- Wet Filament: Prevention, Symptoms & Drying - July 18, 2024

- Sovol SV08 – Best PrusaSlicer Settings & Profile - June 26, 2024

- Sovol SV08 – Best Orca Slicer Settings & Profile - June 26, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

Wet filament leads to printing errors. I will show you how to prevent, identify and dry wet filament.

Table of Contents:

The Problem: Hygroscopy

Some filaments such as PLA and ABS only absorb moisture from the air slowly and in small quantities. If they are stored open, they are saturated after a few days, which means that they will not absorb any more moisture.

Filaments such as PETG, on the other hand, absorb moisture more quickly and in larger quantities. Here, saturation occurs within a few days or even within a day.

Very hygroscopic filaments such as nylon absorb moisture extremely quickly and in large quantities. Here, saturation can occur after just a few hours.

The more moisture a filament contains, the more printing errors occur. It is therefore best to prevent the filaments from absorbing moisture in the first place.

Prevention: Dry Storage

The correct storage method for preventing wet filament depends on how hygroscopic the filament is. The first rule is to keep the filament in the vacuum packaging in which it was delivered until it is used for the first time.

Filaments that do not absorb moisture as quickly like PLA or ABS do not necessarily need to be stored dry after the first use, as long as they are used up within a few weeks. It is sufficient to protect them from direct sunlight. Only when they are stored for longer should they also be protected from other environmental factors.

The most effective and cost-effective method of storing filament safely and dryly is to use silica gel in an airtight container. This can be a plastic box with a seal or a vacuum bag, for example.

The silica gel absorbs the humidity in this container and thus protects the filament from moisture.

All other filaments should be stored dry at all times as long as they are not being printed.

Some filaments such as nylon or PVA should even be kept dry during printing, especially if the humidity is very high and/or the printing project takes several hours.

But how do you notice that the filament is wet and that printing errors may be due to this? What are the symptoms of moisture in the filament and when should you start active drying?

