- Is a Wash & Cure Station Worth It? Creality UW-03 Review - April 29, 2024

- Z Seam | How to Hide & Avoid | Cura & PrusaSlicer - April 20, 2024

- Qidi Tech Q1 Pro – Best Orca Slicer Settings & Profile - April 9, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

In the search for a reliable 3D printer, the Flashforge Adventurer 5M Pro* boasts high-speed printing and compatibility with a variety of filaments, including ABS.

This Flashforge Adventurer 5M Pro review will closely examine if it stands up to these claims, providing you with the details you need to judge its value and performance for professional or hobbyist use.

The Flashforge Adventurer 5M Pro is an FDM 3D printer that specializes in temperature-sensitive filaments such as ABS.

Build Volume: 220 × 220 × 220 mm

Speed: Standard 300 mm/s, maximum 600 mm/s

Extruder: Direct Drive Extruder

Print Bed: Textured PEI

Leveling: Fully automatic

Nozzle Temp.: 280 °C

Bed Temp.: 110 °C

Pros:

✓ Closed print volume

✓ Internal air filter

✓ High print speed

✓ Integrated camera

Cons:

× Relatively small build volume

× Filament holder on the back

Table of Contents:

Key Takeaways

- The Flashforge Adventurer 5M Pro is designed for professionals and hobbyists, featuring a fully enclosed structure, easy nozzle swaps, automatic leveling, and high-speed printing with advanced filament support, catering to a wide user base.

- User-friendly setup and operation characterized by ‘10 Minute Quick Setup’, an intuitive 4.3-inch color touchscreen interface, and straightforward calibration make the Adventurer 5M Pro accessible to first-time users and professionals alike.

- Advanced features including a diverse filament compatibility with a maximum extruder temperature of 280 °C, high-speed print capabilities outpacing classic Cartesian printers, and seamless software synchronization with third-party slicing alternatives demonstrate the Adventurer 5M Pro’s versatility and sophisticated design.

Unboxing to First Print: Setting Up the Adventurer 5M Pro

The printer arrives with a Quick Start Guide that guides you through safely removing foam packaging, as well as other included components. The initial setup process after unpacking is smooth, with the spool holder installed with provided screws and an Allen wrench, and the build plate unlocked by removing four screws to prepare the printer for use.

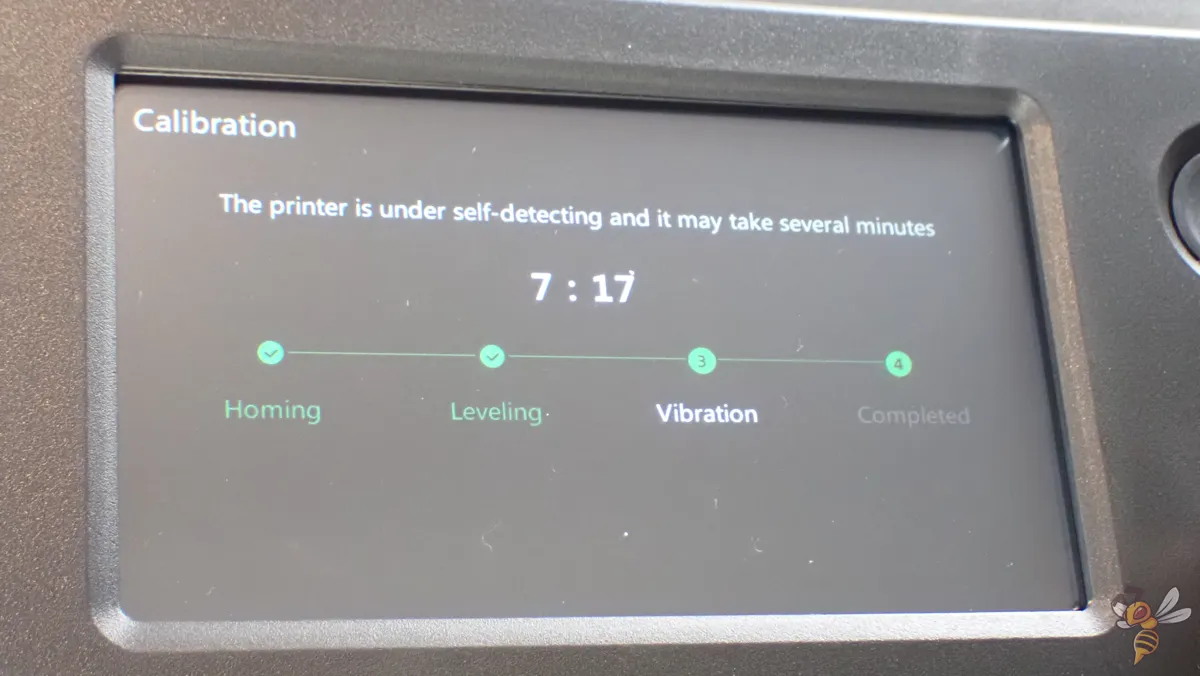

Initial calibration is performed by following on-screen prompts, with some expected vibrations and noise during the process.

