- Wet Filament: Prevention, Symptoms & Drying - July 18, 2024

- Sovol SV08 – Best PrusaSlicer Settings & Profile - June 26, 2024

- Sovol SV08 – Best Orca Slicer Settings & Profile - June 26, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

In this article, we compare the Ender-3 V3 SE to the Ender-3 V3 KE from Creality. Our direct comparison details key differences like print speed, features, and user experience to help you make an informed decision.

Learn whether the KE’s advanced features justify its higher price tag or if the SE’s affordability is the sensible choice for your 3D printing endeavors.

Table of Contents:

Key Takeaways

While both the Ender-3 V3 KE and the Ender-3 V3 SE hail from the same lineage, there are distinct differences that set each apart. These differences become apparent when looking at the key features that influence print quality, speed, and usability.

The Ender-3 V3 KE distinguishes itself with several upgrades that enhance its performance. It boasts:

- A maximum printing speed of 500 mm/s, derived from its advanced hardware such as an X-axis linear rail and improved hotend.

- A maximum printing temperature of 300 °C instead of 260 °C.

- A filament sensor.

- A PEI print bed surface.

- A touchscreen interface.

These features make it a perfect choice for those seeking high-speed printing with a lot of quality of life features.

On the other hand, the Ender-3 V3 SE, while not as feature-rich as its sibling, is a solid choice for those on a budget. It delivers reliable printing, a comparable good print quality, and a maximum speed of 250 mm/s. However, it lacks a filament sensor and touchscreen, which can be found in the KE model.

Despite these differences, with a few upgrades such as the PEI print bed, the Ender-3 V3 SE can still deliver a satisfying 3D printing experience.

Comparison Chart: Ender-3 V3 KE vs. SE

Here’s a detailed comparison table for the Creality Ender-3 V3 KE and Ender-3 V3 SE 3D printers:

| Feature | Ender-3 V3 SE | Ender-3 V3 KE |

|---|---|---|

| Year Released | 2023 | 2023 |

| Build Volume | 220 × 220 × 250 mm | 220 × 220 × 240 mm |

| Technology | FDM | FDM |

| Physical Size | 349 × 364 × 490 mm | 433 × 366 × 490 mm |

| Bed Material | PC Spring Steel | PEI Spring Steel |

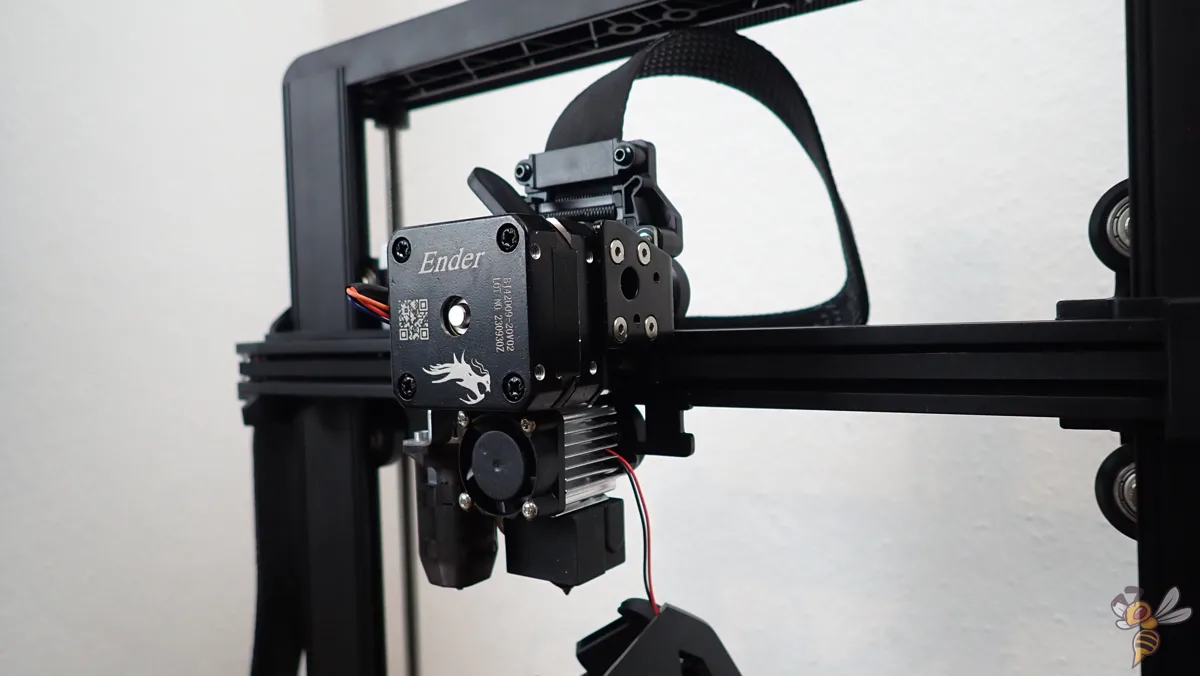

| Extruder Type | Sprite Direct Drive | Sprite Direct Drive with upgraded all-metal hotend |