Symptoms: Identifying Wet Filament

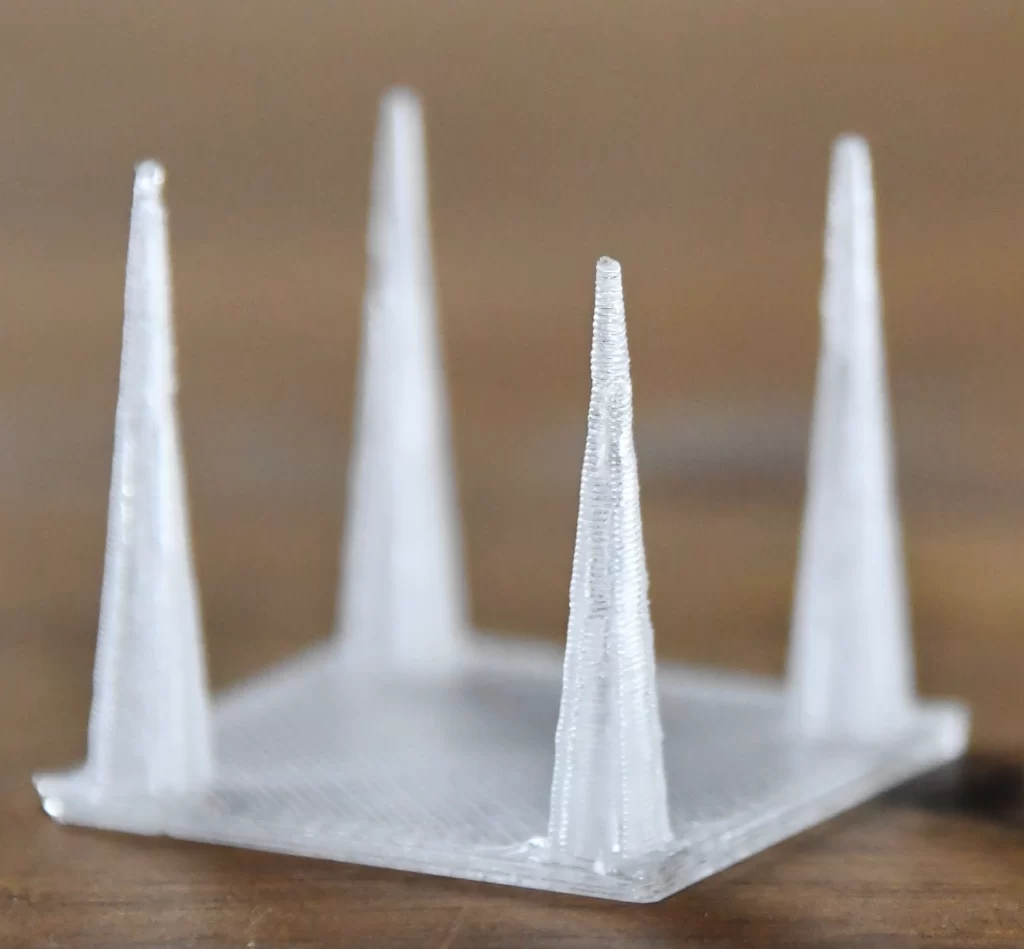

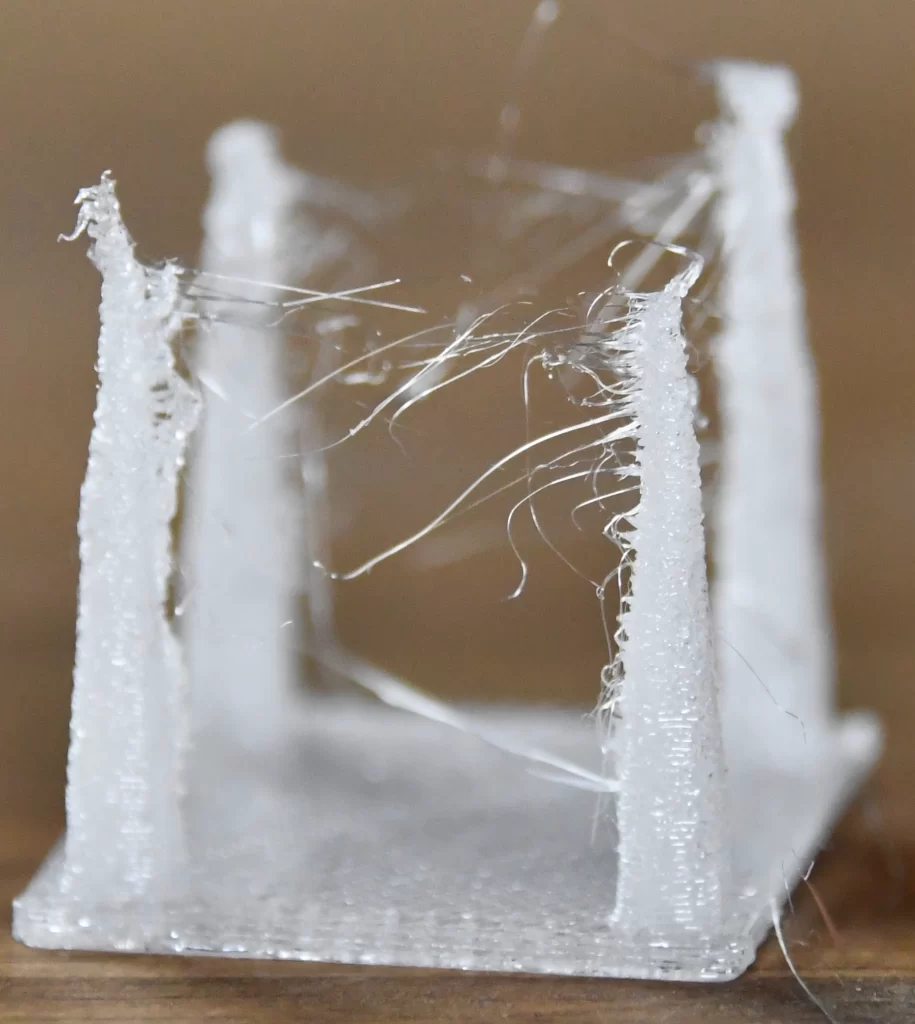

Regardless of which filament you are working with, there are a few symptoms that can indicate moisture or too much moisture in the filament. The first symptom is stringing, a printing error that often indicates too much moisture in the filament.

