- Z Seam | How to Hide & Avoid | Cura & PrusaSlicer - April 20, 2024

- Qidi Tech Q1 Pro – Best Orca Slicer Settings & Profile - April 9, 2024

- Creality Ender-3 V3 Review – Will CoreXZ be the New Trend? - March 27, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

For high print quality, it is important that the print adheres well to the build plate. Many fans ensure this with printing plates made of special material, coatings, heatable printing plates, hairspray, Blue Tape and more.

But what if the model is a bit too sticky and can’t be released easily? How do you get your part off the plate without damage, possibly even off a costly hotplate with a sensitive surface? There are actually a few methods that have proven successful.

Table of Contents:

General Options

For a good print result, it is important that the first layer in particular is built up cleanly on the printing plate. For this, it is necessary that the liquid, hot filament adheres well to the plate. It must not slip or warp, because otherwise all subsequent layers will be printed uncleanly.

There are various ways to achieve this good adhesion. Printing plates with an extremely smooth surface made of glass or a metal can ensure this. Some filaments adhere better to the print bed than others. But also aids like Blue Tape, spray adhesive*, hairspray or even special glue sticks for 3D printing* are used to improve the adhesion. So it seems for the time being that good adhesion is rather difficult to achieve …

In fact, however, when the print bed and the component cool down, it often enough turns out that the adhesion is too good. The model simply doesn’t want to come off the print bed, at least not without the use of brute force methods. And these would possibly damage the component with its filigree details.

In fact, there are a few ways to remove even extremely well adhered prints from the build plate. One way is to carefully spray the part with a solution of 50 percent alcohol and 50 percent water. The method works well at least if you’re using a build plate as very smooth glass. After a few seconds, you will hear a soft crackling sound: the plastic will easily detach from the printing plate.

If that doesn’t work, you have a few other ways to remove your print from the build plate – without destroying the model right away or damaging the plate. If the plastic bonds too well with the plate, it often doesn’t help much, especially with expensive glass surfaces.

Force

By its very nature, this is the first option that comes to mind for desperate 3D printing fans: the model can be released with sheer force. A firm grip, a bit of twisting, pulling, pushing – and often that’s enough to get the plastic off the build plate. But not always.

Before you force the printing part and build plate, you should let the model cool down completely. This is because the material hardens as it cools, and the printing part is more stable. So you won’t damage it so easily even with a hard grip. And then, of course, you don’t approach it with brute force right away, but try a delicate but emphatic grip first.

If that is not enough, try a light shock. Take a rubber mallet or similar soft tool and give the plate or component a light blow. The blow should not be so hard that you crack or dent the printing part or shatter the plate. However, it should be enough to cause a slight vibration.

This is because you will set the material in motion with the force of the blow. Since the build plate and model are made of different materials, the printing exerted is transmitted differently in the material. In concrete terms, this means that while the softer plastic model is compressed a little, the plate remains stable – and the plastic detaches from the printing bed.

Most of the time, even then, the model doesn’t just fall off the build plate. You still have to take it down with some authority in your grip. But this works much easier than before the blow!

Tools

The rubber mallet just mentioned is also a tool, but we are talking about other tools here. You surely have a spatula made of hard plastic or metal in your house. Most of the time, these tools are already supplied by the 3D printer manufacturer – so use them!

The simplest method of loosening a stubborn printing piece is the Archimedean lever: You run the sharpened spatula in a small corner between the model and the printing plate. Hold it firmly, lift the spatula a little and tilt it again and again. Sometimes you push the right-hand corner of the tool upwards, sometimes the left-hand side.

Move the spatula deeper and deeper between the plate and the model, back and forth a little. The spatula will slowly get more and more play, and your model will slowly detach from the build plate.

But be careful: a sharpened metal spatula is a weapon! If you are too impatieant, you will leave unsightly scratches on the building plate, damage your printed model and possibly cause yourself injuries. A tool like this is prone to slipping – and your hand is the only brake in the vicinity!

Spatulas, blades and other scraping tools come in different sizes and shapes. There is a reason for this: Not every scraper always fits. So just try out which tool you can use to find a starting point on whichever edge.

If the tools that come with the 3D printer don’t fit, you can stock up on your own at hardware stores and craft stores. Most of the time, the tools that come with the printer are of dubious quality anyway. When buying tools, make sure that the handles are ergonomically shaped and have a rubber coating. That way, they fit well in your hand and you won’t slip off as easily. So this is also a question of safety.

Ideally, you should stock up on a set of different tools. Blades made of hard plastic are very resistant. Sometimes, however, the bendable, flexible blade made of stainless steel is better suited. Very thin spatulas will grip even the smallest grooves, while thicker spatulas will allow you to exert a little more force. Also important to know: The thin stainless steel blades can damage the surface of your printing plate.

