- Z Seam | How to Hide & Avoid | Cura & PrusaSlicer - April 20, 2024

- Qidi Tech Q1 Pro – Best Orca Slicer Settings & Profile - April 9, 2024

- Creality Ender-3 V3 Review – Will CoreXZ be the New Trend? - March 27, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

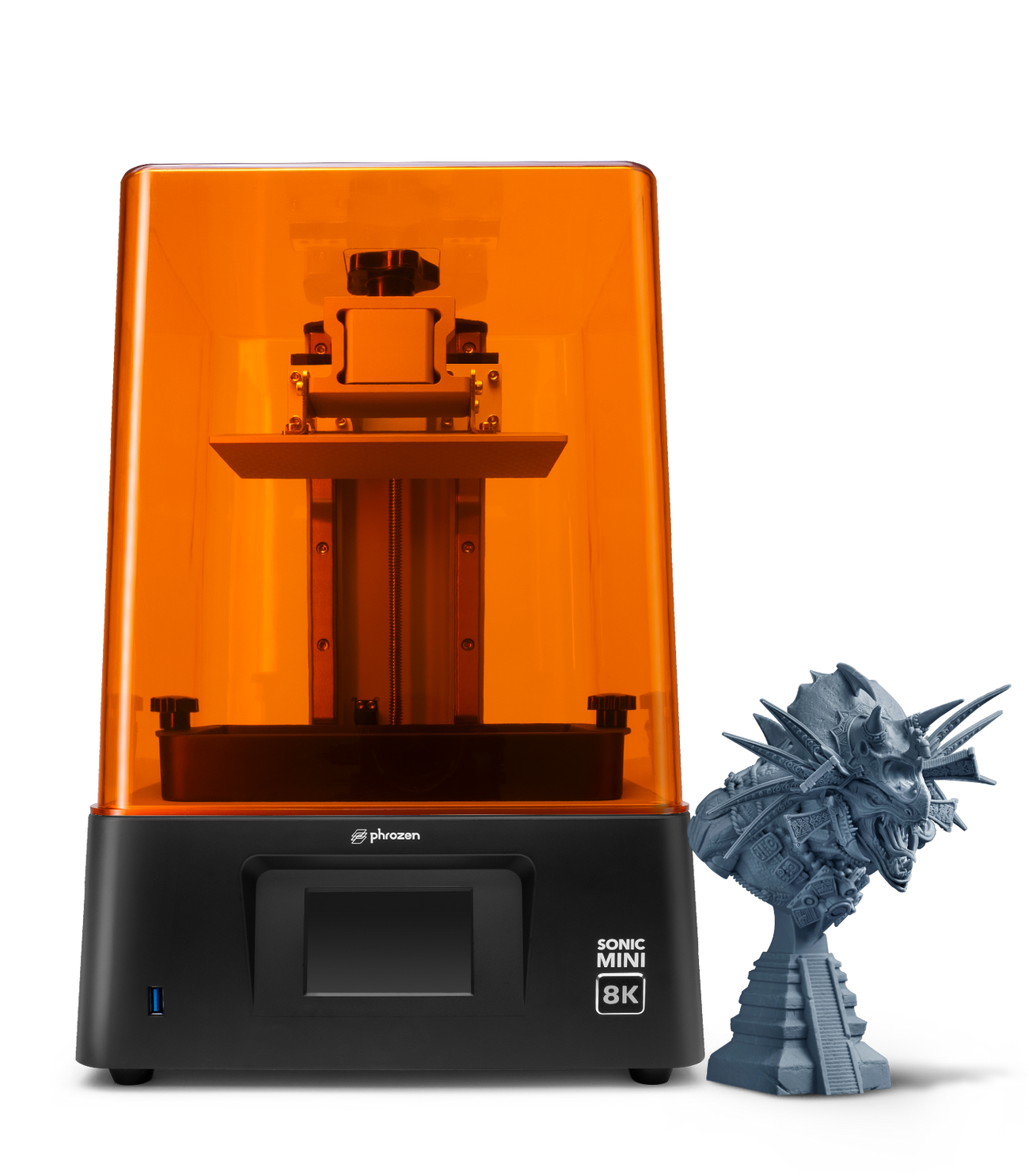

It wasn’t that long ago when 4K became the impressive new standard for resin 3D printers. 50 microns and the move to 35 microns was amazing and opened up whole new possibilities. Now, with the Sonic Mini 8K*, a whole new era seems to be dawning as it undercuts the previous XY resolutions even further with its 22 µm.

The Phrozen Sonic Mini 8K has a print volume of 165 x 72 x 180 mm, an 8K LCD screen and thus comes to an XY resolution of 22 µm (1152 ppi). With a layer thickness of 0.01 mm, extremely precise details can be printed that are equivalent to the quality of fine injection molded parts.

In this hands-on test and detailed review, you’ll find out how the print quality really is in the end, what features the Sonic Mini 8K has, and how user-friendly it is.

There is a successor available by now. Here is my review of it: Phrozen Sonic Mini 8K S Review – Better than the Original?

As one of the first resin 3D printers, the Sonic Mini 8K has a pixel size below 25 μm.

LCD resolution: 8K (7500 × 3240)

LCD size: 7″

XY-resolution: 22 µm

Layer height: 0,01-0,30 mm

Build volume: 165 × 72 × 180 mm

Speed: max. 80 mm/h

Pros:

✓ Very accurate

✓ Easy to use

✓ Short curing times

✓ Double z-axis

Cons:

