- Wet Filament: Prevention, Symptoms & Drying - July 18, 2024

- Sovol SV08 – Best PrusaSlicer Settings & Profile - June 26, 2024

- Sovol SV08 – Best Orca Slicer Settings & Profile - June 26, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

The TwoTrees SK1* shines with its impressive print speed of up to 700 mm/s, but also has other very practical features. From the effortless self-calibration that results in excellent print quality, to details such as the easily accessible filament holder and the CoreXY structure for increased stability, this printer impressed me in many ways.

I have tested the SK1 in detail and share my experiences in this in-depth review.

Who should buy the SK1 from TwoTrees?

If you are looking for a fast, precise and user-friendly 3D printer, the SK1 could be just the thing for you. It is ideal for beginners and advanced users who value speed, print quality and ease of use.

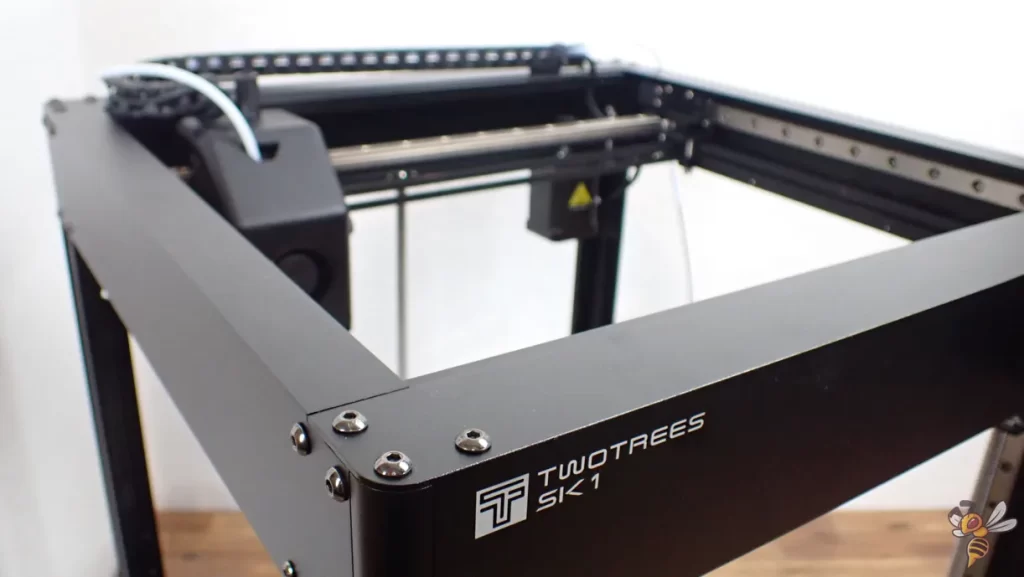

The TwoTrees SK1 is a medium-sized 3D printer with a CoreXY design.

Build Volume: 256 × 256 × 256 mm

Speed: max. 700 mm/s; normal 300 mm/s

Extruder: Direct Drive

Print Bed: PEI, magnetic, flexible

Leveling: Automatic

Firmware: Klipper

Nozzle Temp.: 300 °C

Bed Temp.: 100 °C

Connectivity: WiFi, Ethernet, USB

Pros:

✓ High printing speed

✓ High print quality

✓ Sturdy design with CoreXY system

✓ Versatile with high filament compatibility

✓ Easy operation

Cons:

× High noise level (65 dB at 300 mm/s)

× Extruder cannot be decoupled manually

Table of Contents: [show]

My Verdict – What Sets the TwoTrees SK1 Apart From Other 3D Printers?

The TwoTrees SK1 stands out from other 3D printers primarily due to its maximum printing speed of 700 mm/s. The innovative Z-Tilt Auto-Leveling technology, combined with Mesh Bed Compensation, ensures a precise and uniform first layer.

The CoreXY system with linear rails offers additional robustness and precision, which is unusual in this price range. The PEI magnetic bed, on the other hand, does – although TwoTrees has also come up with something practical here (more on this later).

One potential drawback of the SK1 is that it can get noisy at high print speeds.

Despite this drawback, I am very impressed by the high print quality at the enormous print speeds. It combines speed, precision and ease of use in one device, making it an excellent choice for a wide range of 3D printing applications.

3D printing can be difficult – especially in the beginning. Many beginners struggle with print errors, poor print bed adhesion, or don’t know how to properly set up the slicer.

That’s why I created an online course to get everyone up to my expert level and as quickly as possible.

