- Wet Filament: Prevention, Symptoms & Drying - July 18, 2024

- Sovol SV08 – Best PrusaSlicer Settings & Profile - June 26, 2024

- Sovol SV08 – Best Orca Slicer Settings & Profile - June 26, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

PLA is one of the most widely used plastic filaments in 3D printing. The material PLA is easy to handle. Beginners as well as printing experts like to work with this filament. It is one of the most common alternatives to plastic and therefore suitable for various 3D printing objects with numerous uses.

However, it happens that this filament has some sources of error or defects during printing, such as minor bumps or rough surfaces.

To avoid or compensate for these unsightly side effects in 3D printing with PLA filament, PLA can be smoothed or dissolved using various approaches.

PLA can be dissolved by solvents such as acetone, ethyl acetate, methyl ethyl ketone, tetrahydrofuran and caustic soda (sodium hydroxide). This allows cleaning of 3D printer nozzles, smoothing PLA prints and dissolving PLA support structures.

Table of Contents:

- 1 PLA

- 2 How to Dissolve PLA

- 3 How to Smooth PLA

- 4 Safety First

- 5 Solvents for PLA – Pros & Cons

- 6 Related Questions

- 6.1 Where can I get the chemicals to dissolve PLA?

- 6.2 How to use the solvents for dissolving PLA

- 6.3 What is the cost of the chemical agents for dissolving PLA

- 6.4 Can I mix solvents to dissolve PLA?

- 6.5 Can I still use the means for dissolving PLA in 3D printing elsewhere?

- 6.6 Will my 3D printed object be damaged by dissolving PLA

- 7 Conclusion

PLA

Whether a filament dissolves easily depends on numerous factors. In the case of the popular PLA filament, there are other points that play a role in the dissolving of the filament in addition to the composition:

- Filament quality

- Thickness (thickness) of the filament

As with all other products from the 3D printing segment, it is recommended that you set high-quality standards from the very beginning when purchasing your filaments.

The environmentally friendly chemical nature of PLA

The filament PLA, which is frequently used in the 3D printing segment, belongs to the polyactide (PLA) group of plastics. PLA is often also referred to as polylactic acid.

It is considered environmentally friendly because it is made from renewable raw materials, such as sugar and starch, using lactic acid bacteria. Mixing with other biological raw materials is feasible and often necessary.

Definition of PLA in one sentence

In its original structure and in its pure form, PLA is a BIO plastic that only becomes usable for the intended application through additives or further components.

It is also this composition of the PLA filament with other components that can positively or negatively influence the dissolution of the filament. The results in 3D printing depend primarily on the properties of the polyactides, which can vary in molecular mass, degree of crystallization and added copolymers.

From the most popular products made in 3D printing with PLA filaments, we list the following for you:

- Drinking straws

- Disposable cutlery

- Ballpen

- Disposable tableware

- Sheets in fruit and vegetable growing

- Application in medical technology (e.g. some implants)

How to Dissolve PLA

If you are looking for a smooth and neat build of your 3D printed object, dissolving a substrate is one of the best methods. I’m sure you’ve wondered if PLA is even dissolvable. The answer is simple:

PLA is a soluble filament.

In most cases, chemical products are used to dissolve PLA, although there are also gentle treatment options. But there are also environmentally and health-friendly variants.

Which options the consumer uses to dissolve PLA is purely a matter of choice. Experts in this field work with different options, depending on the type of print objects.

Some of the chemical agents for dissolving PLA are easy to get, for others it is more difficult, because they require some precautions and are not easily purchasable. Some solvents can lead to harmful effects if used incorrectly.

However, if you take the help from this guide into account, you can’t go far wrong when dissolving PLA. Various chemical products for dissolving PLA are listed below:

- Acetone

- Ethyl acetate

- MEK (methyl ethyl ketone)

- Tetrahydrofuran

- Sodium hydroxide (caustic soda)

Acetone

Acetone is widely used and a product that almost everyone has at home. It is often used when dissolving PLA, but has the disadvantage that the PLA surface becomes softer and somewhat stickier.

Therefore, caution is required so that your 3D printed object is not destroyed when using acetone. Just try it on a very small print area.

If you wonder which quantity is the right one, it is better to use it sparingly at first. You can always increase the amount.

Acetone is also very easy to get online – like this one from Amazon*.

