- Wet Filament: Prevention, Symptoms & Drying - July 18, 2024

- Sovol SV08 – Best PrusaSlicer Settings & Profile - June 26, 2024

- Sovol SV08 – Best Orca Slicer Settings & Profile - June 26, 2024

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

Laser engraving and cutting machines with a 10W laser module are now available from many manufacturers. However, a hybrid device with a cutter module and a super practical camera for positioning is rarely seen.

The xTool 10W hybrid laser* has an enclosed housing that is ventilated via an exhaust hose. It can cut and engrave many materials. The accompanying software simplifies workflow and provides recommended settings for most materials.

In this hands-on review, I’ll introduce you to its features in detail and show you examples of the quality you can expect and the possibilities this device opens up for you.

Check Price at:

Table of Contents:

Key Takeaways

- Available with a 5W and 10W laser module.

- Can cut by laser, engrave and cut thin materials with a knife.

- A suitable, intuitive software is available for the device.

- The smoke produced by the laser is removed by a fan through an exhaust hose.

Who Should Buy the xTool M1?

The xTool M1 Laser is worthwhile for anyone who wants to cut and engrave with a laser, as well as cut thin materials with a knife. In addition, the device is enclosed and equipped with an exhaust hose, so it can also be used well indoors.

Advantages & Disadvantages

PRO:

- High performance

- Camera view simplifies positioning

- Autofocus Laser

- Easy change between laser and knife

- Closed volume with exhaust air hose and ventilation

- Intuitive software

- Spacers (prisms)

CON:

- Not compatible with LightBurn

- In the case of plywood, the laser lens and the light barriers must be cleaned frequently because of the smoke that occurs when the glue burns.

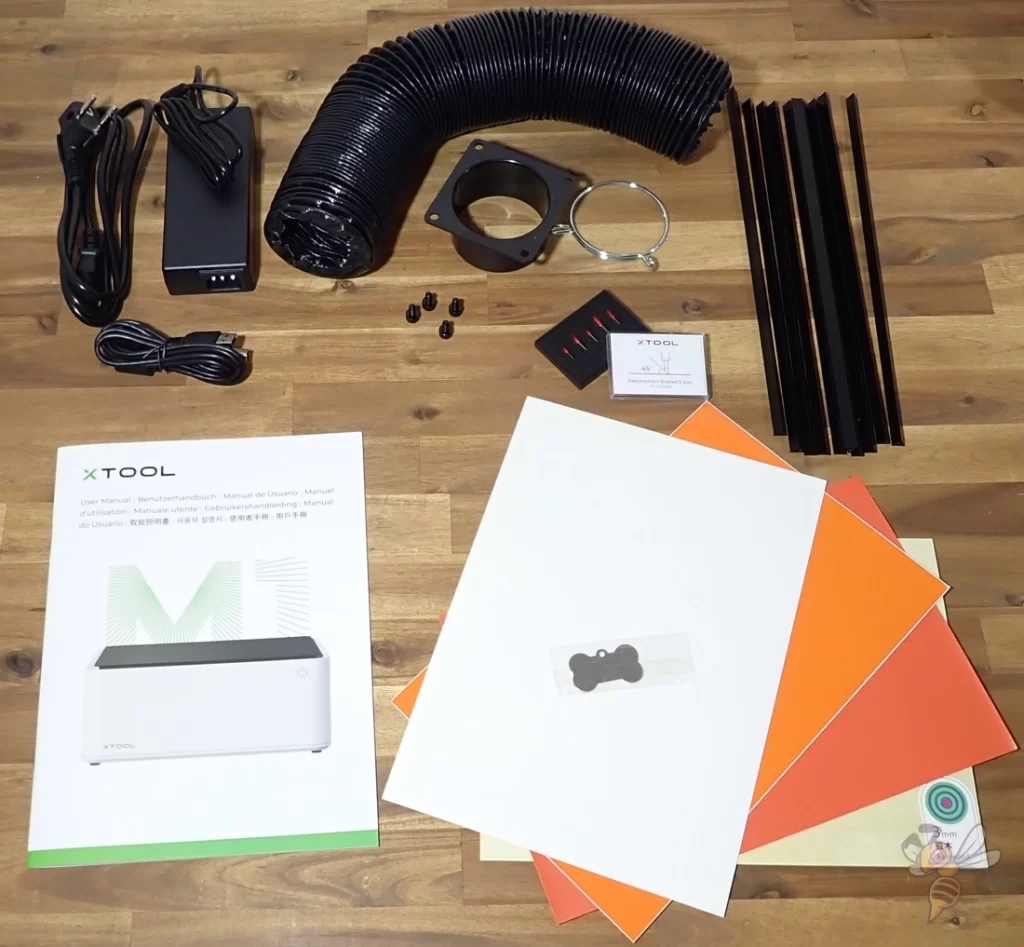

Scope of Delivery & Assembly

Everything is included in the scope of delivery of the xTool M1 to test all its features. In addition to the fully assembled machine, the package also includes test materials, adhesive pads for cutting, replacement blades and the exhaust hose.