× Small print volume

× No air filter

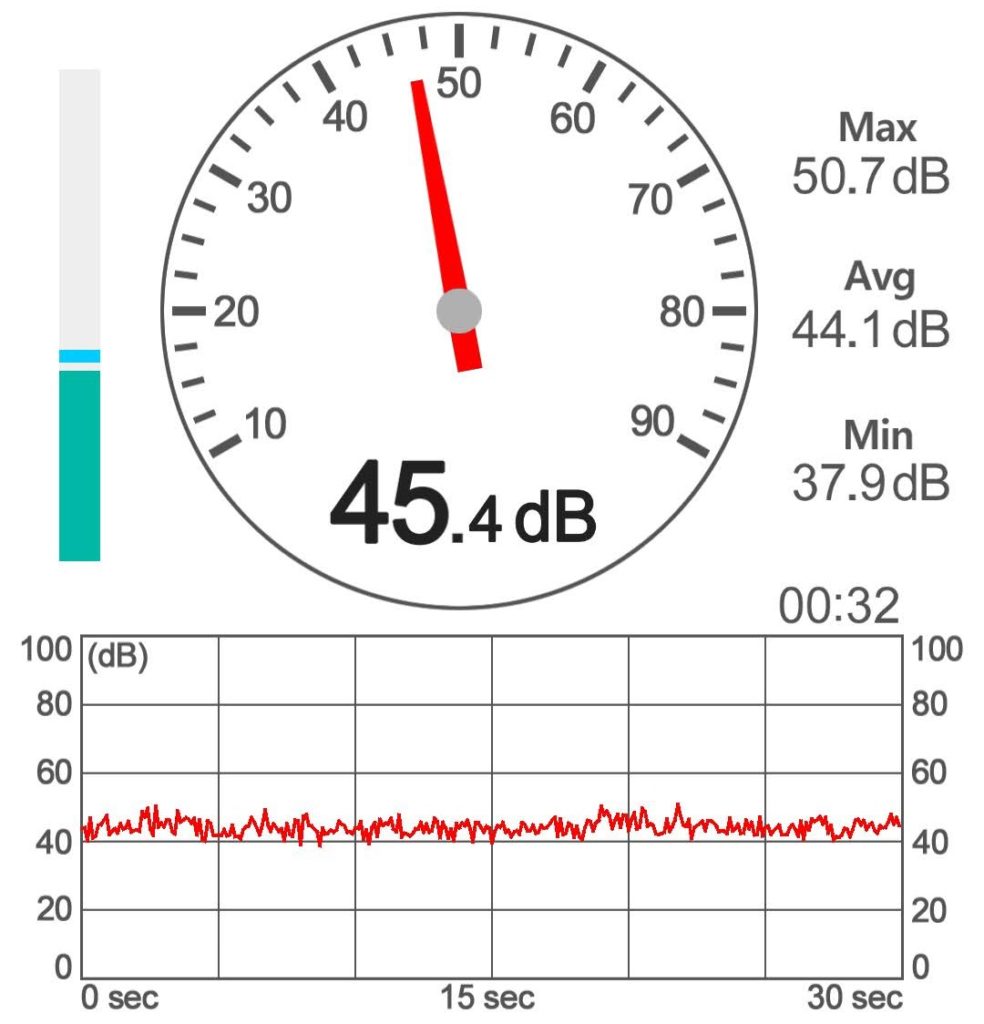

× Somewhat loud with max. 45 dB

Table of Contents:

- 1 Key Takeaways

- 2 Who Should Buy the Sonic Mini 8K?

- 3 Pros & Cons> Sonic Mini 8K Review

- 4 Technical Specifications > Sonic Mini 8K Review

- 5 Scope of Delivery > Sonic Mini 8K Review

- 6 Assembly > Sonic Mini 8K Review

- 7 Features > Sonic Mini 8K Review

- 8 8K Resin > Sonic Mini 8K Review

- 9 Noise Level > Sonic Mini 8K Review

- 10 Print Speed > Sonic Mini 8K Review

- 11 Operation > Sonic Mini 8K Review

- 12 Print Quality > Sonic Mini 8K Review

- 13 Slicer > Sonic Mini 8K Review

- 14 Useful Accessories > Sonic Mini 8K Review

- 15 Is the Sonic Mini 8K Worth It?

Key Takeaways

- 22 µm XY resolution thanks to 8K LCD screen (!)

- 0.01 to 0.3 mm layer thickness

- Sturdy construction, no vibrations

- Very easy operation and assembly

- Compatible with ChiTuBox

Who Should Buy the Sonic Mini 8K?

The Sonic Mini 8K is suitable for anyone for whom accuracy is a top priority. The difference between the 22 µm resolution of the Sonic Mini 8K is only noticeable in the finest details compared to a 35 µm resolution like the Mars 3 for example. For hobbies like painting miniatures or printing jewelry, the higher price of the Sonic Mini 8K is therefore definitely justified.

Pros & Cons

> Sonic Mini 8K Review

PRO:

- Extremely accurate

- Medium print volume

- Easy operation

- As good as no assembly

- Very uncomplicated print bed leveling

- Compatible with ChiTuBox

- Good print bed adhesion

CON:

- Somewhat loud with approx. 45 dB due to the fans of the powerful light source

Technical Specifications

> Sonic Mini 8K Review

- LCD: 7.1” mono LCD screen

- Light source: Linear Projection LED Module

- XY resolution: 22 µm (1152 ppi)

- Layer thickness: 0.01 – 0.30 mm

- Printing speed: max. 80 mm/h

- Operation: 3.5” touch screen

- Slicer: ChiTuBox

- Connectivity: USB

- Size: 290(L) x 290(W) x 420(H) mm

- Print volume: 165(L) x 72(W) x 180(H) mm

- Weight: 15 kg

As one of the first resin 3D printers, the Sonic Mini 8K has a pixel size below 25 μm.

LCD resolution: 8K (7500 × 3240)

LCD size: 7″

XY-resolution: 22 µm

Layer height: 0,01-0,30 mm

Build volume: 165 × 72 × 180 mm

Speed: max. 80 mm/h

Pros:

✓ Very accurate

✓ Easy to use

✓ Short curing times

✓ Double z-axis

Cons:

× Small print volume

× No air filter

× Somewhat loud with max. 45 dB

Scope of Delivery

> Sonic Mini 8K Review

Except for 3D printer resin, the Sonic Mini 8K comes with everything you need to get started with your first test prints.

For the resin, I would recommend the 8K resin from Phrozen, which was specially developed for this printer. I tested the printer with this resin. Whether you can achieve the overwhelming 8K accuracy with a “normal” 3D printer resin such as the plant-based resin from Anycubic* is unclear – but I somewhat doubt it.

No matter which resin you get, you should definitely get some more disposable resin filters* or a reusable resin filter*. When you pour the used resin back into the bottle, make sure no partially or fully cured resin pieces end up in the bottle. You will also need isopropyl alcohol* for cleaning.

Normally, the scope of delivery of resin 3D printers also includes basic equipment for personal protective equipment. This includes disposable gloves and masks. The Sonic Mini 8K only comes with a pair of disposable gloves and no masks. The developers probably figured that everyone has disposable or FFP2 masks available by now anyway, and by omitting them they avoid some cost and unnecessary waste.

Included with the Sonic Mini 8K are the following items:

- After Sales Service Card

- a pair of disposable gloves

- Power cable

- Plastic funnel

- Metal and plastic scraper for print plate and resin tank

- Tools required for assembly

- USB stick with test models, slicer software and instructions

Assembly

> Sonic Mini 8K Review

Assembling the Sonic Mini 8K is extremely easy. Unlike FDM printers, most resin 3D printers come fully pre-assembled.

