- Wet Filament: Prevention, Symptoms & Drying - July 18, 2024

- Sovol SV08 – Best PrusaSlicer Settings & Profile - June 26, 2024

- Sovol SV08 – Best Orca Slicer Settings & Profile - June 26, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

Poor print bed adhesion is one of the main reasons for frustration in 3D printing. Many users quickly resort to normal glue sticks or even hairspray to increase the print bed adhesion. But there are also special products like the Magigoo glue stick* that creates a perfect adhesion for all standard filaments.

The Magigoo glue stick is applied like a normal glue stick and creates a perfect print bed adhesion for all standard filaments. The print object comes off almost by itself as soon as the print bed has cooled down and it can be easily removed from the print bed with a damp cloth.

Why the Magigoo glue stick is better than a normal glue stick, which types and alternatives are available and how it performs in the practical test, you will find out in this detailed review.

Table of Contents:

Key Takeaways

- Special 3D printing glue stick suitable for all standard filaments.

- The liquid adhesive spreads perfectly on the print bed (unlike normal glue sticks which often clump).

- Magigoo glue sticks are so long-lasting that one application costs only a few cents (100 to several hundred applications, depending on the print bed size).

- The print object comes off almost by itself as soon as the print bed has cooled down.

- A damp cloth with water is sufficient for cleaning.

Who Should Buy the Magigoo Glue Stick?

If you often have problems with print bed adhesion and warping, the Magigoo glue stick is ideal for you. It offers perfect print bed adhesion, prevents warping and is very easy to use. Even if the purchase price is quite high, it is so long-lasting that an application costs only a few cents.

Advantages & Disadvantages – Magigoo Glue Stick

PRO:

- Perfect print bed adhesion

- No warping

- Simple application

- Easy cleaning (damp cloth)

- Long-lasting (> 100 applications)

- In the long run cheaper than normal glue sticks

CON:

- Initial price is quite high

- Two further work steps (apply and clean print bed)

Magigoo Application

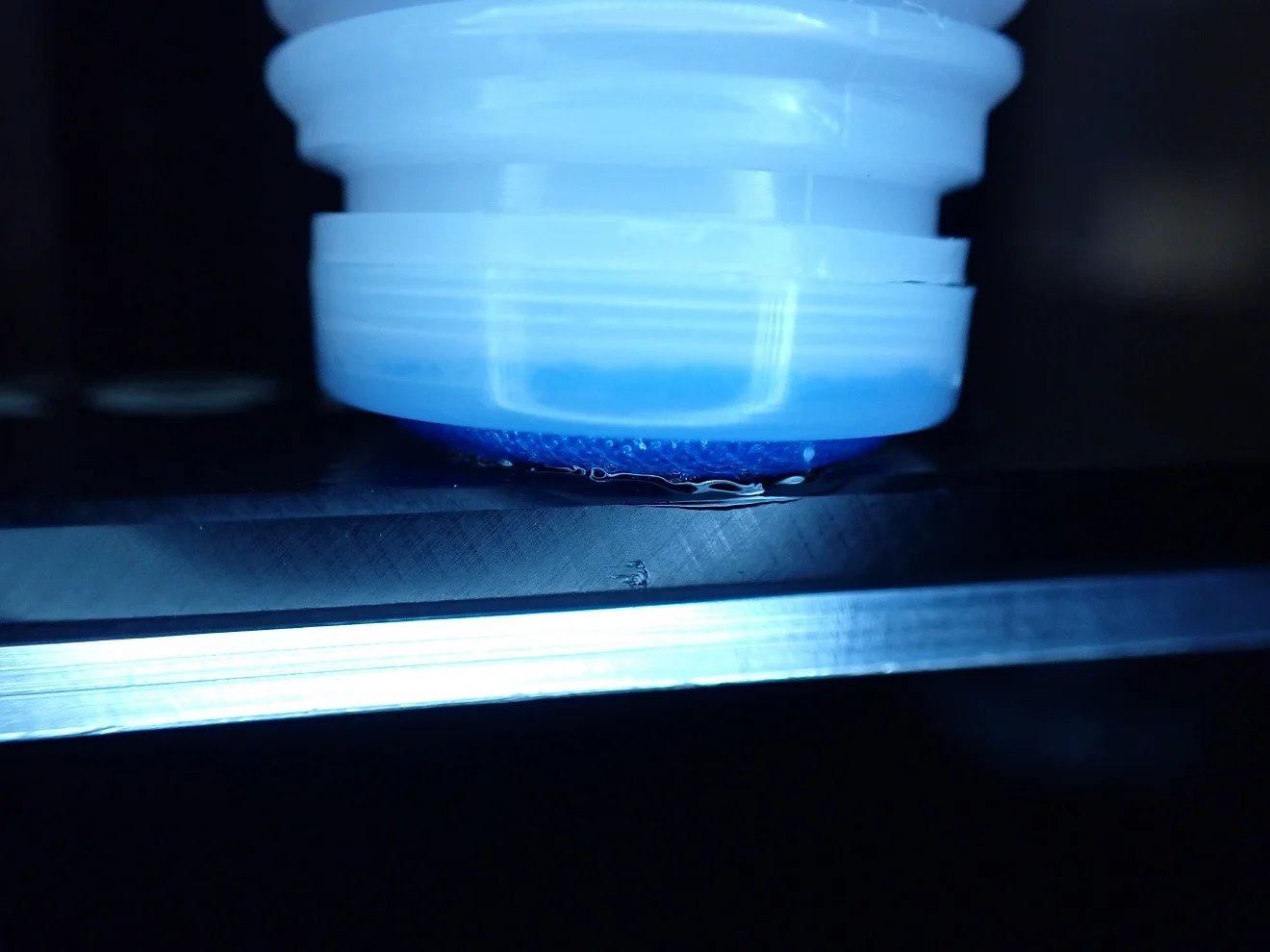

The application of the Magigoo glue stick is very comparable to other glue sticks. The big difference is that the adhesive of Magigoo is a liquid. Through the felt applicator, the liquid glue flows onto the print bed and hast to be evenly distributed.