The course covers everything you need to know about FDM 3D printing to get perfect results every time. Click the link below to learn more about the content and what to expect (and don’t worry: there are no tests! Learn at your own pace, completely stress-free).

Unboxing & First Impressions

When unboxing the TwoTrees SK1 3D printer, you immediately notice how user-friendly it is designed. The printer arrives almost completely pre-assembled, which makes it much easier to set up.

Apart from the transport locks, which need to be removed, only the filament holder and the display have to be mounted.

My first impression of the SK1 was entirely positive. The high-quality workmanship and the sturdy metal frame with linear rails immediately give the impression that this printer is designed for high speeds.

Another highlight is the option of upgrading the frame with an enclosure. This is particularly useful for printing with materials such as ABS, which require a more stable ambient temperature.

The scope of delivery of the SK1 includes:

- The printer itself: Already pre-assembled and almost ready to use.

- Tools for assembly and operation: Everything you need to set up and maintain the printer.

- Filament holder: Easy to install and practically positioned.

- Display and display holder: For clear and simple control of the printer.

- Screws: All necessary screws are included.

- 250 g PLA filament: Ideal to start printing immediately (but only enough for a few small test prints).

Technical Specifications

- Print volume: 256 × 256 × 256 mm

- Extruder type: Near-Range Dual-Gear Direct Drive

- Print bed: PEI Magnetic Bed, Mesh Leveling

- Max. printing temperature: 300 °C

- Max. print bed temperature: 100 °C

- Speed: Up to 700 mm/s, recommended 300 mm/s

- Filaments: Wide compatibility, including PLA, ABS, PETG, TPU

- Display: 4.3-inch IPS touchscreen, full-color

- Connectivity: WiFi, Ethernet, USB

- Slicer: Cura, PrusaSlicer, Lycheeslicer, Simplify3D, etc.