| Hot-end Type | Standard | Upgraded, more powerful heater core |

| Auto Leveling | CR-touch | CR-touch |

| Assembly Time | 15 minutes | 15 minutes |

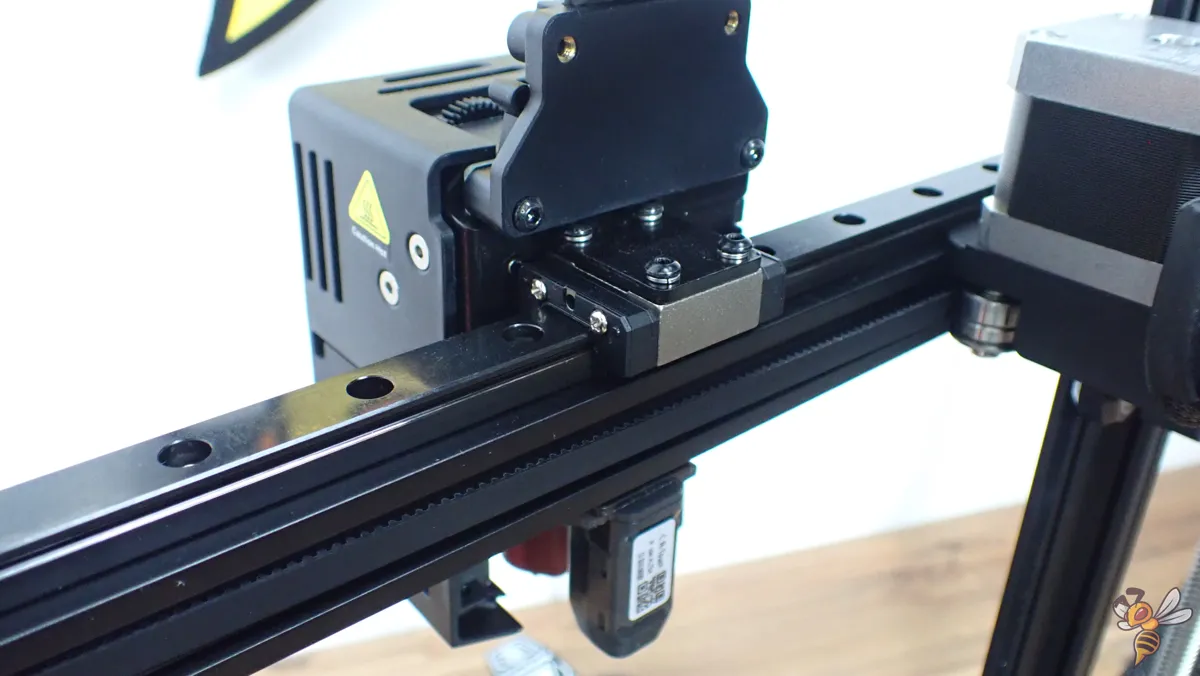

| Linear Rail System | On Y Axis | On X and Y Axis |

| Display Screen | 3.2” Color Knob Screen | 4.3″ Color Touch Screen |

| Filament Detector | No | Yes |

| Dual Z-axis | Yes (1 motorized) | Yes (2 motorized) |

| File Transfer | SD Card, USB-C Cable | USB drive, LAN, Creality Cloud APP |

| Supported Filaments | PLA, PETG, TPU | PLA, PETG, ABS, TPU, ASA |

| Heatbed Temperature | 100℃ | 100℃ |

| Nozzle Temperature | 260℃ | 300℃ |

| Max. Printing Speed | 250 mm/s | 500 mm/s |

| Typical Printing Speed | 180 mm/s | 300 mm/s |

| Max. Acceleration | 2500 mm/s² | 8000 mm/s² |

| Nozzle Diameter | 0.4 mm (default) | 0.4 mm (default) |

| Layer Height | 0.1 – 0.35 mm | 0.1 – 0.35 mm |

| Printing Accuracy | ± 0.1 mm | ± 0.1 mm |

| Filament Diameter | 1.75 mm | 1.75 mm |

| Slicing Software | Creality Print, Cura, Simplify3D | Creality Print, Cura, Simplify3D |

