- Wet Filament: Prevention, Symptoms & Drying - July 18, 2024

- Sovol SV08 – Best PrusaSlicer Settings & Profile - June 26, 2024

- Sovol SV08 – Best Orca Slicer Settings & Profile - June 26, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

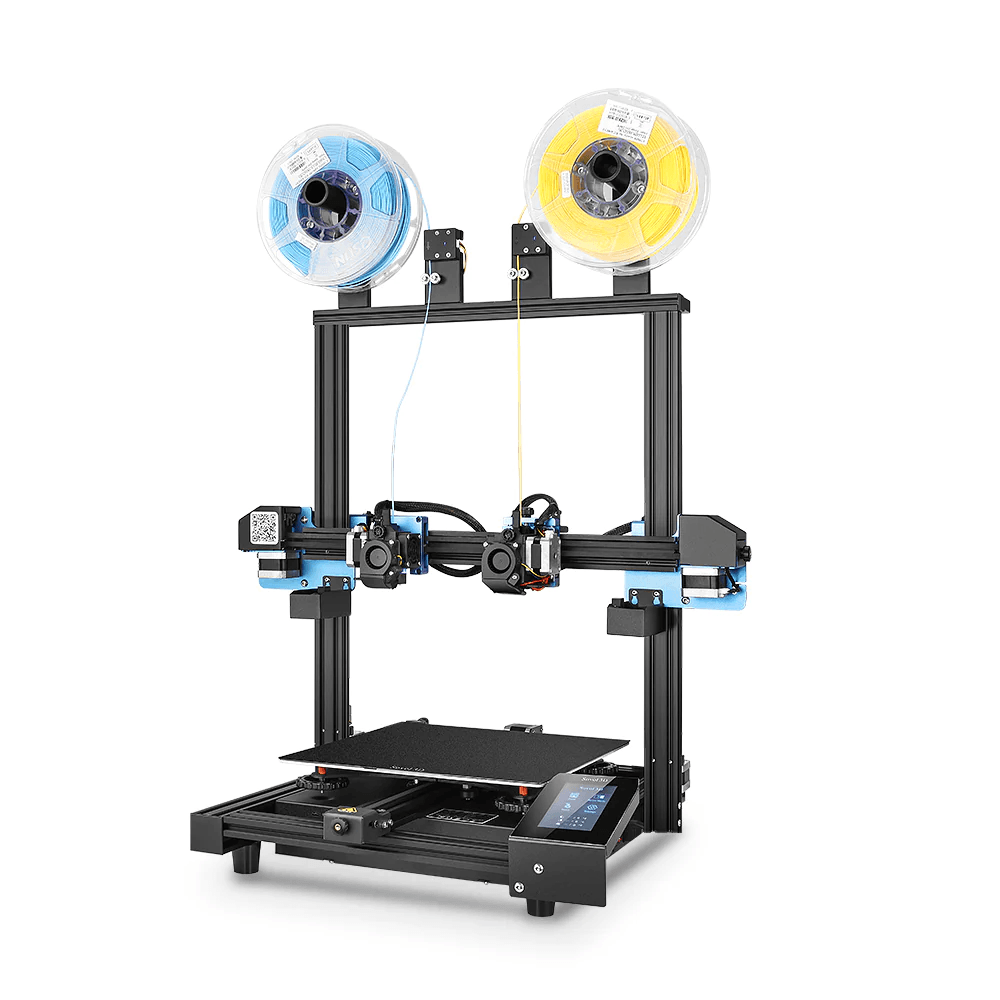

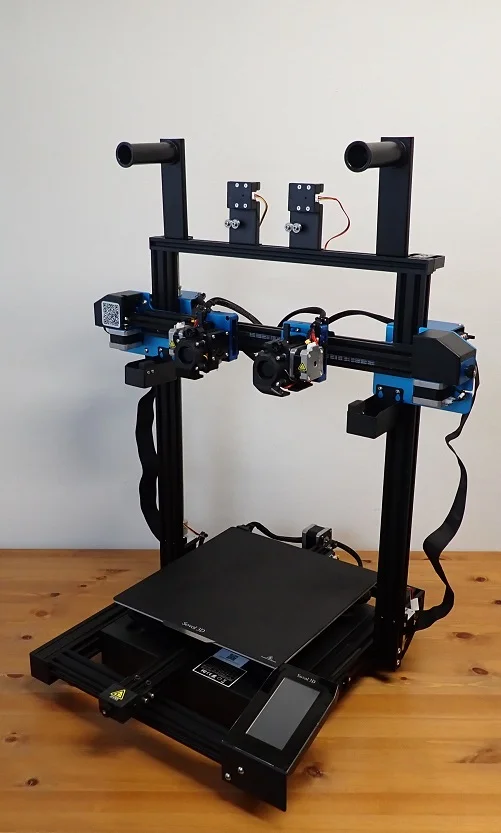

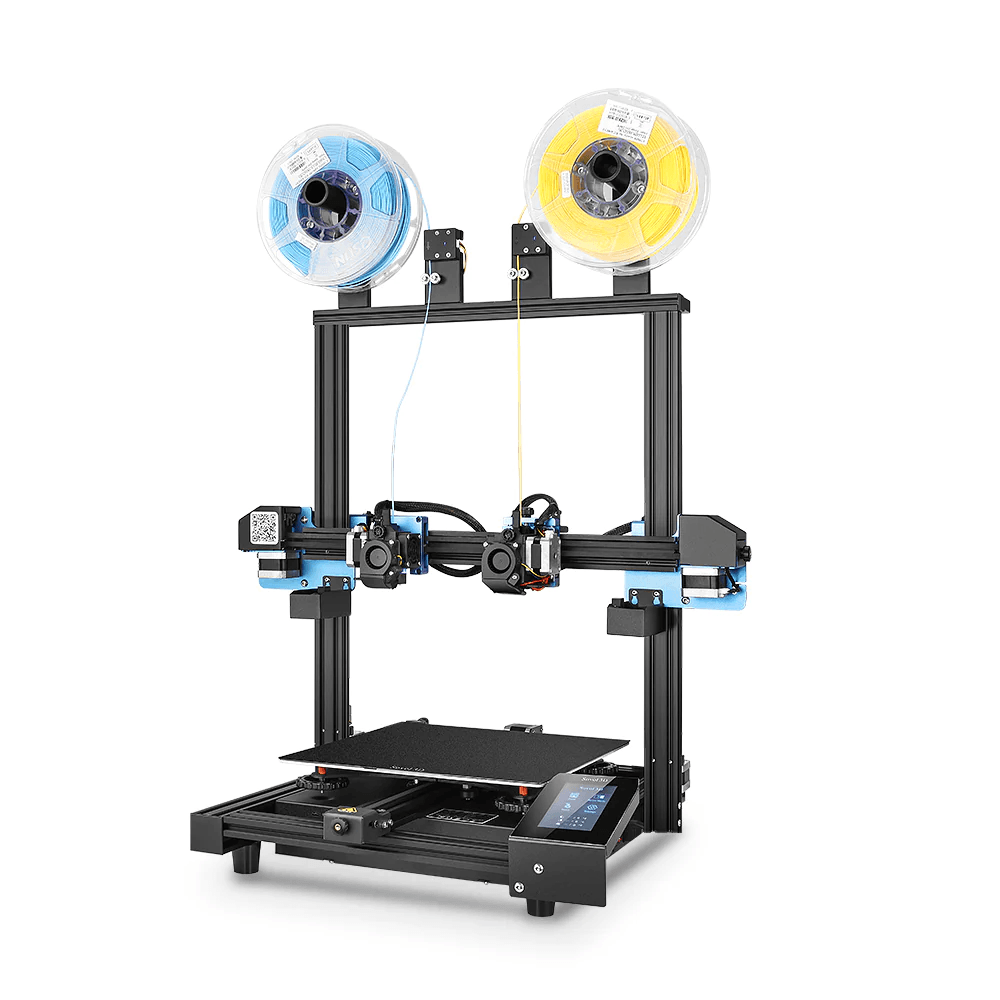

The Sovol SV04 is an IDEX 3D printer with two independent direct drive extruders. This allows for two-color objects or soluble support structures. It has an accuracy of 0.1 mm, automatic print bed leveling and a magnetic flexible print bed.

In this hands-on test and review, you’ll learn how easy it is to set up the Sovol SV04*, what features it has, what print modes it has, and what kind of print quality you can expect from it.

Check Price at:

Table of Contents: [show]

Key Takeaways

- 2 direct drive extruders

- 4 print modes: Dual Mode, Mirror Mode, Duplicate Mode, Single Mode

- 0.1 mm accuracy

- PLA, TPU, TPE, HIPS, ABS, PETG, WOOD, PC, PA, PVA, ASA

- Sturdy construction, easy assembly

Who Should Buy Sovol SV04?

The Sovol SV04 is suitable for anyone who wants to print in two colors or with soluble support structures. It is suitable for beginners with some technical understanding as well as for professional users.

Advantages & Disadvantages

> Sovol SV04 Review

PRO:

- 2 extruders: Can print 2 colors or 2 objects at the same time

- Automatic print bed leveling

- Filament sensors

- Touchscreen

- Direct drive extruders

- Magnetic flexible print bed

- Wide range of filaments (PLA, TPU, TPE, HIPS, ABS, PETG, WOOD, PC, PA, PVA, ASA)

- Easy setup and operation

CON:

- Calibration of the extruder can be daunting for beginners (but is explained very well in the manual)

Technical Specifications

> Sovol SV04 Review

DEVICE

- Technology: FDM (Fused Deposition Modeling), IDEX (Independent Dual Extruders)

- Assembly: Partially pre-assembled

- Size: 653 x 625 x 803 mm

- Weight: 15 kg

- Frame Material: Aluminum

- Operation: 4.3-inch color LCD touch screen

PRINTING

- Extruder: Direct Drive (extruder sits directly in the print head)

- Print volume: 300 x 300 x 400 mm

- Layer thickness: 0.1 mm

- Nozzle quantity: 2

- Nozzle diameter: 0.4 mm

- Max. Nozzle temperature: 260 °C

- Max. Print bed temperature: 100 °C

- Max. Print speed: 120 mm/s (60 mm/s recommended)

- Filaments: PLA, TPU, TPE, HIPS, ABS, PETG, WOOD, PC, PA, PVA, ASA

- Filament diameter: 1.75 mm

- Print bed: spring steel, flexible, magnetic

- Print bed leveling: Automatic (3D Touch)

- Resume Print: Yes

- Filament Sensor: Yes

SOFTWARE

- Connectivity: SD card, USB

- File formats: STL, OBJ, AMF, DAE

- Slicer: Sovol3DCura, Cura, Simplify3D, Repetier-Host

Scope of Delivery

> Sovol SV04 Review

The Sovol SV04 comes with two different colored filament samples and the necessary tools for assembly. However, the two filament rolls are only enough for a few test prints, which is why you should order more filament when you buy the printer so that you don’t run out immediately.