Only use the various tools when your print model has completely cooled down and hardened. Otherwise, you will deform it when trying to separate it from the build plate.

Dental Floss

Dental floss is extremely strong and very thin. You may have already noticed unpleasantly that the synthetic thread cuts into the skin when you use a little more force when cleaning your teeth. You can use this effect to loosen strongly adhering printing parts from the build plate.

To do this, hold the two ends of the floss thread firmly in both hands. Place the thread at the bottom of the crack between the print model and the printing plate, on the side opposite you. Now slowly but forcefully pull the thread toward you.

The fine floss will not cut the plastic of your model but will slip into the tiny space between the two materials. The waxed surface ensures that this works without much resistance. Dental floss is thinner than any blade, so you can get into spaces that are too fine for any putty knife.

The great thing about the method is that it often works even when the printed part has not yet cooled down completely but is still a little warm.

Heat

Actually, you should wait until your model has cooled down completely and only then detach it from the build plate. Why heat the heating bed again now? The reason is simple. The materials of the print bed and the model are different. And they react differently to heat and cold.

When cooling down, the plastic of your model contracts somewhat. You know this: If the effect is too great, we speak of a noticeable shrinkage. This natural shrinkage during cooling is often enough for the model to easily detach from the build plate – but this is not always the case.

If you heat your print model, the plastic not only becomes warm and soft, but also expands in the process. We summarize: As it cooled, the plastic, which adheres firmly to the build plate, contracted. Now we heat the heating bed and the plastic again, so that the solid, inert material of the build plate expands only a little, but your plastic model expands more.

In many cases, these forces, which act in quick succession and in opposite directions, simply cause the model to jump off the build plate. By the way, you should not turn the heating bed up too high: 70 degrees Celsius is the maximum. Any higher and the model will become so soft that it could warp – and you don’t want that. Besides, a higher temperature could make the model stick even more tightly to the build plate.

If you do not have a heating bed, you can still use the effect: Place the printing plate with the model on the heater or carefully heat the printing plate from below with a hairdryer. For safety reasons, however, you should refrain from experimenting with ovens, stovetops, microwaves or even soldering irons!

Cold

Plastic changes its volume very strongly under the influence of temperature fluctuations: after all, you know about shrinkage rates. Most printing models become visibly smaller when the material cools down. If it is heated, it expands.

The build plate is made of a different material than your print model. This means it expands at a different rate under heat and shrinks at a different rate when cold. Most of the time, the build plate changes much less than the material you are printing with.

You can use this effect to detach your model from the printing plate. You have several options:

- Place the model and printing plate in the refrigerator or outside in the snow on a cold day. As soon as the temperature of the plastic drops far enough, it should detach from the printing plate with an audible noise.

- Work with compressed air: The compressed air should not be set so hard that you destroy your print model. However, the strong airflow may be enough to cause the model to cool down a bit and fall off the build plate.

- Put your model and the build plate in the freezer. Wait some time for the model to cool down and shrink inside – then it will release on its own.

- As an athlete, you may have a gel-filled cooling pad in your refrigerator. Press it against the build plate from below. Perhaps the cold will be enough to loosen the printing model. Alternatively, you can apply ice spray (against sports injuries) from below to the build plate.

Alcohol

Maybe you have isopropyl alcohol* at home. Many people use this volatile alcohol to clean the printing plate. In this case, the alcohol ensures that no greasy dirt or marks remain on the printing plate. These would interfere with the adhesion of the printing material to the plate. The alcohol, therefore, ensures better adhesion.

However, if your print model sticks too strongly to the plate, you can also use the alcohol to loosen it. Apply the isopropyl alcohol near the base of your print model and leave it there for about fifteen minutes. The alcohol will evaporate. The evaporation creates coldness. This alone may cause the model to detach from the build plate.

If this is not the case, a small groove will have formed at least at the edges of the print model where the material has come loose from the building plate. Now you can use a thin knife blade or a spatula to drive into this fine gap and lever your model off the printing plate. If you do not succeed, you can use dental floss as another option.

An alternative to alcohol is hot water: You can either place the printing plate and model on a bowl of hot water and wait until the printing plate heats up and the model falls off. Or you can apply a little hot water to the base of the print model.

The hot water will soften the plastic of your model again. If the water is too hot, your print part will deform – you don’t want that. So this method requires a bit of sensitivity.

Different Options According to the Type of Filament

Some filaments show stronger adhesion than others. The different plastics all have individual properties. And they can be removed from the build plate more or less easily accordingly. Some of the methods presented are therefore more suitable for some filaments than for others.

To give you a rough idea of what is possible with which filament, we list the three most common filaments and the methods that are most likely to lead to success.