Print Quality

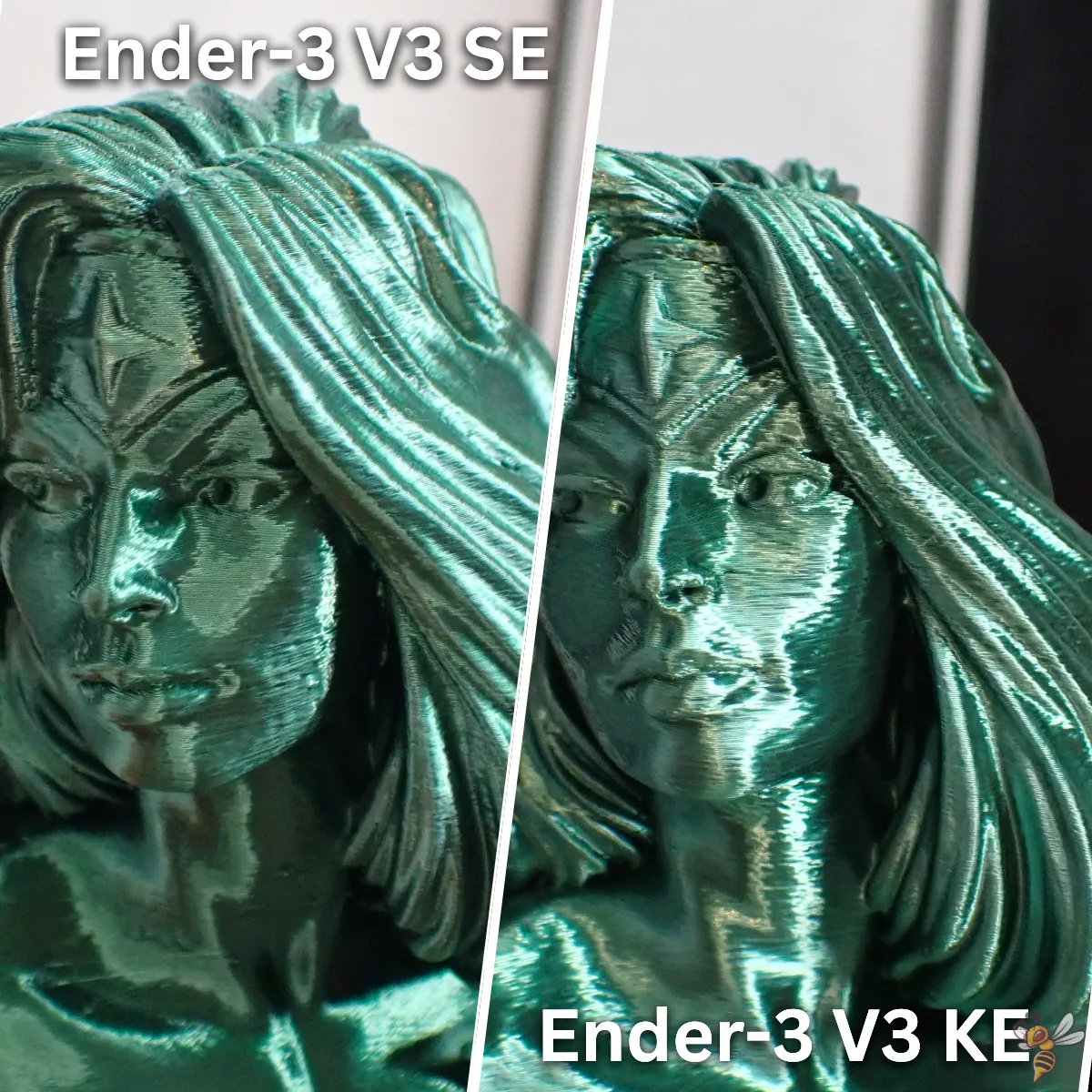

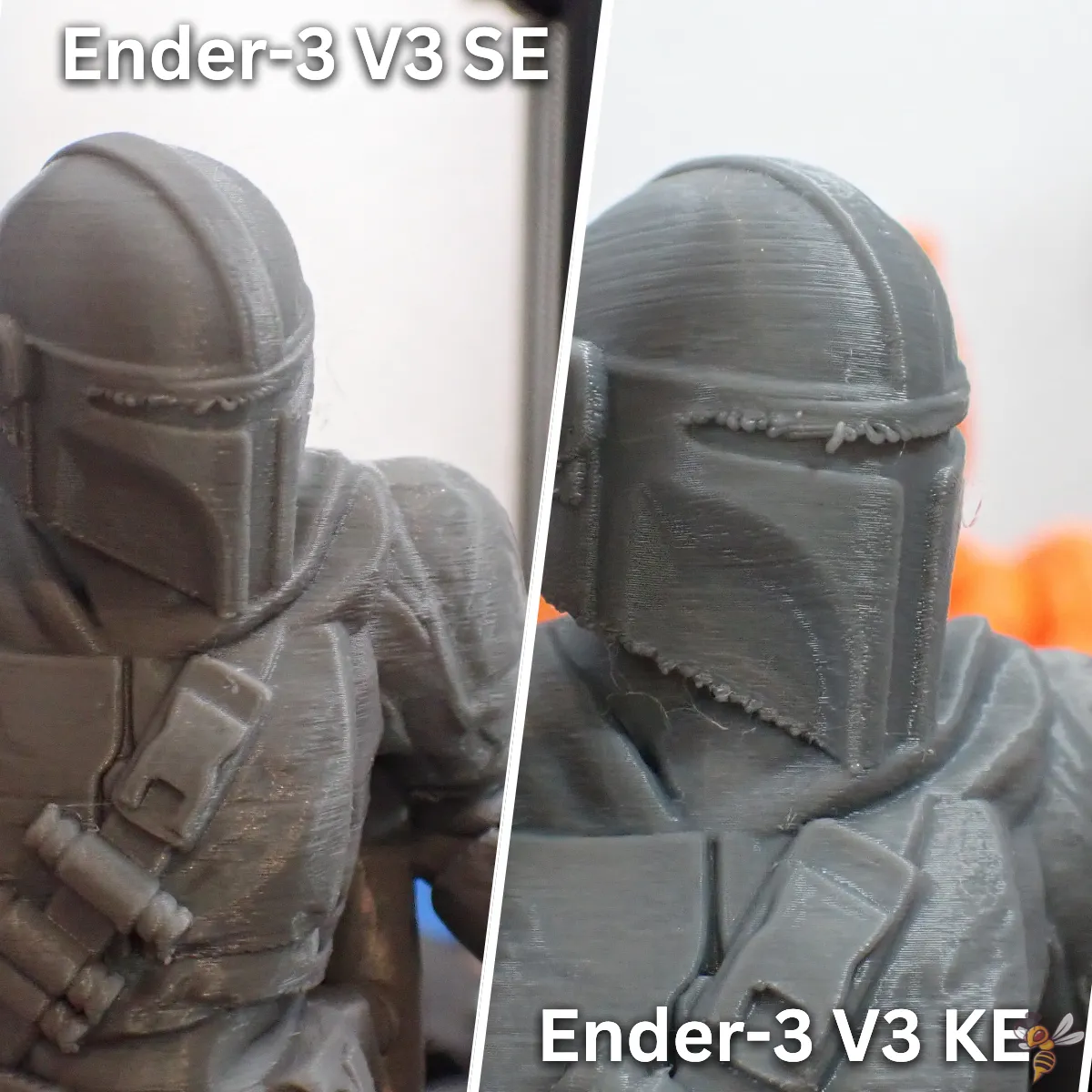

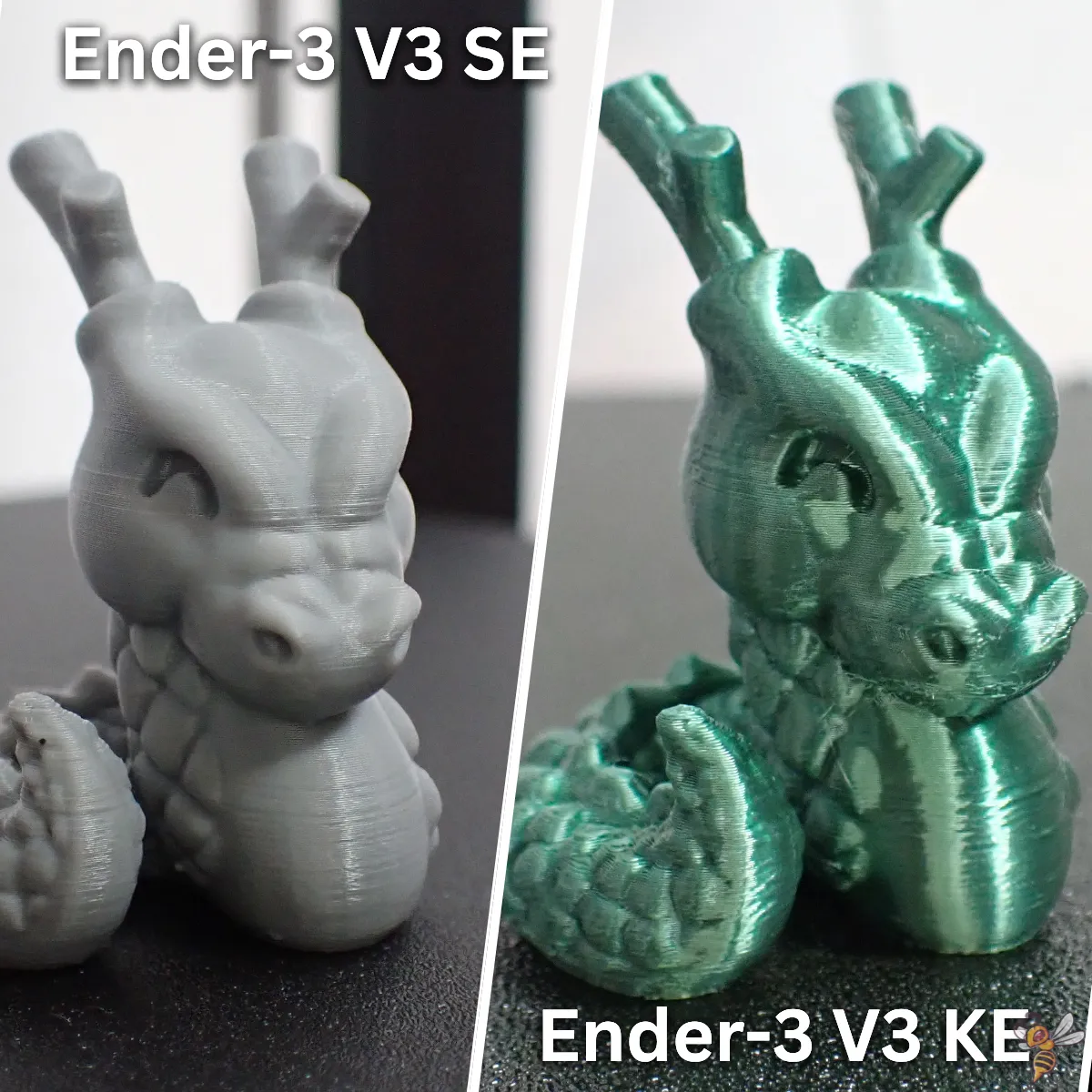