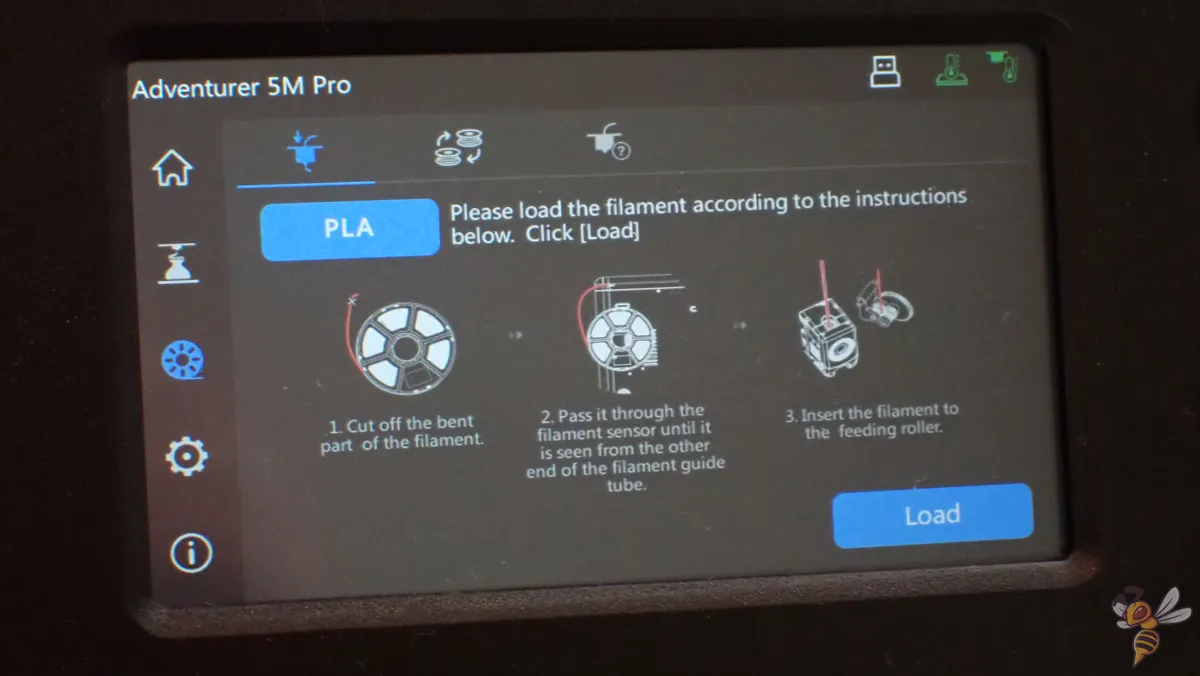

For the first print, you have to feed PLA filament to the extruder after cutting off any bent parts and hanging it on the spool holder, ensuring it passes through the filament sensor. The user guide comprises safety instructions such as not touching the heating nozzle directly and being mindful of moving parts during operation.

Thanks to its ‘10 Minute Quick Setup’ feature, the Adventurer 5M Pro is easy to set up, even for first-time users.

First Impressions

The Adventurer 5M Pro has several standout features that are immediately noticeable when you unbox it:

- Fully pre-assembled design and compact shape for convenience right out of the box.

- Built-in air filters in the enclosure for controlled environmental conditions, providing an enclosed build volume, ideal for ABS and other filaments that require controlled conditions.

- Relatively small print volume of 220 × 220 × 220 mm.

These features make the Adventurer 5M Pro a great choice for those looking to print with ABS and other filaments that need controlled environmental conditions.

The scope of delivery provides everything you need to start printing straight away, including high-quality tools for maintenance and some filament for the first test prints. The Adventurer 5M Pro appears to be engineered for not only functionality but also user convenience.