PLA

PLA prints sometimes stick to the build plate as if cast in concrete. In this case, a heating plate is really worth its weight in gold. Because if you heat the plate to about 70 degrees Celsius, the PLA becomes somewhat soft. This reduces the adhesive strength of the plastic, and you can remove your print models from the glass plate effortlessly.

PLA is not very heat tolerant, so heat is always the best way to get PLA off the build plate. Once the material has softened a bit, it is very easy to lift it with a spatula or a flexible knife and lever it off the printing plate. To do this, use your tool repeatedly in different places all around and work evenly with little force.

The presented method with alcohol does not work with PLA, because PLA reacts more sensitively to heat than to cold. It is important that you allow your model to cool down completely before you heat the hotplate again.

ABS

ABS apparently leads to problems very often, the material simply does not release well. This is because the glass construction plate also expands and contracts again when it cools down. So the plate works together with the print material – and that creates strong tensions wherever the materials touch.

ABS reacts very well to cold. So for this material, refrigerator, snow, freezer or the cooling pad are the best methods. Cold (and even cooler ambient air is enough for this) causes the material to contract strongly and quickly. Then, often with a corresponding noise, detaches itself from the print bed.

Sometimes it is sufficient to open the printing chamber during cooling after printing and let cool air flow in. The ABS then cools faster than the printing bed, and the model comes off. But be careful: cooling too quickly can damage the model! It will then also break away from the printing plate, but will deform in the process. This is because the material cools faster on the outside than on the inside.

With ABS, however, you can also prepare the printing plate so that your model does not stick so strongly in the first place. It is often recommended to coat the print bed with a slimy mixture of ABS and acetone (ABS Juice). This mixture can also be applied to a tape. This serves the same purpose as the frequently used glue stick: The first layer has some adhesion to the print bed, but the model can be easily removed from the slimy surface later.

PETG

PETG not only sticks extremely to the print bed, but also often breaks when you want to remove your model. To prevent this, many hobby 3D printer fans use glue sticks or hairspray. If the build plate is treated with this, the first layer of the print holds well. But the model is also easy to remove afterwards, because it doesn’t stick to the printing plate itself.

Another option is to print directly onto BuildTak*, PEI* or glass*. This is also often recommended. Once PETG has properly cured and firmly bonded to the mild surface of the print bed, it becomes difficult. Often, the printing plate breaks rather than the model comes loose.

For this reason, we can only advise you to simply try out everything possible and learn from your mistakes if necessary. With a little preparatory work, you can avoid too strong adhesion – and in the case of PETG, that definitely makes sense!

Before Printing: Avoid too Strong Adhesion

If you avoid gluing your model to the plate too much from the beginning, you won’t have to worry about the model coming loose. One option is to use a build plate that is adapted to the material you want to print with. In other words, not every build plate is equally suitable for every filament.