Since the printer itself is very large, the packing size is also correspondingly large. With one person, the package is just about or only difficult to carry – depending on how tall you are. Nevertheless, the individual parts in the package are very well protected from transport damage and arranged in a space-saving manner.

The following things are included in the scope of delivery of the Sovol SV04:

- Pre-assembled 3D printer:

- 3D printer base with print bed

- Frame with X-axis and both extruders (the toothed belts are already mounted and pretensioned)

- Display

- 2 filament holders

- 2 filament sensors

- 2 rolls of PLA filament (sample size)

- Tools:

- Spatula for filament residues on the print bed

- Side cutter

- Nozzle cleaner (long thin needle)

- Wrench

- Small screwdriver

- Allen key

- Replacement teflon tube

- All necessary screws

- Cable tie

- Calibration pieces for the x-axis

- SD-USB adapter

- SD card:

- User Manual

- Software and drivers

- Calibration tutorial

- Models

- Tutorial videos

Setup

> Sovol SV04 Review

The assembly of the Sovol SV04 is very simple. The main parts of the 3D printer are already pre-assembled and only need to be connected together. The most complicated part of the assembly is the calibration of the X-axis and the two extruders so that they know their respective positions.

The assembly of the Sovol SV04 is done in the following steps:

- Mount the frame to the base: The frame with the X-axis and the two extruders is fixed to the 3D printer base by 4 screws. The X-axis is already completely pre-assembled and the toothed belts are pre-tensioned.

- Screw the filament holder and filament sensors to the frame.

- Mount the display to the 3D printer base.

- Connect the cables: Since the Sovol SV04 has two extruders, there are also a few more cables to connect than with normal 3D printers. However, all cables are very well marked and already routed so that a wrong connection is not possible.

X-Axis Adjustment

To ensure that the X-axis is perfectly parallel to the base, two pieces of wood of the same size are included in the scope of delivery. This looks a bit improvised at first glance, but you can use it to adjust the X-axis very precisely.

They are placed vertically between the X-axis on both sides and the ground. There is a very good video on the SD card that describes this process well.