Unlike many entry-level lasers, you don’t have to assemble the xTool M1. It comes completely pre-assembled to your home. The only thing you still have to mount is the exhaust hose.

This is included with the basic version of the xTool M1:

Test material: To give you a feel for the different materials that the xTool M1 can process, some samples are included in the delivery.

Adhesive pads: For thin materials that would slip during cutting, there are two adhesive pads with different thicknesses.

Replacement Blades: Unlike the laser, the blades become dull (after prolonged use) and need to be replaced. In the small supplied box are 5 pieces included. You will get by for a long time and in case of need, you can order some separately.

Exhaust air hose: At the back left of the housing is an opening with a fan. The exhaust air hose can be connected to this.

Features & Design

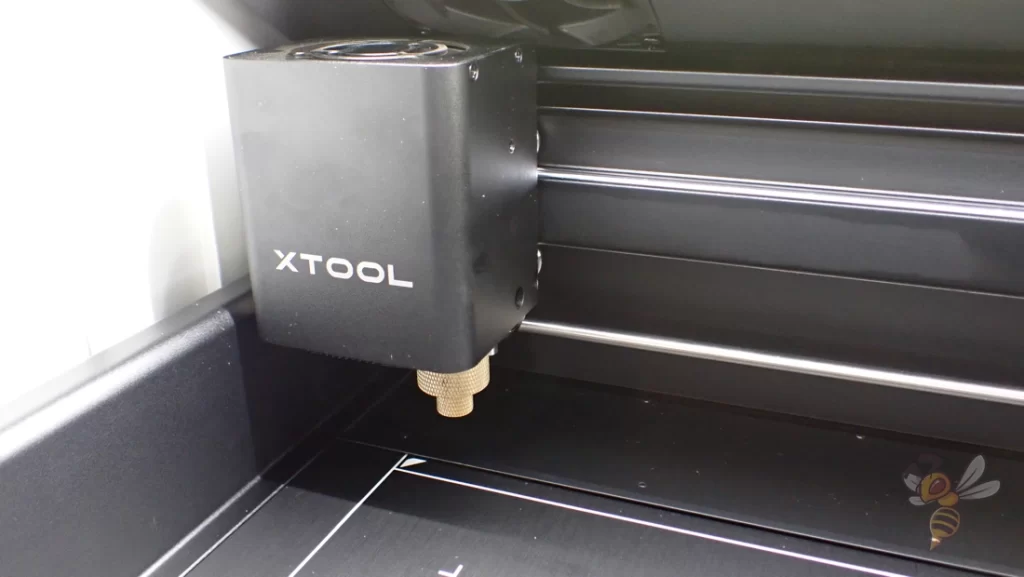

10W Laser Power

The integrated laser has a high power of 10W with a focus point of only 0.08 × 0.08 mm. Not only can you cut and engrave very accurately, you can also cut thick wood or acrylic sheets in one pass.

If you can get by with a little less power, the xTool M1 is also available in a 5 watt version. The only difference here is that you are somewhat more limited when cutting the material thickness.

Otherwise, you can cut and engrave many hard and also soft materials with the powerful laser module. These include, among others, the following materials:

- Wood

- Bamboo

- Acrylic

- Paper

- Fabric

- Leather

- Ceramics

- Matt stainless-steel surfaces

- Painted metal surfaces

- Anodized metal surfaces

- Dark metal surfaces

As already mentioned, a few test materials are included in the scope of delivery. So, you can quickly get an overview of what the laser can do and what not. This way you don’t have to buy different materials at high prices and you know exactly which material you need after the test.

Thanks to the filter glass in the lid, you don’t have to worry too much about radiation protection. However, extreme caution is always required when using a class 4 laser.

Deflected rays from such a laser can also damage your eyes and skin. If you want to be on the safe side, you should not look directly into the focal point of the laser, even with the hood closed, and if you do, then only very briefly and preferably with laser safety goggles.

Real-Time Preview through integrated Camera

There is a high-resolution camera in the back of the housing that always takes a picture of the base as soon as the hood of the housing is closed. This allows you to precisely align the object in the software.

With other laser cutting and engraving machines, there is only the outline mode, where the laser on low-power shows you the rough outline of the object on the material.

With the camera, it is much easier and faster to align the object. You can save a lot of material and time. This is actually one of my favorite features of the xTool M1.