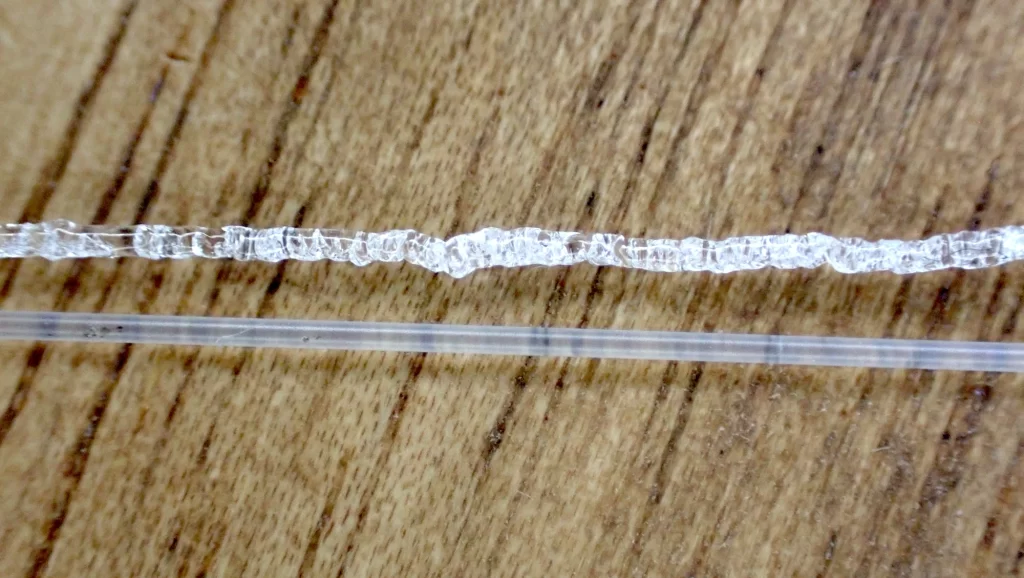

With filaments that are highly hygroscopic such as PETG or nylon, other symptoms can occur such as irregular layers. In extreme cases with nylon, PVA and other highly hygroscopic filaments, moisture is already visible when the filament is extruded from the nozzle. This can result in hissing noises, vapor and bubbling.

However, the further course of action is only clear in the case of serious symptoms. If the filament steams and forms bubbles during extrusion, it is clearly too moist and needs to be dried.

If you only observe stringing, moisture can be a possible cause, but there are also many other reasons that can lead to stringing.

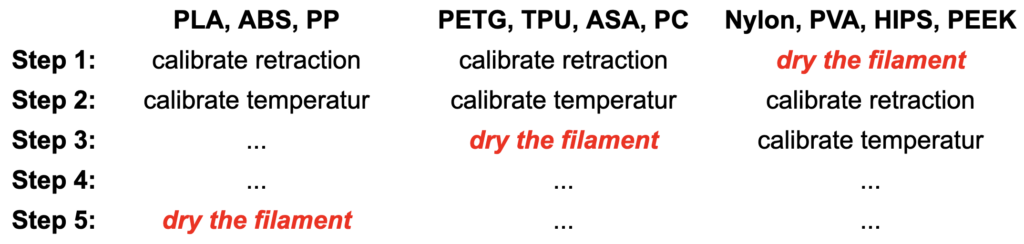

The priority for drying the filament varies depending on the filament used. With PLA and ABS, other measures to prevent stringing should be taken first, such as calibrating the retraction or the printing temperature. Drying has a lower priority.

