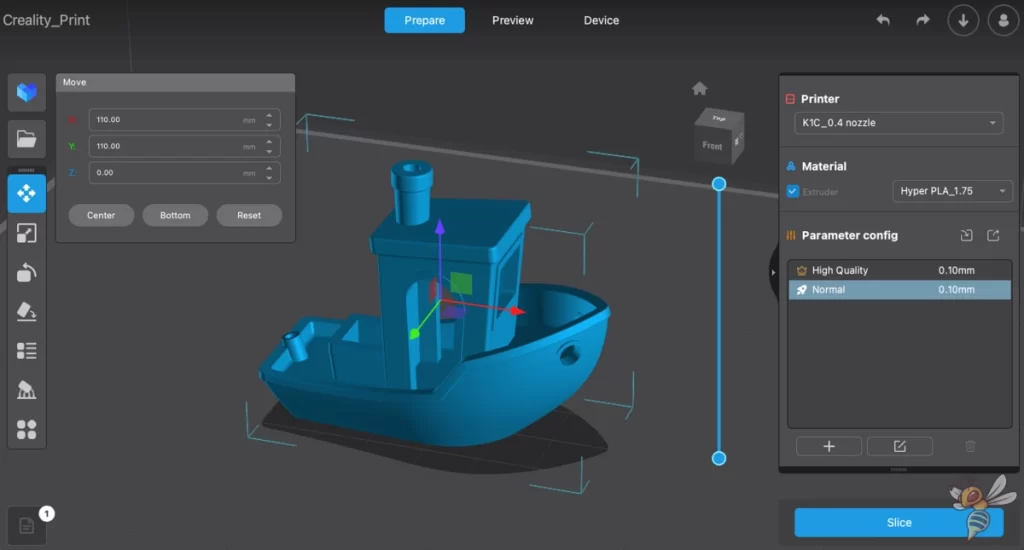

Slicer

The Creality K1C is compatible with Creality Print as well as with Cura 5.0 and later versions.

Personally, I have used the K1C not only with Creality Print and Cura, but also with PrusaSlicer and Orca Slicer. I have created specific profiles for each of these slicers and fine-tuned the settings for this 3D printer.