In addition to aligning the model, the camera also simplifies the reuse of leftovers. If you have already used a piece of wood, you can insert it into the xTool M1 and see directly through the camera how large the next motif can be. So, you don’t need to measure everything like with other devices!

The positioning of the camera in the housing also protects it from smoke. Throughout my testing, I had to clean the laser and light barriers three times, but not the camera. So, this great feature comes without a downside (except for the slightly higher price because of it).

Sealed Housing

When cutting and engraving with a powerful laser, smoke is always produced. This smoke is harmful to health in large quantities.

Laser cutters and engraving machines should therefore always be operated in a well-ventilated room. However, there are also devices such as the xTool M1 that have an enclosed housing with an exhaust hose. If you lay this hose so that the exhaust air goes outside, you can also use it at home.

Another big advantage of the sealed enclosure is the protection from the laser beams. Most low-budget lasers are open devices that require you to wear laser safety goggles whenever you are in the same room as the laser.

Because the xTool M1 has a sealed housing with a filter disk, you can also use it at home with a clear conscience without having to wear laser safety goggles.

Nevertheless, you should not look too long directly into the focus point of the laser, because the light is very bright and can cause damage eventually.

Cutting Module

The print head contains the cutting module next to the laser. It is easy to remove because it is magnetically mounted. It comes with several blades, so you can use it for a long time without having to order more.

The blades are so sharp that you can cut thin and soft materials cleanly and quickly. Especially for vinyl, they are perfect, with which you can make customizable T-shirts and other fabrics. But it is also possible to cut leather, paper, felt and stickers.

To keep these materials from slipping when you cut them, two different adhesive pads are included. They each offer a different adhesive strength to provide the right adhesion for the different materials.

What I particularly like about the cutting module is that you can change the blades so quickly and easily. The magnetic storage is a really good idea and extremely user-friendly.

Autofocus

A big problem with many laser cutters and engravers is focusing the laser. With most machines, you need a focusing aid to adjust the laser for each new material.

If the focus of the laser is not adjusted properly, the spot on the material will be too large and out of focus. This will give you less accuracy when engraving and less power and more burn marks when cutting.

The xTool M1 has an ingenious autofocus and can determine the thickness of the material independently. Since the bottom of the material is always the same distance from the laser, and the device can measure the distance of the laser to the top, it can determine the thickness from this.

In my practical test, this also worked wonderfully, except for wooden boards that were slightly bent. And there, of course, it calculated the thickness from the highest point to the base. But as long as the deviation was relatively small, this was absolutely no problem, since the focus point offers some leeway.

Spacer

When the laser cuts through a material and hits the substrate, burn marks appear under the material. This is especially noticeable on light wood. You can prevent a large part of these burn marks by placing the material a little higher.

For this purpose, prisms are included in the scope of delivery on which you can place the material. The material of the prisms is insensitive to laser beams. So, you never have to replace them.

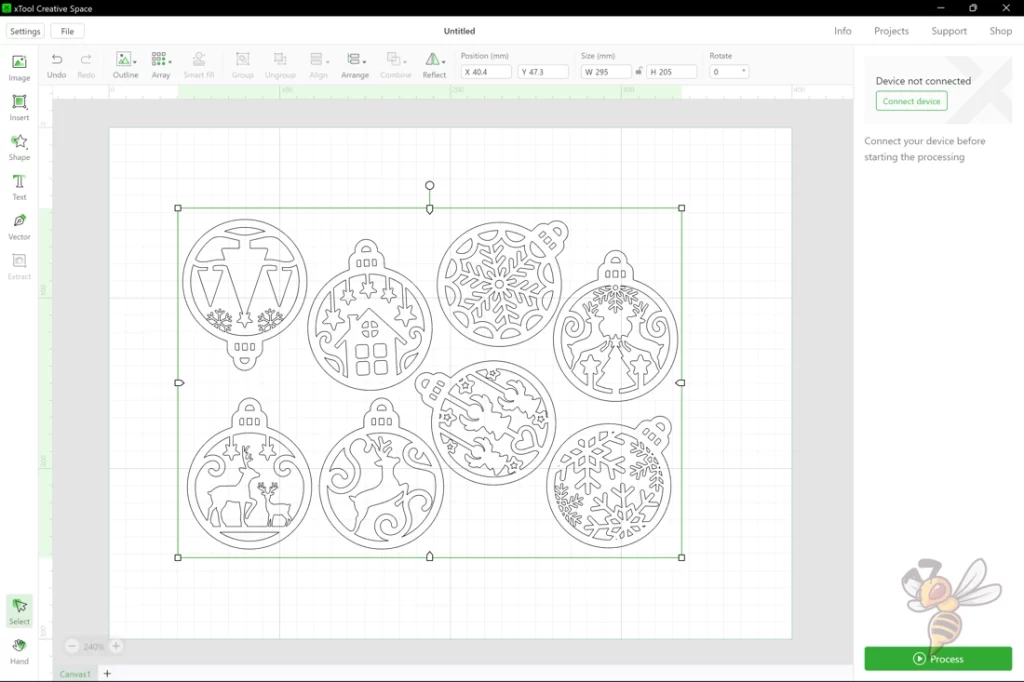

Software

The xTool M1 is operated with the accompanying xTool Creative Space software. It is available for Windows and macOS and is very intuitive to use.