However, the more hygroscopic the filament is, the more likely it is that moisture in the filament is the cause of the stringing, making drying a higher priority.

If moisture in the filament is not the cause of your printing errors, or you generally want to get perfect results every time as quickly and easily as possible, you should take a look at my 3D printing course. In over 60 lessons, you’ll learn everything you need to know about 3D printing!

3D printing can be difficult – especially in the beginning. Many beginners struggle with print errors, poor print bed adhesion, or don’t know how to properly set up the slicer.

That’s why I created an online course to get everyone up to my expert level and as quickly as possible.

The course covers everything you need to know about FDM 3D printing to get perfect results every time. Click the link below to learn more about the content and what to expect (and don’t worry: there are no tests! Learn at your own pace, completely stress-free).

Drying: Best Methods

The simplest but least effective method of drying wet filament is passive drying with silica gel in an airtight container – in other words, just like storage. With this method, you can only extract small amounts of moisture from the filament over a certain period of time. If you suspect that your PLA or ABS filament may be wet, you should first dry it with silica gel for a few days before resorting to an active drying method and possibly wasting money.

For very wet filament, however, active drying methods are necessary to avoid printing errors. The best active methods are either a normal oven or a specialized filament dryer.

The problem with a kitchen oven is that you can never be completely sure whether there will be a temperature overshoot during heating or whether the temperature is generally very inaccurate. If this is the case, it can quickly happen that your filament melts inside.

So wait some time until the temperature has stabilized before you put the filament in. Apart from that, this method is a good improvised way to get quick results.