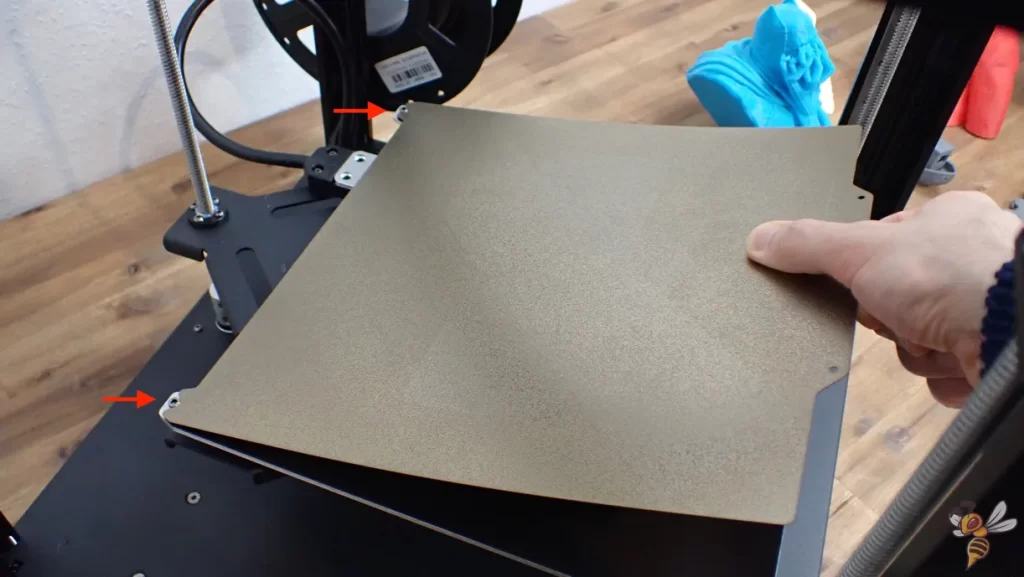

Print Bed & Leveling

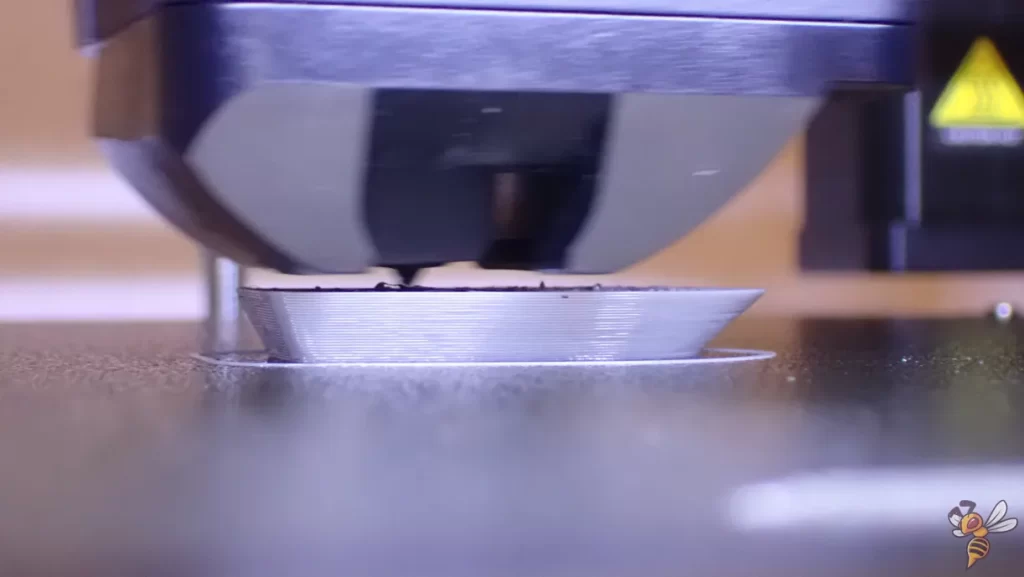

The print bed of the TwoTrees SK1 consists of a PEI magnetic bed, which not only ensures excellent adhesion of your print objects, but also makes it much easier to remove the finished prints. PEI print beds are currently my favorite.

Two screws at the rear end of the printing plate are particularly practical, allowing the flexible print bed to snap into place. This makes positioning the print bed much easier, as it is always immediately in the right position.

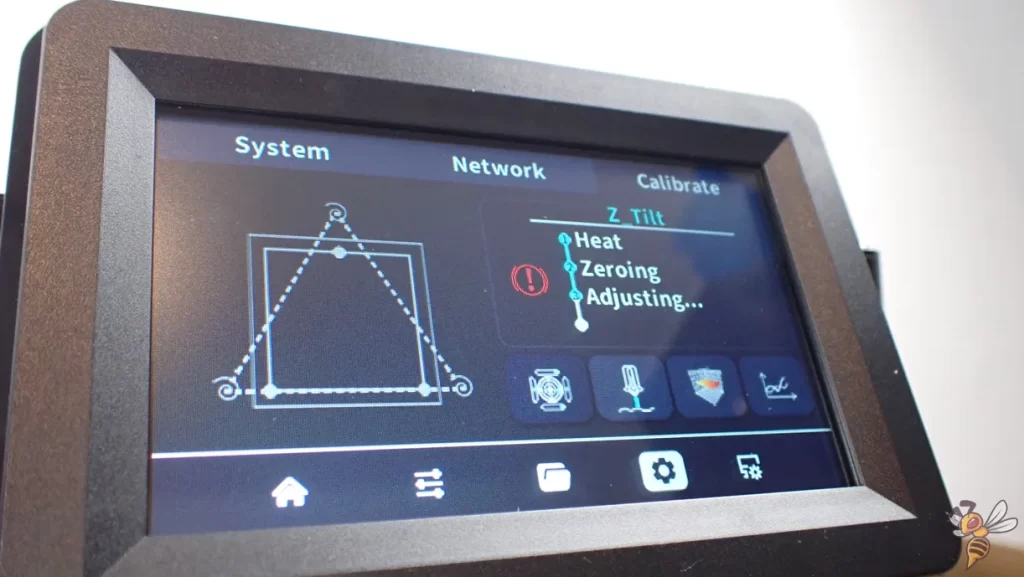

Another highlight is the SK1’s advanced leveling system. The printer features automatic z-tilt leveling and mesh bed compensation, which aligns the print bed precisely and evenly.

However, you still have to adjust the z-offsets manually. This is easily done with a sheet of paper and the whole process is also conveniently supported via the printer’s menu.

The combination of automatic and manual leveling ensures that the print bed is perfectly aligned, which is essential for high-quality print results. The combination of automatic leveling with manual z-offset adjustment is currently very common among modern 3D printers.