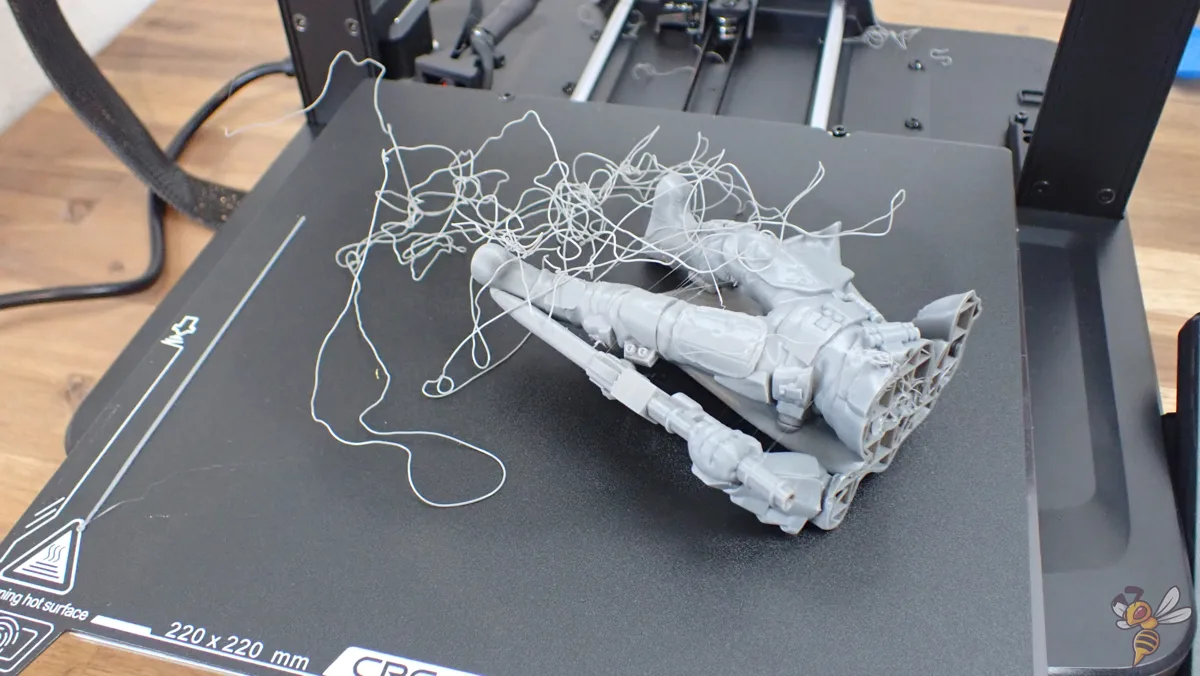

When it comes to print quality, both Ender-3 models shine in their respective price ranges. After detailed calibration, they provide excellent print quality, which is a testament to their advanced features and meticulous design.