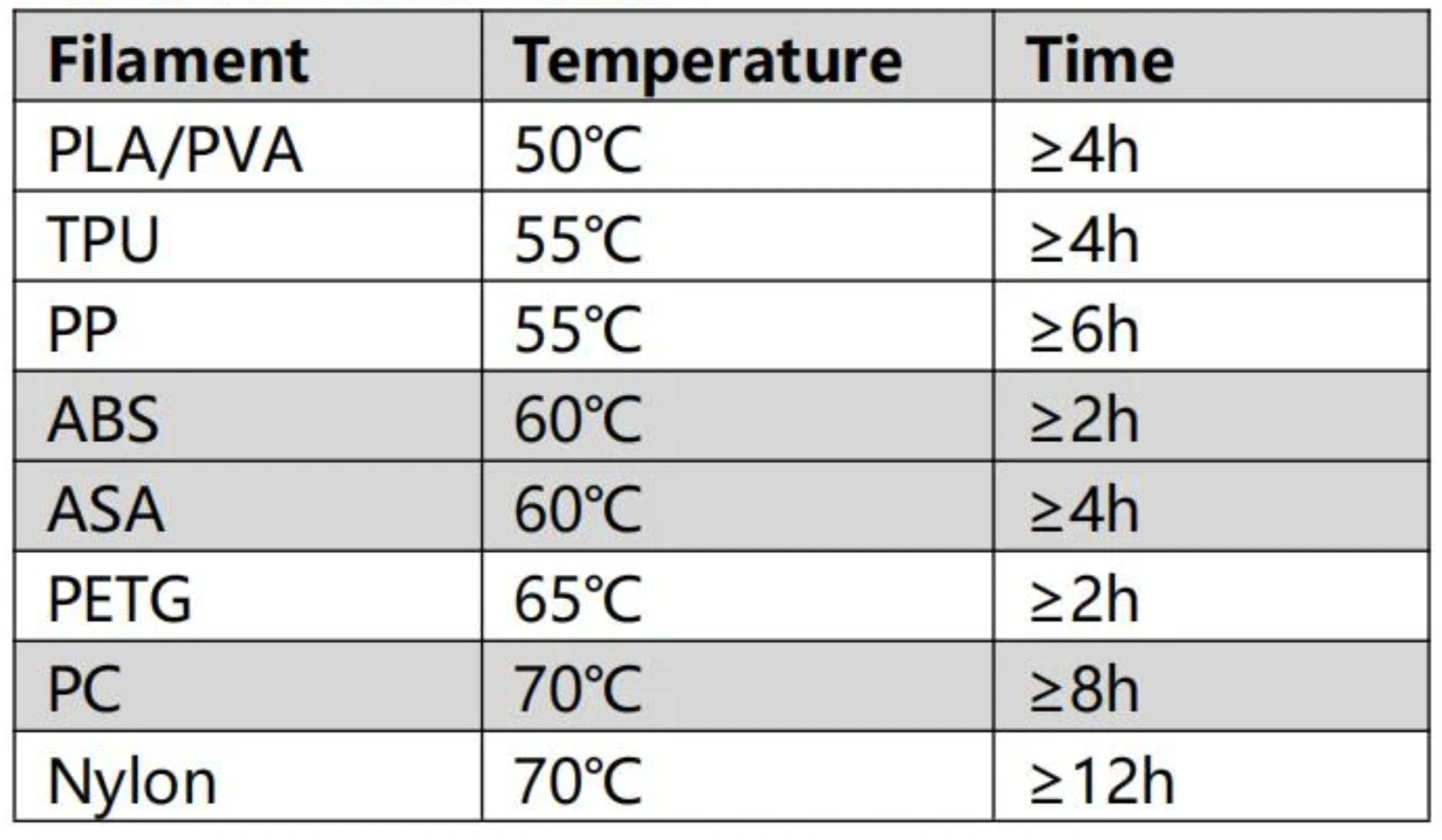

Here are my recommended temperatures and time periods for drying different filaments in a kitchen oven:

However, you can dry moist filament faster, safer and better with a filament dryer.

As an example, I have here the NT1 filament dryer from Fixdry*. Two spools fit into this filament dryer.

Such filament dryers were specifically designed for this purpose and can dry the filament fast and reliably. Temperature overshoots, which can occur in an oven, also do not occur here.

The Fixdry NT1 is a filament dryer that can fit 2 filament spools at once, can dry while printing and can be set to max. 70 °C and 48 h.

With the NT1 filament dryer, you can set temperatures of up to 70 °C and a maximum drying time of 48 hours. This means that all filaments are covered.

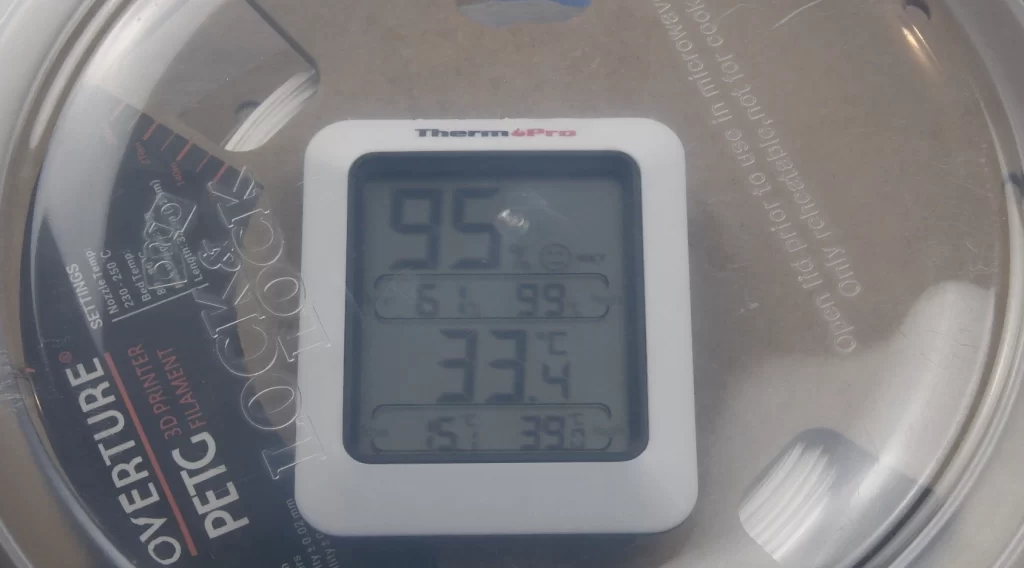

To demonstrate the drying effect, I stored PETG filament in this airtight container with water in my attic for a few weeks. In the summer, the temperature regularly exceeds 30°C, turning the container into a steam sauna.