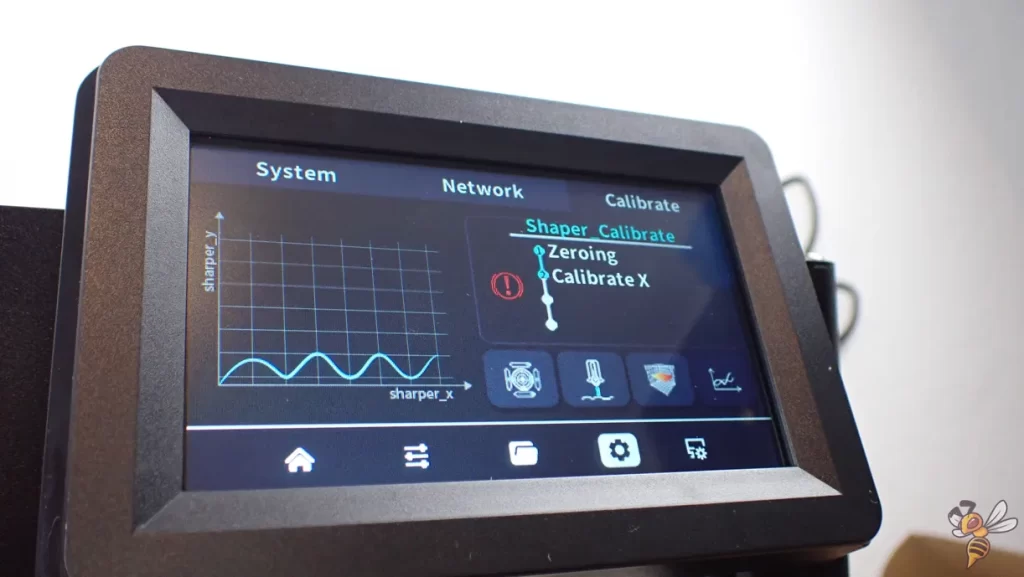

Input Shaping

“Input Shaping” is an advanced feature of the TwoTrees SK1 that is critical to improving print quality, especially at high speeds. This feature focuses on compensating for the vibrations that occur during the printing process.

All modern 3D printers with print speeds of over 200 mm/s have one version or another of this feature. It is usually called Input Shaping, sometimes Calibration Compensation or a completely new definition. However, the aim is always the same: to avoid printing errors caused by vibrations at high printing speeds.

Vibrations are a natural consequence of fast movements of the print head and motors. Without appropriate measures, these vibrations can lead to blurring or irregularities in your prints. These printing errors are called ringing or ghosting.

This is where input shaping comes into play: it analyses the specific vibration characteristics of your printer and dynamically adjusts the movements of the print head to minimize these vibrations.

Print Volume & Stability

The TwoTrees SK1 offers a print volume of 256 x 256 x 256 mm, which means you can realize a variety of projects, from small, detailed objects to medium-sized creations.

Thanks to the robust CoreXY system and the sturdy metal frame, which is equipped with precise linear rails, the printer remains stable even at high printing speeds. This design minimizes vibrations and movements that can lead to irregularities in the print results with other printers.

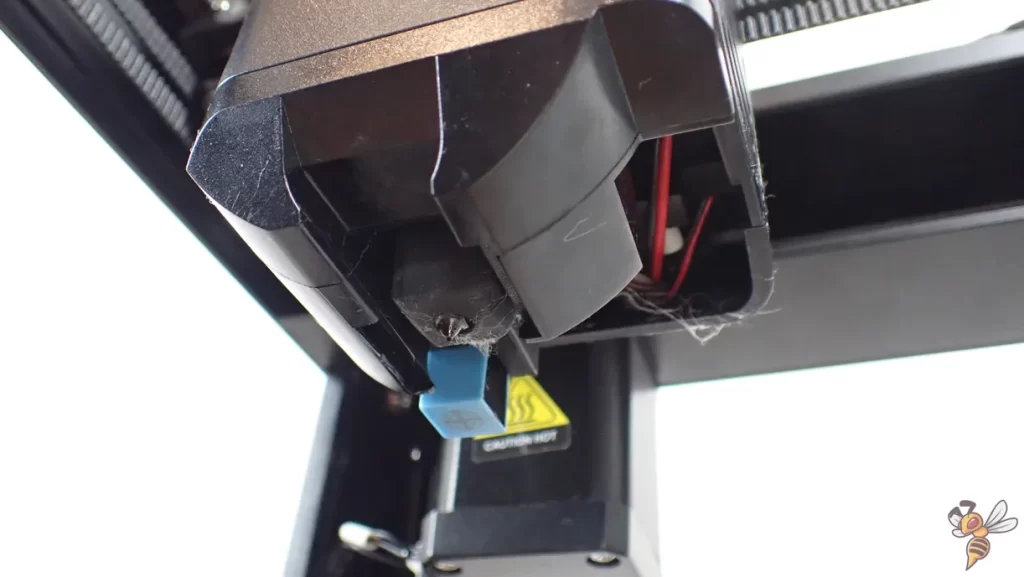

Extruder

The SK1 is equipped with a Near-Range Dual-Gear Direct Drive extruder. The direct drive means that the filament is fed directly into the nozzle. This results in improved responsiveness and accuracy when printing, especially with filaments that require precise handling, such as flexible or very soft materials.