We’ve tested several objects on both printers, all printed with a layer height of 0.1 mm, and the results were quite impressive.

TIP: Learn how to calibrate your 3D printer to get perfect results every time in my 3D printing course: FDM 3D Printing: The Comprehensive Course from A to Z

(The course teaches everything you need to know for FDM 3D printing in over 60 lessons. The course will get beginners up to my level in no time!)

However, a slight edge goes to the SE model when it comes to overhangs. The SE’s print quality was slightly superior on overhangs, while the overhangs on the KE always sagged a bit despite activating the bridge settings in Cura. This is an area where the part cooling system plays a crucial role in enhancing overhang performance and contributes to overall cleaner prints.

That being said, print defects like stringing and other issues are quickly eliminated in both models with calibration of the nozzle temperature and retraction. Both printers also have the input shaping feature, which eliminates print errors like ringing or ghosting, ensuring that the final product is as precise and clean as possible. Additionally, rapid model cooling plays a significant role in enhancing the overall print quality.

Maximum Printing Speed

| Model | Printing Time on the SE | Printing Time on the KE |

|---|---|---|

| Wonder Woman | 9h 21m | 5h 25 |

| Captain America | 10h 25m | 6h 15m |

| Mandalorian | 7h 30m | 4h 14m |

The print speed is another area where the Ender-3 V3 KE stands out. Its advertised maximum speed of 500 mm/s significantly outperforms the SE model’s 250 mm/s, thanks to these advanced firmware and hardware enhancements:

- An additional fan in the print head

- A linear rail on the X-axis

- Motion advance for more precise filament flow

- Higher thermal conductivity in the hotend

In reality, the Ender-3 V3 KE has a typical speed of between 250-300 mm/s, while the Ender-3 V3 SE operates at a slightly slower pace, usually ranging from 180-200 mm/s.

The Ender-3 V3 KE has a faster printing acceleration than the SE. Thanks to the linear rail on the X-axis, the KE model can reach a maximum acceleration of 8000 mm/s², significantly outperforming the SE model’s maximum acceleration of 2500 mm/s².

This improvement in acceleration is critical for faster printing speeds, allowing the KE model to rapidly change its printing direction without compromising on print quality.

Additionally, the linear rail on the X-axis provides smoother and more precise movement, further enhancing the printer’s performance and reliability during high-speed printing.

While print speed is an important consideration, it should not be the sole determinant in choosing between these two models. Both printers offer reliable printing and excellent print quality, and both are capable of producing detailed, high-quality prints.

Connectivity

When it comes to connectivity, both Ender-3 V3 SE and Ender-3 V3 KE offer reliable and versatile options.

The Ender-3 V3 SE has a standard SD Card slot and a USB-C port. These options allow for convenient transfer of print files from your computer to the printer. The SD Card slot, in particular, is useful for those who prefer to work offline or want to avoid potential disruptions from computer software updates or crashes.

The Ender-3 V3 KE, on the other hand, takes connectivity a step further. It has two USB ports, LAN connectivity and supports the Creality Cloud APP. This means you can connect the printer to your home network and manage print jobs remotely. Whether you’re in another room or away from home, you can monitor and control your print jobs with ease with cloud printing.

In conclusion, while both printers offer good connectivity options, the Ender-3 V3 KE has a slight edge due to its network connectivity, cloud printing and app support, providing a more convenient and flexible printing experience.

Filament Compatibility

When it comes to filament compatibility, both the Ender-3 V3 SE and the Ender-3 V3 KE do not disappoint. They demonstrate flexibility by supporting a wide range of filament types.

The Ender-3 V3 SE is compatible with PLA, PETG, and TPU filaments. This compatibility range makes it suitable for a wide variety of printing projects, from simple hobbyist creations to more complex and flexible designs.

On the other hand, the Ender-3 V3 KE takes it a step further by supporting not only PLA, PETG, and TPU but also ABS and ASA filaments because it has a higher nozzle temperature limit of 300 °C. The ability to use ABS and ASA filaments provides an advantage for those seeking to print items that need to withstand higher temperatures or require more durability.

Both printers have a filament diameter of 1.75 mm, which is the standard size for most 3D printers. This means you’ll have a wide variety of filament brands and types to choose from.