Here are the steps of using the Magigoo glue stick:

- Shake Magigoo glue stick

- Press the end onto the print bed to make the adhesive flow

- Spread the liquid adhesive evenly on the print bed

- Remove the object after the print bed has cooled down

- (Optional) Clean print bed with a damp cloth

These steps apply to the classic Magigoo glue stick, which is suitable for PLA, ABS, PETG, TPU and HIPS*. For some more special types of Magigoo, there are extra steps. But more about that later when I go into the different types.

Magigoo can be wiped off with a damp cloth. This is a great advantage compared to other glue sticks that can only be dissolved with solvents or dishwashing liquid with hot water.

Magigoo vs. Normal Glue Stick

I tested the original Magigoo glue stick* and compared it against a normal glue stick. The focus was on the application, the print results or the print bed adhesion, the yield, the removal of the print object and the cleaning of the print bed after printing.

Application: The application of the Magigoo glue stick is similar to that of a normal glue stick. In principle, you distribute the adhesive as with a pen on the print bed. The difference with the Magigoo glue stick, however, is that the glue is liquid and is applied by pressing on the felt applicator.

Since the glue is liquid, the glue layer is much more even than with a regular glue stick. The glue from a normal glue stick is solid and can clump. The surface of the print bed is then no longer completely even, which can reduce the accuracy of the first layers.

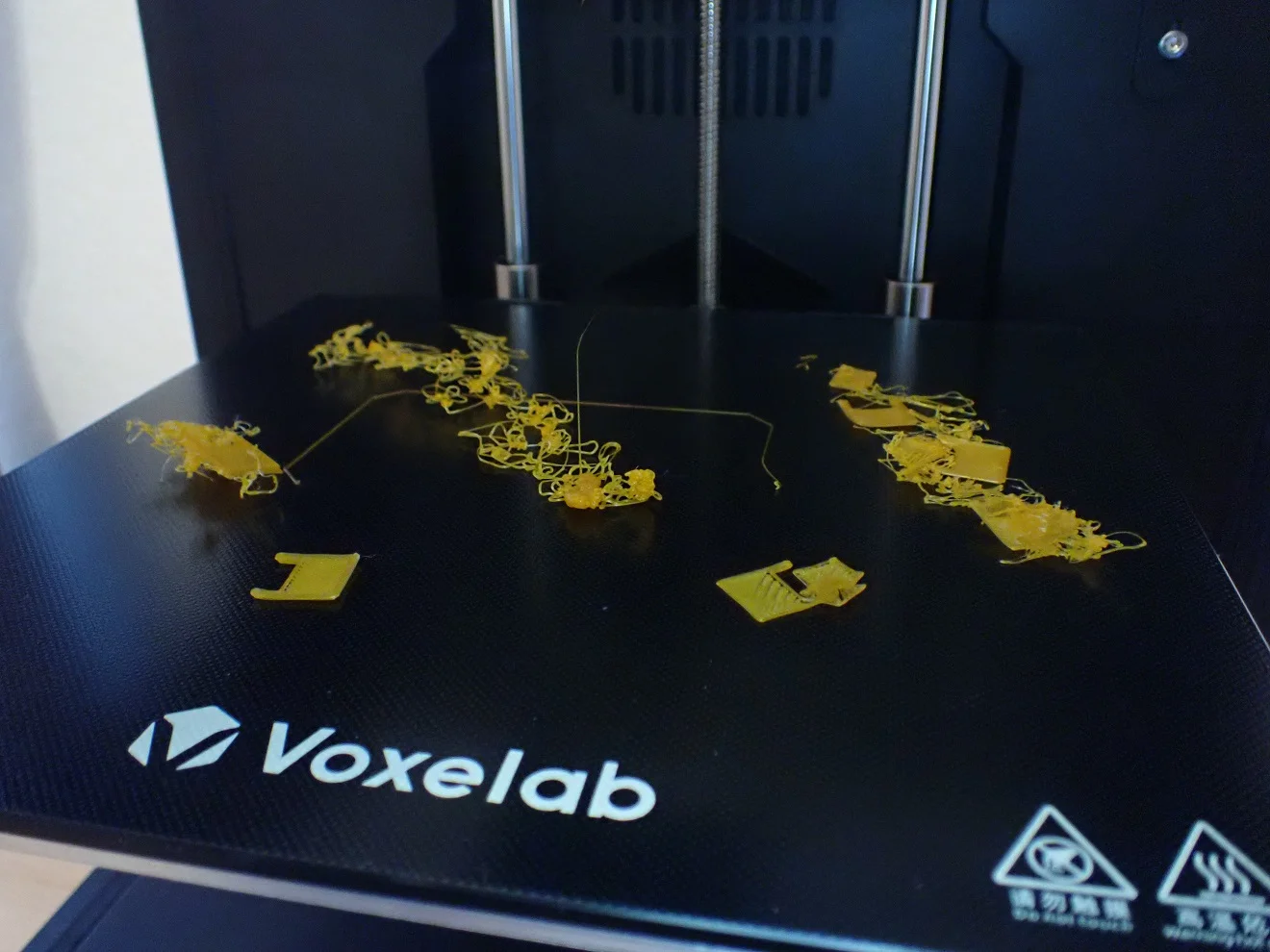

Print results / print bed adhesion: To test the improved print bed adhesion with both glue sticks, I printed filigree objects on different print bed surfaces with suboptimal settings. I adjusted the settings so that the first layer would not adhere to the print bed without glue sticks.