The dual gear system in the extruder ensures even and consistent feeding of the filament. This is particularly important at fast printing speeds or with materials that require a constant feed rate in order to achieve optimum printing results.

Unfortunately, however, the filament can only be loaded and unloaded via the menu. I miss the simple lever mechanism that is available on almost all other 3D printers. This would allow the filament to be loaded and unloaded manually.

Integrated LED Light Strip

A particularly practical feature of the TwoTrees SK1 is its integrated LED light strip.

The LED light strip ensures even illumination of the print bed and thus also highlights fine details of the print objects. This allows printing errors to be detected quickly.

Touchscreen & Menu

The TwoTrees SK1 is equipped with an intuitive touchscreen, which makes operating the 3D printer considerably easier. The menu is clearly structured and user-friendly, allowing you to quickly access all important functions.

It’s nothing special compared to other modern 3D printers, but it doesn’t have any disadvantages worth mentioning. And I personally find the positioning at the top very practical!

Slicer

The TwoTrees SK1 is compatible with various slicers, including popular software such as Cura, Simplify3D and PrusaSlicer.

I used the SK1 with Cura. On the USB stick was a rough guide on how to create a profile for it. After some calibration, I then had print settings that achieved good results.

You can check out my Cura settings in this article: TwoTrees SK-1 – Best Cura Settings & Profile

TIP: Learn how to calibrate your 3D printer to get perfect results every time in my 3D printing course: FDM 3D Printing: The Comprehensive Course from A to Z

(The course teaches everything you need to know for FDM 3D printing in over 60 lessons. The course will get beginners up to my level in no time!)

Print Quality

The TwoTrees SK1 impresses with its excellent print quality thanks to the input shaping, which effectively prevents ringing or ghosting even at high print speeds.

To test the print quality of the SK1 in detail, I printed various challenging objects. All these objects were printed with a layer height of 0.1 mm and a speed of 300 mm/s. These parameters were chosen to test the printer’s capabilities under real-life conditions.

I mainly used PLA filament from SUNLU* for this test.

First, I printed the 3DBenchy, which was already available pre-sliced on the supplied USB stick. The result was very impressive, almost perfect and in just over 16 minutes!