You can control the xTool M1 via USB directly through the software. In combination with the built-in camera, you can see directly where your pattern is being lasered, engraved or cut.

The software database contains many materials and their recommended settings. So, you can quickly start creating your objects without searching for the optimal settings.

And if you’re lacking some inspiration for what to create next, there’s also a library of projects you can make happen.

The only thing I would improve with the software is that you can’t set the order of the cuts or engravings. Typically, the software calculates the optimal order, but sporadically, it is wrong and the project will not be perfect.

Also, you can’t group and color different lines like you can in other software like Lightburn. Especially with very complex projects, this can help to keep the overview.

Results

Christmas Decorations

The first project I did with the xTool M1 were wooden Christmas decoration. It was a project that is not only useful for me, it should also be a test how the laser without air system copes with tiny details.

You can see burn marks in some places. But due to the prisms as spacers, these traces can be avoided for the most part – especially on the back.

Due to the ingenious camera and the simple positioning, it was easy to position the individual balls as space-saving as possible on the wood. Since it was so easy to load and position new patterns, the production degenerated somewhat into mass production …

Dinosaur Puzzle

The next project was a dinosaur puzzle for kids. This was a test for the combination of engraving and cutting. The result is mostly good, but in some places there are stronger burn marks. With a little alcohol, I was able to remove most of them.

However, what I noticed with this pattern is that you can’t set the order of the individual objects in the software. The individual objects to be engraved were engraved across the entire width like a printer, line by line from top to bottom. It would have been more efficient if the individual objects were engraved one after the other in one piece to save on travel movements.

Decorative Wooden Box

The combination of cutting and engraving is particularly interesting. Therefore, I made this decorative wooden box. It has a lot of details and is therefore also susceptible to burn marks.

After optimizing the settings, I was able to cut and engrave the box without any burn marks. Since the laser is very well focused, the parts fit together perfectly. If the beam was not well focused and wider, there would be too much air between the parts and they would not hold without glue.

Image Engraving

In the xTool software you can also import pictures. Of course I had to try this feature and engraved a picture on a leaf that was cut out at the same time.

The result is quite satisfying, but there is still room for improvement. In the settings you can also specify the density of the lines. For images, the interaction between this density, the laser power and the speed determines how well the image is projected onto the surface.

Sticker

Since the scope of delivery also included adhesive paper for stickers, I had to test it as well. I was afraid at first that I would waste half the paper until I found the right settings. But luckily, there were recommended parameters that worked perfectly right away!

Cleaning the Laser

After some time in operation, the laser generates so much smoke that some of it can deposit on the protective glass. Especially when working with plywood, this protective glass must be cleaned regularly because of the adhesive it contains.

The cleaning is easy with a little trick. Normally, you would have to open the baseplate of the xTool M1 to get to the protective glass. But with a small mirror, you can see what you are doing.

To clean it, you can use a cotton swab and gently rub it over the glass until it stops picking up dirt.

Useful Accessories and Upgrades

Although the xTool M1 already comes with everything you need to create near-perfect projects, there are still a few upgrades that may be worth your while.

Air Assist Set: When laser cutting wood, there are always a few burn marks. There are a few tricks to reduce these marks, but an air assist helps much better and can even avoid them altogether.

Smoke cleaner: If you want to filter the smoke out of the machine, for example because you can’t direct the exhaust hose outside in a meaningful way, this smoke cleaner is definitely worth it! It filters 99.97% of all particles from the air.

RA2 Pro Rotator: With this upgrade, you can also work on round objects. This includes wine glasses, cups, Christmas tree balls and rings.

Riser Base with Honeycomb Plate: If you want to work the rotary or taller objects, this is the upgrade for you. It also comes with a honeycomb plate that eliminates the need for prisms. This results in fewer burn marks.

Is the xTool M1 Worth It?

The xTool M1* is worthwhile for anyone who would like to free his/hers creativity at home. If it could 3D print, it would be the perfect maker tool! But even without 3D printing, you can create endless objects with it.

Due to its high quality and the reproducible good results, it is also suitable to earn money with your own business or to fill the household budget a little!

Check Price at:

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.