In conclusion, while both printers offer a good range of filament compatibility, the Ender-3 V3 KE has a slight edge due to its ability to print with ABS and ASA filaments.

Usability

When it comes to usability, there are significant differences between the Ender-3 V3 SE and KE. These differences primarily lie in the print bed, filament sensor, and touchscreen interface.

We should explore these aspects for a more comprehensive understanding.

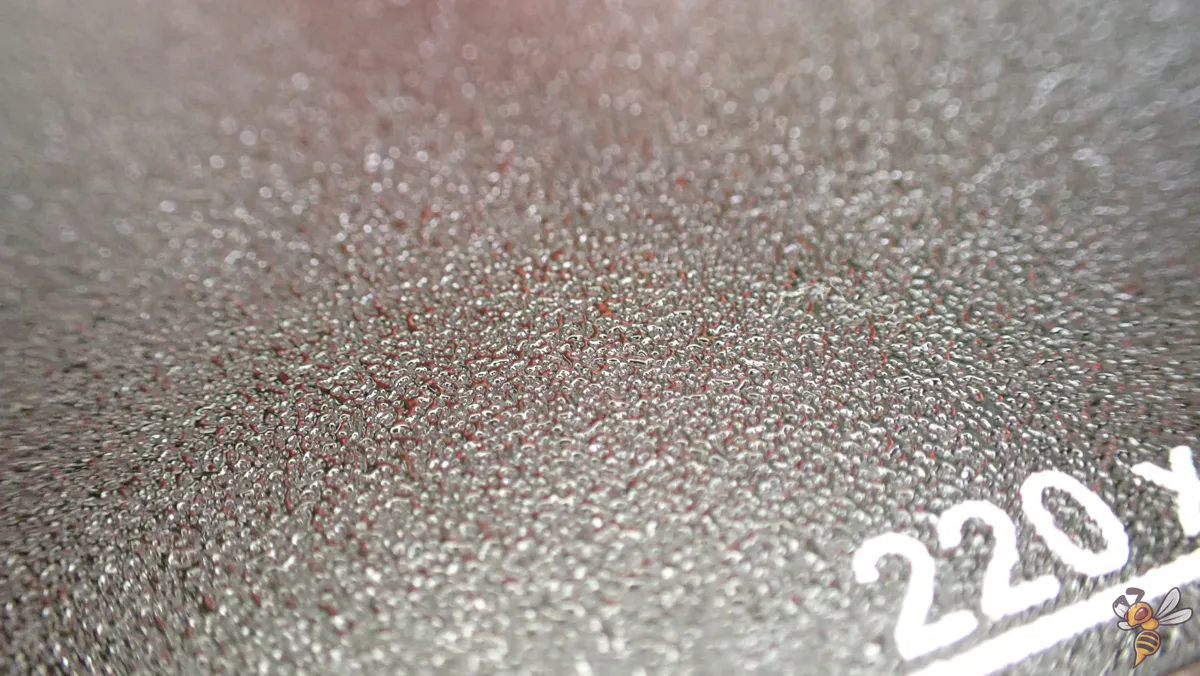

Print Bed Surface

The print bed is a distinguishing feature between the two models. The Ender-3 V3 SE and Ender-3 V3 KE print beds are the same size and shape, but the difference lies in the coating. The Ender-3 V3 SE print bed has a PC coating, while the KE print bed has a superior PEI coating.

The PEI coating on the Ender-3 V3 KE print bed provides better adhesion and results in smoother prints. On the other hand, the PC coating on the SE model’s print bed can sometimes make adhesion challenging, requiring the use of a large raft and adhesive.

However, a PEI print bed can be bought as an optional upgrade for the SE, which we highly recommend for improved print quality (Link to the official store*).

Despite the differences in their print beds, both printers offer reliable printing and good print quality, and both are capable of producing detailed, high-quality prints. However, the PEI print bed of the KE model does give it a slight edge in terms of usability and convenience.

Note: Both the Ender-3 V3 SE and Ender-3 V3 KE models come equipped with the same automatic bed leveling feature. This feature greatly simplifies the process of ensuring a level print bed.