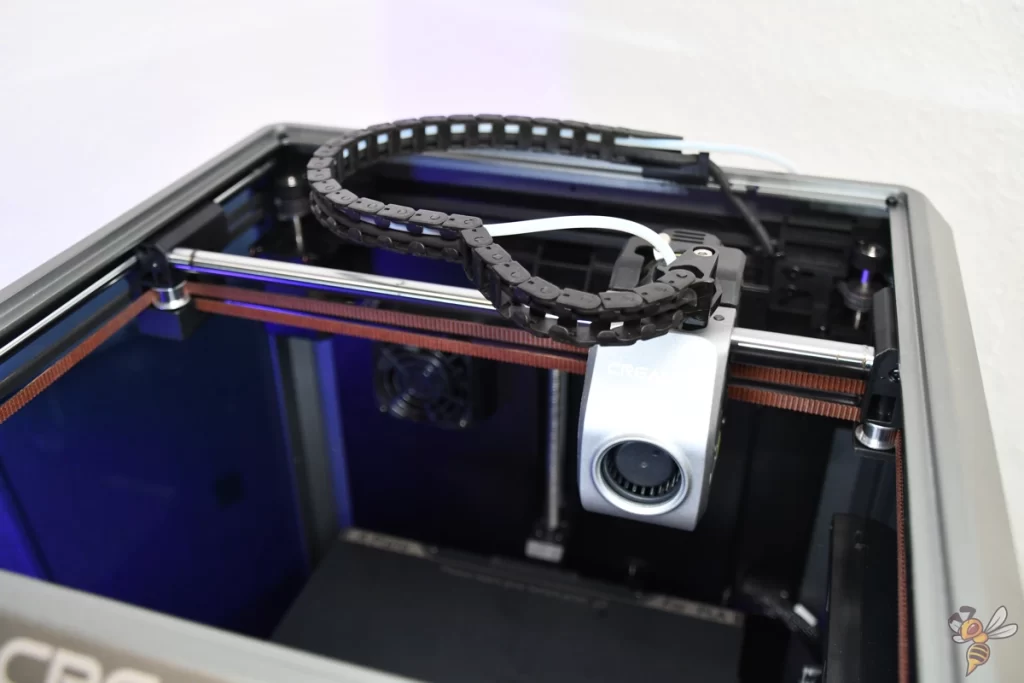

Print Speed

The Creality K1C has the same impressive maximum print speed of 600 mm/s and a standard speed of 300 mm/s as its predecessors. A 3DBenchy can be printed in just 16 minutes with almost perfect quality.

This speed is made possible by features such as input shaping, a stable design, the CoreXY system and a high maximum acceleration of 20000 mm/s².

Input shaping is a technique used in 3D printing to compensate for printer wobble when the printer is moving fast. This allows the printer to print quickly without causing printing errors such as ringing or ghosting.

Print Quality

Since I was already familiar with the high print quality of its predecessors, it was no surprise that the K1C has an almost perfect print quality without much calibration effort.

To roughly calibrate the 3D printer, I printed a 3DBenchy and a Cali Dragon. After adjusting the printing temperature and retraction, I was able to achieve excellent print quality even with carbon fiber filament.

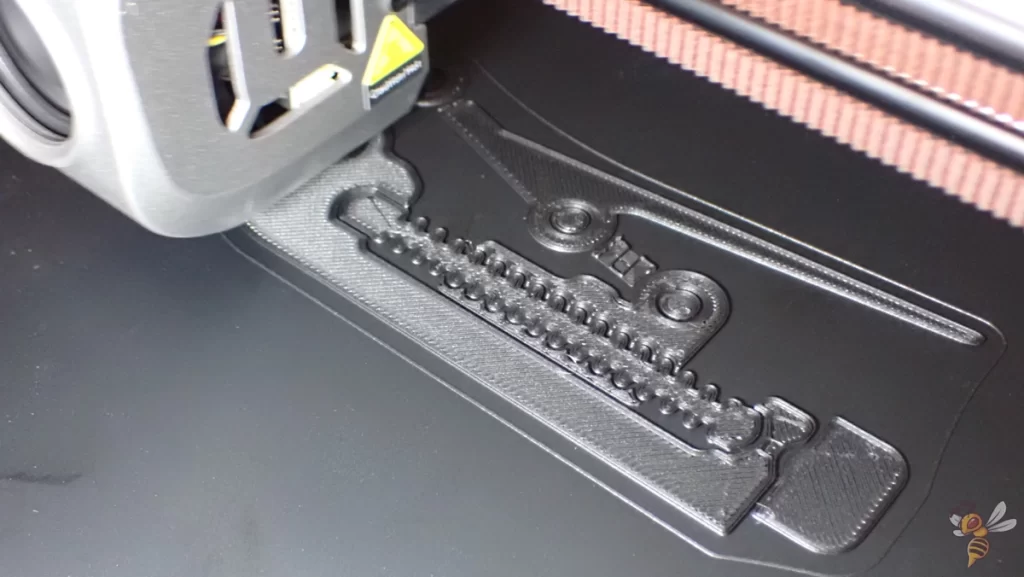

The first real object after calibration was the Print in Place Claw. My aim was to select objects that are both challenging to print and have to withstand mechanical forces. Exactly the field of application for carbon fiber filaments.

At first glance, the print quality is perfect. Only on closer inspection is there very slight stringing, but this can be easily removed with the fingers without leaving any traces.