Aesthetics Meet Innovation: Examining the Adventurer 5M Pro

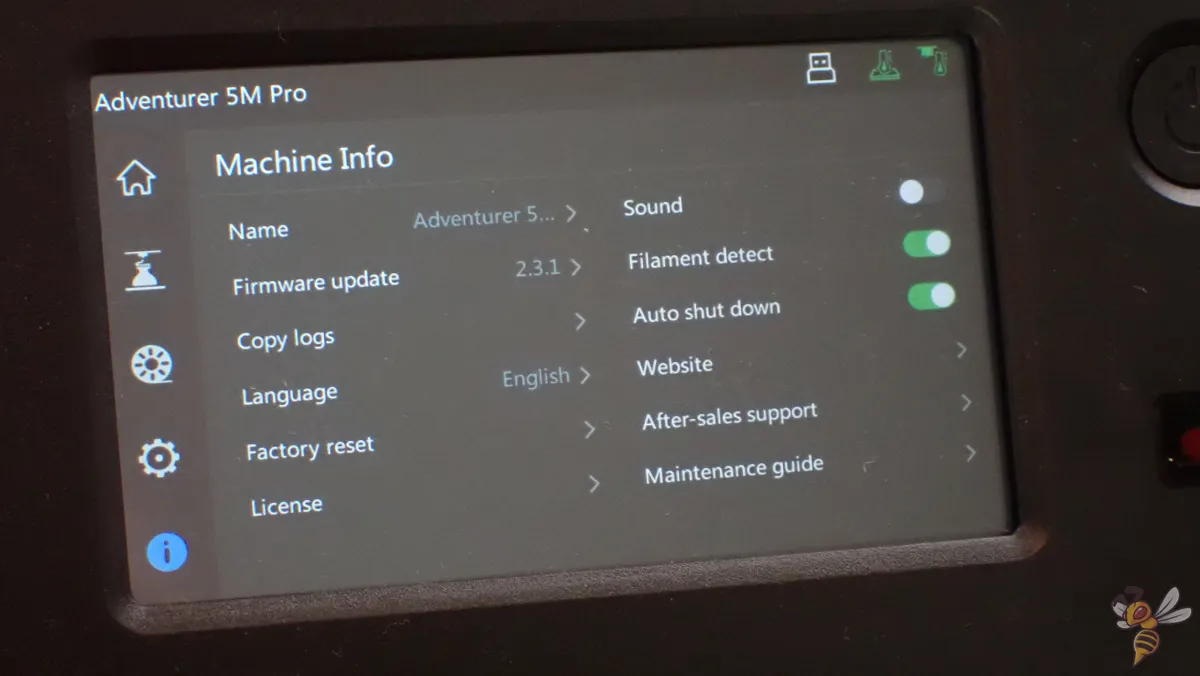

Superior design is a distinguishing feature of the Adventurer 5M Pro. Its aesthetics are striking, with a fully enclosed design, a magnetic front door, and a top panel for easy extruder access. But it’s not just about looks; the Adventurer 5M Pro also boasts a suite of advanced features, like real-time print monitoring and an auto shutdown function after print completion, which is nice to save on energy costs.

The Adventurer 5M Pro isn’t just visually appealing – it’s designed for high performance. With a 4.3” Color Touch Screen, a build volume of 220 x 220 x 220 mm, and an upgraded fast-heating nozzle, it’s designed to deliver premium output for a variety of users. But to truly understand its capabilities, let’s delve deeper into its build, user interaction, and ventilation systems.

Sleek and Sturdy: Assessing the Build

The design of the Adventurer 5M Pro includes:

- Fully enclosed design with a magnetic front door, top panel, and a magnetic bed

- Streamlined appearance with no exposed wires or mechanical components

- Durability of materials used in its build

This design showcases an attention to detail, emphasizing user convenience without sacrificing aesthetics and attesting to the printer’s sturdiness.

Functional elements like the externally mounted spool holder complement the printer’s practical design, improving the efficiency of the printing workflow. However, I and many other users would have preferred the filament holder to be mounted on the side. In certain setups, it is very inconvenient to change the filament this way.