While I was able to significantly increase the print bed adhesion with a regular glue stick, some corners of the first layer still did not adhere properly. No matter which print surface I used, I could not create a perfect adhesion with a normal glue stick.

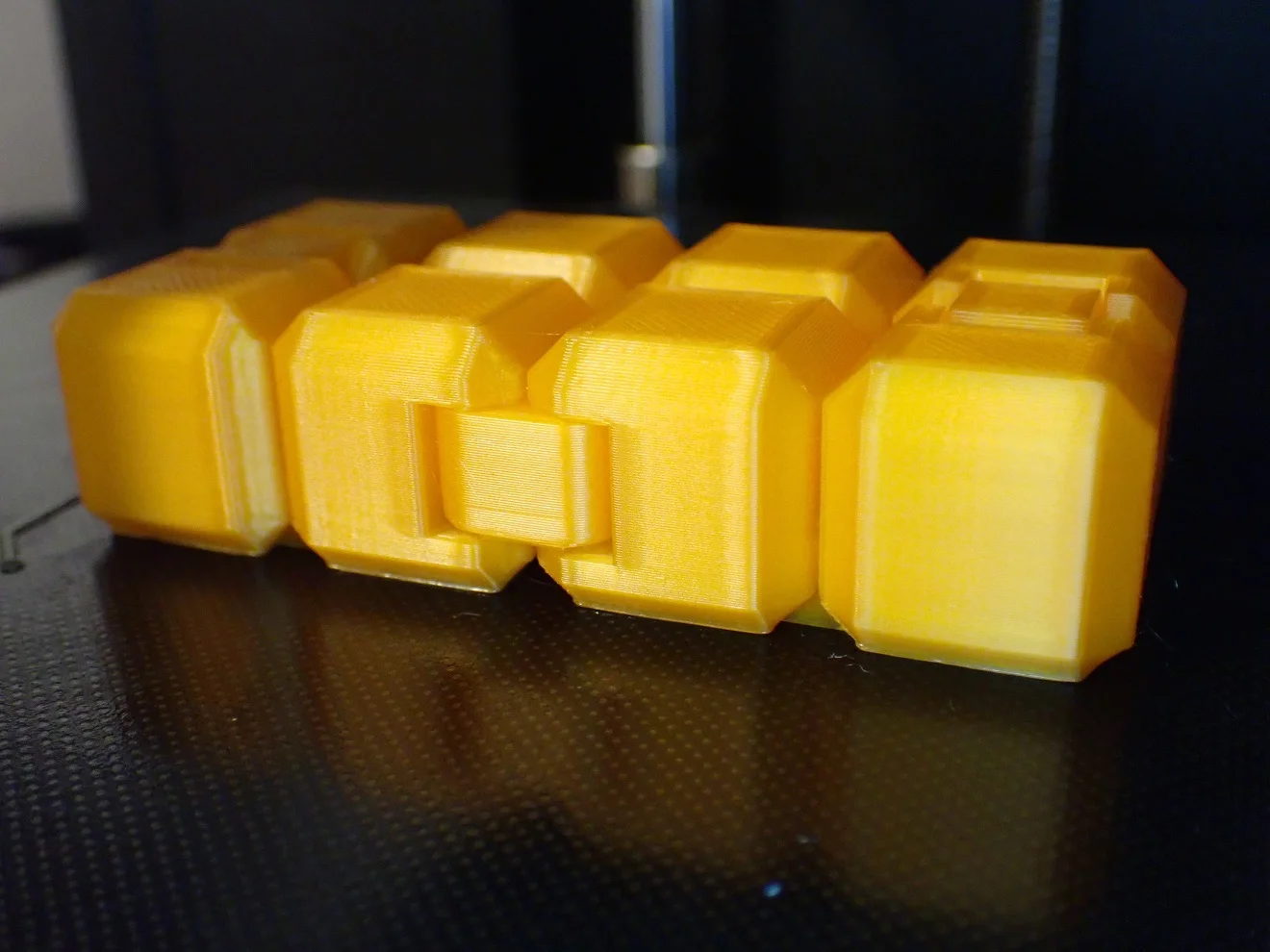

With the Magigoo glue stick, I could create a perfect print bed adhesion on every print bed surface. Even the most delicate objects adhered to the print bed without problems and with poor settings!

Yield: Depending on how big a normal glue stick is, it lasts for 10 to 30 applications. The Magigoo glue stick is significantly more expensive than a normal glue stick, but it lasts between 100 and several hundred applications, depending on the size of the print bed.

Magigoo even recommends reapplying the glue stick before each print, because one application costs only a few cents and a failed print costs more due to wasted filament and electricity costs. Switching to the Magigoo glue stick is definitely worth it (both cost-wise and because of the better performance)!

Removing the print object: Removing the print object is often quite difficult with normal glue sticks. Depending on which type you use, the object may be firmly attached to the print bed after printing. However, some types can be easily removed by hand. What all normal glue sticks have in common is that the underside of the printed object is sticky and needs to be cleaned.

With the original Magigoo glue stick, the printed object comes off almost by itself after the printing plate has cooled down. With certain types of Magigoo, you have to help a little with a spatula. The big advantage here is that the underside of the printed object is not sticky.

Print bed cleaning: The cleaning of the print bed of the Magigoo glue stick is done with a wet cloth. Normal water is sufficient! In contrast to normal glue sticks, this is a great advantage, as normal glue sticks can only be removed from the printing plate and the print object with cleaning agents and hot water.

