- Wet Filament: Prevention, Symptoms & Drying - July 18, 2024

- Sovol SV08 – Best PrusaSlicer Settings & Profile - June 26, 2024

- Sovol SV08 – Best Orca Slicer Settings & Profile - June 26, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

Cura Coasting in the slicer Cura is a particularly useful function in 3D printing. You can use it to counteract printing errors such as stringing. The prerequisite for this is that you use the option correctly and make the appropriate settings.

How is Cura Coasting used and what should be taken into account?

Cura Coasting is used in most cases to avoid stringing. This gives the model a smooth surface while keeping misprints within limits.

To avoid stringing with Cura Coasting, it is important that you use the function correctly. This article will help you in this regard. You will learn here what you have to pay attention to when using Cura Coasting. This is especially useful for beginners who are not yet fully familiar with 3D printing and the functions of their device.

Table of Contents:

Test Prints

As with almost all changes to print settings, you need to test them somehow. If you don’t have a suitable test object ready to calibrate your 3D printer, you can see our favorites in this post and get to their respective download links:

Related Post:

Stringing Test | Best 3D Printer Calibration Objects

Cura Coasting

The benefit of Coasting in Cura is primarily to combat stringing. For this, it is necessary to perform the retraction cleanly during 3D printing. For this, it is crucial that the feeder has full control over the filament.

In concrete terms, this means that no more liquefied material drips out of the nozzle after the stop command. Otherwise, filaments could form at the start of the empty run during printing. This is a frequent problem, especially with Bowden systems. Sometimes this also leads to blobs or zits on the model.

With Cura Coasting, you can remedy this situation. Coasting in this context is comparable to a car shifted into neutral. In this case, the filament feed is stopped early before the end of the layer in order to take the pressure off the hotend.

The still liquid material that drips from the nozzle is then used to close the gap. If the actual idle cycle then begins, no more filament drips out of the nozzle. This automatically reduces the risk of stringing.

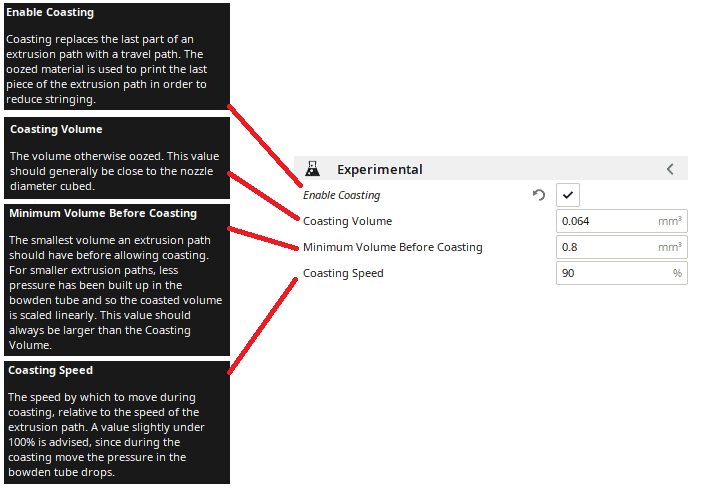

The most practical value so far has been 0.064 mm³ as the coasting volume. Experiment with this value by changing it in 0.01 mm³ steps and making test prints.

The setting “Minimum Coasting Volume Before Coasting” should be left at 0.8 mm³.

Application

With Cura, you work with the volume of the material when coasting. However, you are faced with the challenge of calculating yourself which value is suitable. Contrary to what Ultimaker states, the equation “nozzle size * speed” has also proven useful in this case – alternatively, it is recommended to take the nozzle size to the power of three.

However, you should not accept this information without first checking it. It always depends on the used filament and your printer for which value you decide, otherwise under-extrusion will occur with too much coasting.

In this respect, use test prints to avoid mistakes. Sometimes it can take a little time at the beginning until you find the right setting for you.

If you set the coasting too high, your model will have small holes at the end of the layers. In this case, you do not have enough material to fill all the layers. This is usually already displayed in the slicer software. The advantage of this is that you can detect the problem before printing and take countermeasures in good time.

How to proceed if the Cura Coasting has no effect?

If you make the necessary settings and stringing still occurs afterward, you should take a close look at the nozzle of the 3D printer. If this is damaged or pitted, for example, it can also lead to errors. In this case, it is often no longer possible for it to retain the liquefied material – even coasting can no longer help. You can’t avoid replacing the part in this case.

Even if the nozzle of the 3D printer is clogged, there may be flow problems. In this case, however, you will not have to replace the spare part. It is sufficient to clean the nozzle. If you want to avoid this scenario, simply clean the nozzle after each print. In this way, you ensure that you can put your device into operation immediately if necessary. This saves you long waiting times.

Invest in a high-quality 3D printer

If you want to achieve good results with your device, you need to invest in good quality. This will ensure that you have a variety of options and features for editing your model. Also, more expensive products tend to be easier to use and less likely to have printing problems and issues with settings like Cura Coasting.

You should also opt for a high-quality printer if you produce models for professional use. In this case, the printer will be used frequently and intensively. If it is a robust device, you can be sure that it will last for a long time. This saves you from having to buy a new one in the near future and, ultimately, from additional expenses.

With a “good” 3D printer, you also have the advantage that the device delivers the best results even in mass production. So you don’t have to expect any compromises in terms of quality.

In this context, however, it should also be noted that high-quality models are somewhat more expensive. In this case, you have to accept expenses starting at 500 dollars. Printers for professional use can even cost more than 700 dollars.

If, on the other hand, you are only looking for a model with which you can familiarize yourself with 3D printing without a large financial investment, a cheaper product is recommended. However, you will have to settle for limited functionality in this case. However, users nowadays have the option to upgrade their printer if necessary. For example, you can retrofit it with a heated print bed. This gives you more options when it comes to processing the filaments.

Related Questions

How can defects in 3D printing be detected in time?

You don’t have to rely solely on your know-how and the settings in the slicer software when it comes to the quality of the 3D print. In this case, be sure to use test prints. You can use them to see if errors creep in when printing the material. You can also detect stringing in good time this way. If the result does not meet your expectations, you can make changes to the settings in good time.

Under no circumstances should you go into mass production without this measure. This applies all the more if you have not yet worked with the filament in question. You often don’t know how your printer will react to it. If several products are damaged, you as an entrepreneur may incur losses. Counteract this scenario by proceeding carefully.

What do beginners have to pay attention to?

If you’re a beginner when it comes to 3D printing, there are a few things you need to consider. First of all, you should choose a device that suits you and your needs. Then, familiarize yourself with the printer’s main features and settings.

Make test prints at the beginning to detect errors in time. This is especially the case if you are not too familiar with the filament in question. Also make sure in advance that your device is capable of processing the material of your choice. Beginners should rather use PLA at the beginning.

The correct alignment of the print bed is essential for the success of a print. In this regard, several attempts are often necessary, especially at the beginning. If in doubt, install a leveling sensor – especially if you want to rely on automatic leveling of the print bed for 3D printing.

Conclusion – Counteract Misprints

If there are errors in your 3D print, this is first of all a great annoyance for you. In this case, the model may become unusable. You may then have to print it out again.

For you, this is associated with considerable additional effort and expense. With Cura Coasting, you can counteract this scenario. If you follow the instructions above, stringing in 3D printing will soon be a thing of the past.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.