User Interaction: Touchscreen and Interface

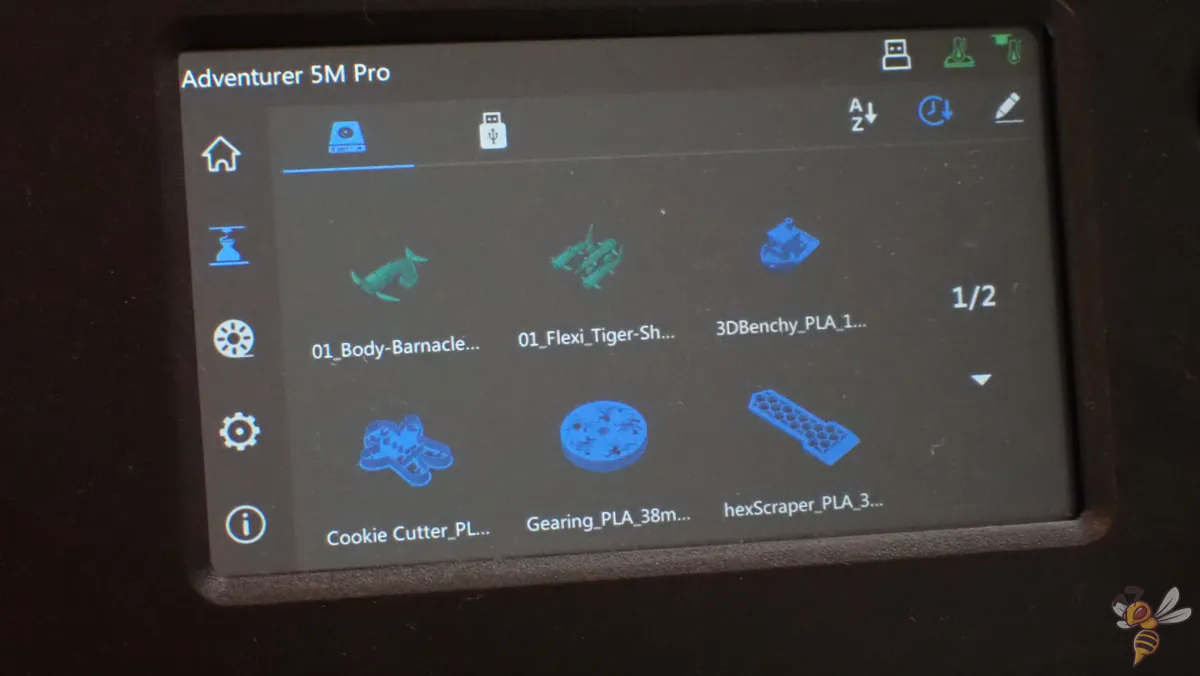

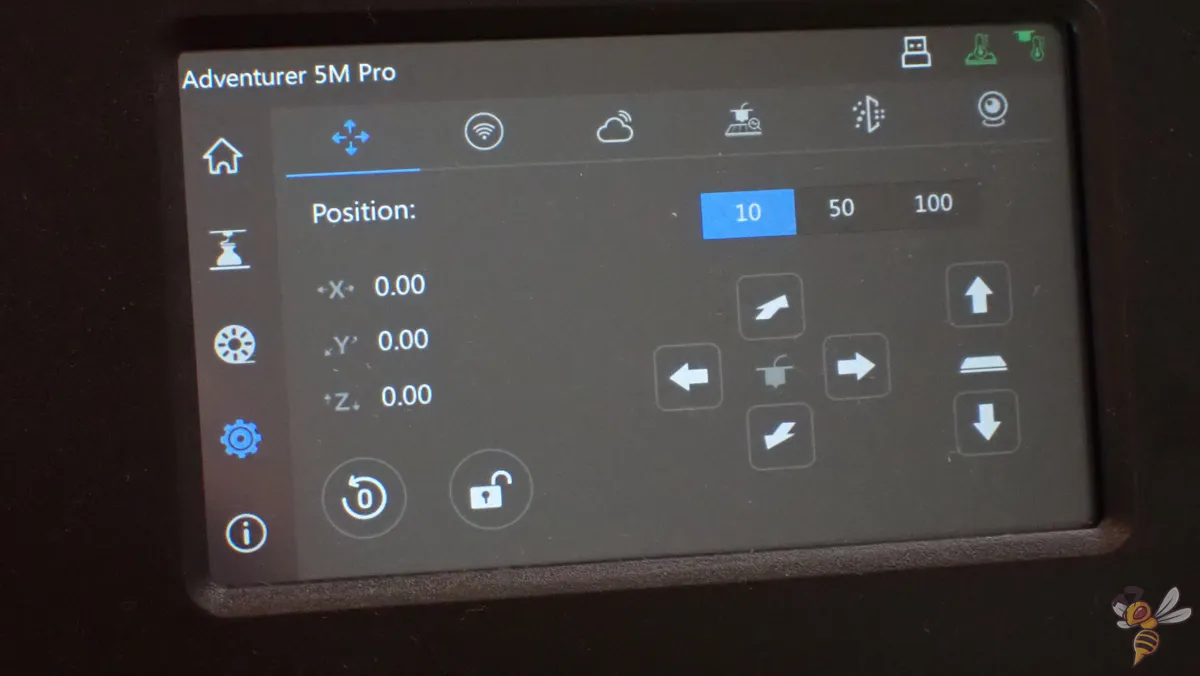

Interacting with the Adventurer 5M Pro is a breeze, thanks to its 4.3-inch color touchscreen LCD. This user-friendly and intuitive user interface allows easy navigation through settings, with menus conveniently located on the left side of the screen. During the 3D printing process, the touchscreen provides essential information such as time elapsed and print temperature, keeping users informed every step of the way.