Print Bed Leveling

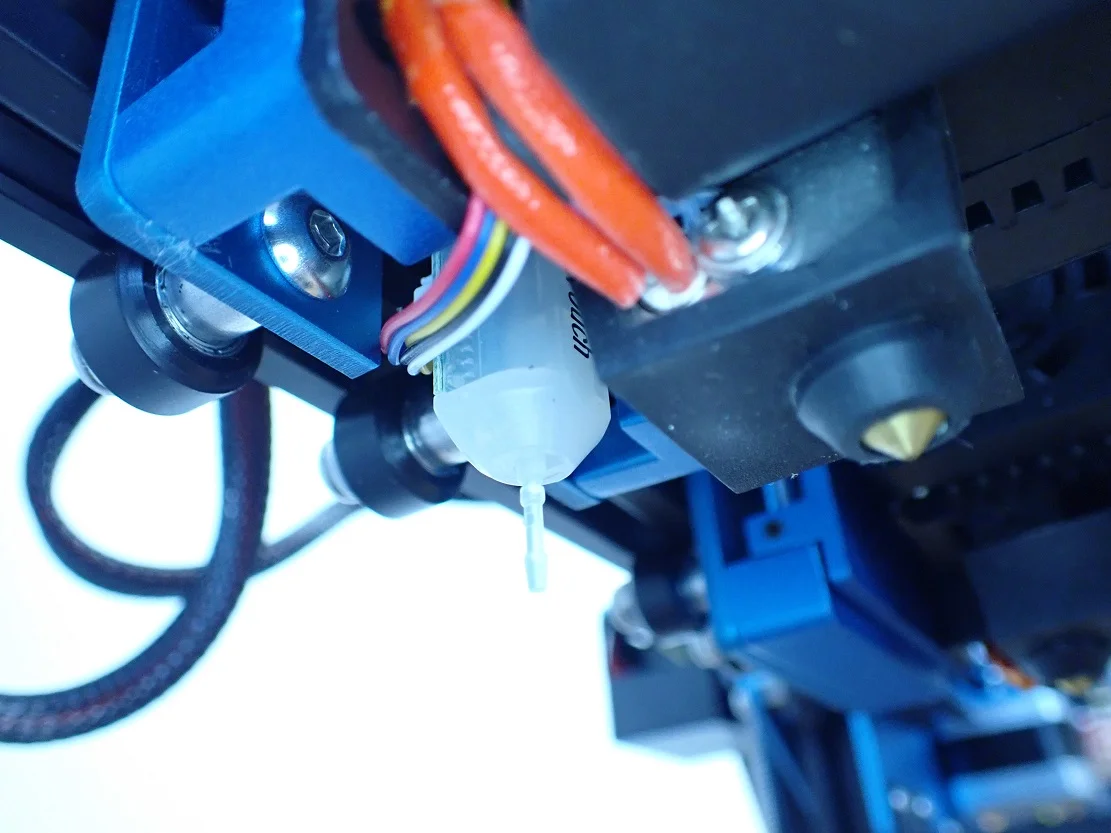

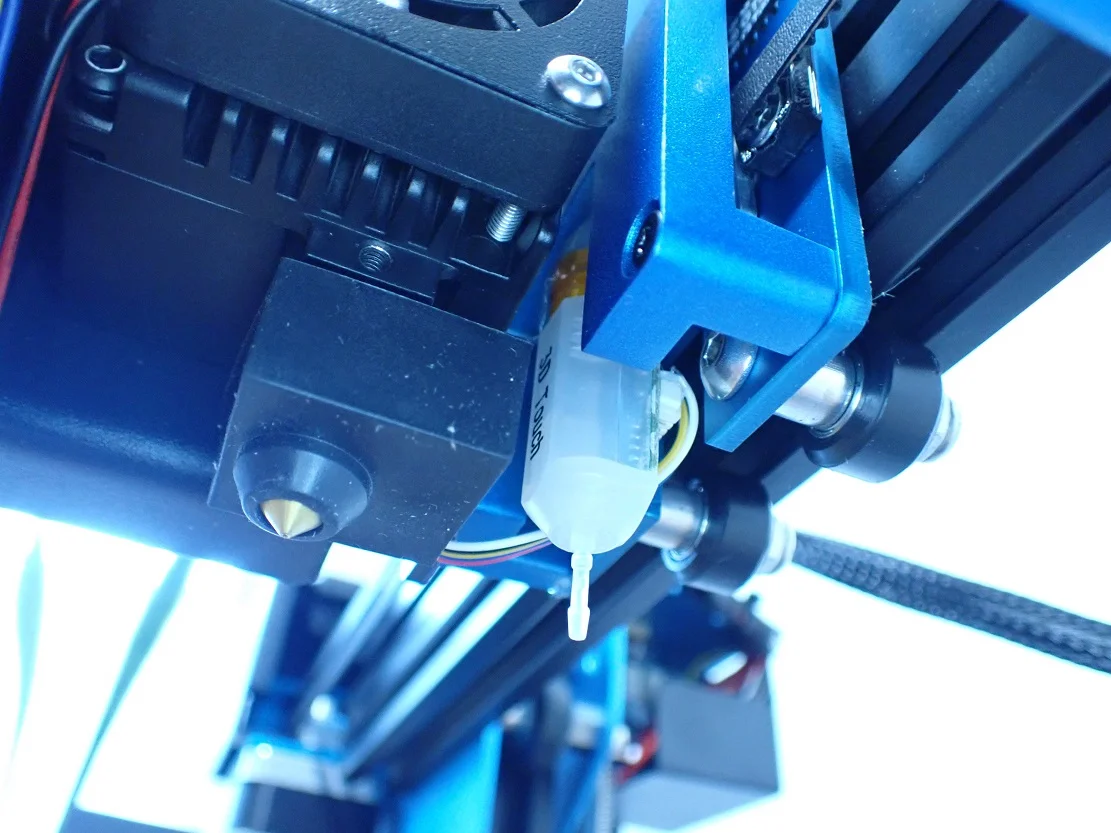

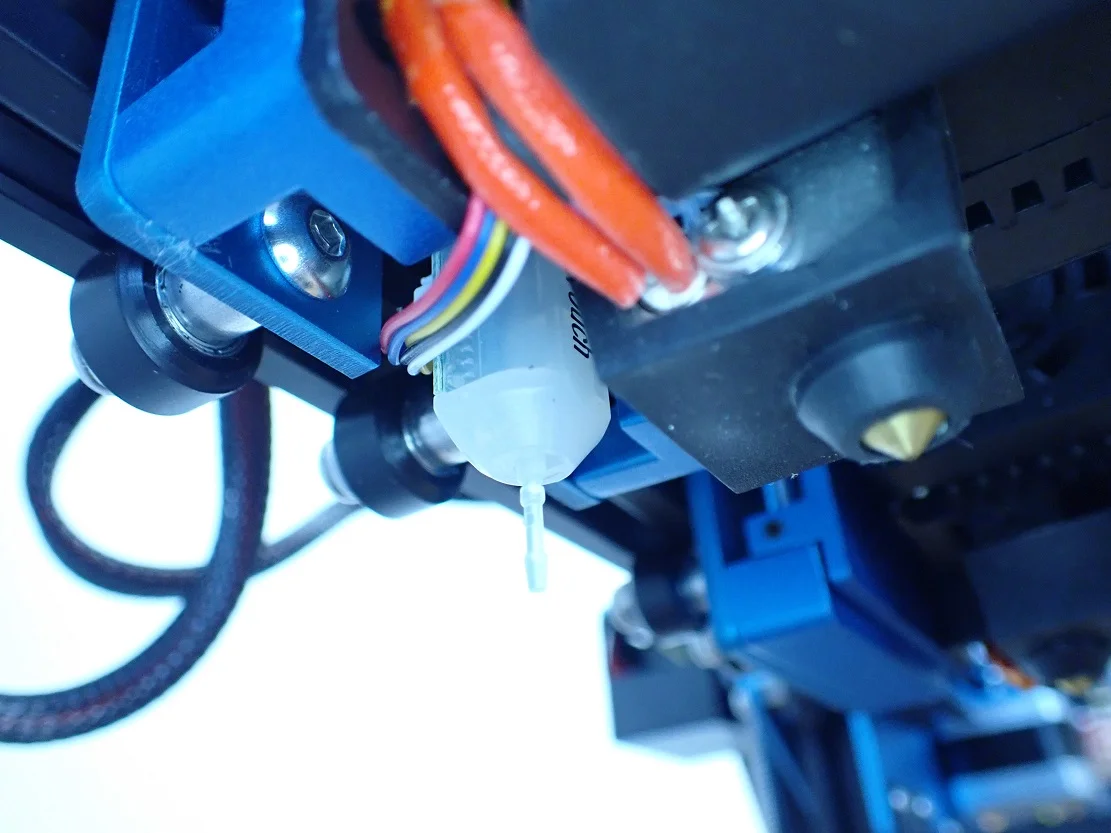

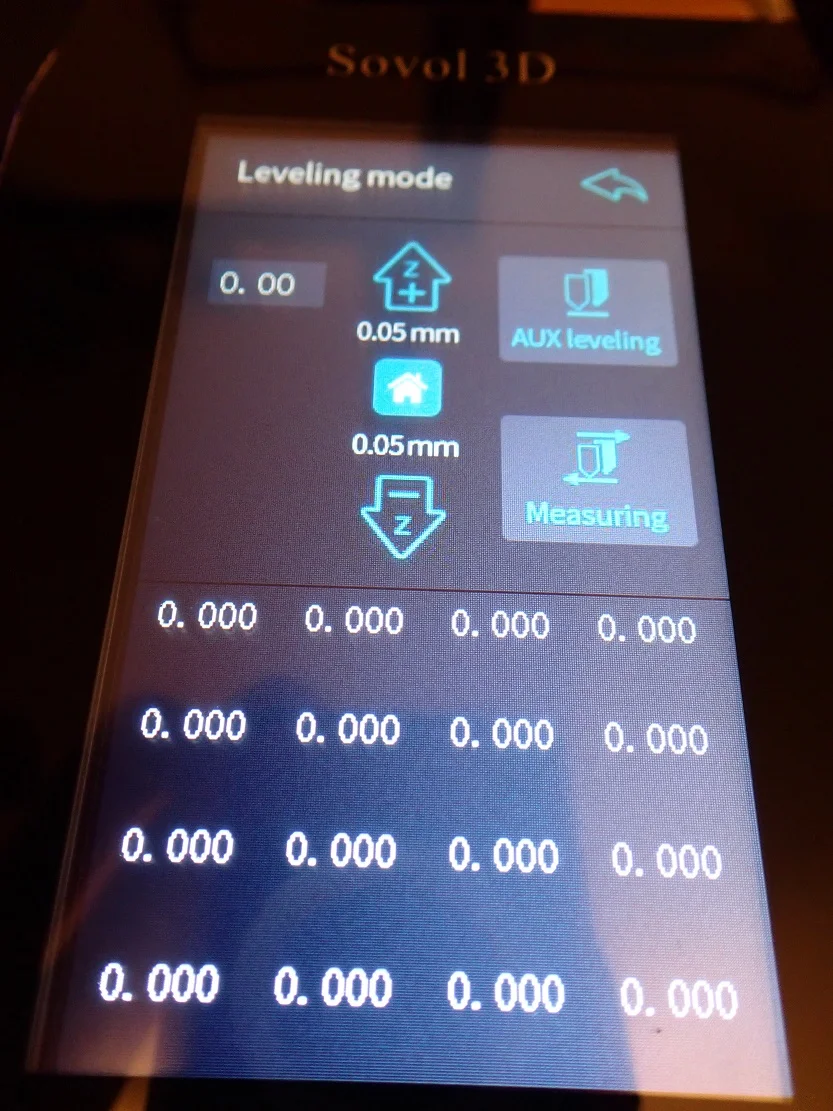

The left extruder has a 3D-Touch, a sensor for automatic print bed leveling. However, before you use the automatic print bed leveling, you must manually level the print bed once and adjust the Z-offset.

Due to the automatic print bed leveling, the printer remembers the inclination of the print bed and compensates it automatically during printing. For this to work on the right extruder as well, you need to set the Z-offset here as well. For this purpose, there is a device on the right extruder with a screw to adjust the height of the nozzle.

Before you do all this, however, I recommend you install the latest firmware for the Sovol SV04. For me, the adjustment of the Z-offset did not work properly before the update, resulting in extremely poor print bed adhesion. After the firmware update, the process was very easy and done within a few minutes.

Extruder Adjustment

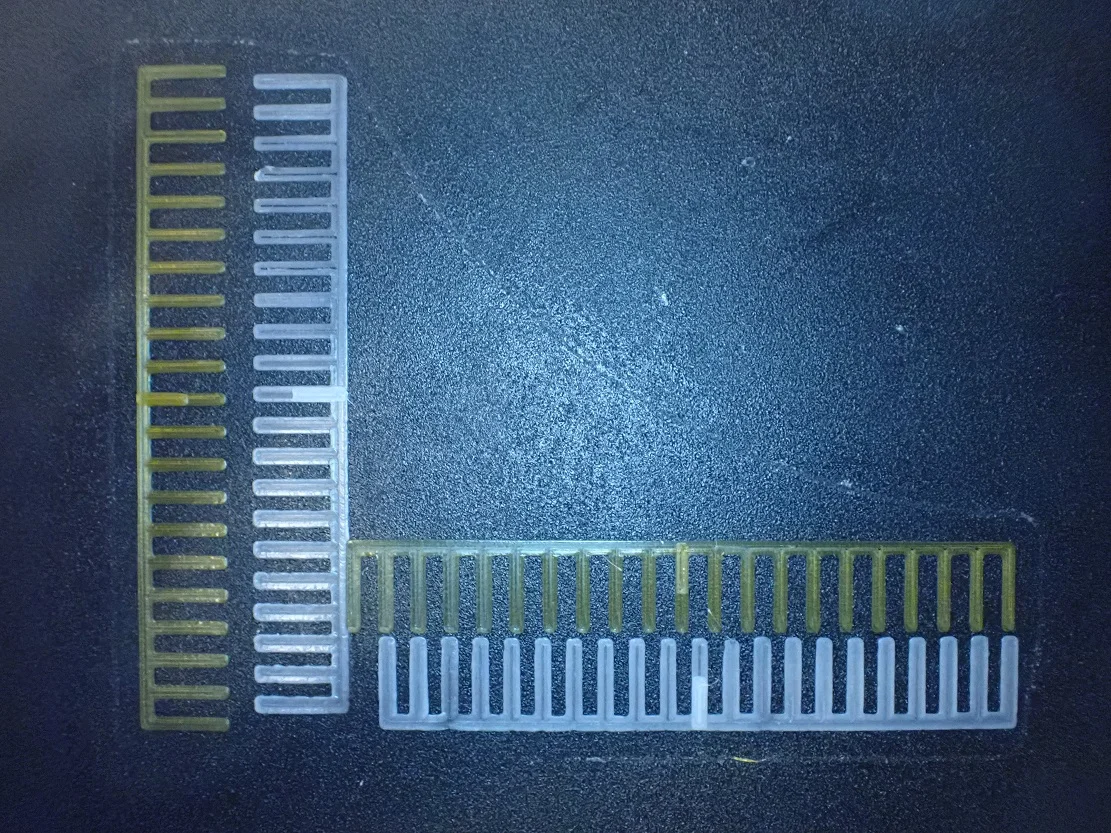

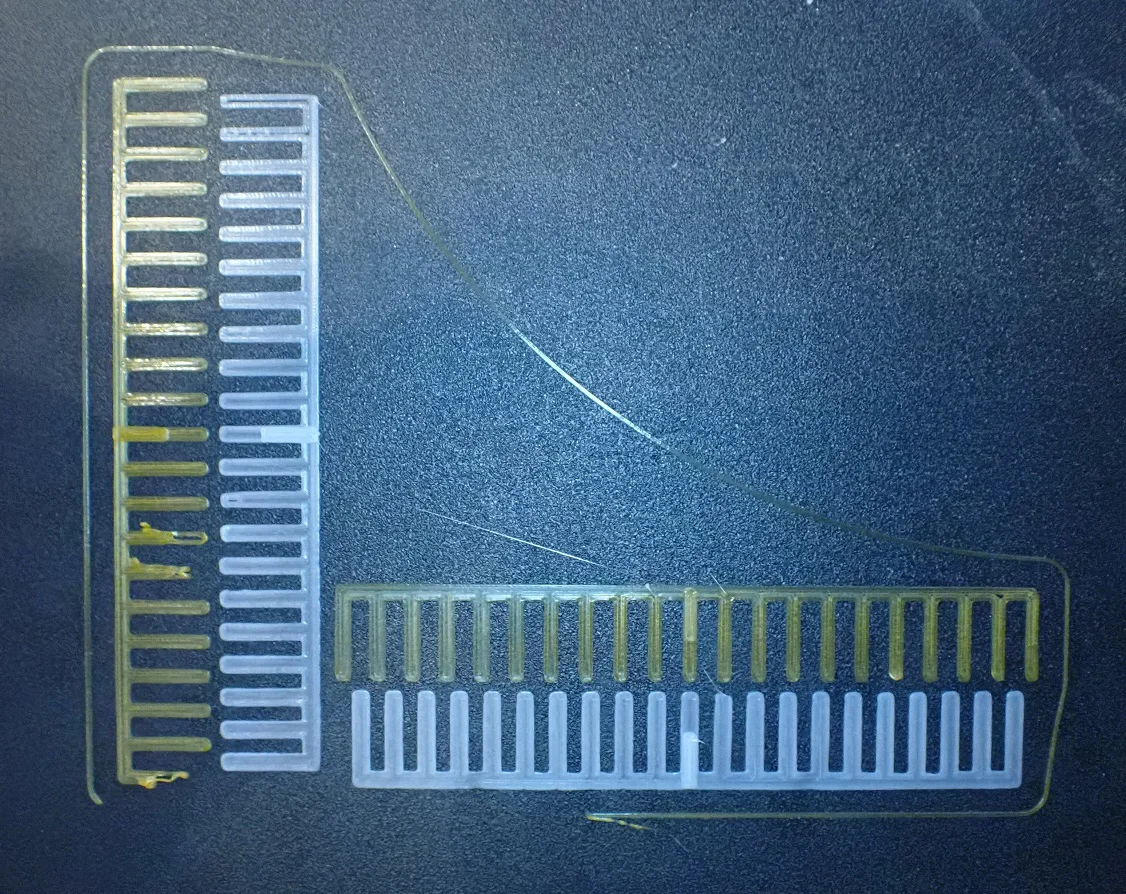

After you have adjusted the X-axis and the print bed, you still have to calibrate the two extruders underneath each other. There are special calibration objects on the SD card for this purpose, which basically work like a mechanical caliper.

You print a scale in dual mode with each nozzle. These scales are slightly different and show you how many tenths of a millimeter they are apart. With a little math, which is also explained in a very easy-to-understand manual on the SD card, the offset can be entered and compensated in the 3D printer menu.

Features

> Sovol SV04 Review

Besides the most important feature of the Sovol SV04*, the two extruders, this 3D printer also has many other quality-of-life features that will be presented in the following lines.