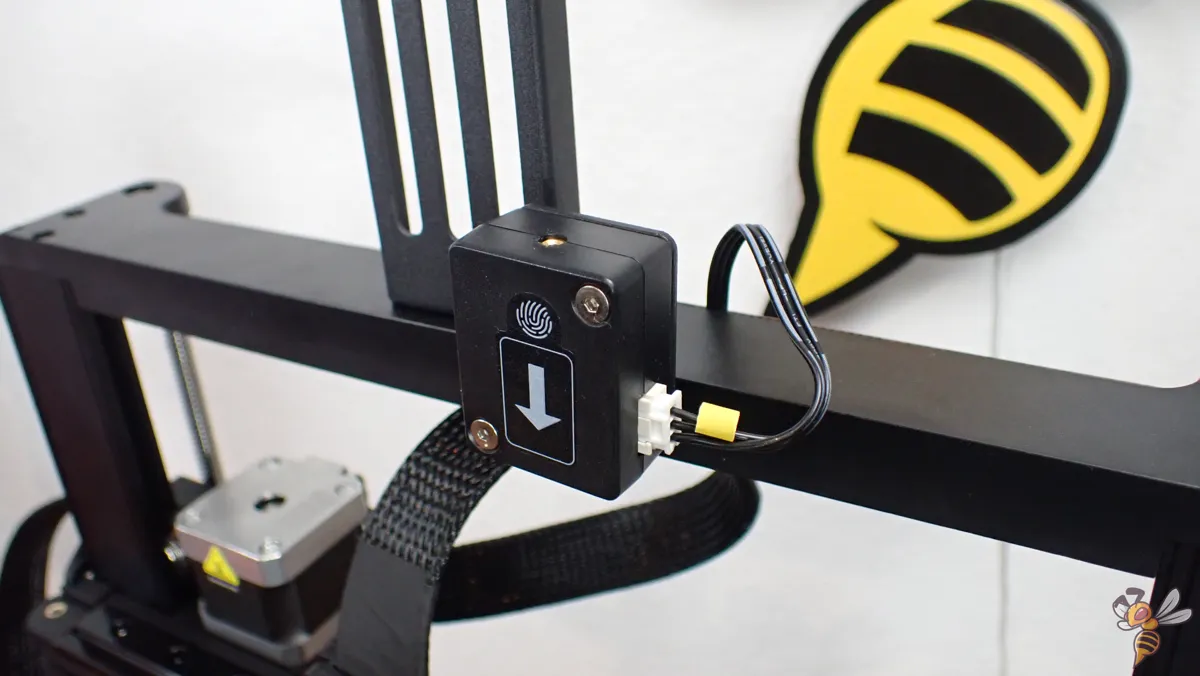

Filament Sensor

The presence of a filament sensor also sets these two models apart. The Ender-3 V3 KE model includes a filament sensor, which automatically pauses printing as soon as the filament is used up or broken. This auto filament loading feature is especially useful for large prints, as it allows you to comfortably reload filament and continue printing without having to monitor the printer constantly.

On the other hand, the SE model does not have a filament runout sensor. This means that you need to ensure there is enough filament on the spool to complete the desired object before starting the print. Without a filament runout sensor, if the filament runs out during printing, the printer will continue printing in the air, leading to a failed print.

While the filament sensor is a convenient feature, it’s not a game-changer and shouldn’t be the sole reason for choosing one printer over the other. However, for those who frequently carry out large prints, the filament sensor in the Ender-3 V3 KE could prove to be a useful feature.

Touchscreen

Lastly, the display is worth discussing. The Ender-3 V3 KE features a 4.3-inch color touchscreen that offers:

- A newly designed software UI

- Enhanced navigation bar

- Multi-platform connectivity

- Model visualization

This touchscreen interface makes the KE model more user-friendly and intuitive to use.

The Ender-3 V3 SE, on the other hand, comes with a 3.2-inch color screen with a rotary knob. Using the rotary knob takes some getting used to, but it can be just as fast as using a touchscreen once you get the hang of it.

The decision on which 3D printer to choose shouldn’t be based solely on the type of display. While a touchscreen is a convenience in everyday use, the type of display is ultimately a matter of personal preference. Most users probably prefer a touchscreen, but the rotary knob on the SE model works just fine once you get used to it.

Recommendation

After evaluating the key features, print quality, speed, and usability aspects of both models, we have a clear recommendation. Should budget not be an issue, the Ender-3 V3 KE is recommended. Here are the reasons why:

- Advanced firmware

- Faster printing speeds

- Filament sensor

- PEI print bed

- Touchscreen interface

All of these features contribute to a superior 3D printing experience.

Nevertheless, the Ender-3 V3 SE maintains a strong value proposition given its price point. It’s a solid, budget-friendly choice that delivers reliable printing and good print quality. While it lacks some of the features of the KE model, these can be added as upgrades if needed.

For those opting for the SE model, it is strongly suggested to consider upgrading to a PEI print bed. This upgrade can significantly improve print adhesion and results during the printing process, making the SE model a more compelling choice.

In conclusion, both the Ender 3 V3 KE and the Ender 3 V3 SE are quality 3D printers that offer excellent value. Your final choice will ultimately depend on your specific needs, budget, and preference.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.