PLA on Glass Bed With and Without Magigoo

Many hobby 3D printers like the Ender 3 V2, Voxelab Aries or Ender 2 Pro have a textured glass surface as a print bed. Glass is very suitable for most standard filaments, but offers under certain circumstances too little adhesion for filigree first layers of PLA.

Since the combination of PLA and a glass print bed is very common, I compared the print bed adhesion with and without Magigoo.

The result: even with active cooling on the first few layers, I was able to successfully increase the print bed adhesion through Magigoo to the point where I was able to print this Infinity Cube (link to object) without issue. Without Magigoo, of course, there was massive warping and a failure of adhesion and resulting misprint.

So if you have problems with print bed adhesion on a glass print bed, Magigoo is the perfect solution. I was really amazed at how strong the adhesion actually is, even though you couldn’t see that much adhesive on the glass surface.

Magigoo Types

Besides the original Magigoo glue stick which is suitable for most standard filaments, there are also special variants that are also suitable for exotic filaments. Their name “PRO” indicates that they are especially aimed at professional users who appreciate a guaranteed print bed adhesion to avoid unnecessary costs of a misprint.

Magigoo Original

Suitable for: PLA, ABS, PETG, HIPS, ASA, TPU

The original Magigoo glue stick* is suitable for all standard filaments and is perfect for the hobby area. It is easy to apply, guarantees a perfect adhesion to the print bed and prevents warping or a complete detachment of the print object.

It lasts for at least 100 applications and is therefore cheaper in the long run than a normal glue stick. The special adhesive releases the print object directly as soon as the print bed has cooled down.

There are no stubborn residues on the print bed or the print object. The print bed can be easily cleaned afterward with a damp cloth with normal clear water.

Magigoo PRO PC

Suitable for: PC filaments* (polycarbonates)

This variant of the Magigoo glue stick has been specially developed for PC filaments. PC has such different properties that the original Magigoo glue stick does not deliver the best performance.

Otherwise, the application is exactly the same as the original Magigoo glue stick. Also, the cleaning is the same, a wet cloth is enough to remove the glue from the print bed.

Magigoo PRO PA (Nylon)

Suitable for: PA filaments* (polyamide or nylon)

The Magigoo PRO PA glue stick was developed for nylon filaments and guarantees a warp-free print bed adhesion for all nylon filament types. As with the original Magigoo glue stick, the PA glue stick also has the magic release after the print bed has cooled down.

Magigoo PRO PP

Suitable for: PP filaments* (polypropylene)

PP or polypropylene is a very popular plastic in the industry. It is stable, durable and relatively cheap. Since it is difficult to print and cannot be processed by cheap 3D printers, it is all the more important not to produce misprints.

The Magigoo PRO PP glue stick was developed for this type of filaments and offers a perfect print bed adhesion for these filaments. Despite the specialization on this exotic filament, the Magic pro PP glue stick also has the property that it can be washed off with normal water and releases the print object effortlessly on a cool print bed.

Magigoo PRO Flex

Suitable for: Flexible filaments

Although you can also print TPU with the original Magigoo glue stick, for specialized flexible filaments like TPR or other TPE variants, the Magigoo PRO FLEX helps better in creating a good print bed adhesion.

It is applied in the same way as the other glue sticks from Magigoo, but differs in the release of the object after printing.

To best remove the printed flexible filament from the printing plate without causing damage, you need to soak the entire printing plate in water for about 30 minutes to 2 hours. After that, the printed object should be very easy to remove.

Magigoo PRO HT

Suitable for: High-temperature filaments like PEEK

The original Magigoo glue stick has only a certain temperature range. In order to allow print bed temperatures of up to 150 °C, the Magigoo PRO HT was developed. This makes it ideal for filaments such as PEEK.

The application and release of the object after printing are identical to the original Magigoo glue stick. Simple water is sufficient to clean the printing plate.

Magigoo PRO PPGF

Suitable for: Glass Filled Polypropylene Filaments (PPGF)

This Magigoo glue stick variant was developed for glass-filled polypropylene filaments. It is similar to the Magigoo PRO PP glue stick, but differs in the print object removal after printing.

Since the adhesive effect of this glue stick is extremely high, the print bed must be heated to over 80 °C to be able to remove the print object from the print bed. The print bed adhesion is usually so strong with this variant that you have to use a spatula to remove the print object from the printing plate.

Magigoo PRO Metal

Suitable for: Metal Filament BASF Ultrafuse® 316L

The Magigoo Pro Metal is specially designed for the BASF Ultrafuse® 316L filament. To print this metal filament it needs a very high print bed adhesion to avoid warping.

The print bed adhesion created by the glue stick is so strong that you cannot simply detach the printed object from the print bed. Just as with the glue stick variant for flexible filaments, you have to put the printing plate in water for 30 minutes up to 2 hours to be able to detach the printed object.

Magigoo Large Format (120 ml)

Suitable for: PLA, ABS, PETG, HIPS, ASA, TPU

The original Magigoo glue stick is also available in an XXL version with a spreader roller. As you can imagine, the application is much more efficient and faster. In addition, the large supply of glue is enough for hundreds of applications.

The main advantage of this variant is the fast application of the adhesive, which is especially interesting for professional users. If you want to treat numerous printing beds with the adhesive, the application with a spreader roller is much faster than with a glue stick.