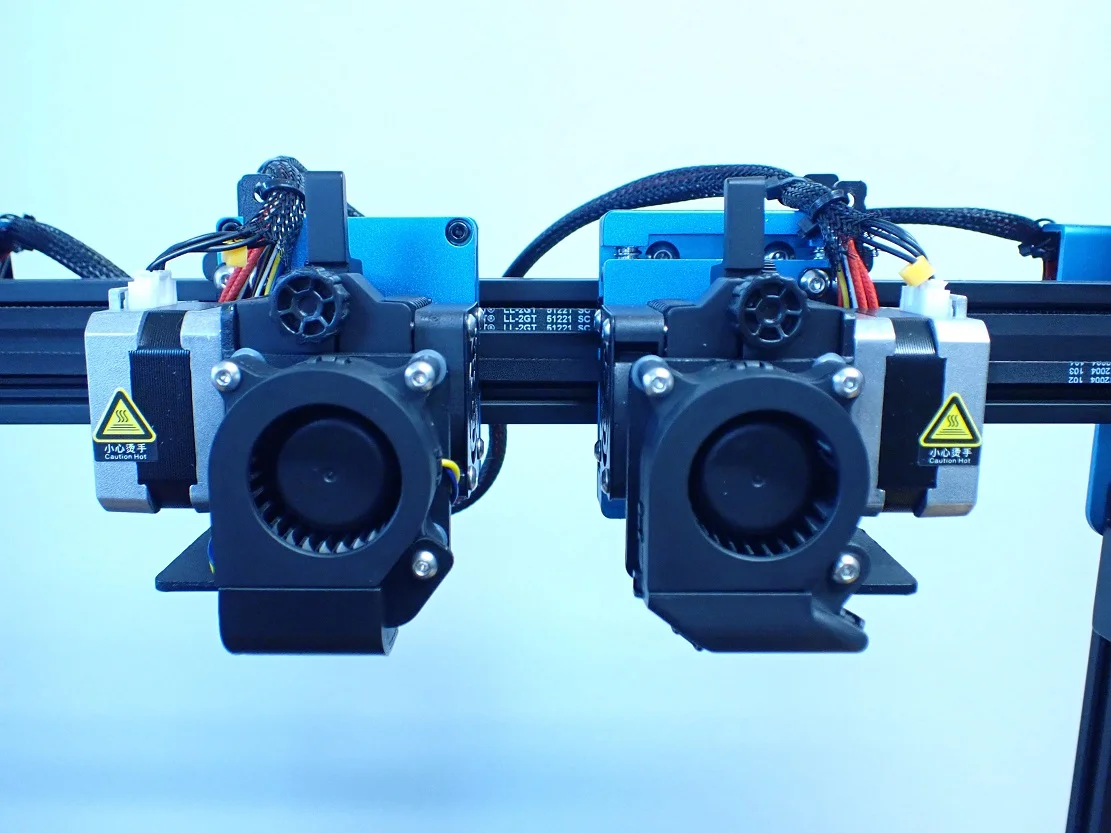

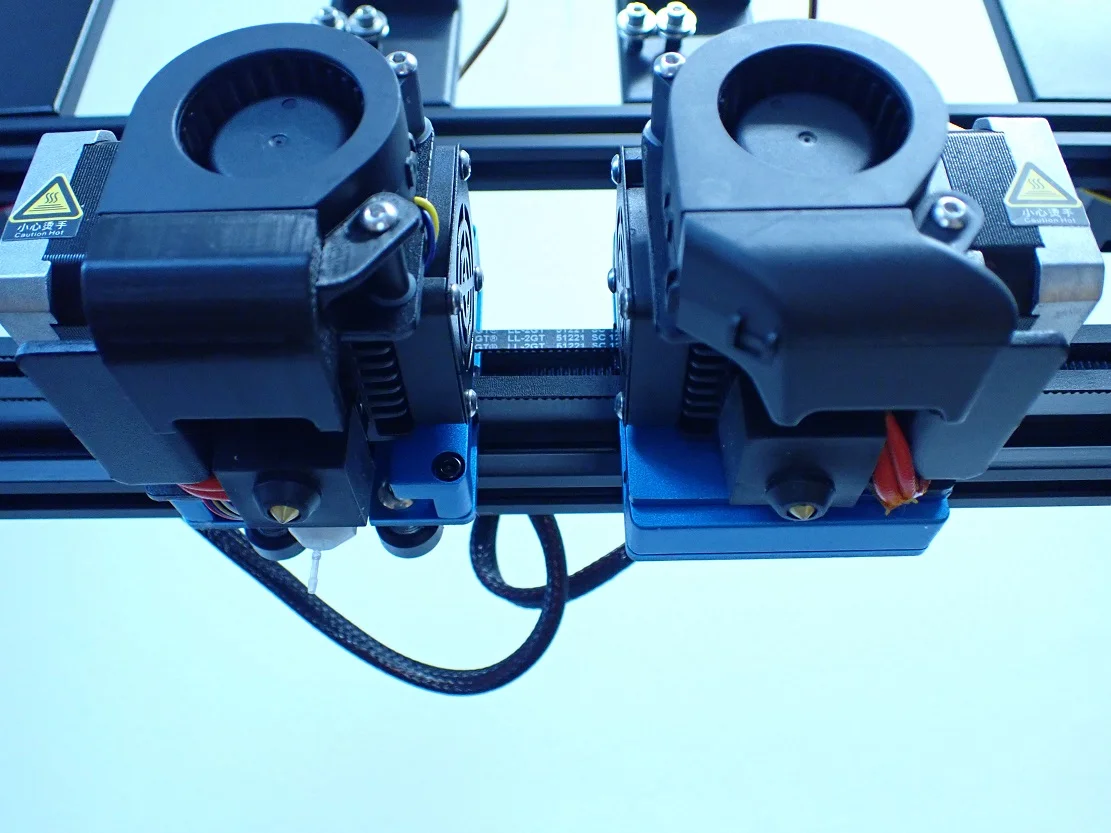

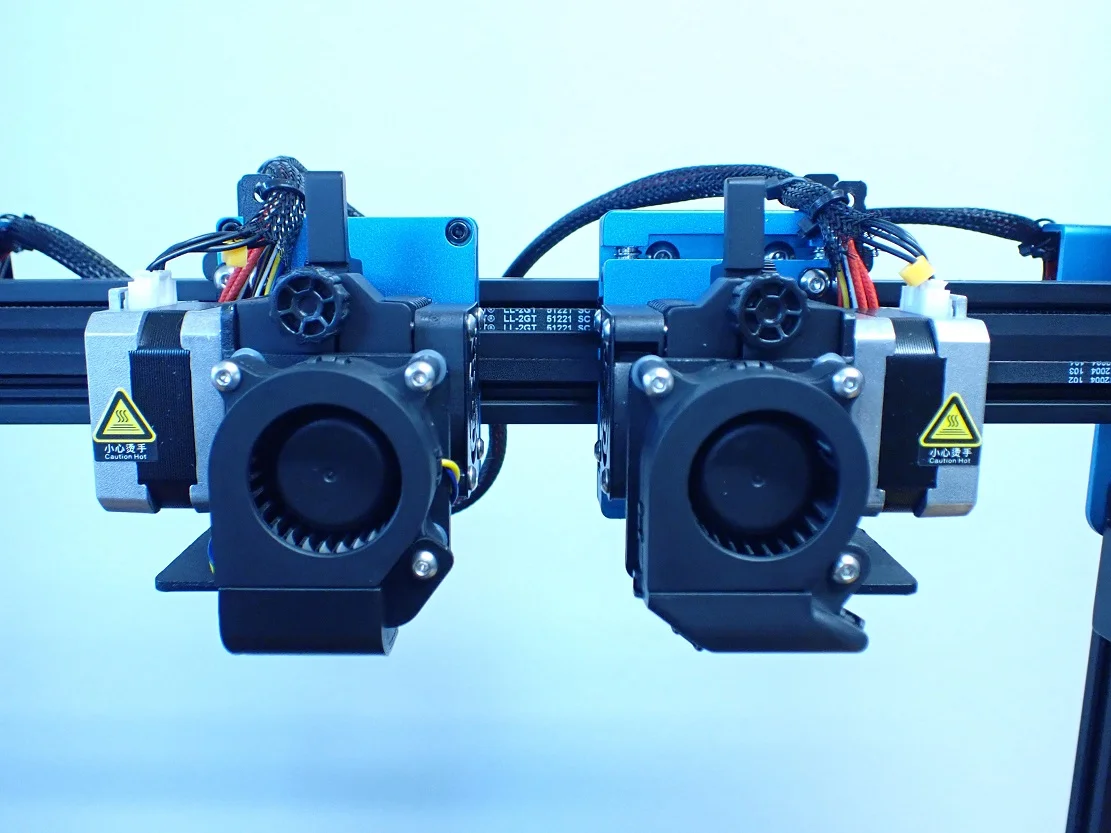

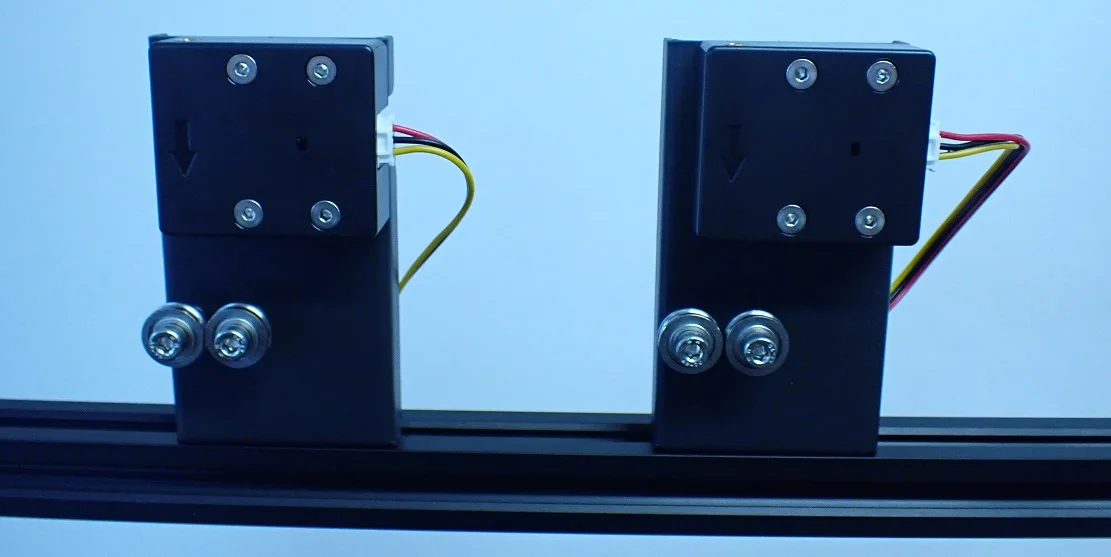

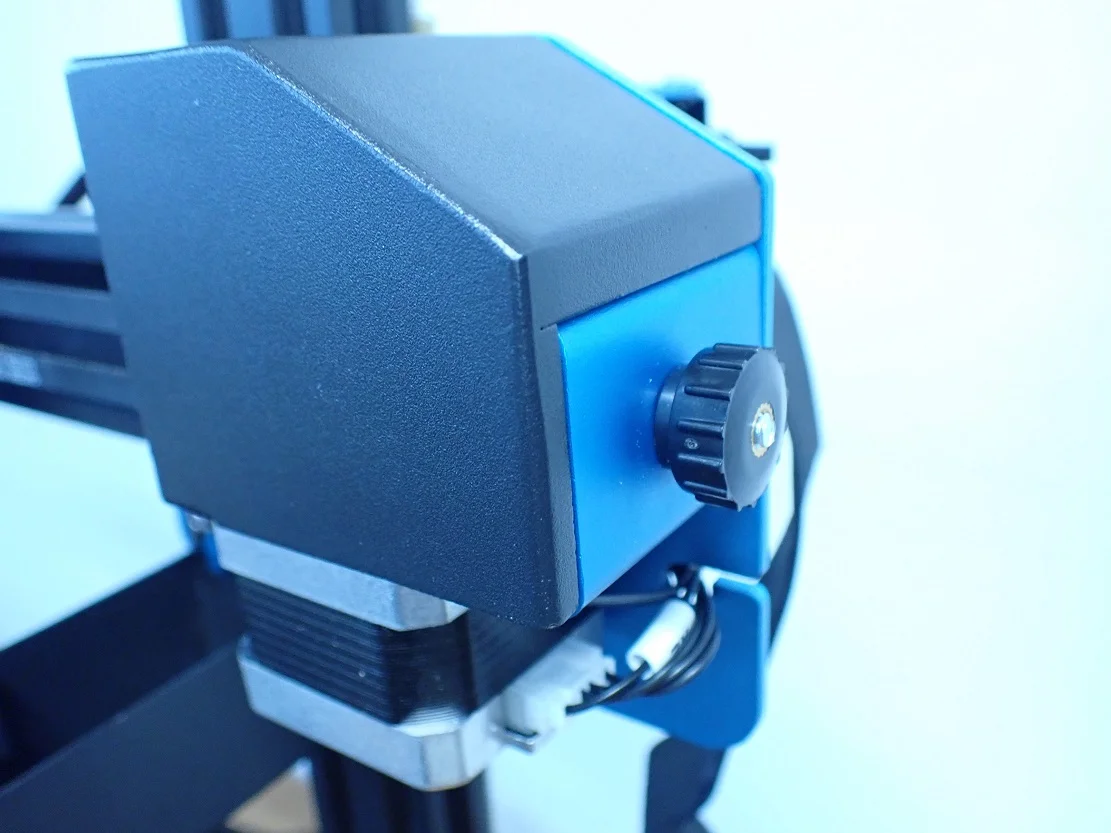

IDEX – Two Print Heads

The Sovol SV04 has a so-called IDEX extruder system (Independent Dual Extruders). This means that there are two extruders (or two complete print heads with nozzles, etc.) on the X-axis, which can be moved independently of each other. The independent movement is only limited by the other extruder – depending on the print mode. Since they are on the same axis, they cannot of course be in the same place at the same time.

With an IDEX system there are many possibilities to combine the two extruders:

- Single Mode

- Dual Mode

- Mirror Mode

- Duplicate Mode

Single Mode

In single mode, the Sovol SV04 resembles a normal FDM 3D printer. It uses only one extruder to print the object in this mode.

This mode definitely has its justification, since there are many buyers who buy an IDEX system not only because of the other modes, but also want to print normal objects in between. The Sovol SV04 is therefore not a “one-trick pony”, but very versatile.

Dual Mode

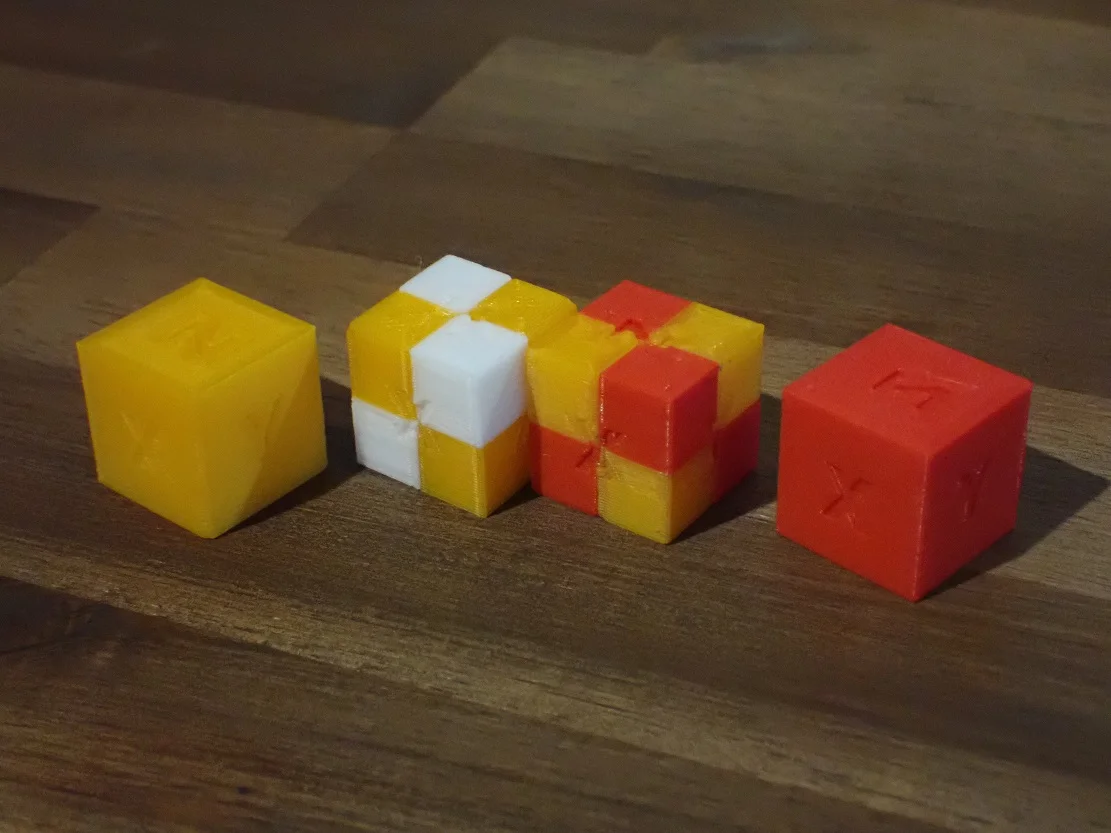

One of the most commonly used modes of IDEX 3D printers is the Dual Mode, where an object is made of two different filaments.