As you can see in the picture, the filament was stored in a very humid environment. This led to very wet filament, as evidenced by the test print images shown earlier. Now, let’s put the filament in the dryer and see if the results improve.

As expected, the drying process eliminated all symptoms of wet filament, just as it should. To ensure this dryness is maintained for future prints without the need for active drying, we are testing the effectiveness of a new storage method.

I have now placed the filament in an airtight container with silica gel. After a week, we will test the print results again. As hoped, the outcome is perfect once more!

Summary

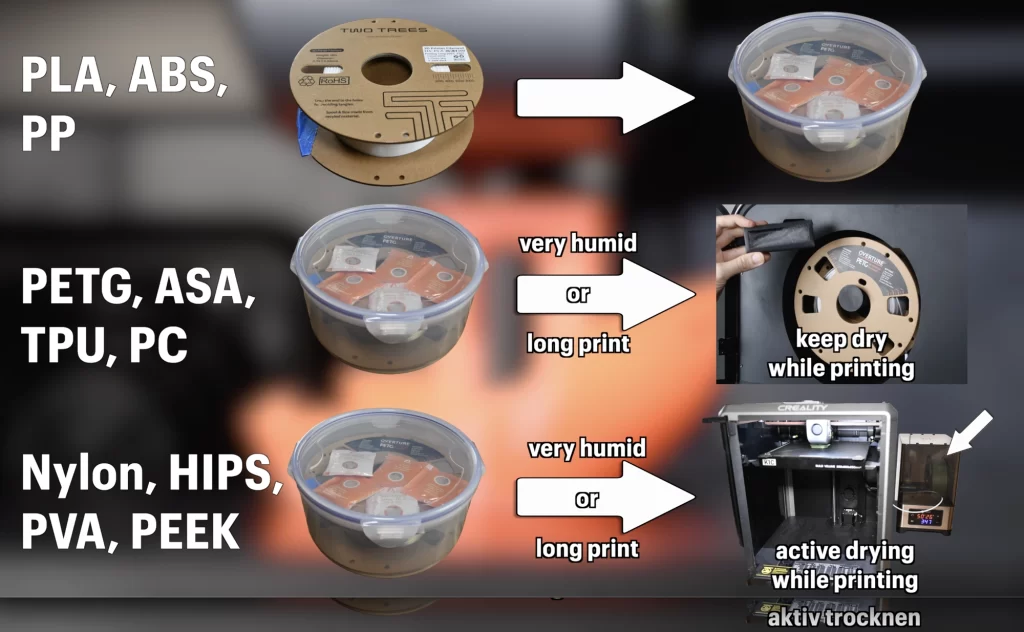

To summarize, you can use the somewhat hygroscopic filaments PLA, ABS and PP for a few weeks without special storage or drying. After that, you should store them in a dry place. Active drying is not necessary for these filaments in most cases and is only advisable if you have ruled out all other causes of printing errors.

All other filaments must be stored dry immediately and after each use. The highly hygroscopic filaments PETG, ASA, TPU and PC should also be kept dry during printing in very humid ambient conditions or for print jobs that last longer than a few hours. Active drying is only necessary if printing errors occur, but then as one of the first measures.

The extremely hygroscopic filaments nylon, HIPS, PVA and PEEK should even be actively dried during printing in order to avoid printing errors. If you are only using HIPS or PVA as a support material, this is not absolutely necessary, as printing errors such as stringing are usually irrelevant here.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.