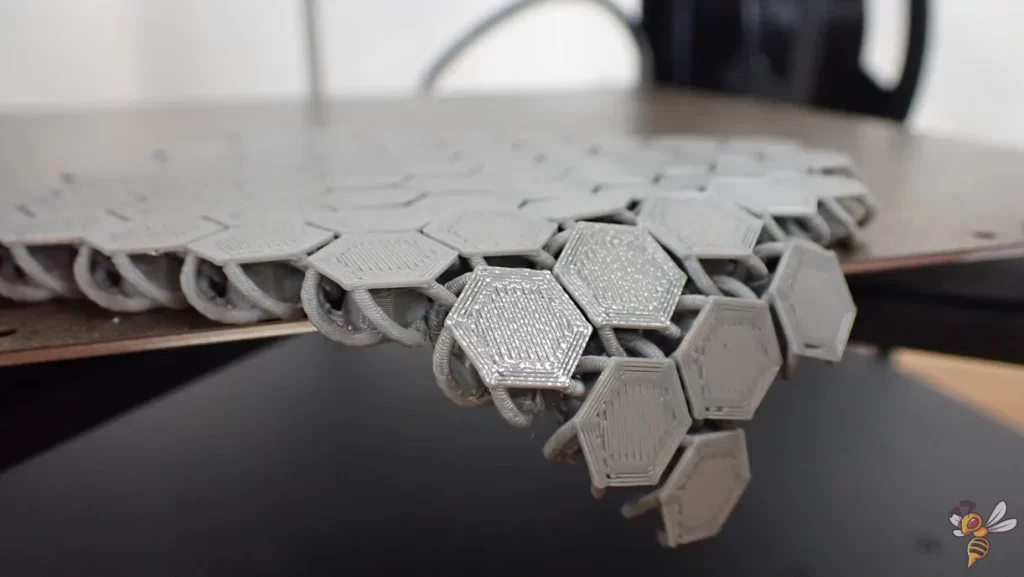

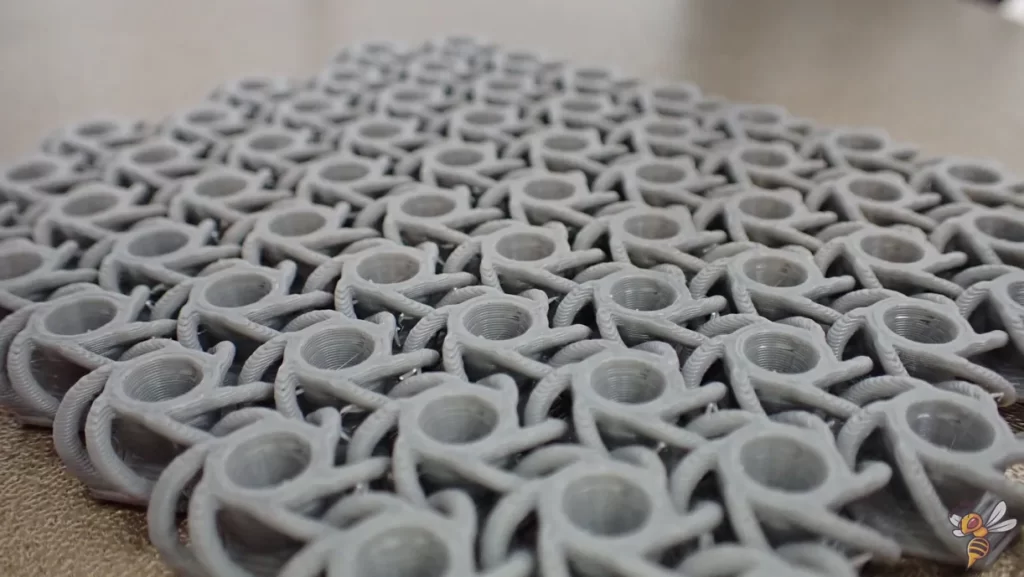

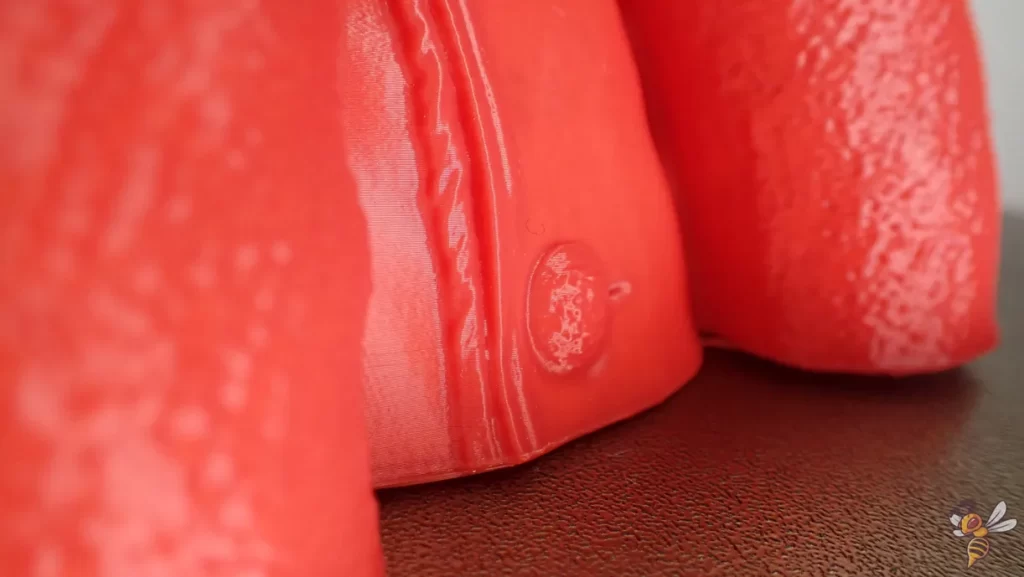

The second print was the so-called NASA Fabric, a model with complex geometry that would challenge the printer. Apart from slight stringing, which is not uncommon with such geometries, there were no printing errors.

Then I printed a bust of Santa Claus. Thanks to the low layer height of 0.1 mm, the details came out very well. Here, too, there were no printing errors.