In this mode, the extruders alternate in each layer to print the corresponding filament. This allows either two-color objects to be created or soluble support structures to be printed that are dissolved in a liquid after printing (e.g. PVA in water).

When a nozzle is heated to printing temperature and the filament is loaded, the filament slowly exits the nozzle. To prevent this excess material from being deposited on the object after the extruder’s waiting time in dual mode, there are special wipers on both sides that clean the nozzle each time it waits for the next use.

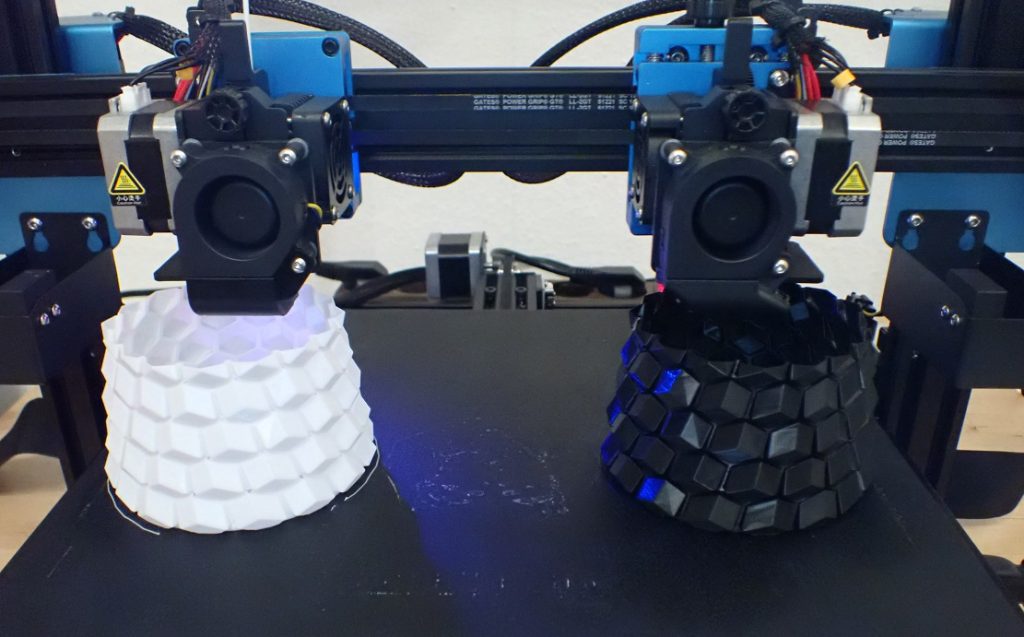

Mirror Mode

In Mirror Mode, two objects are created simultaneously on the left and right side of the print bed. The left extruder prints the original part, and the right extruder prints the mirrored object simultaneously. This mode is quite interesting to watch and somewhat mesmerizing as the movements are mirrored exactly.

Duplicate Mode

In Duplicate Mode, the object is printed twice at the same time. This mode is especially interesting in a professional context, since you achieve twice the output per printer.

The possible size of the objects is of course smaller than in Single Mode, since the two extruders must not get in each other’s way.