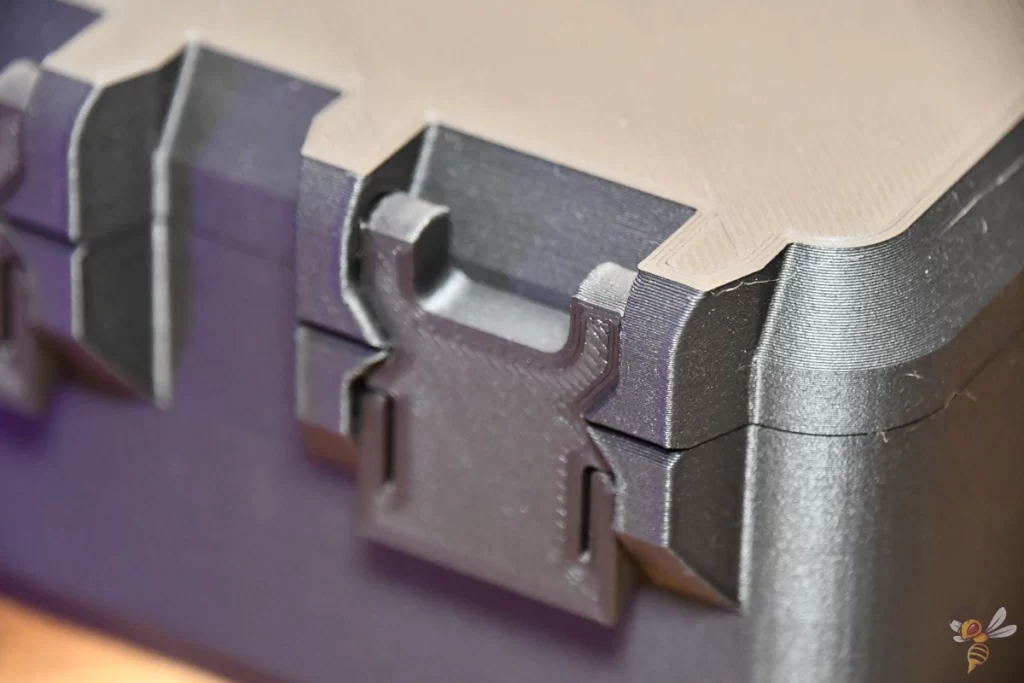

The next object was a SnapLock Storage Box. This print project consists of several parts that need to be snapped together. If the print quality and dimensional accuracy were not right, it would be difficult to join the individual parts together. However, this was not the case and the print quality is similar to a high-quality purchased product. I was particularly surprised by the smooth surface (and that without ironing!).

To print another object that has to withstand high mechanical forces, I printed the Print in Place Vise Grip. And a lot can go wrong with this design if there are printing errors or inaccurate extrusion. However, the quality is absolutely perfect and the tool works perfectly.

The next project was a print-in-place collapsible dagger. I have often printed such daggers and I know that catastrophic print failures occur as soon as the print bed adhesion gives way even slightly. The function is also very sensitive to printing errors. As soon as stringing or over-extrusion occurs, the individual segments would stick together.

However, the result was perfect and the function was given immediately after removal from the print bed. No post-processing was necessary!

