- Is a Wash & Cure Station Worth It? Creality UW-03 Review - April 29, 2024

- Z Seam | How to Hide & Avoid | Cura & PrusaSlicer - April 20, 2024

- Qidi Tech Q1 Pro – Best Orca Slicer Settings & Profile - April 9, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

Besides the actual settings for the Z-seam, there are other settings in Cura that can hide such a seam on the Z-axis. One of these is the Outer Wall Wipe Distance.

The outer wall wipe distance defines the extrusionless distance of the nozzle at the end of an outer wall in Cura. This wipes off excess material on already printed areas of the outer wall to get a smoother Z-seam. The default settings are 0.2 – 0.4 mm.

In this article, you will learn how this setting can affect the Z-seam and what it has in common with coasting.

Table of Contents:

What is a Z-Seam?

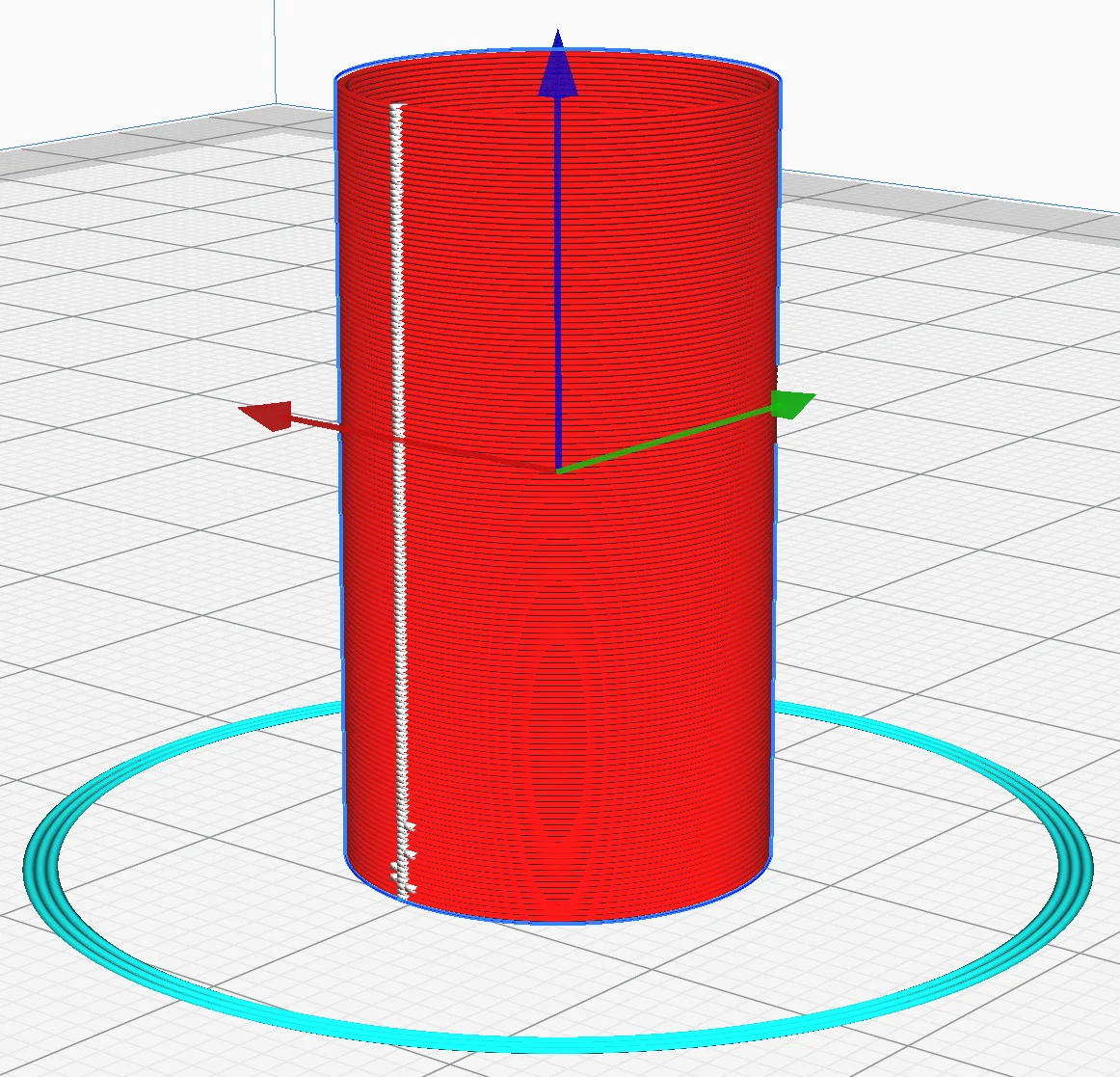

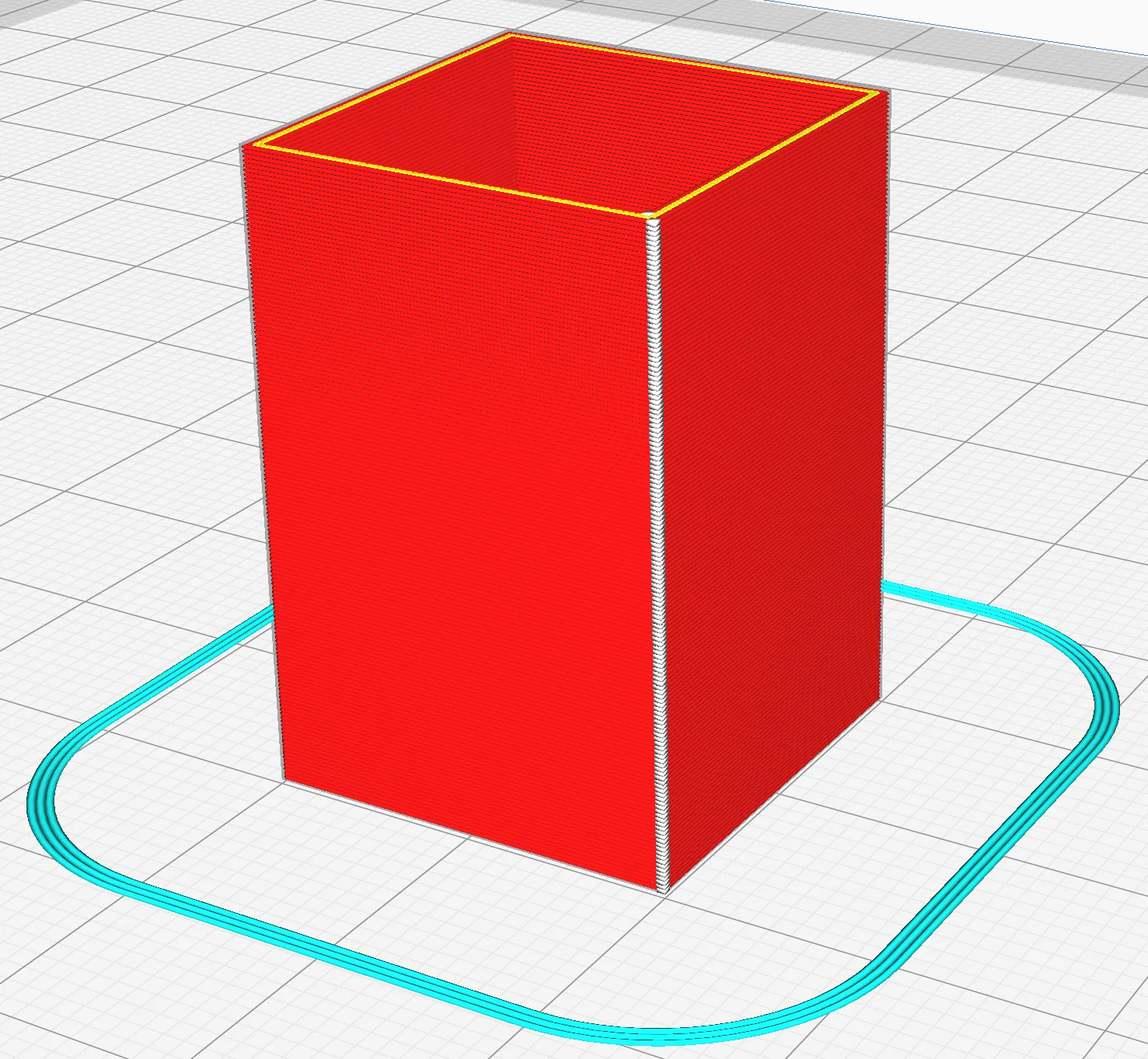

Whenever the nozzle of your 3D printer moves from one layer to the next, there is a break in the extrusion (except in vase mode). Depending on how much or little filament is extruded during this transition, a more or less visible Z-seam will result.

The name comes from the fact that a seam along the Z-axis occurs when the slicer cannot find a suitable corner to hide it. The wipe distance of the outer wall can help to get a less prominent Z-seam in Cura.

What is the Outer Wall Wipe Distance in Cura?

The larger you set the wipe distance of the outer wall in Cura, the longer the nozzle moves over the already printed outer wall without extruding filament.

This movement blurs the transition from the beginning to the end of the extrusion of the outer wall and the nozzle smears excess filament on the already printed outer wall.

If your retraction settings and flow rate are set perfectly, you won’t see much difference here. But if you have problems with blobbing at the Z-seam, the wipe distance of the outer wall can help to print the Z-seam smoother.

You can find the wipe distance of the outer wall under the settings for the walls in Cura. The default settings for the wipe distance are between 0.2 and 0.4 mm.

Outer Wall Wipe Distance vs. Coasting

The wipe distance of the outer wall behaves similarly to coasting. However, on closer inspection, these two settings are very different from each other.

With the wipe distance of the outer wall, the extrusion stops exactly at the end of the line, but the nozzle still moves a bit over the already printed material and wipes off excess material to avoid blobbing and stringing.

Coasting, on the other hand, stops extrusion just before the end of the line. The unwanted extrusion caused by excess pressure in the nozzle often leads to stringing or blobbing. When extrusion stops short of the end of the line, the excess material exits and completes the line. Then it can no longer cause stringing or blobbing. The problem with this is that the distance has to be perfectly set for coasting, otherwise holes can occur.

Complete Guide:

Cura Coasting – What is it and should I activate it?

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.