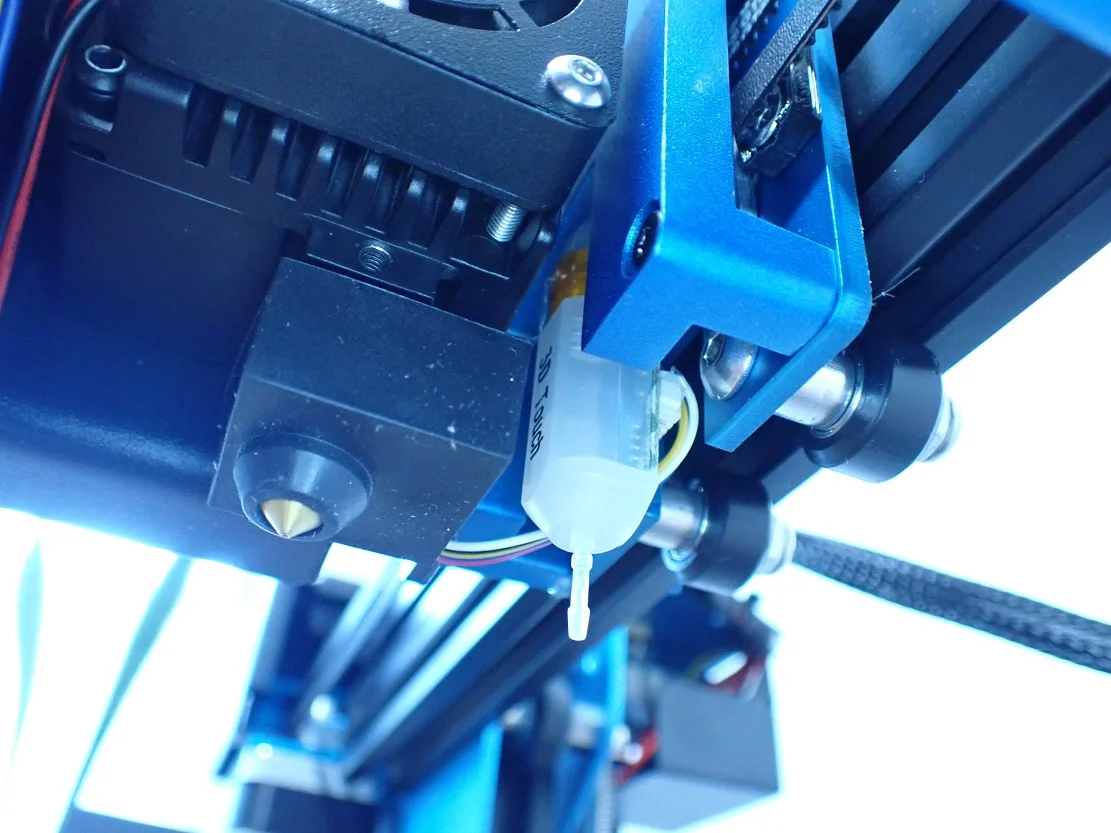

Direct Drive Extruder

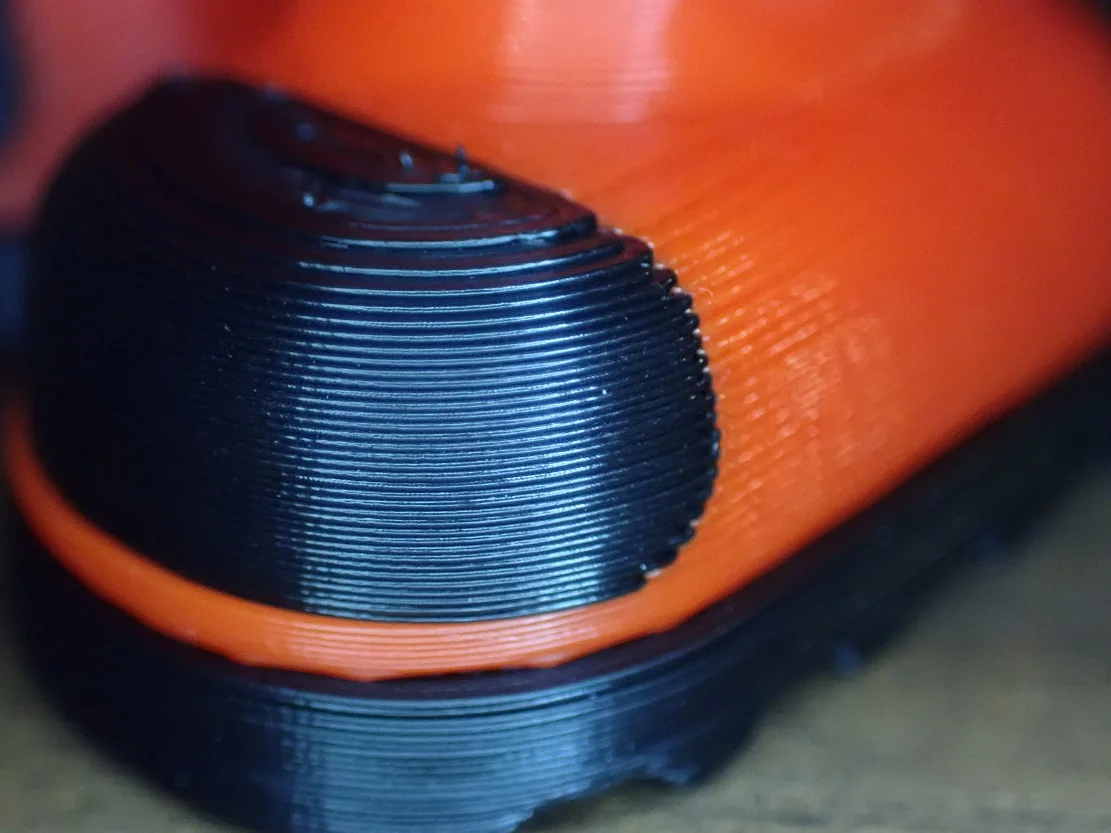

The two extruders installed are direct drive extruders. This means that the extruder sits directly above the nozzle in the print head. This minimizes the distance between the extruder and the nozzle, which improves extrusion accuracy and enables the use of flexible filaments.

Because the nozzle can reach up to 260 °C and the print bed up to 100 °C, you can print many different filament types with both extruders (PLA, ABS, PETG, TPU, ASA, PVA, wood, PC, PA).

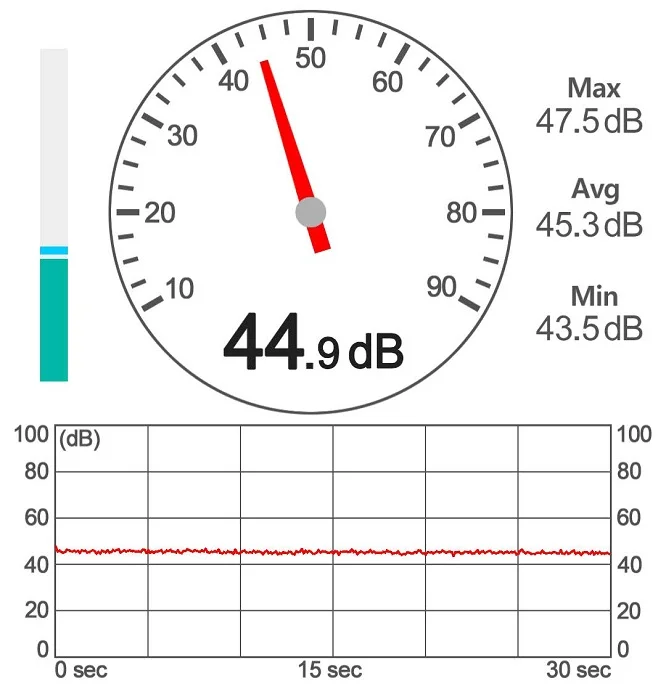

The only downside to the direct drive extruders is that the weight of the print heads has to be kept as minimal as possible to prevent vibration. Unfortunately, this also means that the installed fans are not the best and contribute strongly to the produced noise (about 45 dB).

Automatic Print Bed Leveling

The automatic print bed leveling is done with a built-in 3D Touch. Only the left extruder has this sensor. Print bed leveling is therefore performed via the left extruder, and only the Z offset then needs to be adjusted on the right extruder.

You can also adjust the print bed manually. Especially before the first operation, the print bed should first be roughly adjusted manually, since the sensor cannot compensate too large inclinations.

Print bed leveling is also very important for good print bed adhesion. If the nozzle is too far from the print bed, the filament will not have enough surface area to adhere to the print bed. However, the nozzle must not be too close to the surface either, otherwise either no filament can come out at all, or the first layer is crushed and becomes too wide.

32-Bit Silent Motherboard

The 32-bit silent motherboard is extremely quiet and only the fans for the motherboard can be heard during operation. The installed stepper motor drivers do not beep as it was the case with very old 3D printers.

However, even though Sovol advertises the Silent Motherboard, the printer is not really quiet. The installed fans in the print heads are quite loud because they have to be light to avoid vibrations during printing.

Large Print Volume

An IDEX 3D printer with a small print volume hardly makes sense. Since Mirror Mode and Duplicate Mode need some space too, the print area must be correspondingly large in order to duplicate even medium-sized objects. Therefore, the Sovol SV04 has a very large print volume of 300 x 300 x 400 mm, which can be used as follows:

- Single & Dual Mode: 300 x 300 x 400 mm

- Duplicate Mode: 2 x (150 x 300 x 400 mm)

- Mirror Mode: 2 x (115 x 300 x 400 mm)

As you can see, in Single and Dual Mode large objects are printable in one piece, in the other two modes only medium-sized or very long objects.

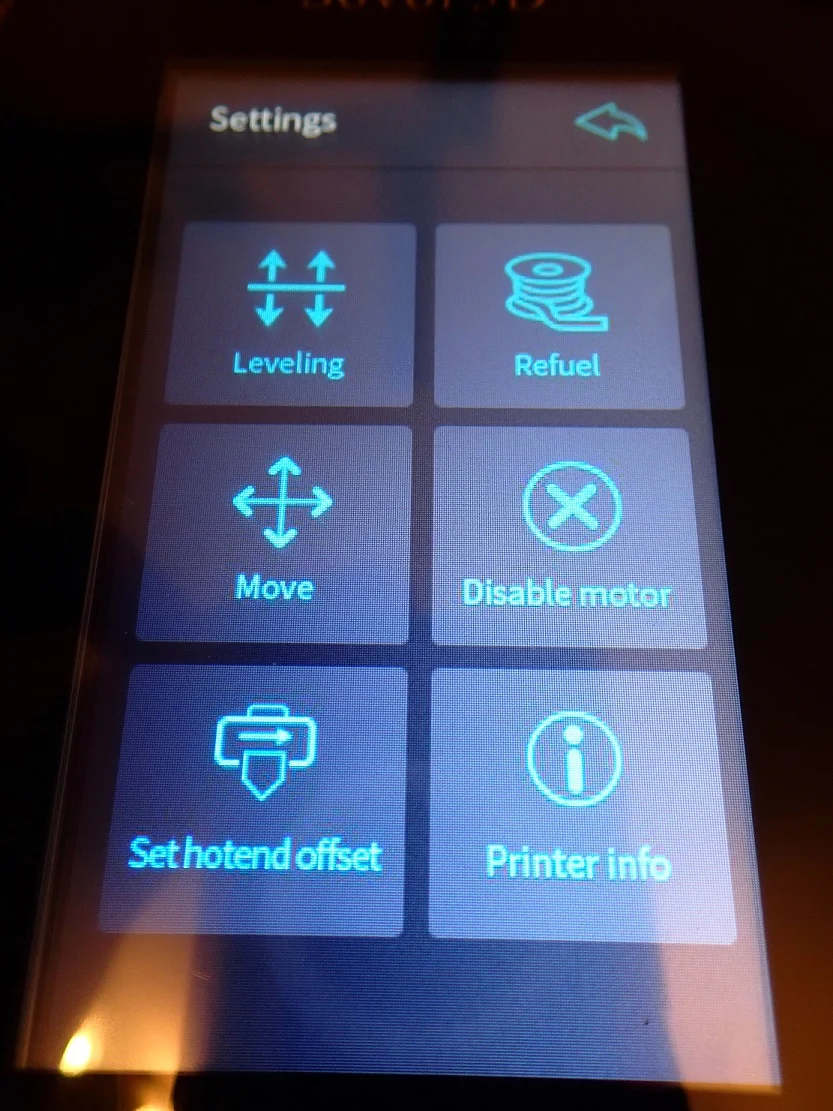

4.3-Inch Touchscreen

For many 3D printers, color LCD screens that are operated with a rotary knob are the standard. Meanwhile, there are more and more 3D printers that have a touchscreen, which makes operation more convenient and faster.