Not only is the touchscreen easy to navigate, but the printer also simplifies user interaction by including a single physical power button.

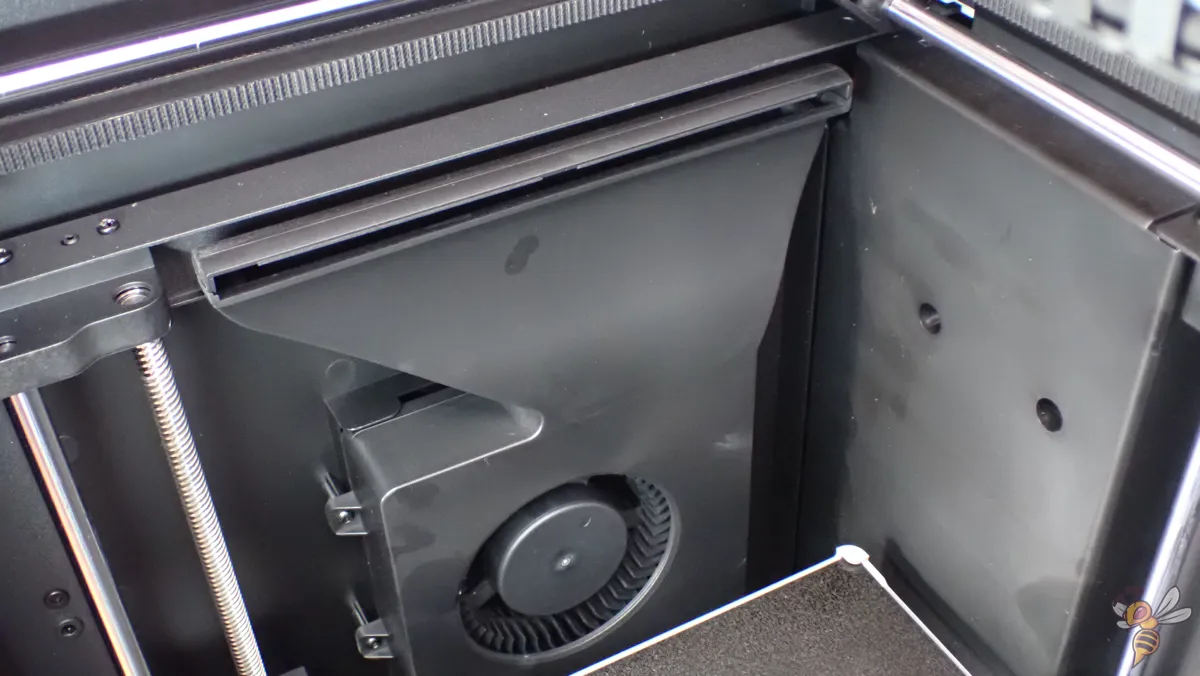

Ventilation and Air Filtration

The Adventurer 5M Pro’s ventilation system is a standout feature. Its internal and external dual air filtration system utilizes a HEPA filter, specifically HEPA13, and activated carbon filters to block 99% of particles and VOCs, enhancing its suitability for indoor use with materials like ABS filament that may release fumes. This makes it perfect for ABS!

To regulate air circulation and temperature during high-speed prints, the Adventurer 5M Pro integrates multiple fans, including a powerful side chamber fan and part cooling fans on the extruder.

Noise Level

One aspect of 3D printing that often goes unnoticed until you’re several hours into a print job is the noise level. The Flashforge Adventurer 5M Pro, when put to the test, registers about 65 decibels of operational sound with the enclosure door open, measured right in front of the printer. This is roughly equivalent to the noise level of a normal conversation.

When the enclosure is closed, the noise level drops below 60 decibels, making it comparably quiet and unobtrusive, akin to background music in a quiet office. These sound levels place the Adventurer 5M Pro comfortably within the average range for 3D printers, especially considering its high-speed printing capabilities.

Putting the Adventurer 5M Pro to the Test

Now, it’s time to evaluate the Adventurer 5M Pro’s performance based on its stated features. Can it truly deliver high-speed printing without sacrificing quality? Does it support a diverse range of filament materials? And how does it work with alternative slicing software?

To answer these questions, we’ll delve into its filament compatibility, print results, and software synchronization.

Material Mastery: Diverse Filament Compatibility

The Adventurer 5M Pro supports a wide range of materials, thanks to its high-temperature capabilities, the enclosure and the PEI build plate. With a maximum extruder temperature of 280 °C, it easily handles ABS filament, while the textured platform increases bed adhesion without the need for additional adhesives. The PEI coated magnetic and flexible build plate ensures excellent adhesion and compatibility with various materials, including ABS.