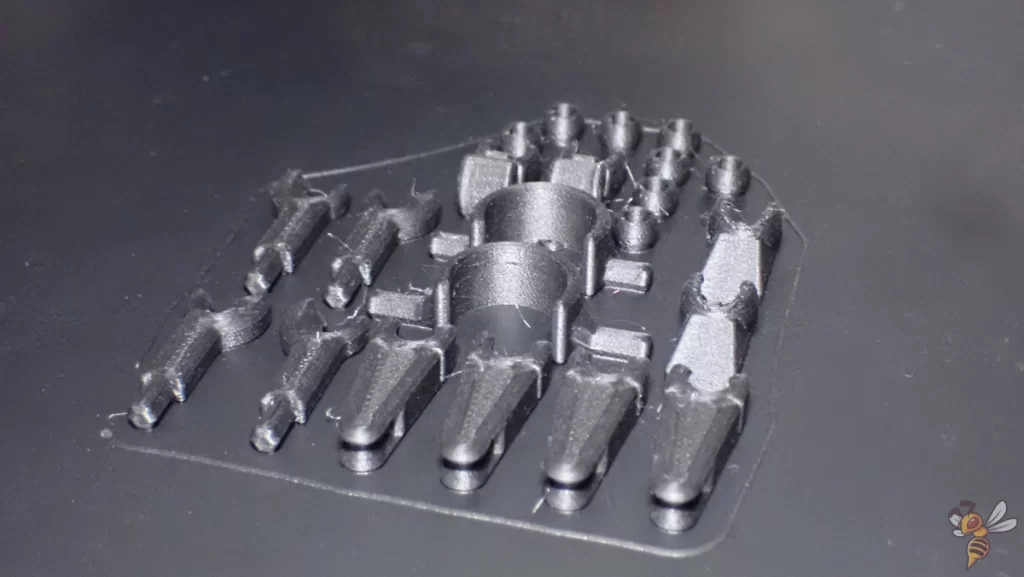

One last small project was the Battery Buddy. This was a final test for the print bed adhesion and precision of the 3D printer. This object consists of several small and very small parts. With many other 3D printers, there would have been major problems with adhesion or difficult to control printing errors such as stringing between the individual objects.

As with the other objects, however, there were no serious printing errors here, just very fine hairs between individual objects, which were easy to remove with the fingers after printing.

Ease of Use

Although the Creality K1C is a 3D printer that specializes in a specific application (carbon fiber filaments), it is very user-friendly and therefore also suitable for absolute beginners. Here are the key features that make it so user-friendly:

The fully automatic print bed leveling reduces the need for manual adjustment and ensures an even first layer.

The AI camera makes it possible to monitor the printing process and intervene immediately in the event of problems. It also supports the creation of time-lapse videos. During my test, I had a case where the AI camera correctly paused the print. I wanted to print a model that normally requires supports. Part of the object failed and a spaghetti error occurred. The camera noticed this immediately and paused the print.

But small details such as the print bed locking into place at the rear and the resume print function, which allows you to continue printing after a power failure, are also great for improving the overall experience.

FAQ – Frequently Asked Questions

The Creality K1C is absolutely suitable for beginners. Features such as automatic print bed leveling, a user-friendly interface on the touchscreen and the included instructions make it easy to get started, even for beginners.

Absolutely! The K1C is specifically designed for printing with carbon fiber filaments and other specialized materials, thanks to its all-metal extruder and tri-metal “unicorn” nozzle.

The K1C can print at impressive speeds of up to 600 mm/s maximum and 300 mm/s as standard speed. A 3DBenchy can be printed in around 16 minutes, making it one of the fastest printers on the market.

Yes, the Creality K1C can be controlled with a smartphone or tablet via the Creality Cloud app, which enables convenient remote monitoring and control.

In terms of volume, the K1C is comparatively quiet, with only around 45 dB, especially in “Silent Mode”. At high speeds, however, it can reach up to 70 dB with the enclosure open.

Thanks to its direct drive extruder, the Creality K1C can process flexible filaments such as TPU perfectly.

Conclusion – Is the Creality K1C Worth it?

In summary, the Creality K1C* offers a good blend of performance, quality and ease of use, making it an excellent choice for a wide range of users – from hobbyists to professional designers.

I was particularly impressed by the excellent processing of carbon fiber filaments and the high printing speed. The small points of criticism, such as the print volume and the noise level, hardly matter in view of the many advantages.

So if you’re looking for a reliable, fast and versatile 3D printer that can also handle challenging materials, the K1C is definitely worth the money.

The Creality K1C is specialized for 3D printing with carbon fiber filaments. It is also very fast and precise!

What do you think? Have you had any experience with the K1C or are you considering buying one? Let us know in the comments!

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.