The Sovol SV04’s 4.3-inch touchscreen gives you quick access to all the important options, and the controls are large enough to be selected with your finger.

The individual modes of the printer must be selected not only in the slicer but also via the menu on the 3D printer itself.

Filament Sensors

Since the Sovol SV04 has two print heads, each using its own filament, there are also two independent filament sensors. They are located at the top of the frame next to the filament holders and guide the filament vertically down to the extruders.

The cables for the filament sensors are already integrated in the frame and cut to the right length. So you only have to connect the cables to the sensor and do not have to lay them yourself.

Flexible Magnetic Print Bed

The large print bed is made of spring steel and is therefore magnetic and flexible. It also has a textured surface to optimize print bed adhesion. This means that you can completely remove the print bed after printing and easily detach the print object or both print objects by slightly bending the print bed.

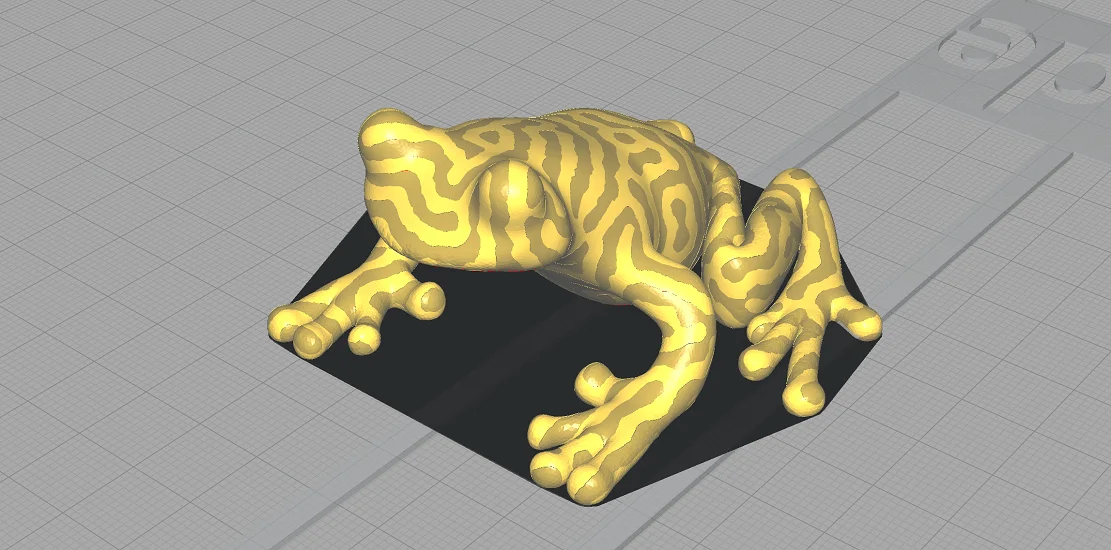

The print bed adhesion is unfortunately not perfect, which is why I had to use Magigoo, a special 3D printer adhesive, for very delicate first layers in my test. Without this adhesive, for example, the complicated first layer of the two-color frog (see below in the print quality examples) did not adhere to the print bed.

Double Z-Axis

The Z-axis, and thus also the X-axis, must be designed to be very stable so that no vibrations can occur during printing. This is especially important with IDEX 3D printers, as the two extruders run simultaneously in some modes, increasing the chance for vibrations.

Therefore, a double Z-axis with two single stepper motors was installed in the Sovol SV04. Due to this design and the calibration of the Z offset of the X-axis, the design is both stable and accurate.

SD Card Instead of Micro SD

I am always happy when a 3D printer is fed with files using an SD card and not a micro SD card. Sure, most of the time the smaller the physical footprint of storage capacities, the better. However, if you have to handle them with your fingers and carry them from A to B, it’s better if the thing is large enough so that it can’t accidentally fall or be difficult to insert into the appropriate slot.

Resume Print

The Resume Print feature is now available on almost every new 3D printer on the market. Through this feature, the 3D printer remembers where it was interrupted by an unforeseen power failure. After the power is restored, the printer starts printing again exactly where it was interrupted.

I tested this feature on the Sovol SV04 by manually interrupting the power supply. The test was successful and the Sovol SV04 even remembered which extruder it had just printed with.

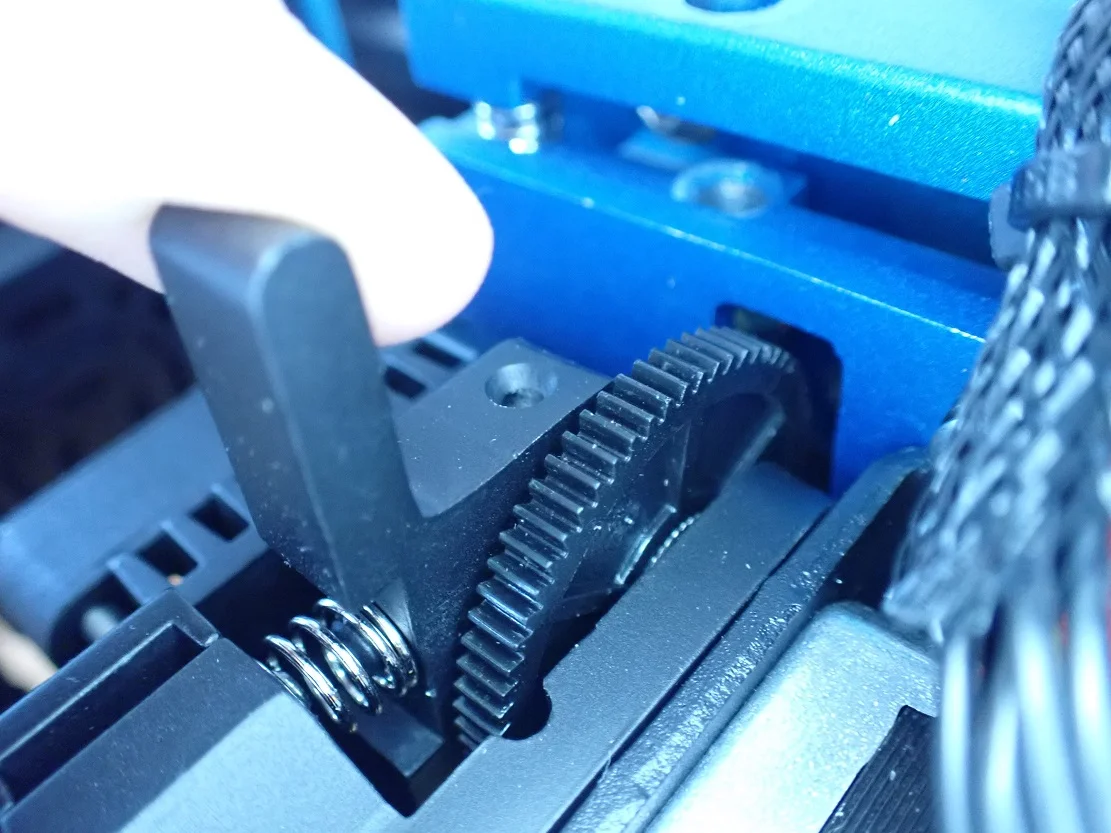

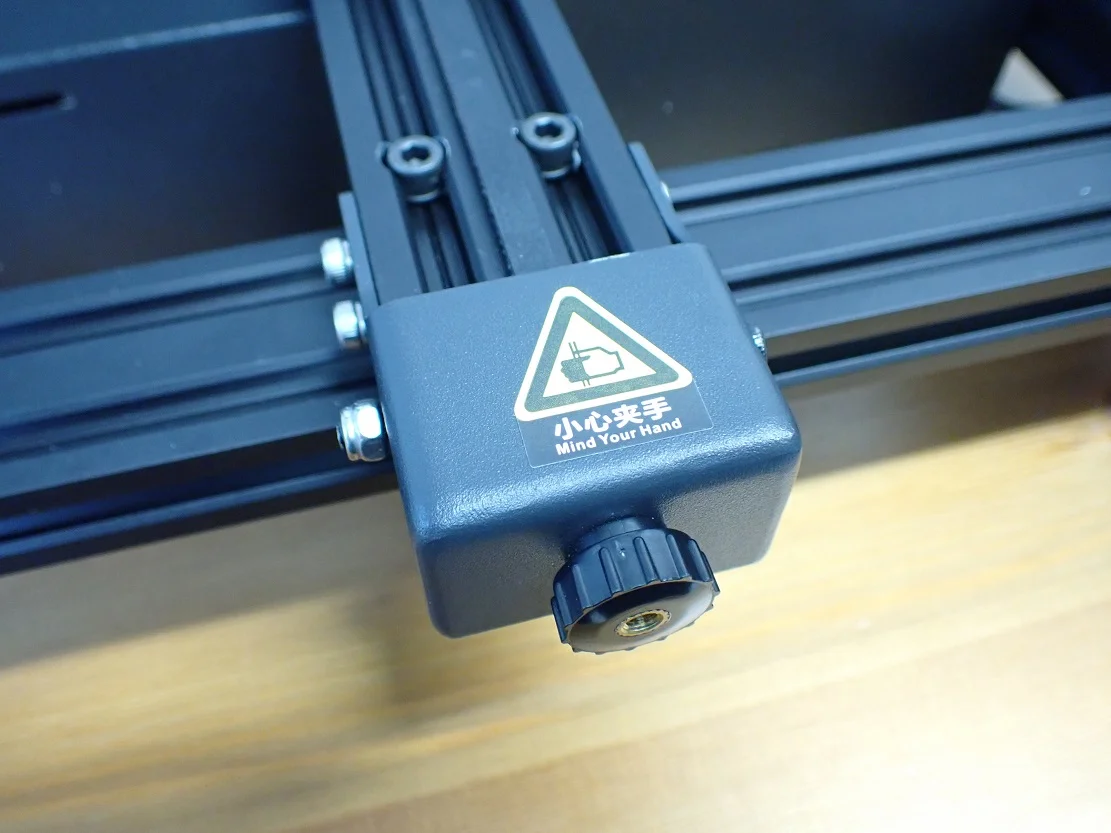

Belt Tensioner

With many DIY 3D printer kits, the toothed belts have to be mounted and tensioned. This is not necessary with the Sovol SV04, since both the print bed and the X-axis are delivered ready assembled. And even if the timing belts are not properly tensioned, you can easily adjust them using the timing belt tensioners.

Since there are two extruders on the X-axis that can move independently of each other, there are also two belt tensioners on the X-axis. Before you make any major changes to the tension, make sure you are using the correct belt tensioner.