I also conducted tests specifically with ABS to illustrate the influence of a closed enclosure and the high print bed temperature on print quality. I printed a box using ABS filament with various settings to test this.

With the enclosure door open or the print bed temperature set too low, massive warping occurred, and the first layer often failed to adhere properly to the print bed. However, with the print bed temperature adequately set to over 100 °C and the print volume fully enclosed, printing with ABS filament was seamless, showing no signs of warping or other print defects.

This clearly demonstrates the Adventurer 5M Pro’s capability to handle temperature-sensitive materials like ABS when the optimal environmental conditions are maintained.

It can also print with flexible filaments like TPU, thanks to its direct drive extruder. The Adventurer 5M Pro is compatible with:

- PLA

- PETG

- TPU

- ABS

- ASA

- Carbon fiber reinforced PLA and PETG

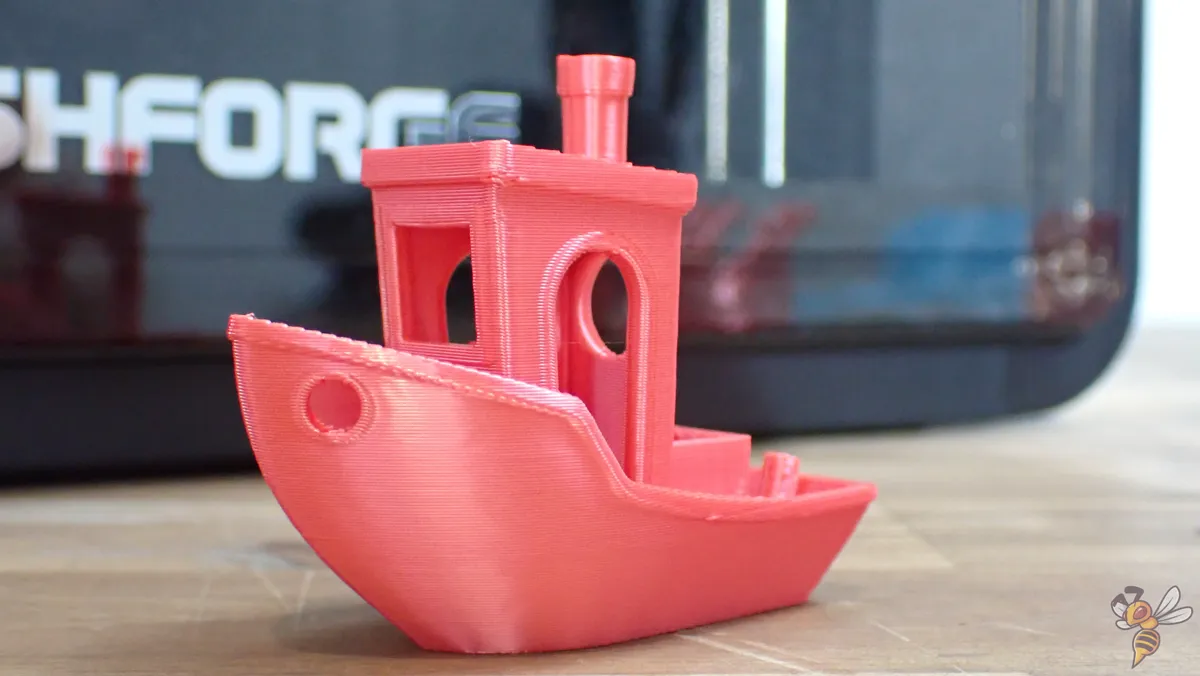

Quality at Speed: Analyzing Print Results

Regarding print quality at high speeds, the Adventurer 5M Pro is truly exceptional. It offers:

- Maximum acceleration of 20,000 mm/s²

- Maximum print speed of 600 mm/s

- Outpaces classic Cartesian 3D printers by up to 12 times, reducing total production time and embracing rapid prototyping

- Maintains excellent print quality, thanks to its robust design and sophisticated vibration compensation technology.

The printer also combats negative effects like ghosting and ringing that can occur during high-speed printing, ensuring the quality of print results.

However, while its high print speed capability is impressive, the initial software experience with FlashPrint 5 includes only a single profile per nozzle, which can limit the ability to achieve both high speed and high-quality printing without further user customization.

Nonetheless, its CoreXY motion system, quick-change nozzle system, and direct drive extruder all contribute to its ability to handle retraction-heavy models with minimal stringing, enhancing print quality for complex geometries and allowing users to continue printing with confidence, while also optimizing print time.