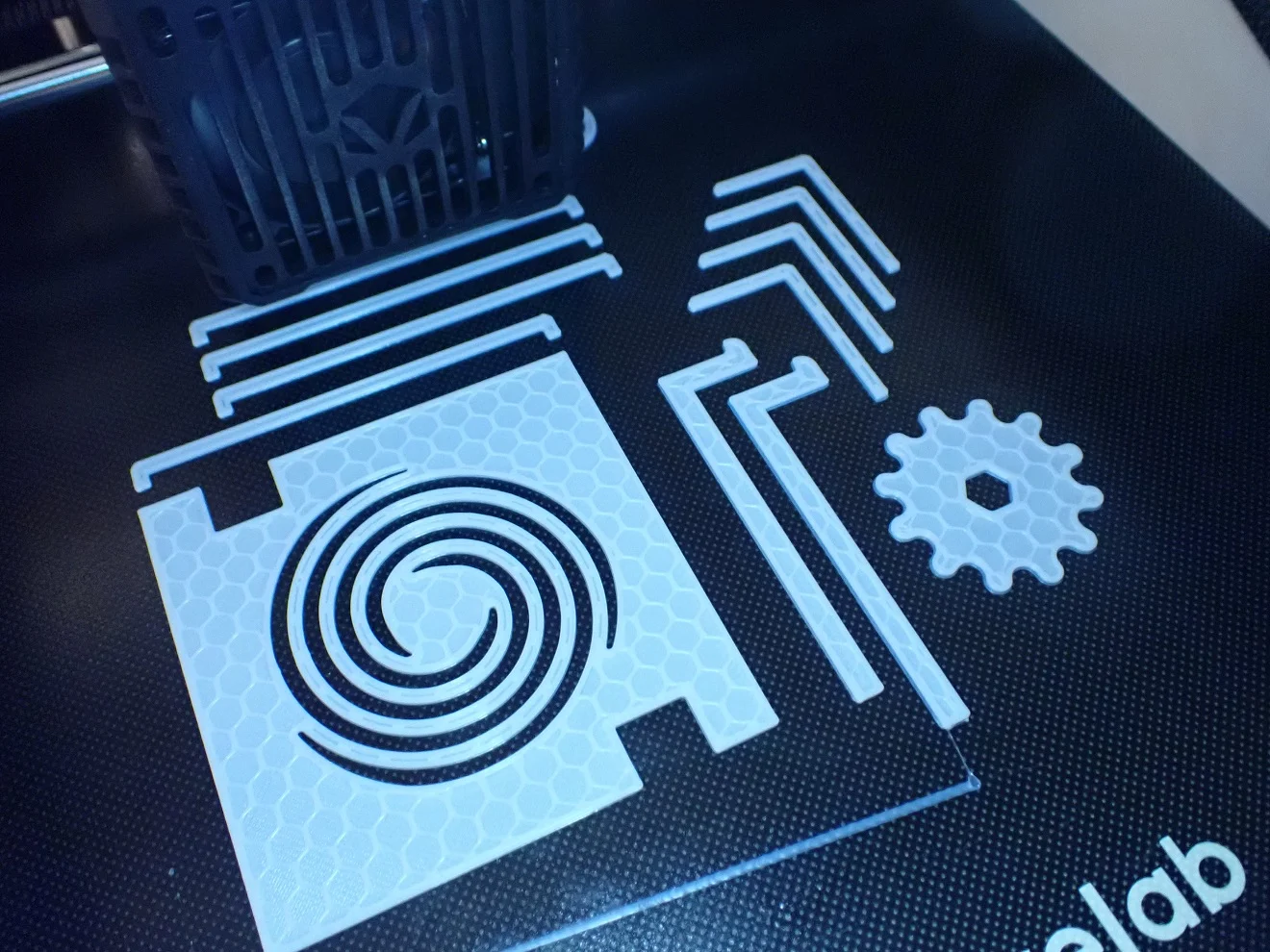

PEI – Printing PLA Perfect Without Adhesive

If you print mainly with PLA, a PEI film* is a good investment for you. It offers a very good print bed adhesion for PLA and makes Blue Tape or glue sticks mostly obsolete.

The print bed adhesion with a PEI film is not as perfect as with Magigoo, but it is sufficient for 90% of your print projects. Only with very filigree first layers, it could be that here and there a corner of the print bed detaches or you get some warping.

PEI films can either be cut to the right size or are directly available in the right size. They are also suitable for other filaments, but not as good as for PLA. If you are not only printing PLA, a Magigoo glue stick is still useful.

Magigoo Compatible Filaments – Table

| Material | Manufacturer | Magigoo Type | Initial Layer Bed temperature (°C) | Default Bed Temperature (°C) | Brim | Brim Width (mm) | Initial Nozzle Temperature (°C) | Default Nozzle Temperature (°C) | Enclosure | Chamber Temperature (°C) |

|---|---|---|---|---|---|---|---|---|---|---|

| Tholus | Kimya | PC | 120 | 120 | 300 | 300 | Recommended | |||

| ABS | Ultimaker | Original | 85 | 85 | yes | 7 | 240 | 230 | ||

| PolyLiteABS | Polymaker | Original | 105 | 95 | 250 | 250 | ||||

| ABS | eSun | Original | 110 | 110 | 240 | 230 | ||||

| ABS | Atomic Filaments | Original | 110 | 110 | 250 | 250 | Recommended | |||

| ABS-T | Filament PM | Original | 110 | 110 | yes | 10 | 250 | 250 | Recommended | |

| ABS “Not Dead” | Filament PM | Original | 110 | 110 | yes | 10 | 250 | 250 | Recommended | |

| ABS-T | Filament PM | Original | 100 | 100 | yes | 10 | 250 | 250 | Recommended | |

| ABS “Not Dead” | Filament PM | Original | 100 | 100 | 250 | 250 | Recommended | |||

| ABS | Intamsys | Original | 90 | 90 | 240 | 240 | Heated Chamber | 55 | ||

| Extrafil ABS | Fillamentum | Original | 110 | 100 | yes | 8 | 240 | 240 | ||

| PolyLiteABS | Polymaker | Original | 105 | 95 | 245 | 245 | Recommended | |||

| PolyLiteABS | Polymaker | Original | 90 | 90 | 240 | 240 | Heated Chamber | 55 | ||