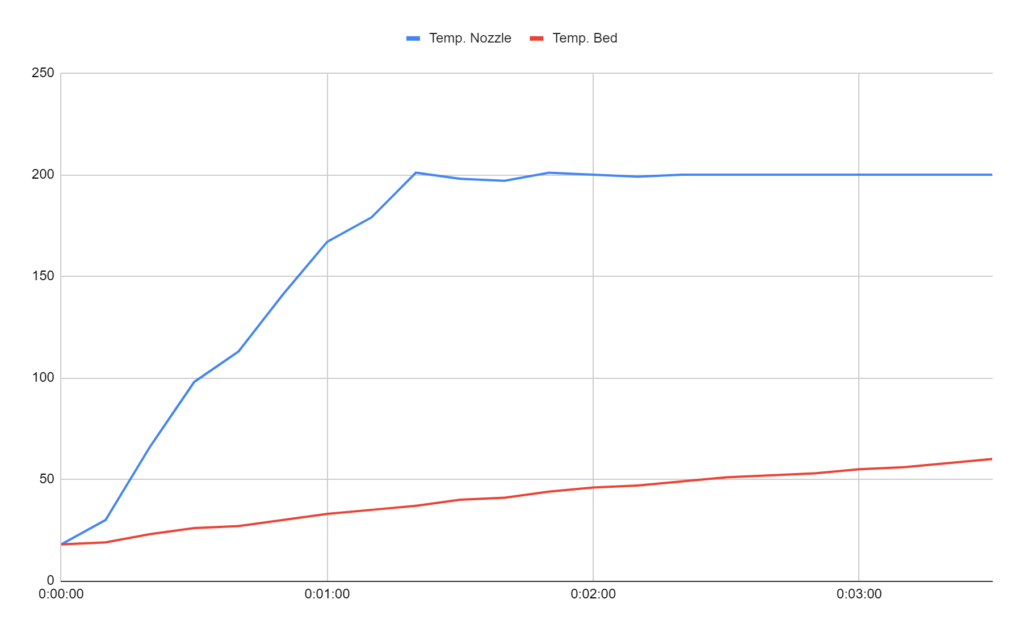

Heating Times

> Sovol SV04 Review

The duration until the nozzle is heated up to 200 °C is about 2.5 minutes. That is not very fast, but not slow either. The print bed takes 3.5 minutes, but this is due to the sheer size of the surface.

There are pre-programmed temperatures for the nozzle for PLA and ABS. However, to prepare the printer for a filament, you must define the temperature for the left nozzle, the right nozzle and the print bed individually.

Noise Level

> Sovol SV04 Review

The Sovol SV04 is relatively loud with 45 dB during printing. This volume corresponds to a quiet conversation or soft radio music. The volume is mainly due to the fans in the print head.

In order to keep the print heads as light as possible, no high-end fans could be installed. However, the compromise is worth it because the print quality is very good.

Print Speed

> Sovol SV04 Review

The printing speed is comparable to most other 3D printers. Recommended are 60 mm/s, maximum are 120 mm/s.

However, the print duration is extended in Dual Mode by switching between the two extruders. As soon as one extruder has printed its filament in the current layer, it moves aside and waits until the other extruder has done the same to continue in the next layer. The result is short windows of time where no printing is done, which significantly increases the print time. But you get very cool effects in dual mode.

Operation

> Sovol SV04 Review

User interface: The 3D printer’s menu is very clear and can be easily operated via the touchscreen. However, it takes a bit of getting used to addressing the individual extruders the first time. Therefore, it is also necessary to enter the temperature for each nozzle, since you could use different filament types at the same time.

Print bed: Magnetic and flexible print beds that can be removed from the 3D printer are very practical to use. This makes it very easy to release the print objects. As soon as you bend the print bed, the object releases almost by itself. Unfortunately, the print bed of the Sovol SV04 does not have perfect adhesion. For filigree first layers, you have to use aids such as Magigoo.

Slicer: The Sovol SV04 is compatible with many slicers. I have used it with the Cure clone Sovol3DCura. If you are familiar with Cura, you will find your way around here very quickly, as the user interface is more or less identical.

Printing: If you’ve never used an IDEX 3D printer before, printing with the Sovol SV04 will take some getting used to. You have to make sure that you are in the right mode. Otherwise, it behaves like many other 3D printers. Apart from the complex calibration, printing basically consists of loading filament, slicing and pressing start.

Slicer

> Sovol SV04 Review

The Sovol3DCura is a Cura clone and can be operated identically. There are different profiles for the individual modes. If you work in Dual Mode or Mirror Mode, there are two different profiles.

You can control the individual extruders by clicking on the different parts of the object and then selecting either the left or right extruder. I had no problems with the default profiles and after a quick calibration for the filament (temperature tower, retraction tower, etc.), I had no problems at all.

Print Quality

> Sovol SV04 Review

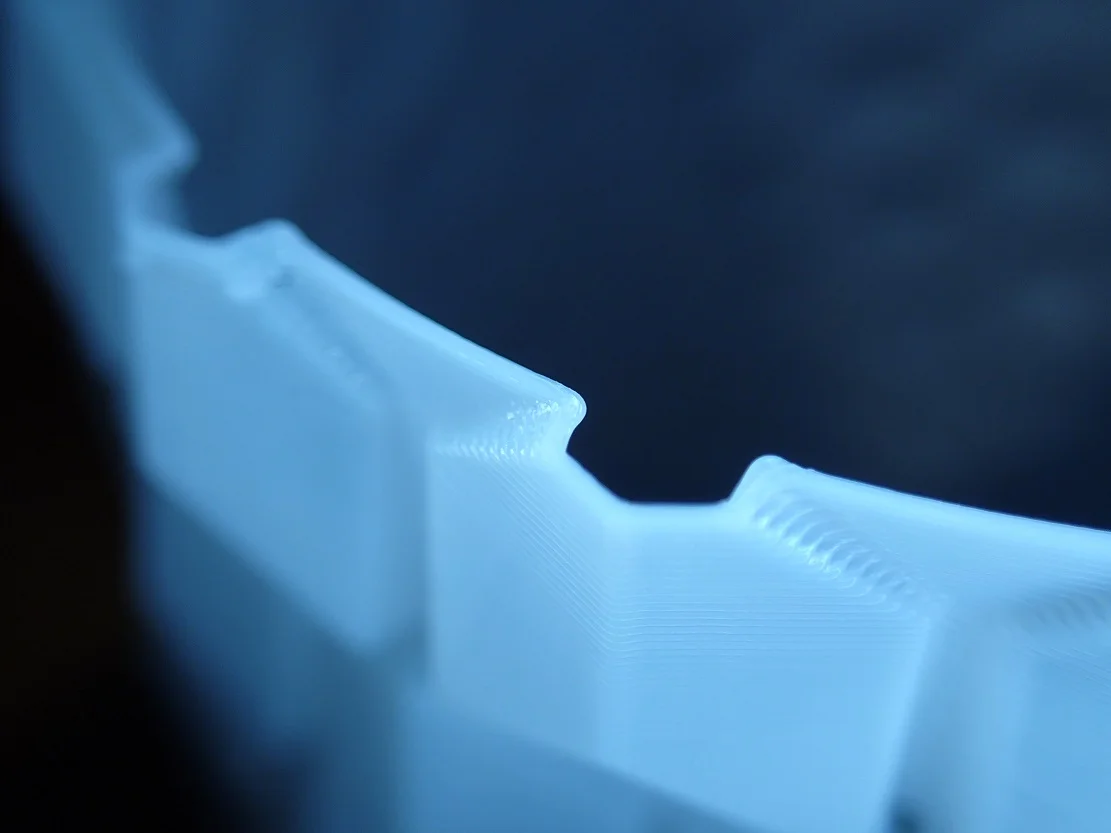

The print quality of the Sovol SV04 is 0.1 mm, even in dual mode. As long as the two extruders are well-calibrated, high-quality objects can be produced with different materials.

I mainly used the Dual Mode and once the Mirror Mode to test the IDEX system. Apart from a few models that were ready sliced on the SD card, I used other objects from websites like Thingiverse.

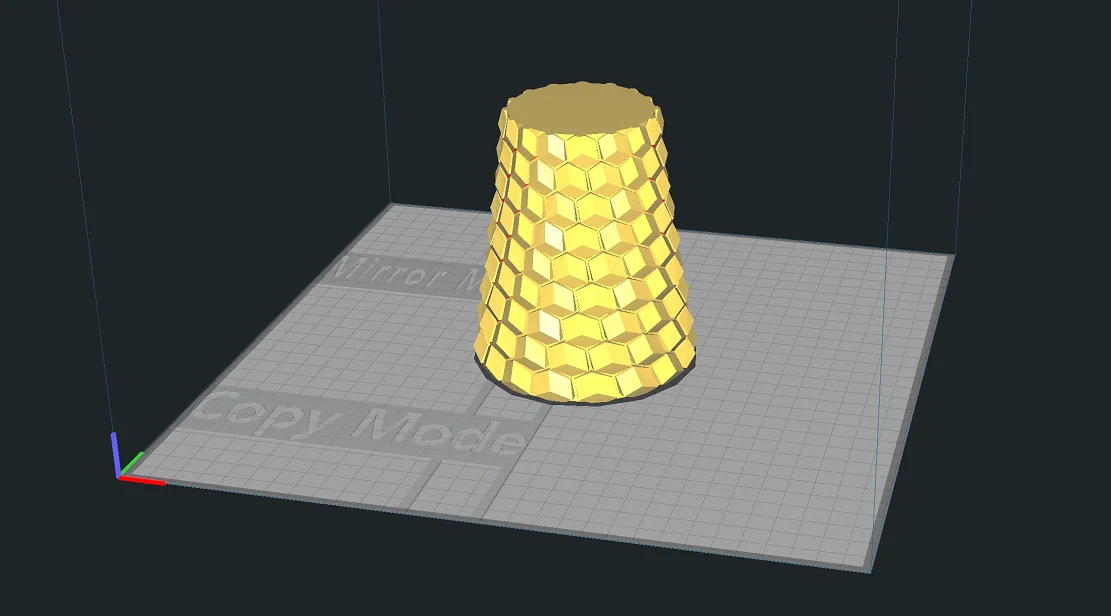

In the Dual Mode, I started with a few simple objects and worked my way up to more and more complex objects. Finally, I printed the very detailed two-color frog (link to object). I’m very impressed with the result, as the frog is also not too big and requires high accuracy.

I tested the mirror mode on a vase (link to the object). In the vase mode of Cura hardly anything can go wrong, but this object was the perfect opportunity to test the mirror mode. The possibility to print an object twice speeds up the printing process by a factor of two.

Check Price at:

Is the Sovol SV04 worth it?

As long as you are looking for a printer that can work with two different filaments to print two-colored objects or soluble support structures, the Sovol SV04* is definitely worth it.

However, it is also suitable for professional applications to increase the output per area, as it can print two objects simultaneously. Its versatility is an advantage for everyone, as it not only has two extruders but can also process a lot of different filaments.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.