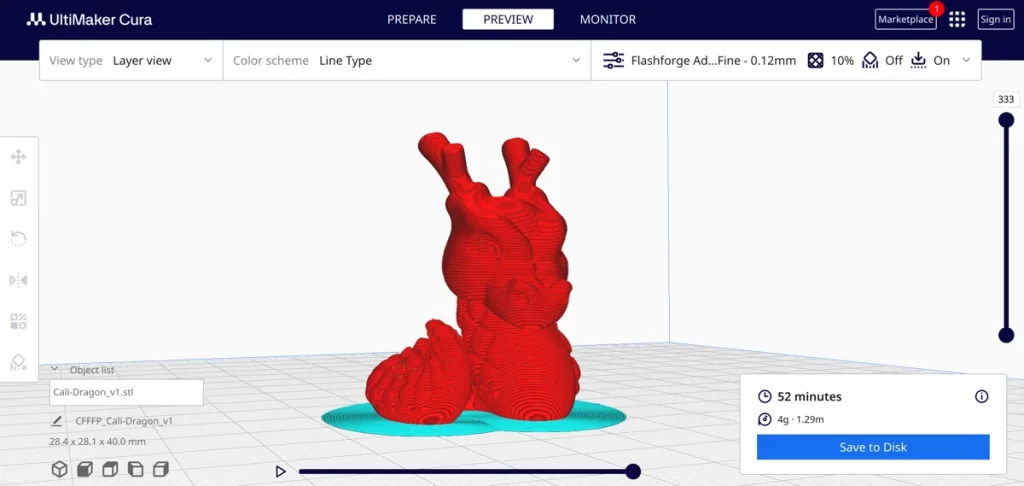

Software: Slicing with FlashPrint and Alternatives

While the proprietary FlashPrint 5 software has its merits, it also has some limitations, including only one profile per nozzle, which may not cater to the needs of experienced users seeking more control over their prints. Thankfully, users who require different slicing capabilities can opt for alternative software like Cura, Prusa Slicer, or Orca Slicer, each offering distinct features and potentially steeper learning curves.

Personally, I found FlashPrint to be somewhat cumbersome and rudimentary, which prompted me to switch to using Cura. However, this transition isn’t straightforward, especially for beginners. In Cura, you’re essentially starting from scratch with a blank profile, which can be intimidating for those who are not yet familiar with the intricacies of slicer settings and configurations.

In this article, you find my Cura settings: Flashforge Adventurer 5M Pro – Care Settings & Profile

Print Quality

The Adventurer 5M Pro truly stands out when it comes to print quality. After extensive calibration, the printer was able to produce several test objects with a print quality ranging from acceptable to perfect.

The first test prints of the finished sliced objects produced an almost perfect print quality. The precision and detail captured in these initial prints were impressive, indicating the machine’s high-resolution capabilities right out of the box.

However, as I transitioned to using Cura for slicing, I encountered the need for meticulous calibration of the print settings. Cura’s extensive customization options, while powerful, required a deeper understanding of the printer’s behavior and the interaction between the software and hardware.

After a period of trial and error, fine-tuning temperatures, print speeds, and retraction settings, I achieved a similarly high level of print quality. This calibration process was critical, as the Adventurer 5M Pro is sensitive to the nuances of slicer settings, which can significantly impact the final output.

Once dialed in, the printer consistently produced test objects with a print quality that ranged from acceptable to perfect. The layers were well-defined, the overhangs were clean, and the intricate details were sharply rendered, demonstrating the printer’s ability to handle complex prints with finesse.