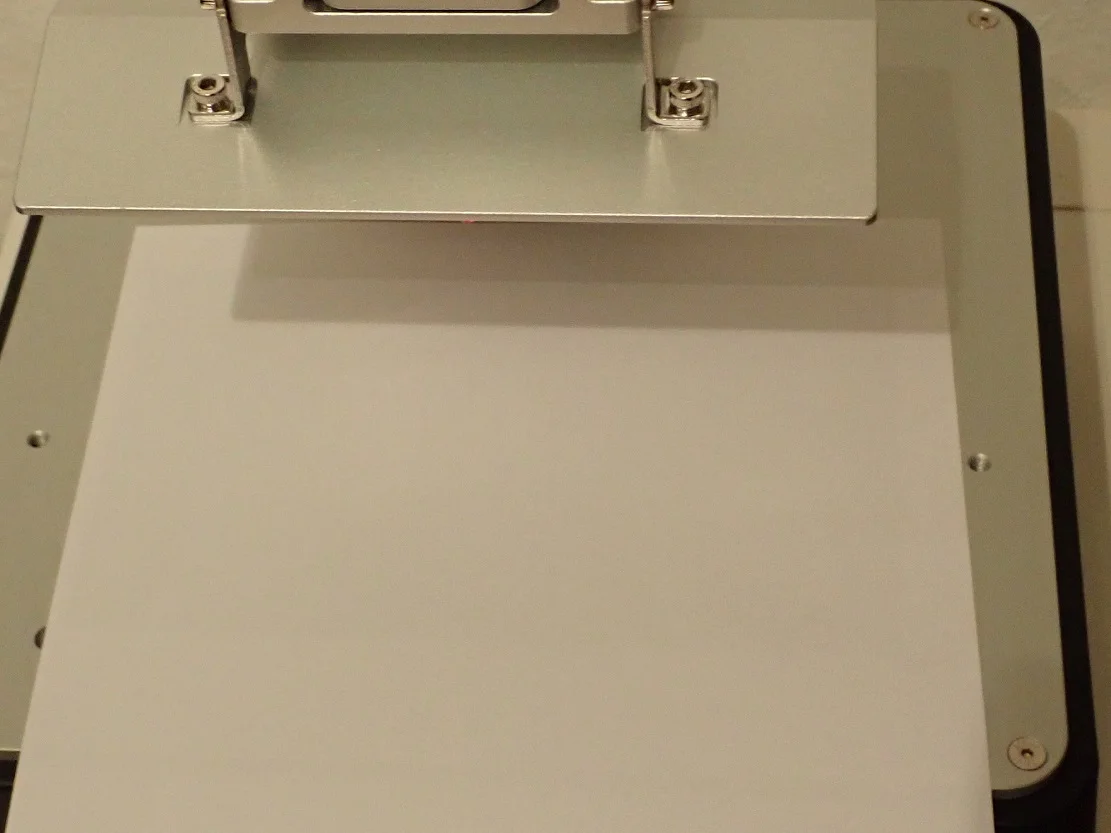

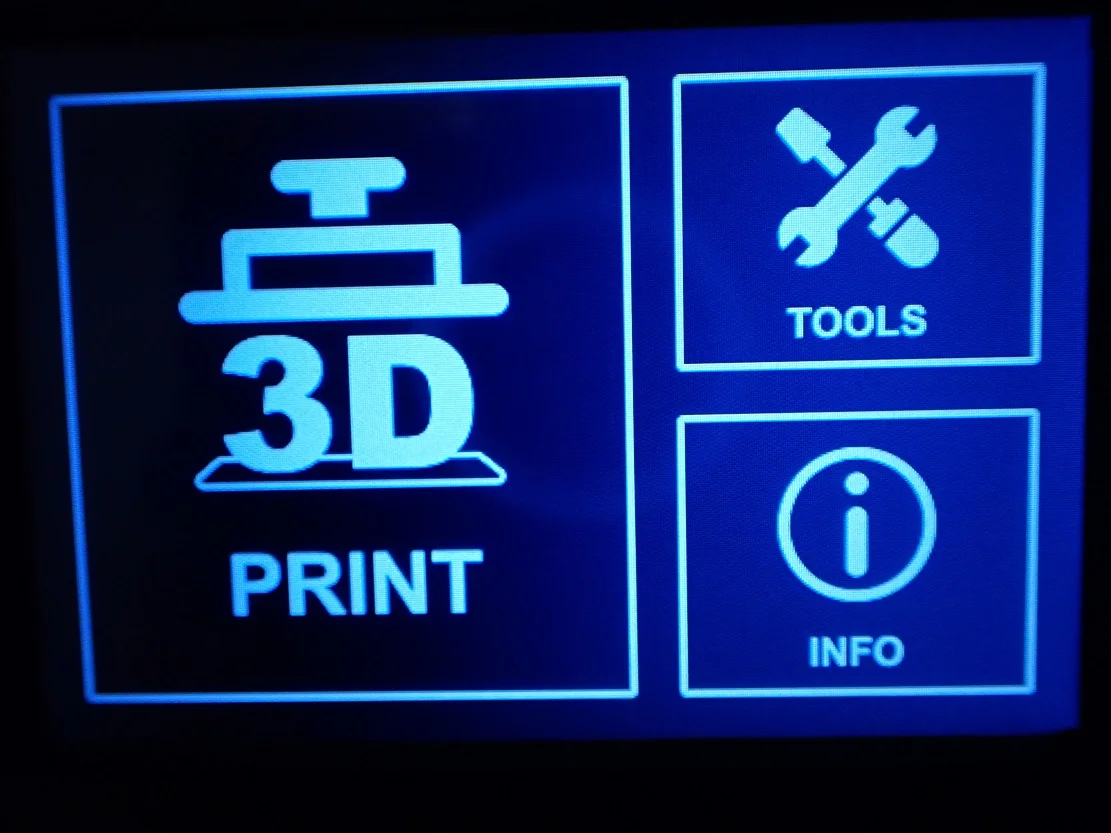

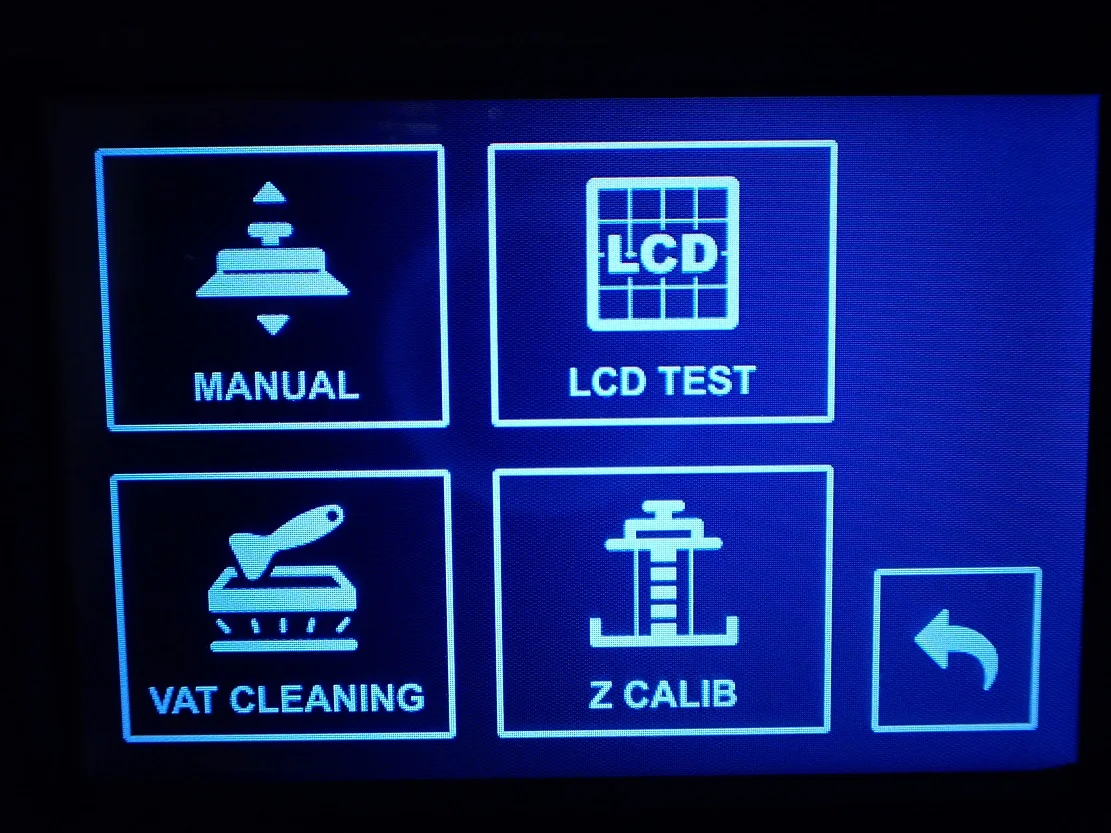

The only thing you need to do before your first print is to test the LCD screen and calibrate the Z-axis or level the print bed.

LCD Screen Test: There is an LCD test in the printer menu. In this test, a certain pattern appears on the LCD screen for a certain amount of time. If you don’t see any defects, the LCD screen is fine. However, it is best to use the protective cover for this, as the UV radiation is bad for your eyes!