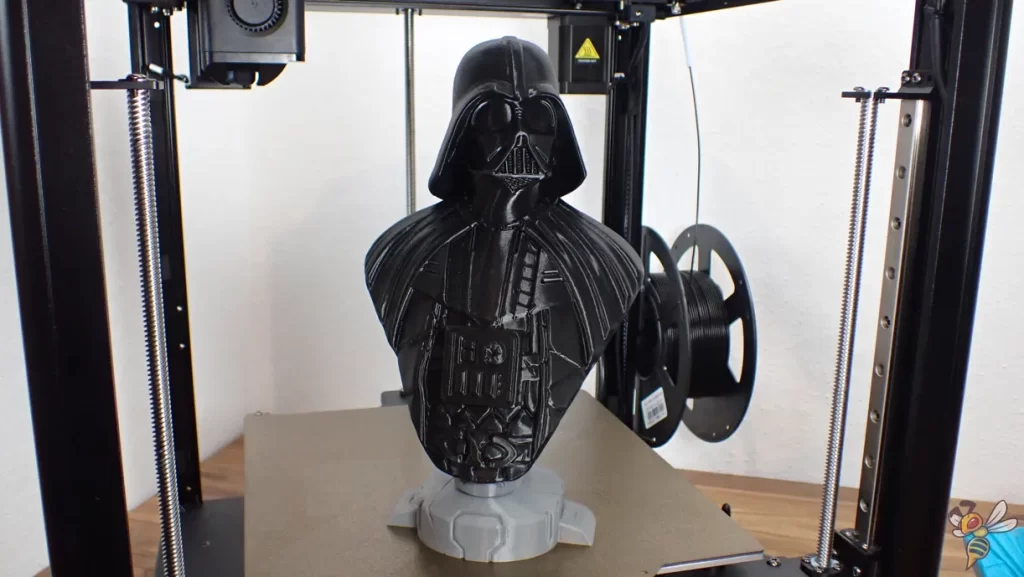

The fourth print I chose was a Darth Vader bust. There were absolutely no defects in this print either, and the result was consistently high quality. The fine details of the bust were reproduced precisely.