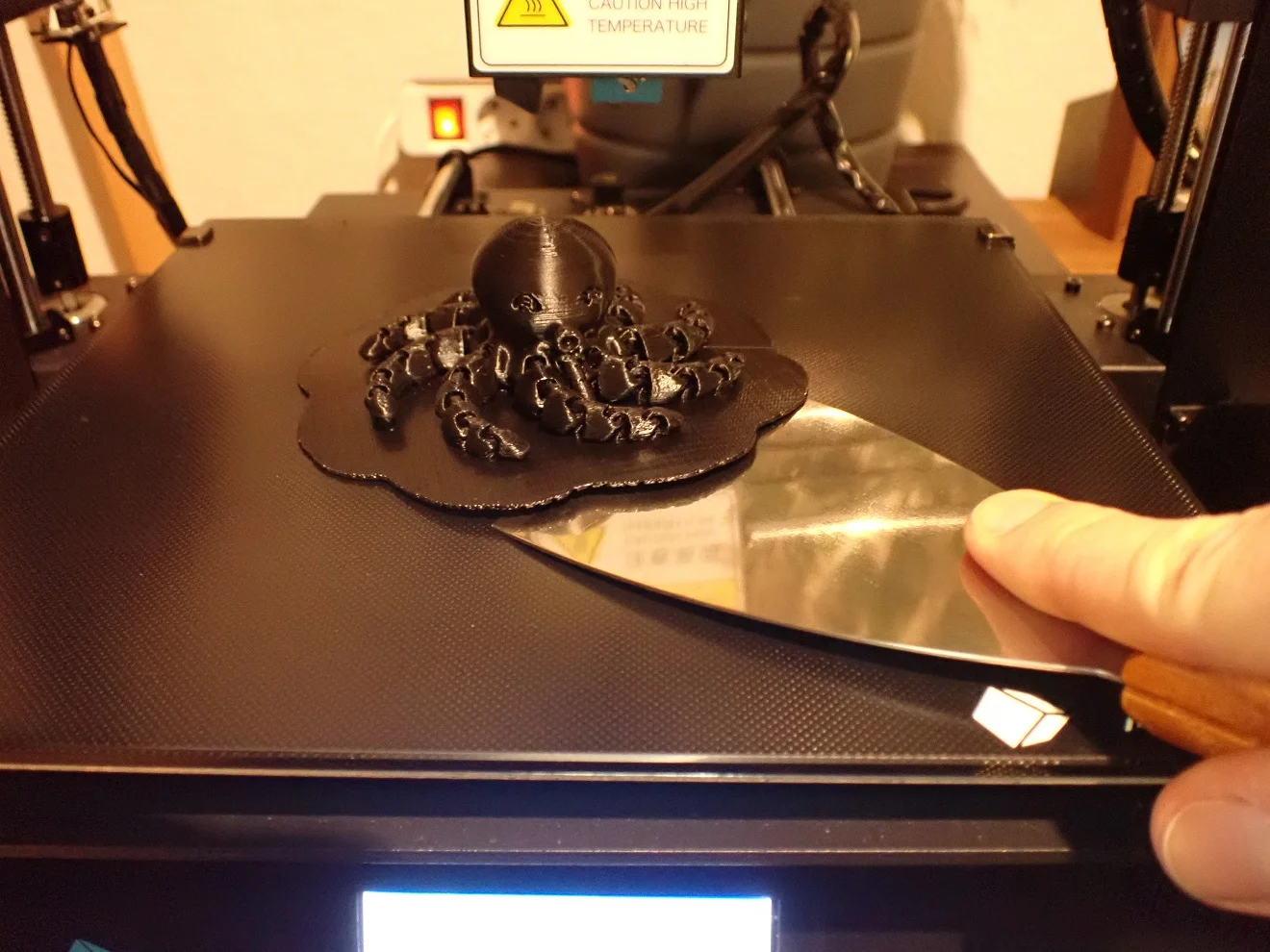

The best build plate that works for almost all filaments is a flexible, magnetic plate*. These plates are simply placed on the heating bed and held in place by magnets. After the model cools, you remove the plate. It is flexible, so it consists of a thin metal sheet.

If you now bend the metal sheet a few times in one direction and in the other, from all four sides, the print model will usually jump off the plate by itself. This is the easiest way to detach a print model from the build plate.

However, these plates are usually not included with the 3D printer, but must be purchased separately. And they also cannot be new in every device. Creality is one of the manufacturers that also offer flexible printing plates for their own 3D printers. In this case, the part is called Creality Ultra Flexible Magnetic Build Surface*.

If, on the other hand, you are printing on a glass plate, you can stick Kapton tape or painter’s masking tape onto the printing plate. This also makes it easier to remove the model. If it does not come off voluntarily, pull the tape off the printing plate. Remember to apply new tape before the next print.

A thin layer of glue stick works similarly on glass plates, and this method is suitable for almost all filaments.

If you want to buy your own glass printing plate or replace an old one, you should choose bososilicate glass*. The glass is designed so that it does not break easily. So, while other glass plates break or crumble under light force, this glass can withstand more violent attempts to remove the print model from the plate. Make sure that the plate actually fits into the printer and can be used – not all glass plates are compatible with all 3D printers.

Tips: Allow 3D Prints to Cool Down

Under the influence of temperature fluctuations, most print models detach themselves from the printing plate. Therefore, it is always a good idea to let the print cool down first. Often the model then breaks away from the plate by itself. You can help with a fan. However, you should make sure that your model does not cool down too quickly: If it contracts on the outside and is still soft on the inside, it will deform.

With a thin and very sharp blade, many models can also be detached from the print bed quite easily. The trick is not to cut the model from the plate. Instead, you use leverage by sliding the blade under the model and carefully bending it. If you print your model onto a raft, it will not be damaged in the process.

If you do not manage to remove your model from the printing plate immediately using this method, use the knife or spatula in a different place and ideally on a different side. Always keep an eye on your fingers: they should be safe!

Conclusion

It is annoying when your model sticks very tightly to the printing plate, but it can always be solved somehow. It will be easier if you prepare the printing plate and adjust the printer settings so that the model can come off by itself when it cools down. However, this is not always possible.

It is most gentle on your print model if you work with different temperatures. Heat your print model and/or the plate to ensure that the model breaks away due to the different material expansion or shrinkage. Refrigerator, freezer, warm water, a hair dryer and similar tools can help you. Even a fan has worked wonders.

If that doesn’t help, you always have a set of tools on hand: Spatulas and various scraper knives as well as blades and scalpels are suitable for sliding under the model. If you carefully play around with the blade, bend it and use it as a lever, you can loosen your print model. However, you should only do this when the material has cooled down and is hard.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.