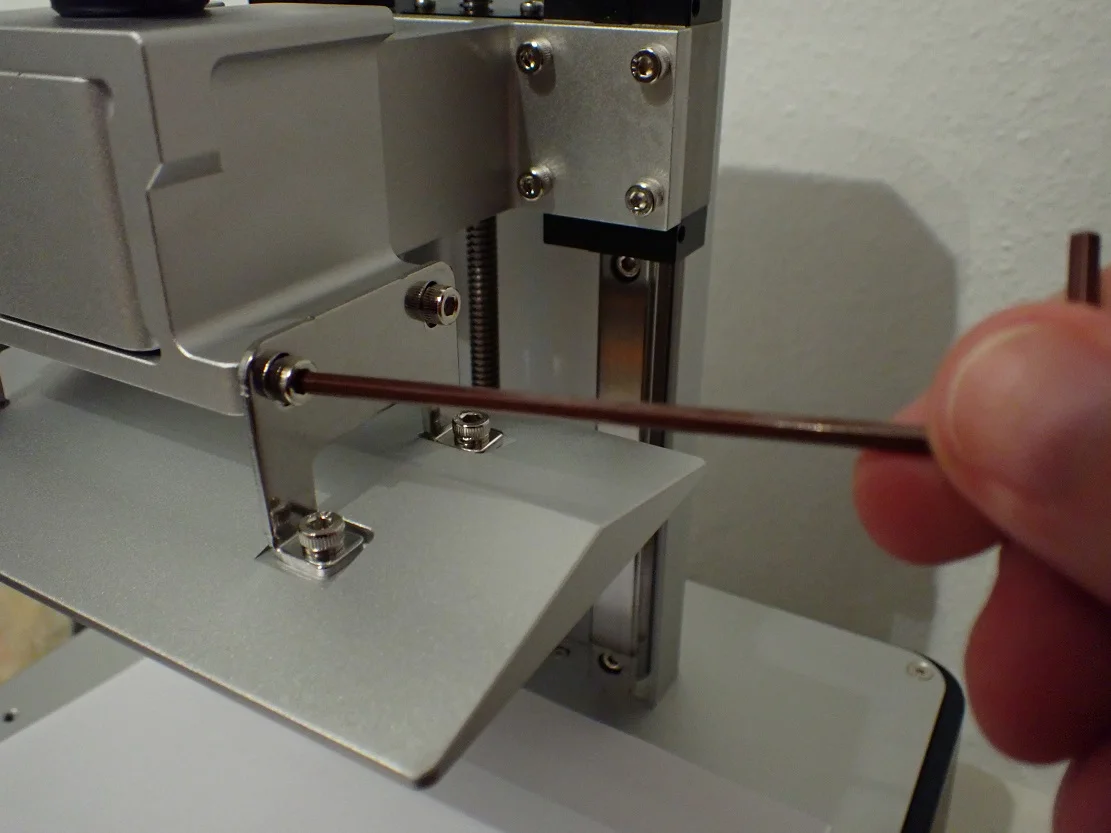

Z-axis calibration / print bed leveling: Leveling the print bed and calibrating the Z-axis at the same time is easier than ever with modern resin 3D printers. On most printers, like the Sonic Mini 8K, you need to loosen the print bed by the screws on the mount, place a piece of normal paper on the LCD screen, move the Z-axis to the home position and then tighten the screws again.

This procedure creates a small gap between the print bed and the LCD screen equal to

the thickness of the piece of paper. By tightening the print bed in position, it is perfectly leveled at the same time.

Recommendation: Before you install the resin tank, fill it with resin and start your first print, I would recommend wetting the FEP foil at the bottom of the resin tank a little bit with a PTFE lubricant* (1 drop is enough). In the past, I often had the case that the 3D print stuck to the FEP foil and not to the print bed. It may be that this is not necessary with the Sonic Mini 8K and the 8K resin, but I have not tried it yet as it has become a standard in my process.

Features

> Sonic Mini 8K Review

Almost all features of the Sonic Mini 8K* are designed for high accuracy. Besides the spectacular accuracy of 22 μm, there are no special features that stand out from other 3D printers. But it shines in exactly the points that enable the high accuracy!

8K LCD Screen

The standard for resin 3D printers for the hobbyist sector was or is actually still around 35 to 40 μm with 4K LCD screens. A few years ago, 50 μm was still the norm and now a whole new level of accuracy is starting with the Sonic Mini 8K.

The LCD screen of the Sonic Mini 8K is 7.1 inches and has a resolution of 7500 x 3240 pixels. The area of the screen is 165 x 72 mm, resulting in an accuracy of 1152 ppi or 22 μm.

Even the Elegoo Mars 3 does not reach this accuracy. It “only” has a resolution of 4098 x 2560 pixels on an area of 143 x 89.6 mm, which gives it a resolution of 35 μm.

With the high resolution of the Sonic Mini 8K, extremely detailed models can be printed that can keep up with the finest injection molded parts. Even without edge smoothing, you can see no or extremely few steps with the naked eye, and with moderate edge smoothing, the object is nearly perfect.

I have already tested many of the modern resin 3D printers like the Elegoo Mars 3 or the Anycubic Photon Mono X 6K. The accuracy of the Sonic Mini 8K still surprised me!

Laser Engraved Print Bed

Good print bed adhesion is essential for successful 3D printing. The various manufacturers are always trying to increase the adhesion of the printing plate with better and newer methods.

With resin 3D printers, you usually find a roughened surface in one way or another. Phrozen has chosen a laser engraved print bed for the Sonic Mini 8K. Due to the laser engraving, the printing plate has many small engraved lines that greatly increase the surface.

This gives the cured resin more surface to adhere to. In none of my test prints did I have any problems with print bed adhesion and the surface is still robust enough not to be easily scratched by the spatula.

Linear Projection LED Module

To produce the high accuracy of the Sonic Mini 8K, it needs a powerful light source and a sophisticated system for exposure. Phrozen has chosen an LED module with a linear projection for this purpose.

Normally, the light from the LED is projected directly onto the resin via the LCD screen. With the Sonic Mini 8K, the light is directed via a highly reflective mirror to get the light beams hitting the LCD screen as parallel as possible. This allows even better accuracies and the accuracy is much more homogeneous over the entire printing area.