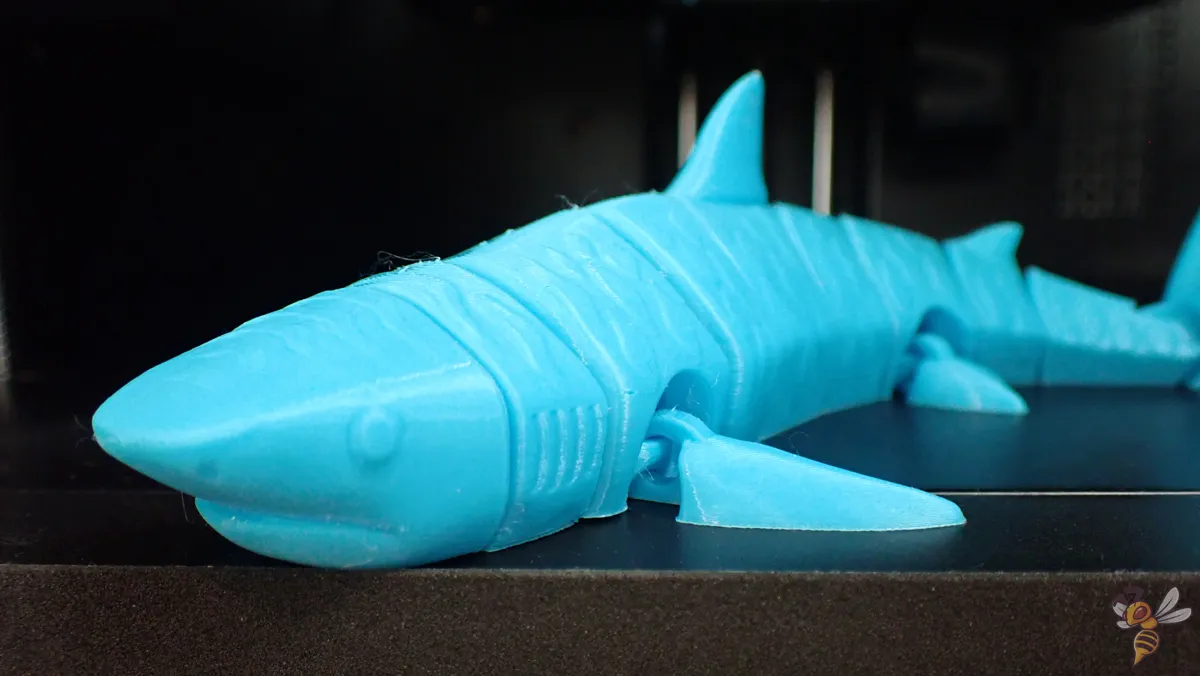

As a final test of the print quality, I embarked on printing two different models with moving parts, which are often challenging for any 3D printer due to their intricate design and the requirement for precision. The first test was a print in place flexi tiger shark, which required no support and had articulated joints right off the print bed. The second test was a print in place flexi humpback whale, similarly designed for movement without assembly.

Both models were printed almost perfectly. The flexi tiger shark’s joints moved smoothly without any post-processing, and the detail in the gills and fins was remarkable. Similarly, the flexi humpback whale’s articulation allowed for a fluid motion that mimicked the majestic swimming of its real-life counterpart. The layer adhesion was excellent, with no visible layer separation, and the surface finish was smooth, which is particularly important for moving parts.

These tests not only showcased the Adventurer 5M Pro’s capabilities in handling prints with moving parts but also highlighted the importance of proper slicer calibration. The results were a testament to the printer’s potential for producing high-quality, functional objects, making it a valuable tool for both prototyping and educational purposes.

The Adventurer’s Journey Concludes: Is the 5M Pro Worth It?

Upon thorough evaluation, it becomes evident that the Adventurer 5M Pro* is a top-tier choice for users in search of a specialized 3D printer for ABS and other warping-prone materials. Its high-speed printing capabilities are flawlessly executed, and despite some software issues, these can be overcome by switching to alternative slicers like Cura.

The Adventurer 5M Pro offers:

- Impressive blend of speed, quality, and versatility

- Worthy investment for both professionals and hobbyists

- Robust 3D printer that delivers on its promises

- Sure to impress with its performance

The Flashforge Adventurer 5M Pro is an FDM 3D printer that specializes in temperature-sensitive filaments such as ABS.

Build Volume: 220 × 220 × 220 mm

Speed: Standard 300 mm/s, maximum 600 mm/s

Extruder: Direct Drive Extruder

Print Bed: Textured PEI

Leveling: Fully automatic

Nozzle Temp.: 280 °C

Bed Temp.: 110 °C

Pros:

✓ Closed print volume

✓ Internal air filter

✓ High print speed

✓ Integrated camera

Cons:

× Relatively small build volume

× Filament holder on the back

Frequently Asked Questions

What materials can the Adventurer 5M Pro handle?

The Adventurer 5M Pro can handle a wide range of materials, including ABS, PLA, PETG, TPU, ASA, and carbon fiber reinforced PLA and PETG, providing versatility for various 3D printing needs.

Does the Adventurer 5M Pro support high-speed printing?

Yes, the Adventurer 5M Pro supports high-speed printing with a maximum print speed of 600 mm/s.

How user-friendly is the Adventurer 5M Pro?

The Adventurer 5M Pro is highly user-friendly, offering a large touchscreen interface, easy nozzle swaps, automatic leveling, and a ’10 Minute Quick Setup’ feature.

What is the print volume of the Adventurer 5M Pro?

The print volume of the Adventurer 5M Pro is 220 x 220 x 220 mm, providing a sizable space for printing projects.

Are there any limitations to the Adventurer 5M Pro’s software?

Yes, the proprietary FlashPrint 5 software has limitations, such as allowing only one profile per nozzle. However, users can use alternative slicers like Cura, Prusa Slicer, or Orca Slicer for more control over their prints.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.