Ethyl acetate

Ethyl acetate is an ethyl acetate formed from acetic acid and ethanol. This chemical compound performs well in dissolving PLA. The pleasant-smelling chemical (smells of strawberry and banana) belies a potential danger that should not be underestimated.

Ethyl acetate is highly flammable, which must be taken into account, especially during storage. You should only use the chemical separately and not together with other products.

Methyl ethyl ketone (MEK)

Methyl ethyl ketone is a highly effective solvent. However, experts advise against the use of this highly dangerous chemical, especially at home.

Tetrahydrofuran

Tetrahydrofuran, also oxolane, is mostly used in the industrial sector today for the complete dissolution of PLA and other materials.

At the same time, this chemical bomb is a very dangerous material.

It has a very low flash point, which makes it highly flammable. In addition, tetrahydrofuran can cause severe damage to health when inhaled over time. Therefore, according to the latest findings, one tries to keep the handling of oxolane as low as possible today.

The vapor of the tetrahydrofuran smoothes PLA surfaces. Under no circumstances should you inhale these vapors.

Caustic soda (sodium hydroxide)

When looking for a substitute for tetrahydrofuran, caustic soda* is recommended. It is more readily available, but should also be treated with caution.

It is also used, for example, also in drain cleaners, which reflects the intensity of the agent. For dissolving or smoothing PLA, the following mixture has proven effective:

Dissolve 120 grams of caustic soda in 1 liter of water.

The PLA carrier is dipped into the solution bath for smoothing. You should definitely wear special gloves and protective goggles during this process. The containers for the caustic solution and the storage of caustic soda should also meet high safety standards.

When it comes to caustic soda for dissolving PLA, the opinions of consumers vary widely. Some achieve very good results with this chemical agent. Others criticize sodium hydroxide as highly aggressive and report unpleasant experiences with easy flammability.

Therefore, experts strongly recommend that consumers use the above concentration of 120 grams per 1 liter of water.

Material Safety Data Sheets recommend that when using any of these products, be sure to wear safety glasses, special gloves, and possibly an apron so your clothes don’t get corroded.

How to Smooth PLA

The chemical products mentioned make dissolving or smoothing PLA very easy. However, because of the high risk potential for the environment and health, there are other alternatives.

Three promising alternatives in dissolving and smoothing PLA that can solve your problem:

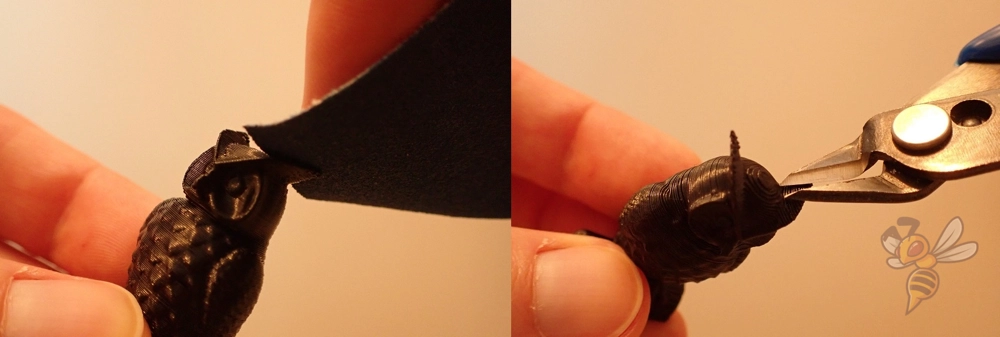

- Use the same build material and support material in 3D printing: If you use the same filament for the support material in 3D printing as for the building material, you will achieve better results on the 3D printed object from the outset. It may be possible to dispense with smoothing or dissolving the filament entirely. A sandpaper or an X-Acto knife can be used to remove the carrier material.

- Tools for welding PLA surfaces: A good alternative solution if you do not want to use chemicals for dissolving or smoothing PLA is to use tools for welding PLA surfaces. This gives you a smooth and clean surface on your 3D printed object after printing.

- Primer spray after sanding: When finishing your 3D print, you will never be able to remove all layer lines even by sanding. The surface will therefore still look unfinished and uneven. This can be compensated or prevented by using a filling and sandable primer paint spray. The layers dry out quickly. Now sand the primer down to the surface.