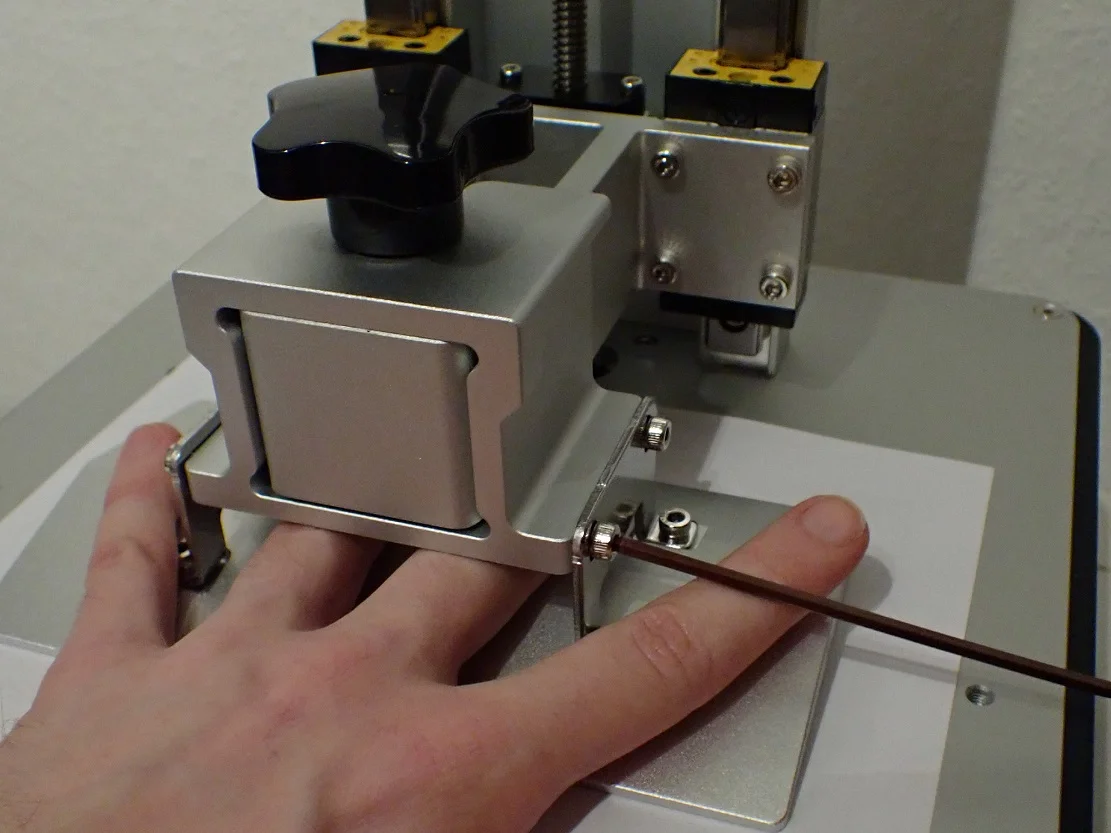

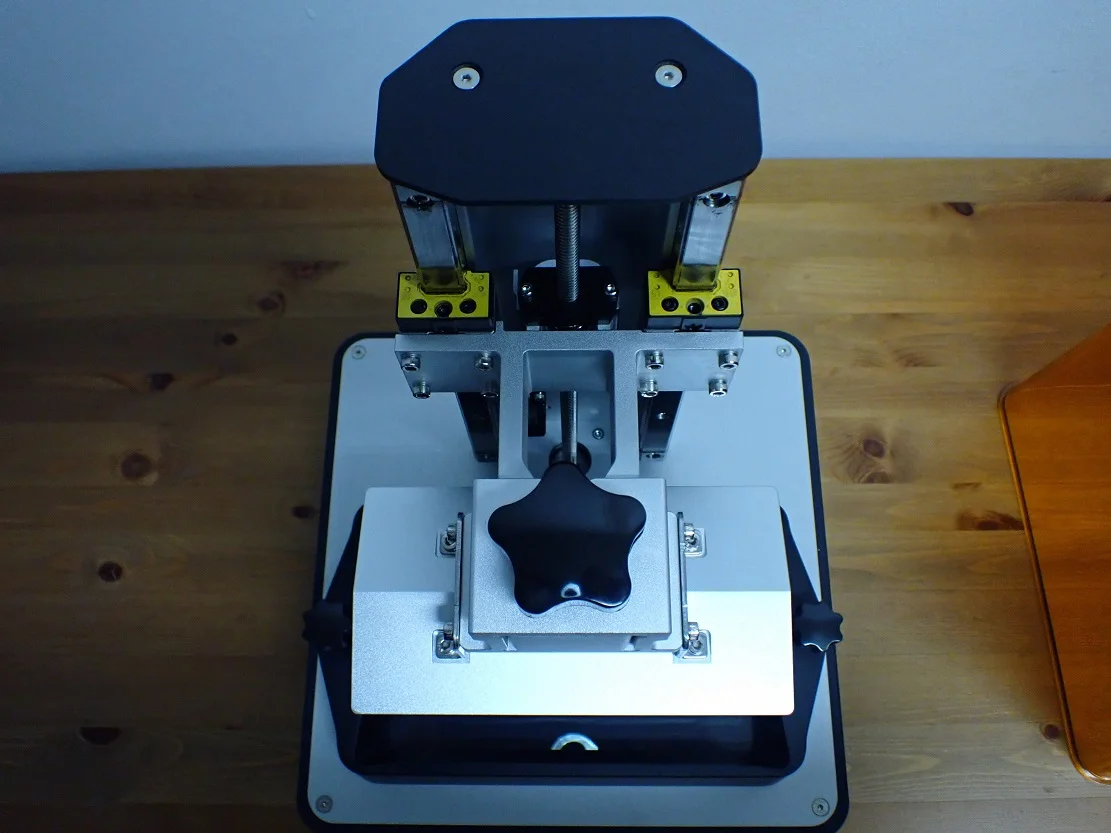

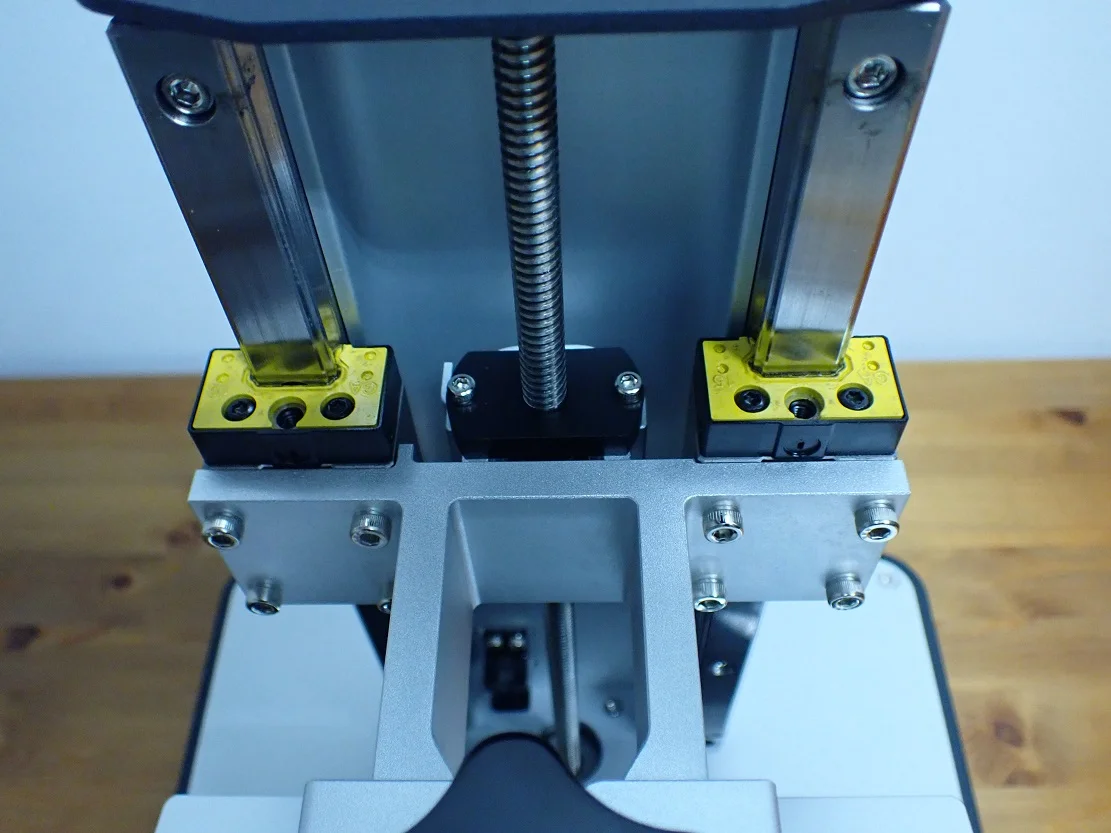

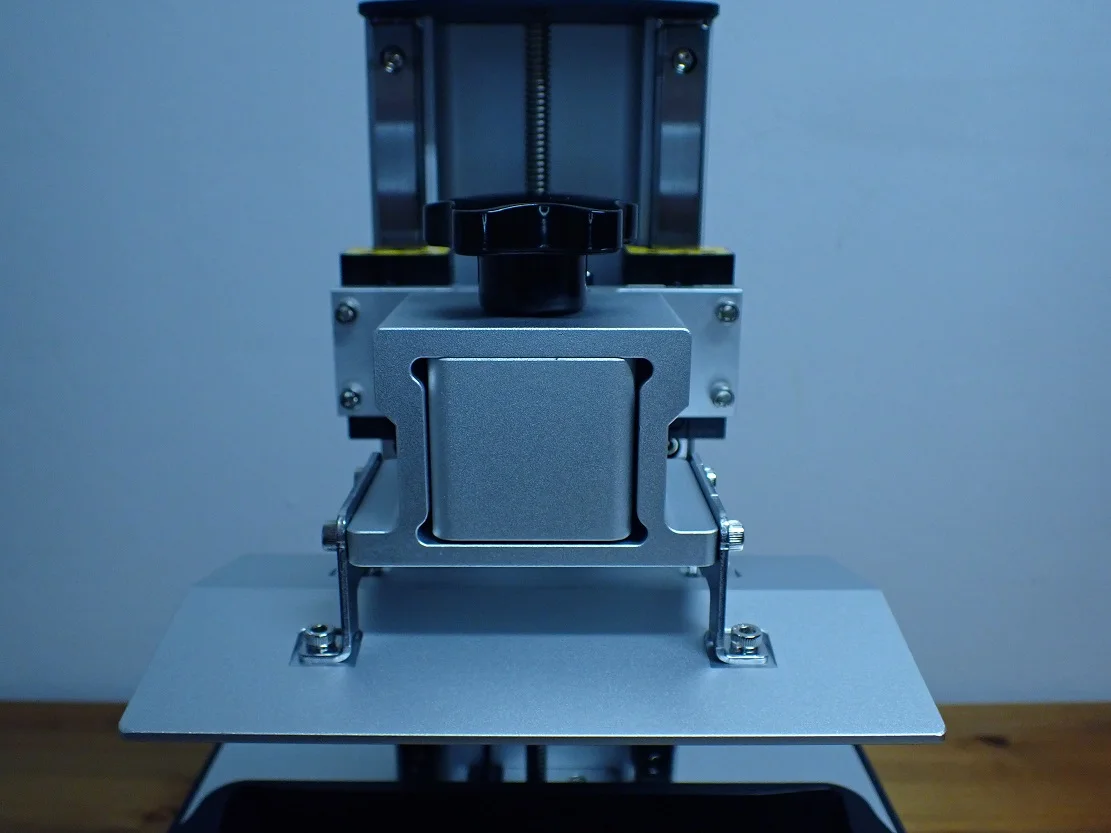

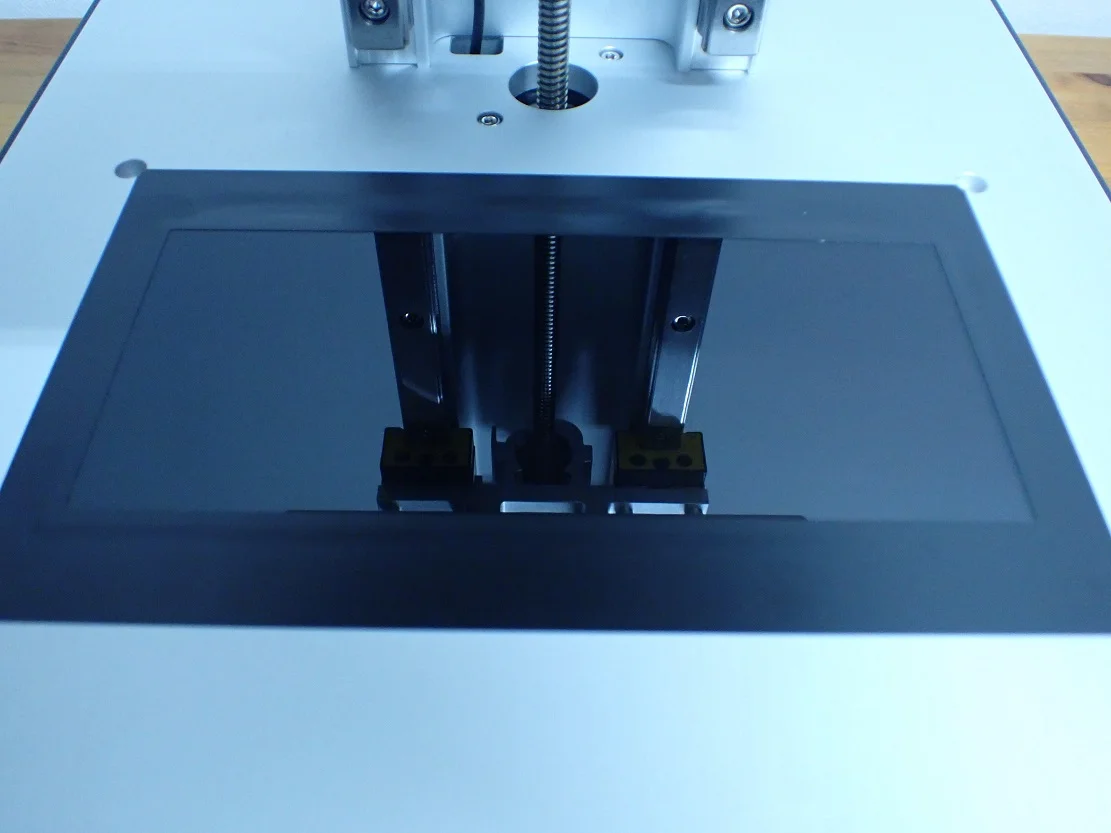

Double Z-axis

A high XY resolution of the LCD screen is not enough to get a good print quality. Accuracy in the Z direction must also be ensured. To ensure this, the Sonic Mini 8K has a double Z-axis with two individual stepper motors.

This design not only makes the Sonic Mini 8K extremely stable, but it also allows layer thicknesses of 0.01 mm to be realized.

Stable Print Bed Mount

The print bed is mounted by 4 screws to the print bed mount, which in turn is clamped to a stable block on the Z-axis with a turning screw.

Due to this design, you do not easily adjust the leveling of the print bed when you remove the print object from the printing plate and there are no vibrations during the movement of the Z-axis that could have a negative effect on the print quality.

Resin Tank with Snap-In Function and Max Fill Line

It is virtually impossible to insert the resin tank incorrectly into the 3D printer. There are four screws on the bottom that fit perfectly into matching holes of the printer housing. Thus, the tank locks exactly where it belongs and can not slip. In addition, the tank is fixed with two screws on the left and right.

The maximum resin fill line probably doesn’t seem like the most spectacular feature, but I remember the first resin 3D printers that didn’t have such a line. If your estimate was a little too high, the resin could overflow from the resin tank and make a huge mess. Therefore, the maximum fill line is for me the feature with the greatest price-performance ratio ever 😉

8K Resin

> Sonic Mini 8K Review

A good LCD screen with high-quality exposure technology and a precise Z-axis alone are not enough to achieve perfect prints. The resin used must also be created accordingly.

Phrozen has developed a special 8K resin for extreme resolutions for this purpose. I have tested the Sonic Mini 8K with this 8K resin from Phrozen. The results are very impressive as you can see below in the print quality examples.

What I have not tested is whether this high quality is also possible with normal resin. So if you have a big stock of normal resin at home, I would start with that first and wait for the results before you buy the 8K resin.