| Extrafil ABS | Fillamentum | Original | 110 | 110 | 245 | 245 | Recommended | |||

| PolyLite ABS | Polymaker | Original | 105 | 95 | 245 | 245 | Recommended | |||

| PolyLite ABS | Polymaker | Original | 105 | 95 | yes | 8 | 250 | 250 | Recommended | |

| Easy ABS | Fiberology | Original | 110 | 110 | yes | 10 | 245 | 245 | Recommended | |

| ABS | Fiberology | Original | 110 | 100 | yes | 10 | 240 | 240 | Recommended | |

| ABS | Fiberology | Original | 110 | 100 | yes | 10 | 240 | 240 | Recommended | |

| ASA Natural | BASF Innofil3D | PC | 110 | 110 | 280 | 275 | ||||

| ASA | Fillamentum | PC | 110 | 110 | 250 | 250 | ||||

| ASA+ | 3DPrima | Original | 100 | 100 | 230 | 230 | Recommended | |||

| ASA | Filament PM | Original | 100 | 90 | yes | 20 | 240 | 240 | Recommended | |

| ASA | Fiberology | PC | 110 | 110 | 265 | 265 | ||||

| Durabio | Mitsubishi Chemicals | PC | 110 | 100 | yes | 7 | 260 | 260 | Recommended | |

| PP CF | Lehmann Voss | PP | 80 | 80 | yes | 8 | 280 | 280 | Recommended | |

| PP CF | Lehmann Voss | PP | 60 | 60 | yes | 8 | 260 | 260 | Recommended | 50 |

| PET CF | BASF Innofil3D | Original | 80 | 75 | 260 | 260 | ||||

| Innovatefil PET-CF | Smart Materials | Original | 80 | 75 | 260 | 260 | ||||

| Novamid 1030CF | DSM | PA | 70 | 65 | 270 | 270 | ||||

| PAHT CF15 | BASF Innofil3D | PA | 80 | 75 | 260 | 260 | ||||

| LUVOCOM 3F PAHT CF 9742 BK | Lehmann Voss | PA | 80 | 75 | 260 | 260 | ||||

| Nylon X | Matterhackers | PA | 90 | 80 | yes | 8 | 265 | 265 | ||

| PolyMide PA6-CF | Polymaker | PA | 75 | 70 | 280 | 280 | ||||

| Nylforce CF | Fibreforce | PA | 95 | 90 | yes | 7 | 265 | 265 | ||

| CF15 | Fillamentum | PA | 110 | 100 | yes | 20 | 250 | 250 | Recommended | |

| Nylforce CF | Fibreforce | PA | 110 | 100 | yes | 15 | 265 | 265 | ||

| Novamid 1030CF | DSM | PA | 90 | 85 | 270 | 270 | Recommended | |||

| CF-Nylon | 3DPrima | PA | 110 | 100 | yes | 15 | 275 | 275 | Recommended | |

| Nylon X | Matterhackers | PA | 90 | 90 | yes | 10 | 270 | 270 | Recommended | |

| PA12CF | Fiberology | PA | 110 | 110 | 265 | 265 | Recommended | |||

| CPE | Ultimaker | Original | 75 | 75 | yes | 7 | 240 | 240 | ||

| XT-Clear | Colorfabb | Original | 75 | 75 | 240 | 240 | ||||

| PCTG+ | Essentium | HT | 90 | 90 | 245 | 245 | ||||

| CPE HG100 | Fillamentum | Original | 80 | 80 | 235 | 235 | ||||

| PET-G PRO | Atomic Filaments | Original | 75 | 75 | yes | 8 | 235 | 235 | ||

| CPE HT | Fiberology | PC | 110 | 110 | yes | 10 | 270 | 270 | ||

| X-Strand GF30-PA6 | Owens Corning | PA | 75 | 70 | 260 | 260 | ||||

| PA6/66-GF20 Flame retardant | Clariant | PA | 70 | 70 | yes | 10 | 240 | 240 | ||

| Nylon G | Matterhackers | PA | 90 | 80 | yes | 8 | 265 | 265 | ||

| LUVOCOM 3F PAHT GK 9874 NT | Lehmann Voss | PA | 75 | 70 | 260 | 260 | ||||

| PolyMide PA6-GF | Polymaker | PA | 75 | 70 | 280 | 280 | ||||

| Nylforce GF | Fibreforce | PA | 95 | 90 | yes | 7 | 265 | 265 | ||

| PA GF20 Flame Retardant | Clariant | PA | 80 | 60 | yes | 10 | 270 | 270 | Recommended | |

| X-Strand GF30-PA6 | Owens Corning | PA | 85 | 80 | 260 | 260 | ||||

| Nylforce GF | Fibreforce | PA | 100 | 95 | yes | 15 | 265 | 265 | ||

| GF-Nylon | 3DPrima | PA | 110 | 100 | yes | 15 | 275 | 275 | Recommended | |

| PA12GF | Fiberology | PA | 110 | 110 | yes | 10 | 265 | 265 | Recommended | |

| X-Strand GF30-PP | Owens Corning | PPGF | 100 | 20 | yes | 20 | 270 | 270 | Recommended | |

| Ultrafuse PP GF30 | BASF Innofil3D | PPGF | 100 | 20 | yes | 20 | 240 | 240 | Recommended | |

| X-Strand GF30-PP | Owens Corning | PPGF | 110 | 60 | yes | 20 | 270 | 270 | Recommended | |

| Ultrafuse PP GF30 | BASF Innofil3D | PPGF | 110 | 60 | yes | 50 | 240 | 240 | Recommended | |