TIP: If you can, do not use a grinding machine. The vibrations could damage delicate printed objects to the point of making them unusable. It is better to use gentle sandpaper. If you really want to use a grinding machine, approach your print object cautiously.

A primer paint spray also contains a small amount of chemicals, but is far less harmful than corrosive solvents used to dissolve PLA.

Then use colors of your choice to paint your 3D artwork, giving it an expression of aesthetics and beauty.

Safety First

Hazardous solvents

You don’t like the alternative methods to chemicals and don’t see any other options to chemistry for dissolving and smoothing the filaments? Then for the sake of your health, follow this advice for your 3D printing projects at home:

Two chemicals that are even more dangerous than others: DCM or methylamine.

These two products should be completely avoided at home. If methylamine or dichloromethane are used as solvents for PLA in the industrial sector, carefully defined protective measures are taken there.

The importance of the safety data sheet

The safety data sheets for chemical products for dissolving PLA are like the fine print. They are rarely read. But experts recommend doing just that.

For your own safety, we also recommend that you study the safety data sheet included with the purchase of a solvent. Often the safety instructions are also printed on the packaging, cans, containers or bottles.

Solvents for PLA – Pros & Cons

PRO

- Chemical solvents work reliably, quickly and cleanly;

- they can be used to support complex or internal structures;

- while complying with safety standards, they are easy to handle.

CON

- Chemical solvents may draw moisture from the printed object; therefore, it is advisable to keep it in a temperature and humidity controlled environment until final completion;

- chemicals necessary to dissolve PLA plastic can be harmful and dangerous.

Related Questions

Where can I get the chemicals to dissolve PLA?

Some agents, such as acetone, can already be found in every household in the form of nail polish or are available in drugstores or online. Highly dangerous substances, on the other hand, are not so easy for private individuals to obtain.

On the other hand, you can easily order many of these solvents on the Internet today. Away from the digital life, you can find the solvents for your needs in the following places:

- Ethyl acetate: drugstores, health stores, auto supply stores, possibly hardware stores.

- Methyl ethyl ketone (MEK): hardware stores, paint and wallpaper stores, possibly pharmacies

- Tetrahydrofuran: Home improvement stores, tool and craft stores.

- Caustic soda (sodium hydroxide): pharmacies, some drugstores, hardware stores

How to use the solvents for dissolving PLA

In any case, careful handling is recommended due to the potential danger of the solvents for health and the environment. Normally, the chemicals react immediately with the PLA. Depending on the concentration, they dissolve the polymer faster or slower.

The intensity of the dissolution also depends on the concentration. The dissolution of PLA should not lead to the destruction of your 3D-printed object. Protect yourself during the use of the solvents by wearing gloves and possibly a respirator. You should not use too aggressive agents at home anyway.

What is the cost of the chemical agents for dissolving PLA

It is not possible to name a fixed price. Acetone, however, is one of the solvents with rather low costs. The prices of other agents, such as caustic soda, ethyl acetate, methyl ethyl ketone or tetrahydrofuran, vary considerably.

Among the most important components for pricing are the quality of the solvent, the quantity, and the store or online store where you purchase the best agent for your needs.

Can I mix solvents to dissolve PLA?

Mixing of solvents is strongly discouraged. The mixing of chemical products, especially caused by laymen, can cause dangerous chemical reactions ranging from fire to explosions.

Can I still use the means for dissolving PLA in 3D printing elsewhere?

Yes. The named solvents from this guide are versatile. Extruder heads can be cleaned very well with MEK or acetone. However, make sure that the printer is completely switched off during the cleaning process.

Will my 3D printed object be damaged by dissolving PLA

A print object can possibly be damaged by dissolving PLA with the solvents mentioned. However, if you approach this matter professionally and responsibly, nothing will happen to your printed piece and it will have a smooth and attractive surface.

You can try out the reaction of the solvent on a print sample or get advice in specialist stores for 3D printing. Many consumers have also found the right agent through exchanges with other consumers.

Conclusion

In 3D printing, as in all other areas of design, minor and major inconveniences can arise. For all challenges, on the other hand, there are experts who already have proven solutions ready.

Even dissolving PLA is not a Sisyphean task. Whether you prefer to use effective chemical products or consider more gentle options is always in the eye of the beholder and is your personal decision.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.