But if you don’t want to waste time and take any risks, I can highly recommend the 8K resin! It is very easy to handle, the supports can be removed easily and without defects. The only downside to the 8K resin (as with most other resins) is that they irritate the respiratory tract and are generally not good for the environment or your health. So I usually print with the plant-based resin from Anycubic* which is a bit more pleasant for everyone involved.

Like most other 3D printer resins, you will need to clean the 8K resin with isopropyl alcohol* and dispose of it accordingly. To learn how to properly dispose of objects contaminated with liquid resin, read this article. How to properly dispose of isopropyl alcohol-resin mixtures is explained in this detailed guide.

Related Post:

3D Printer Resin Disposal | Step by Step

Noise Level

> Sonic Mini 8K Review

The powerful light sources of modern resin 3D printers demand their price. The Sonic Mini 8K’s powerful system also needs to be cooled effectively. This cooling is done via built-in fans, which produce quite a lot of noise during printing.

During printing, I could measure a volume of 44 dB on average. Once the printer is in a closed room, you can no longer hear it. However, concentrating in the same room as the 3D printer would be difficult. 40 to 45 decibels correspond to quiet music or birds chirping.

However, I don’t see the noise levels of resin 3D printers as dramatic in general, since you shouldn’t be in the same room as the printer anyway. The fumes released by the 3D printer are toxic and you should ideally only be in the same room to start and stop printing (and with an FFP2 mask) and then ventilate thoroughly.

Print Speed

> Sonic Mini 8K Review

The printing speed of resin 3D printers behaves completely different from FDM 3D printers. It is influenced by the following factors:

- Exposure strength: The stronger the light source, the more energy hits the resin, causing it to cure faster. Today, exposure systems are so powerful that normal resins are cured within a few seconds.

- Layer thickness: The smaller the layer thickness, the longer the printing takes. With each layer, the resin must be cured for a certain time and the Z-axis must be realigned. If you use a layer thickness of 0.01 mm, the print will take about three times longer than if you use a layer thickness of 0.03 mm. Thus, a print with the highest accuracy can quickly take several dozen hours or even a few days.

- Resin used: The different resins also require different exposure times. The 8K resin I used for this test requires about 2 seconds of exposure time on the Sonic Mini 8K. Other resins can take twice that amount of time, which directly affects the print time.

So the 80 mm/h figure is extremely undetailed and calculated for a standard accuracy. As you will see in the examples below, some of my test prints took over 50 hours because I used a layer thickness of 0.01 mm. And this is definitely not 80 mm/h, but rather 5 mm/h, which I gladly accept in return for this enormous accuracy!

Operation

> Sonic Mini 8K Review

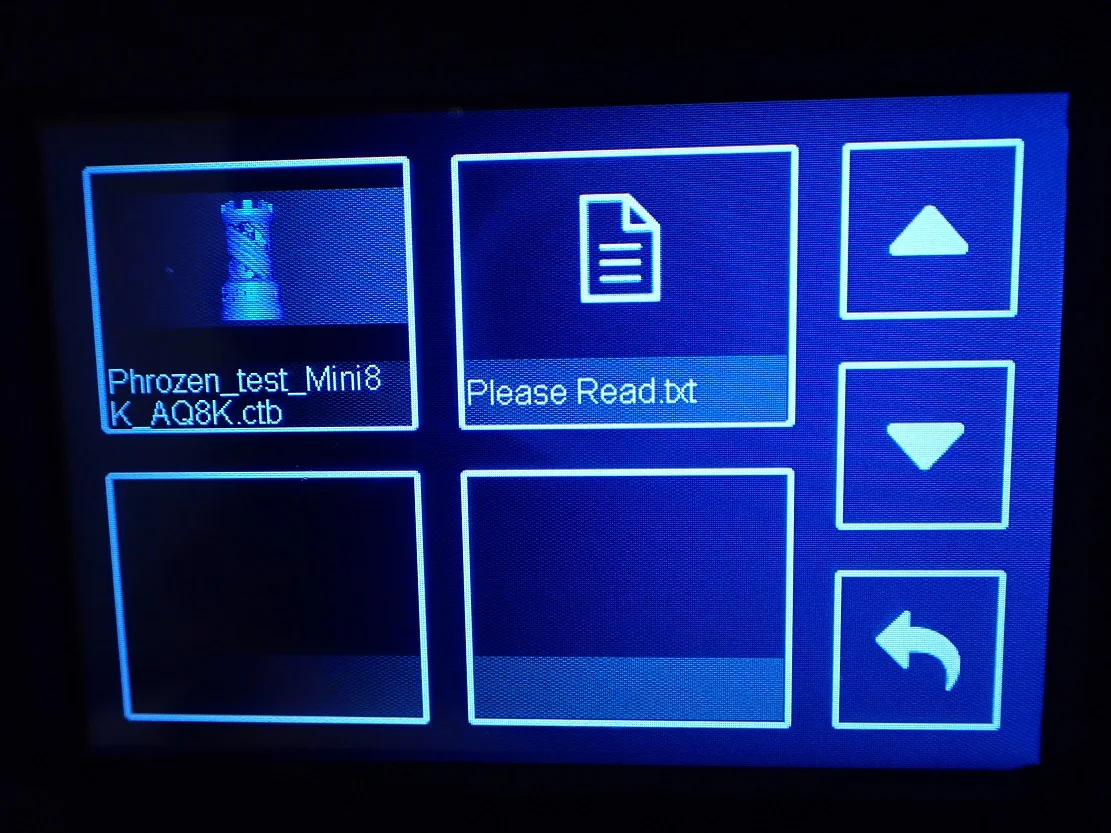

UI: The menu of the Sonic Mini 8K is pleasantly spartan. You can find all the important functions with just a few touches and you are even shown thumbnails (small preview images) for the print files. There is even a cleaning program for the resin tank that exposes the entire surface for a certain amount of time so you can simply peel the partially cured resin off the FEP film.

Print bed: The print bed adhesion is perfect. In all my hour-long test prints, I never had the problem of an object detaching from the printing plate in an uncontrolled way. On the other hand, the print bed adhesion is not too extreme. Detaching print objects with the spatula is easy to do by lightly levering from the side and can be done without scratching.

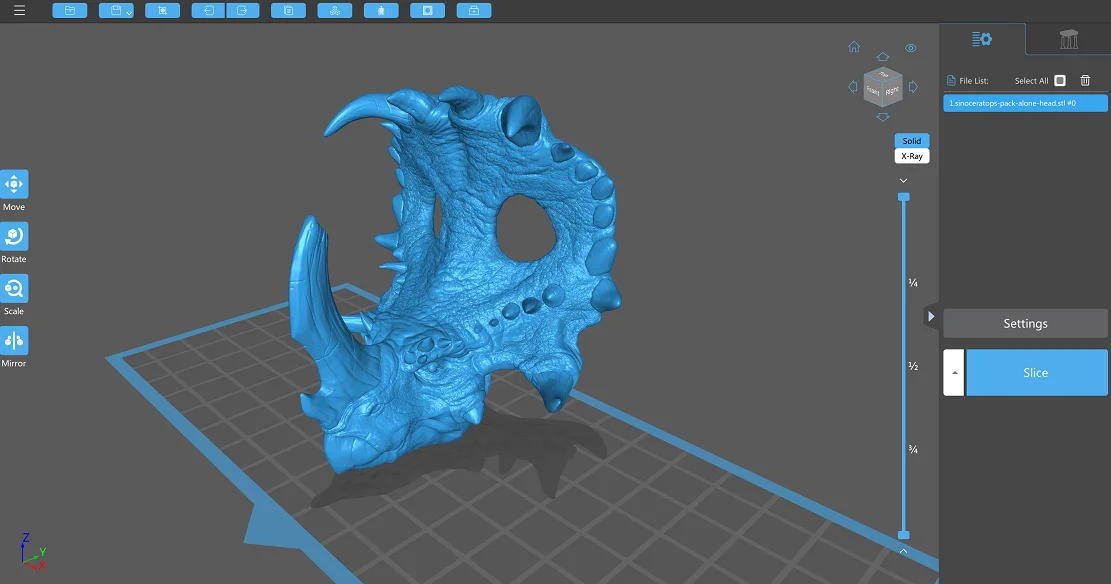

Slicer: I used the Sonic Mini 8K with ChiTuBox. Since I use this slicer for all my resin 3D printers, it was not difficult to find the right settings. Setting supports is very easy and you can hollow out objects to save resin.