| X-Strand GF30-PP | Owens Corning | PPGF | 50 | 50 | yes | 15 | 270 | 270 | Heated Chamber | 50 |

| Ultrafuse PP GF30 | BASF Innofil3D | PPGF | 50 | 50 | yes | 15 | 270 | 270 | Heated Chamber | 50 |

| X-Strand GF30-PP | Owen’s Corning | PPGF | 90 | 50 | yes | 15 | 270 | 270 | ||

| Aquasys180 | Infinite Material Solutions | HT | 280 | 280 | Recommended | |||||

| Ultrafuse 316L | BASF Forward AM | Metal | 100 | 100 | 245 | 245 | Recommended | |||

| Ultrafuse 316L | BASF Forward AM | Metal | 100 | 100 | 240 | 240 | Recommended | |||

| Nylon | Ultimaker | PA | 90 | 80 | 245 | 245 | ||||

| Zytel 3D1000FL | DuPont | PA | 100 | 90 | yes | 8 | 280 | 275 | ||

| PA6/66 Flame Retardant | Clariant | PA | 90 | 80 | yes | 10 | 240 | 240 | ||

| Novamid 1030 | DSM | PA | 80 | 80 | yes | 7 | 270 | 260 | ||

| Novamid 1070 | DSM | PA | 95 | 85 | yes | 20 | 280 | 270 | ||

| Nylon Pro | Matterhackers | PA | 70 | 70 | yes | 7 | 255 | 245 | ||

| LUVOCOM PAHT 9825 NT | Lehmann Voss | PA | 70 | 70 | 265 | 265 | ||||

| PolyMide CoPA | Polymaker | PA | 70 | 70 | 260 | 260 | ||||

| Bridge | Taulman3D | PA | 70 | 60 | yes | 20 | 245 | 245 | ||

| Nylon | Filkemp | PA | 70 | 70 | 245 | 245 | ||||

| 645 | Taulman3D | PA | 70 | 60 | yes | 20 | 245 | 245 | ||

| 680 | Taulman3D | PA | 70 | 60 | 245 | 245 | ||||

| PA6 Flame Retardant | Clariant | PA | 90 | 80 | yes | 10 | 250 | 250 | ||

| PolyMide PA12 | Polymaker | PA | 80 | 80 | 260 | 260 | ||||

| F3 PA Pure Lite | Fiberthree | PA | 75 | 75 | 280 | 280 | ||||

| F3 PA Pure Pro | Fiberthree | PA | 70 | 70 | 265 | 265 | ||||

| HTN | Essentium | PA | 85 | 85 | 275 | 275 | ||||

| 910 | Taulman 3D | PA | 90 | 80 | yes | 8 | 260 | 260 | Recommended | |

| PolyMide CoPA | Polymaker | PA | 80 | 80 | 260 | 260 | Recommended | |||

| Nylon X | Matterhackers | PA | 75 | 75 | yes | 8 | 260 | 260 | Recommended | |

| PAJET | Filament PM | PA | 110 | 110 | yes | 20 | 240 | 240 | Recommended | |

| Novamid 1030 | DSM | PA | 100 | 100 | yes | 15 | 270 | 260 | Recommended | |

| Novamid 1070 | DSM | PA | 110 | 100 | yes | 15 | 280 | 270 | Recommended | |

| Nylon PA12 | Fiberology | PA | 110 | 110 | yes | 10 | 265 | 265 | Recommended | |

| PC | Ultimaker | PC | 105 | 105 | 270 | 270 | ||||

| PolyMax PC | Polymaker | PC | 110 | 110 | 270 | 260 | Recommended | |||

| PolyLite PC | Polymaker | PC | 110 | 110 | 270 | 260 | Recommended | |||

| PC-PBT | Polymaker | PC | 110 | 100 | 280 | 280 | Recommended | |||

| PC-FR | Polymaker | PC | 110 | 100 | 270 | 270 | Recommended | |||

| PC-ABS | Polymaker | PC | 100 | 100 | 280 | 280 | Recommended | |||

| PolyLite PC | Polymaker | PC | 110 | 110 | yes | 15 | 210 | 210 | Recommended | |

| PolyMax PC | Polymaker | PC | 110 | 110 | yes | 15 | 210 | 210 | Recommended | |

| PC-S | Kimya | HT | 140 | 140 | yes | 15 | 300 | 300 | Use Air Manager | 50 |

| PC-S | Kimya | HT | 140 | 140 | yes | 15 | 310 | 310 | Heated Chamber | 60 |

| PC-ABS | Filament PM | PC | 110 | 110 | yes | 10 | 260 | 260 | Recommended | |

| PC-ABS | Filament PM | PC | 100 | 100 | 260 | 260 | Recommended | |||

| PEEK | 3D4Makers | HT | 150 | 150 | yes | 10 | 400 | 400 | Recommended | |

| PEEK | Solvay | HT | 150 | 150 | yes | 10 | 420 | 420 | Recommended | |

| LUVOCOM 3F PEEK | Lehmann Voss | HT | 160 | 160 | yes | 10 | 390 | 390 | Heated Chamber | 90 |