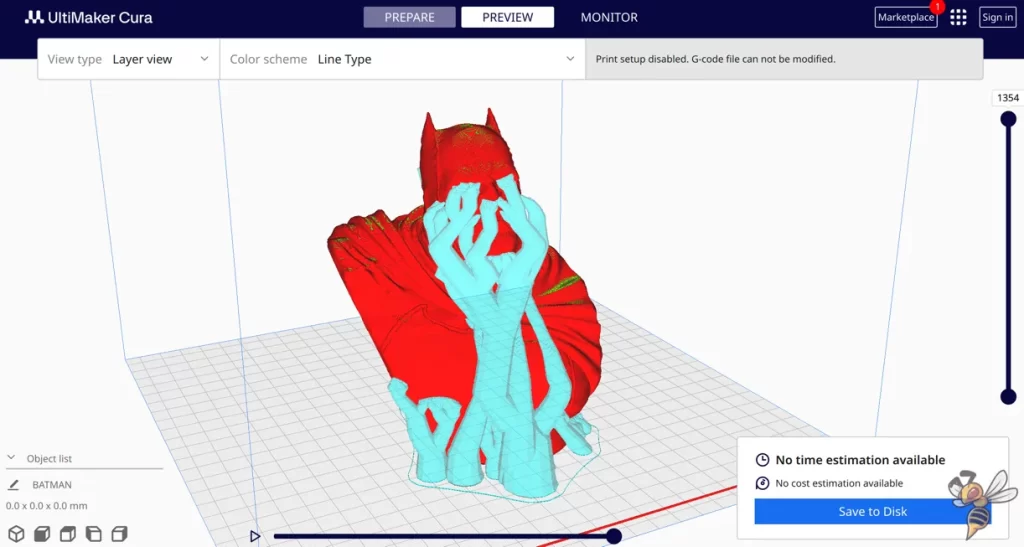

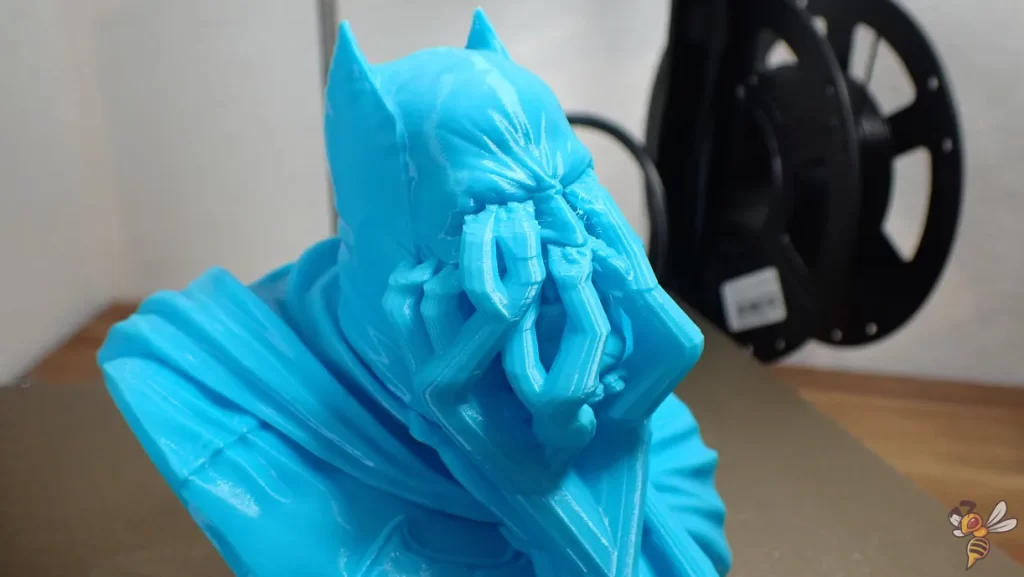

The last print was a Batman bust. I deliberately left the tree supports on as I needed them for a future video. Apart from that, the print quality was flawless here too.

Overall, I am very impressed with the print quality of the TwoTrees SK1. After a quick calibration of the retraction and print temperature, I was able to successfully print all print objects on the first pass with mostly near perfect quality. That’s exactly how it should be!

The combination of high printing speed and precise detail reproduction makes this printer an outstanding tool. However, the SK1 is quite loud at higher speeds…

Noise Levels

The volume of the TwoTrees SK1 when printing is around 65 dB, which is comparable to the background noise of a normal conversation with peaks as loud as a passing car.

This volume can be perceived as relatively loud in an otherwise quiet room. The travel movements of the printer, i.e. the movements of the print head without extrusion, are particularly noticeable.

You can of course reduce the speed of the travel movements in the slicer. But such an adjustment will of course reduce the printing speed.

The high noise levels, coupled with the high-pitched sounds, makes the SK1 unusable for quieter environments. In my case, the printer was still audible even several rooms away. This aspect is particularly relevant for users who want to set up the printer in a living or working area, where a low noise level is desirable.

Print Speed

The print speed of the TwoTrees SK1 is one of its outstanding features. During my tests, I mainly worked with a speed of 300 mm/s. This speed is already a significant advantage over many other 3D printers.

However, the SK1 offers the possibility to increase the speed up to 700 mm/s. In order to achieve these high speeds and ensure good print quality, precise calibration of the printer is essential. For objects with fine details, however, you should definitely stick to a maximum of 300 mm/s!

The high printing speeds of the SK1 are made possible by several technical features. The printer’s CoreXY system contributes significantly to its high speed and precision by ensuring stable and fast movements of the print head.

In addition, input shaping helps to reduce vibrations, which is particularly important at high speeds.

A huge benefit is the time saving that results from these high print speeds, especially with the SK1’s generous print volume. Projects that would normally take several days can often be completed within a day.

Conclusion

After this practical test of the TwoTrees SK1 3D printer*, I come to a positive overall verdict. This printer impresses with its high printing speed, excellent print quality and numerous user-friendly features such as the simple leveling system and intuitive touchscreen.

Particularly noteworthy is the speed with which even larger projects can be realized, making the SK1 attractive for a wide range of applications.

One aspect that deserves attention, however, is the printer’s high noise level, especially at higher speeds. This could be a major drawback or even a no-go in certain environments.

Despite this shortcoming, I would recommend the TwoTrees SK1 for its overall performance and flexibility. It is an excellent choice for users looking for a fast, accurate and versatile 3D printer!

The TwoTrees SK1 is a medium-sized 3D printer with a CoreXY design.

Build Volume: 256 × 256 × 256 mm

Speed: max. 700 mm/s; normal 300 mm/s

Extruder: Direct Drive

Print Bed: PEI, magnetic, flexible

Leveling: Automatic

Firmware: Klipper

Nozzle Temp.: 300 °C

Bed Temp.: 100 °C

Connectivity: WiFi, Ethernet, USB

Pros:

✓ High printing speed

✓ High print quality

✓ Sturdy design with CoreXY system

✓ Versatile with high filament compatibility

✓ Easy operation

Cons:

× High noise level (65 dB at 300 mm/s)

× Extruder cannot be decoupled manually

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.