Printing: Once the 3D printer is prepared, the resin tank is filled and the hood is closed, printing can be started by selecting the file. During printing, the display shows how much time has elapsed and how long the print is expected to take.

It also shows which layer is currently being exposed. I find this feature quite nice since I can hear in between whether the exposed layer has detached from the FEP film or not. Often, you can quickly identify failed prints, but this has not yet happened with the Sonic Mini 8K.

Print Quality

> Sonic Mini 8K Review

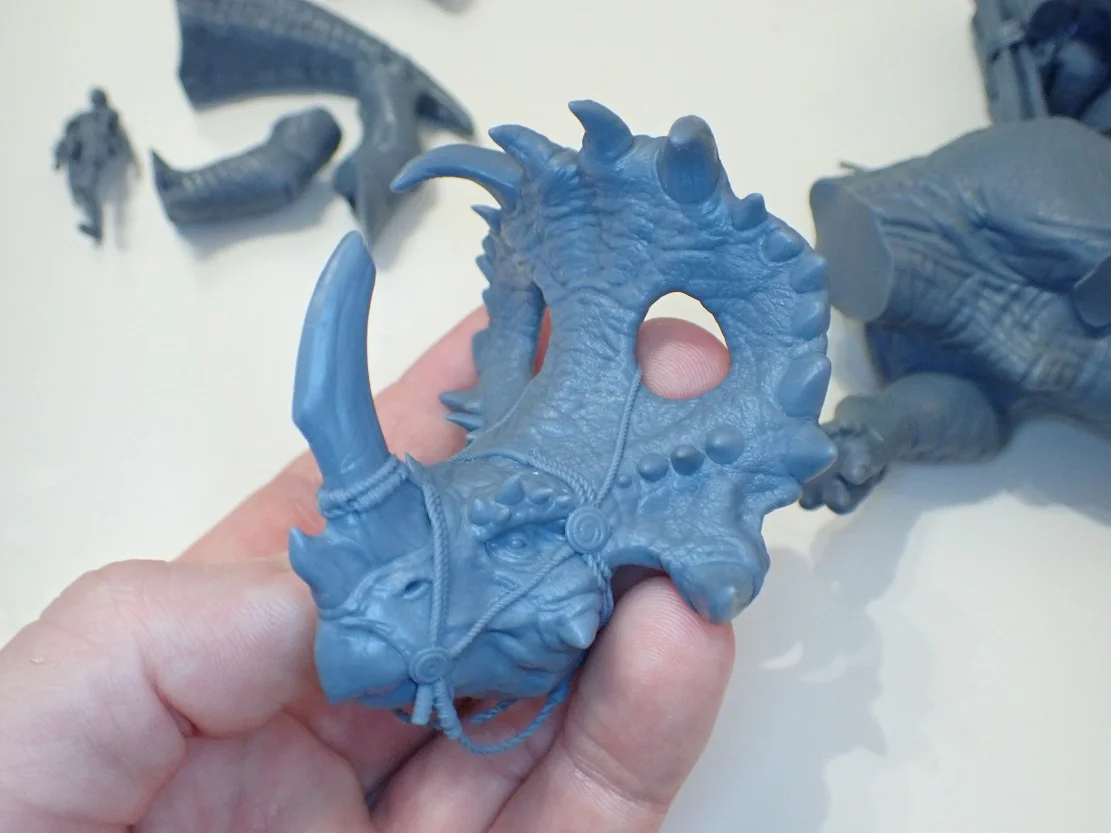

The print quality of the Sonic Mini 8K is 22 μm in the XY direction and 0.01 mm in the Z direction. This makes the print quality extremely accurate and comparable to the finest injection molded parts. In addition, anti-aliasing can be set via the slicer to smooth even the finest steps.

My second hobby besides 3D printing is painting miniatures. Therefore, I have very high expectations regarding the quality of resin printers. Therefore, I was even more amazed by the print quality of the Sonic Mini 8K. It is now quite unlikely that I will buy physical miniatures to paint in the future. The combination of purchasable STL models and the Sonic Mini 8K makes buying physical models unnecessary and even more expensive in the long run.

To demonstrate the high accuracy I have printed a model of “Lord of the Print” on MyMiniFactory – a Sinoceratops that is led on a leash and belongs to a kind of “dino caravan” (link to the model). The model is extremely detailed and perfect for an accuracy test. I had to split it into three separate prints, which took 33, 37 and 55 hours respectively.

I set the layer thickness to 0.01 mm for the highest accuracy. I actually did not manage to find any steps on the model. On the contrary, it is extremely amazing how accurate even the individual skin folds of the Sinoceratops have become. Even the small figure has been printed extremely accurately and even the tiniest details have been preserved.

Slicer

> Sonic Mini 8K Review

Phrozen recommends using the Sonic Mini 8K with ChiTuBox. This slicer is also very extensive in its free version and offers all kinds of features to prepare the print file perfectly.

Especially the features for hollowing out the object (to save resin), setting small holes and the extensive support settings are worth mentioning.

Be prepared for long calculation times if you want to print with the most accurate settings. It can take several minutes to slice and save a complex model.

Learn to print perfect details:

Resin 3D Printer Calibration: Step-by-Step Guide

Useful Accessories

> Sonic Mini 8K Review

As already mentioned above in the scope of delivery, you need the following things in addition to the Sonic Mini 8K:

- Disposable gloves

- FFP2 masks

- Resin

- Disposable resin filters or reusable resin filters

- Isopropyl alcohol

You also need a UV lamp to cure the prints after washing. For this purpose, an ordinary UV lamp for nail polish* is quite sufficient.

Many find washing and curing the object after a resin print very tedious. If you feel the same way, a Wash & Cure station would be a good investment. Such stations effectively wash the print object and have UV LEDs and a turntable that cure the object evenly.

This way you get a clean and perfectly cured object without much effort. At the moment, the stations from Anycubic* and Elegoo* are highly recommended.

As one of the first resin 3D printers, the Sonic Mini 8K has a pixel size below 25 μm.

LCD resolution: 8K (7500 × 3240)

LCD size: 7″

XY-resolution: 22 µm

Layer height: 0,01-0,30 mm

Build volume: 165 × 72 × 180 mm

Speed: max. 80 mm/h

Pros:

✓ Very accurate

✓ Easy to use

✓ Short curing times

✓ Double z-axis

Cons:

× Small print volume

× No air filter

× Somewhat loud with max. 45 dB

Is the Sonic Mini 8K Worth It?

The question of whether the Sonic Mini 8K from Phrozen* is worth it can be answered with a resounding “Yes” if accuracy is important to you and you want to print extremely detailed objects.

Of course, such high accuracy comes at a higher price than 3D printers with comparable print volumes. If you can live with an XY resolution of 35 μm, you’re probably fine with the Elegoo Mars 3. However, if you’re someone like me who cares a lot about details, the Sonic Mini 8K is definitely the better choice!

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.