| PEKK | 3DXtech | HT | 150 | 150 | yes | 10 | 360 | 360 | Recommended | |

| PEKK | Arkema | HT | 150 | 150 | yes | 10 | 360 | 360 | Recommended | |

| Amphora HT5300 | Eastman | HT | 110 | 110 | 270 | 270 | Recommended | |||

| Amphora AM3300 | Eastman | Original | 85 | 85 | yes | 7 | 235 | 235 | ||

| Arnite ID 3040 | Eastman | Original | 90 | 90 | yes | 7 | 270 | 270 | ||

| PET-G | Filament PM | Original | 80 | 80 | 230 | 230 | ||||

| PET-G | Perlon | Original | 75 | 75 | 225 | 225 | ||||

| PET-G | Filament PM | Original | 90 | 90 | 230 | 230 | ||||

| PolyLite PET-G | Polymaker | Original | 75 | 75 | 245 | 245 | ||||

| Easy PETG | Fiberology | Original | 90 | 90 | 240 | 240 | ||||

| PCTG | Fiberology | Original | 100 | 100 | 260 | 260 | ||||

| PolyLite PLA | Polymaker | Original | 60 | 60 | 210 | 210 | ||||

| PolyMax PLA | Polymaker | Original | 60 | 60 | 210 | 210 | ||||

| PolyLite PLA | Polymaker | Original | 60 | 60 | 210 | 210 | ||||

| PolyMax PLA | Polymaker | Original | 60 | 60 | 210 | 210 | ||||

| PLA | Filament PM | Original | 65 | 65 | 210 | 210 | ||||

| PLA | Filament PM | Original | 65 | 65 | 210 | 210 | ||||

| FiberSilk | Fiberology | Original | 50 | 50 | 220 | 220 | ||||

| Impact PLA | Fiberology | Original | 60 | 60 | 235 | 235 | ||||

| Easy PLA | Fiberology | Original | 60 | 60 | 220 | 220 | ||||

| HD PLA | Fiberology | Original | 60 | 60 | 220 | 220 | ||||

| Impact PLA | Fiberology | Original | 60 | 60 | 235 | 235 | ||||

| Easy PLA | Fiberology | Original | 60 | 60 | 220 | 220 | ||||

| HD PLA | Fiberology | Original | 60 | 60 | 220 | 220 | ||||

| 3Diakon | Mitsubishi Chemicals | PC | 100 | 100 | yes | 7 | 260 | 260 | Recommended | |

| PP | Verbatim | PP | 80 | 70 | yes | 20 | 220 | 208 | ||

| PP | Ultimaker | PP | 80 | 70 | yes | 20 | 220 | 208 | ||

| PP Natural | BASF Innofil3D | PP | 80 | 70 | yes | 20 | 208 | 220 | ||

| EVOLV3D Olefin Block Copolymer | DOW | PP | 110 | 70 | yes | 20 | 220 | 220 | ||

| Centaur PP | FormFutura | PP | 80 | 70 | yes | 20 | 220 | 208 | ||

| PP2320 | Fillamentum | PP | 70 | 70 | yes | 20 | 240 | 235 | ||

| PP | Smart Materials | PP | 100 | 90 | yes | 20 | 220 | 220 | ||

| PP | Verbatim | PP | 100 | 90 | yes | 20 | 220 | 220 | ||

| PP Neat | Lehmann Voss | PP | 100 | 20 | 240 | 235 | ||||

| Centaur PP | FormFutura | PP | 100 | 90 | yes | 8 | 220 | 220 | Recommended | |

| PP | Innofil | PP | 110 | 100 | yes | 8 | 230 | 230 | Recommended | |

| SOFTJet PP | Filament PM | Flex | 110 | 110 | yes | 29 | 240 | 240 | Recommended | |

| FL105PP | Braskem | Flex | 100 | 90 | yes | 20 | 230 | 230 | ||

| FL100PP | Braskem | Flex | 110 | 100 | yes | 20 | 230 | 230 | ||

| PP | Ultimaker | PP | 80 | 70 | yes | 20 | 220 | 208 | ||

| PP | Verbatim | PP | 80 | 70 | yes | 20 | 220 | 208 | ||

| PP | Fiberology | PP | 100 | 100 | yes | 10 | 245 | 245 | Recommended | |

| FL900PP-CF | Braskem | PP | 90 | 85 | yes | 15 | 240 | 240 | ||

| FL900PP-CF | Braskem | PP | 90 | 85 | yes | 15 | 240 | 240 | ||

| PP-CF | Braskem | PP | 90 | 85 | yes | 15 | 240 | 240 | ||

| PPS-CF | Treed | HT | 100 | 100 | yes | 8 | 310 | 310 | Recommended | |

| Aquasys 180 | Infinite Material Solutions | HT | 160 | 160 | 280 | 280 | ||||

| FIREWIRE PVDF | 3DXTECH | HT | 70 | 70 | yes | 8 | 260 | 260 | ||

| PVDF-H | 3Dogg | HT | 100 | 100 | yes | 20 | 260 | 260 | ||

| FIREWIRE PVDF | Arkema | HT | 70 | 70 | yes | 8 | 260 | 260 | ||

| Hytrel 3D4100FL | DuPont | Flex | 105 | 95 | yes | 15 | 222 | 220 | ||

| Arnitel 2060 HT | DSM | Flex | 90 | 80 | yes | 20 | 242 | 240 | ||

| Arnitel 2045 | DSM | Flex | 80 | 70 | yes | 8.75 | 245 | 230 | ||

| TPE | Fillamentum | PP | 60 | 20 | yes | 20 | 235 | 235 | Recommended | |

| RUBBERJet TPE 32 | Filament PM | Flex | 110 | 110 | 230 | 230 | Recommended | |||

| TPS 97A | Perlon | PP | 100 | 100 | yes | 10 | 270 | 270 | ||

| TPU95A | Ultimaker | Original | 0 | 0 | yes | 8.75 | 240 | 225 | ||

| FiberFlex 40D | Fiberology | Flex | 60 | 60 | yes | 10 | 215 | 215 | ||

| FiberFlex 40D | Fiberology | Flex | 60 | 60 | yes | 10 | 215 | 215 | ||

| I180 | IGUS | Custom | 110 | 110 | yes | 20 | 260 | 260 |

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.